Discussion of conversion detection correlations between gas and hydraulic oil in machine oil pump

Rong LI,Qing-xin MENGWuhan Vocational College of Software and Engineering Automobile Application System,Wuhan 430056,China Purchase Department,Dongfeng Ongfeng Peugeot Citroen Automobile Company LTD,Wuhan 430056,China

Discussion of conversion detection correlations between gas and hydraulic oil in machine oil pump

Rong LI†1,Qing-xin MENG21Wuhan Vocational College of Software and Engineering Automobile Application System,Wuhan 430056,China2Purchase Department,Dongfeng Ongfeng Peugeot Citroen Automobile Company LTD,Wuhan 430056,China

The oilpump is one of themost important parts for the engine.Its function is to provide oil for engine lubrication system and supply hydraulic pressure for some parts.So the efficiency of oil pump is very im portant.At present,there are mainly two kinds ofmedium detection performance of oilpump,i.e.,gas and oil.The gas hasmany benefits,which are differentwith the use of the environmentmedium.By using the experimentaldata provided by DPCA,the correlations between gas and oilare discussed in this paper.

Gas,Hydraulic pressure,Oil pump

† Rong LI,E-mail:980069945@qq.com

Nowadays,the design of component in automobile industry is trend to be specialized and modularized.The automation of the module assembly has reached a high standard.Thus,in the design and development process of component,we should consider how to finish the assembly and how to finish checking work securely in high precision.

As the engine oil is used to lubricate during the operation,we should check oil pump by using the engine oil after it ismade out,in order to meet the needs of the function.A relatively high cleanliness is needed during the process of engine assembly.Thus,there will be requirement for higher cleanliness when the oil pump leaves the factory.How to meet these requirements and produce and check the products?Themajority of themanufacturer will take the gas instead of engine oil into consideration;however,the requirement of engine factory for the requiredmedium is engine oil instead of gas.Therefore,themanufacturers of engine oil pump should conduct research to use gas to replace engine oil.

1.Definition of the function of the oil pum p and the necessity of checking

The function of the oil pump is to provide lubricatemedium with certain pressure and current to engine and lubricate themoving parts of the engine.In general,the functions of the engine are as follows:adjust the rotation speed corresponding to the current,maximize the pressure,meet the requirement for tightness,change the displacement current and pressure.

2.Contrasts between the two checking medium

We can make a contrast to analyze the advantages and disadvantages between the gas and oil engine.Compared with oil engine,gas molecules are small,with lower viscosity,with no tension in the surface.Thatmeans the gas can pass smaller space more quickly.During the process of the passage,it can demonstrate the influence made by moving parts a longer duration of the engine oil checking.Later,there will be more process to clean the engine oil.The efficiency of the cleaning cannot be done as expected.As a result,this is the reason why most of the businesses would like to choose gas checking instead of engine oil checking.

3.Investigation of the relativity of two medium

As a leading automobilemanufacturer company,DPCA’s checking for supplier is fair strict.They will check from different aspects and standpoints,eleven aspects in total,for example,the process of the development of the products,the process of the designing of the products,the process of the second level supplier’s management.For instance,Supplier A provides the oil pump for DPCA Company.Several problems are found during the DPCA’s approving process.The major problems are as follows:could gas negative pressure take the place ofmonitoring of the three functions in the assembly line?As parameter involves information about the company,data parameters are edited and disposed.

54 engine oil pump were chosen by the supplier(including:4 engine oil pump with high outlet pressure and 2 oil pump with low outlet pressure)after checking by the gas negative pressure,then put it on the oil checking stand to check the flux of the two rotating speed and the outlet pressure.There are the 54 groups of data.

Table 1.Functions of the engine oil pum p

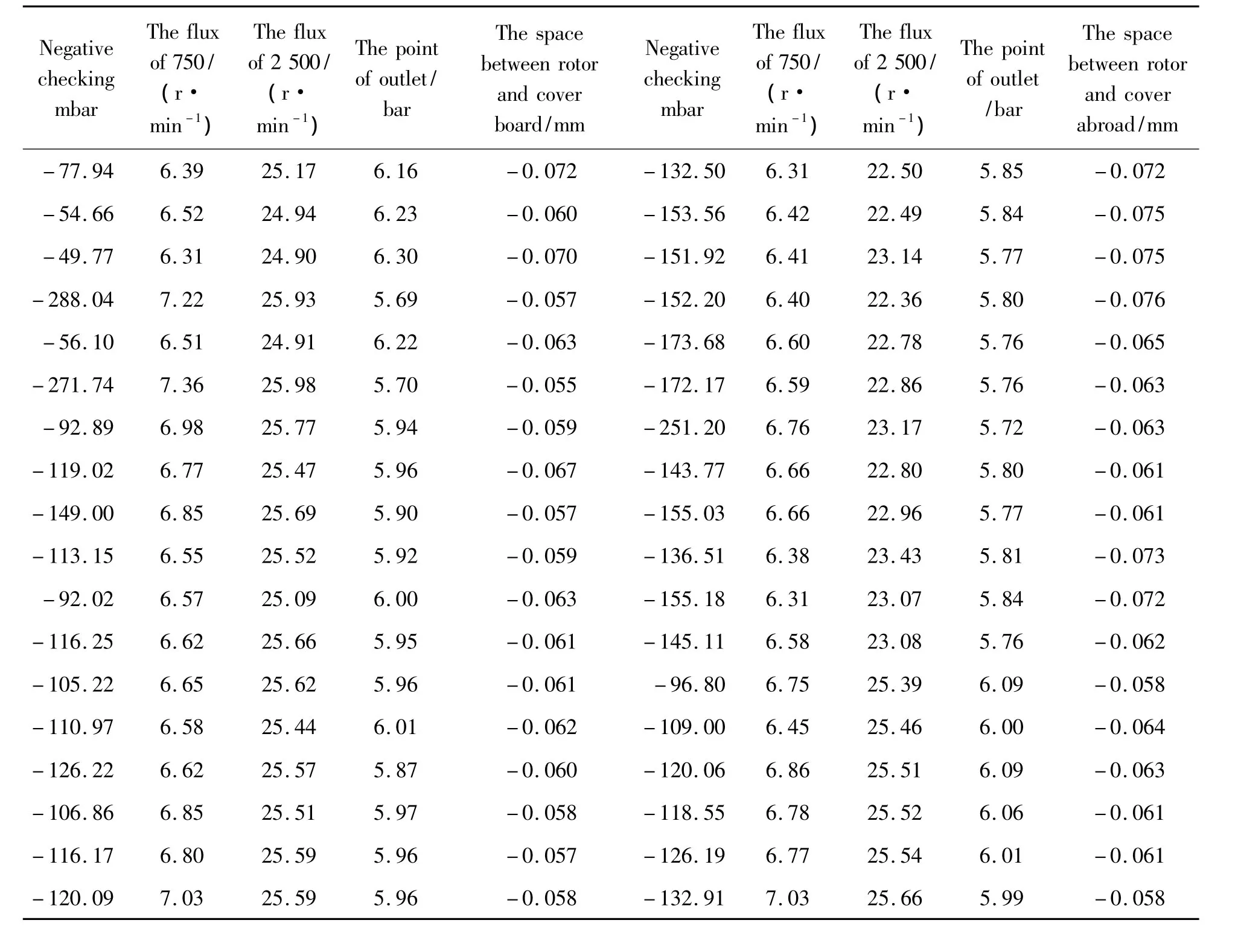

Table 2.54 groups of data after the checking

Countinued Table

Then,we could use the data provided by the supplier to conduct research for the relativity of these pumps.

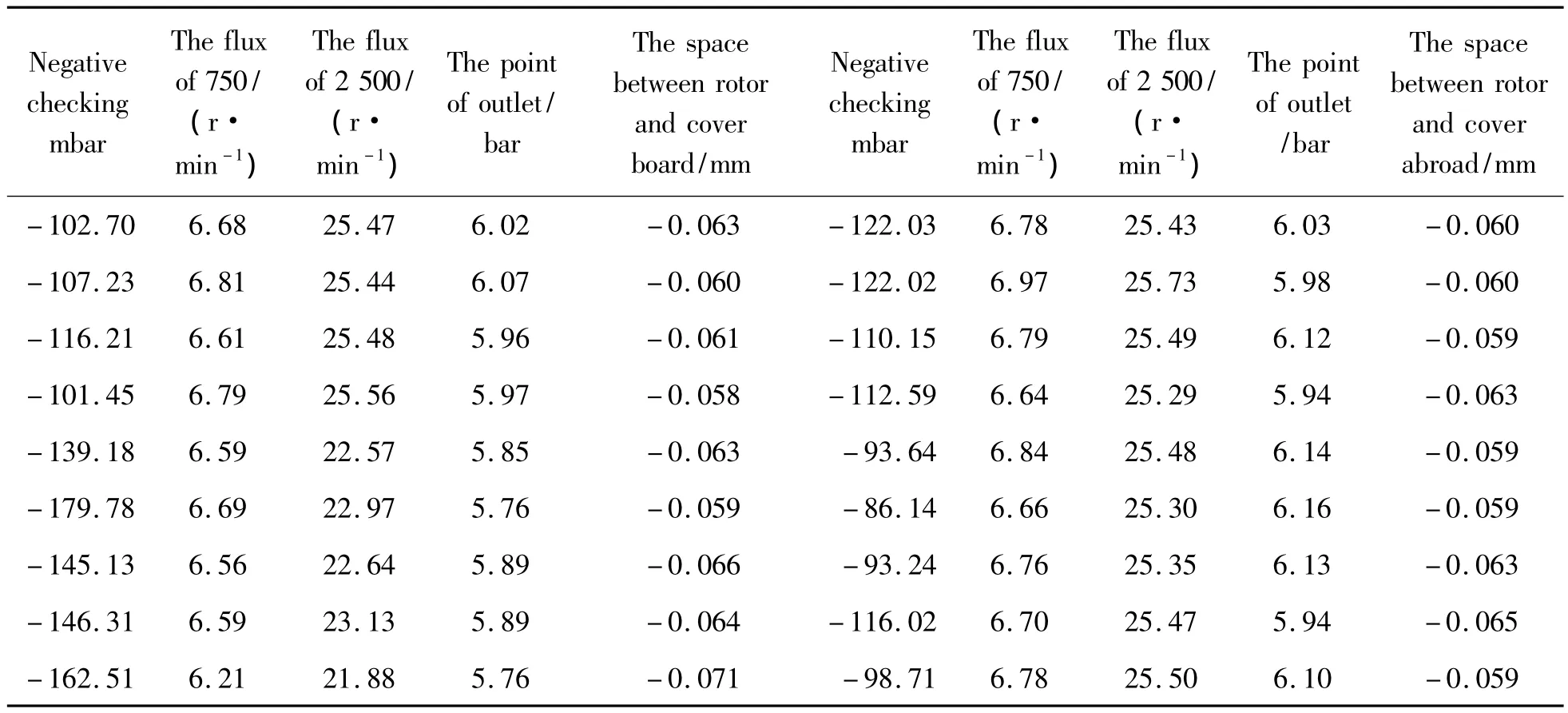

3.1.The relativity of the negative pressure and the outlet pressure

The linear regression derived from calculation:the simple linear regression equation in the following chart;correlation coefficient R points the outlet-negative pressure=0.84 > R standard=0.44,conclusion,gas negative pressure could take the place of monitoring of the three functions in the assembly line.

Figure 1.The fitting line graph in linearmodel

The equation hasmeet the requirements,but in order to assure more relativity of regression and the features,concluded by further imitation:mono basic quadratic equation;correlation coefficient R point of outlet -negative pressure =0.91 > R standard =0.44.

Figure 2.Two fitting linemodel

Although Regression Equation has been founded,what is the scope of accepting each point?We can find the former outliers.That is a point beyond confidence interval by calculation.Others are all within the prediction.By looking at the correlation and coefficient and standard error of regression,it is obvious that simple quadratic curve is better than simple one line curve.Thus we should consider the uncertainty of thewholemeasuring system and limitation of the usage of the simple one line to calculate.

Figure 3.Fitting line plot(1)

Figure 4.Fitting line plot(2)

3.2.The relativity of negative pressure method and the features of the two flow

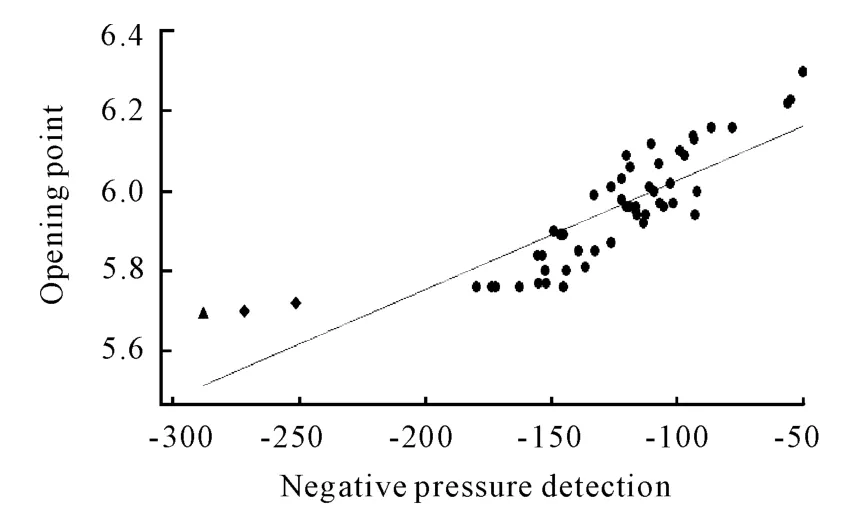

3.2.1.Negative pressuremethod and the flow of 750 r/m in

The linear regression derived from calculation:one could see from the following chart that the correlation coefficient R negative pressure-750 r/min flow=0.32 < R standard=0.354.Conclusion:the flow cannot be replaced by the negative pressure tomonitor

Figure 5.The fitting line graph in linearmodel

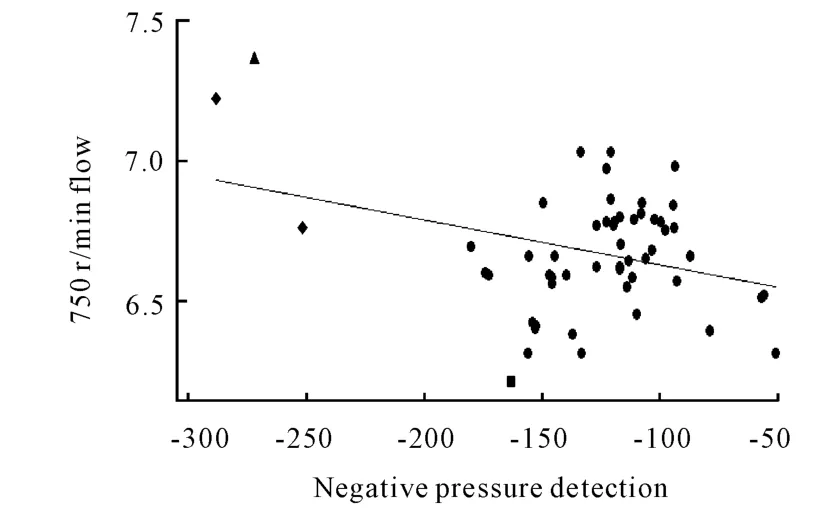

3.2.2.Negative pressuremethod and the flow of 2 500 r/m in

The linear regression derived from calculation:one could see from the following chart that correlation coefficient R pressure -2 500 r/min flow=0.337<Rs standard=0.354.Conclusion:the flow can not be replaced by the negative pressure tomonitor.

Figure 6.The fitting line graph in linearmodel

As for the above relativity,although simple quadratic curve is used,the same relativity and standard cannotmeet the demand.By analysismade with suppliers,there are the conclusions:

1)supplier can use the negative pressuremethod tomonitor the opening pressure

2)supplier cannotmonitor the flow of the two rotating speed in definition by using negative pressure

In order to checking the above deduction:

1)The flow of oil engine pump is related to the maximum space of stator,rotor,shell(experience).

We calculated and made chartof relativity of the maximum gap and flow.We also consider that when oil engine pump is variable displacement pump,it cannot be used to calculate the same displacement

2)Gap detection and the relativity of the features of the two flow

①Gap detection and the flow of 750 r/min:

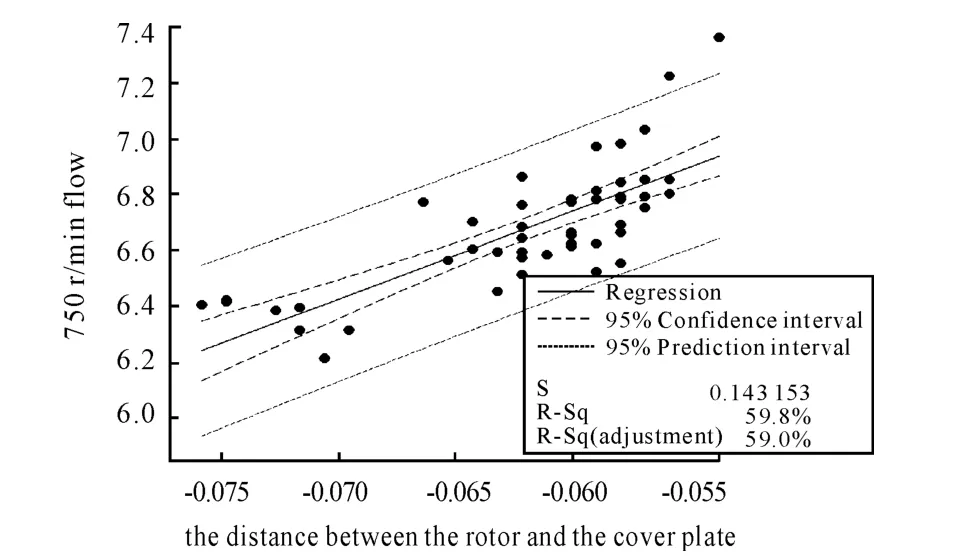

The linear regression derived from calculation:one could see from the following chart correlation coefficient R gap -750 r/min flow=0.77>R standard=0.554 1.Conclusion:Gap detection can take the place ofmonitoring of flow.

Figure 7.The fitting line graph in linearmodel

Confidence interval is also included,as shown in the flowing chart.

Figure 8.Fitting line plot

②Gap detection and the flow of 2 500 r/min

The linear regression derived from calculation:one could see from the following chart correlation coefficient R gap -250 r/min flow=0.63>R standard=0.5541 Conclusion:gap detection can take the place ofmonitoring of flow

Figure 9.Fitting line plot

4.Conclusion

This thesis demonstrates the relativity of the opening pressure of the safety velvet of the oil engine pump and control parameter on-line in several different aspect by using a lot of regression analysis of reliable data.Thus it is proved that oil engine pump used gas asmedium to undertake the task ofmonitoring instead of using one hundred percent of engine oil function.Still,it can supervise itby conversion of themeasurement of relativity.Therefore,we are able tomake full use of the advantage of such medium as gas,which not only can guarantee the cleanliness of the product more effectively but also the monitor function of the productefficiently.As a result,itwill facilitate our work.

[1] Junqiao Xiong,zhifang Yang.Development of test system for oil pump[J].Industrial instrumentation and automation device,2010(4):77-78.

[2] Haifeng Shan,Liu han.The performance of automobile electronic fuel pump test system based on PLC[J].Electrical and Mechanical Engineering,2013(7):794-796.

[3] Rusheng Zhou.Research status and development trend of fault diagnosis technology for hydraulic system[J].Chinese Journal of Mechanical Engineering,2006(9):32-33.

气体与液压油在机油泵性能转化检测中的相关性

李 蓉†1,孟庆新2

1.武汉软件工程职业学院汽车工程学院,武汉 430056

2.神龙汽车有限公司采购部,武汉 430056

机油泵是发动机中的重要零部件之一,功能是为发动机润滑系统提供润滑,并为部分零部件提供液压力,故机油泵的性能至关重要。目前,机油泵性能的检测介质主要有两种:气体和机油,其中气体具有很多的优势,但两者使用环境的介质不同。利用DPCA公司的真实数据对两者的相关性进行了探讨。

气体;液压;机油泵

U464.137+.1

10.3969/j.issn.1001-3881.2014.24.025

2014-08-15

- 机床与液压的其它文章

- Development of remotemonitoring system for hydraulic power station

- Low-noise optimization method for gearbox in consideration of operating conditions*

- Study on the precision ultrasonic densimeter*

- Recognition of license plate based on Fourier Descriptors

- Strong robust control strategy of form ing process in com plex work-pieces with p lastic cement*