超高温材料的研究现状与展望

张磊磊,付前刚,李贺军

(西北工业大学 超高温结构复合材料重点实验室,陕西 西安 710072 )

第一作者:张磊磊,男,1982年生,副教授

fuqiangang@nwpu.edu.cn

超高温材料的研究现状与展望

张磊磊,付前刚,李贺军

(西北工业大学 超高温结构复合材料重点实验室,陕西 西安 710072 )

摘要:超高温材料是航天飞行器长时飞行、大气层再入飞行和跨大气层飞行不可或缺的关键材料,其直接影响了航天飞行器的研制进程并对飞行试验的成败起到了至关重要的作用。综述了C/C复合材料、陶瓷基复合材料、碳化物超高温陶瓷、硼化物超高温陶瓷及氮化物超高温陶瓷等超高温材料近年来的最新研究成果,重点评述了C/C复合材料的组织形成机理、疲劳特性、基体改性及抗氧化行为,Cf/SiC及SiCf/SiC陶瓷基复合材料和超高温陶瓷在制备工艺、力学性能、抗氧化和抗烧蚀等方面的国内外研究现状,探讨了常用几种超高温材料的优缺点并分析了其研究重点,提出了超高温材料当前研究中存在的主要问题,指出了超高温材料未来的研究目标和发展方向。

关键词:C/C复合材料;碳化物;硼化物;氮化物;超高温陶瓷

1前言

飞行器长时飞行、大气层再入飞行和跨大气层飞行的极端环境对结构材料的性能要求越来越苛刻。目前,传统的金属材料的使用温度已经接近其极限,不能完全满足使用要求。新型结构材料问题已显露端倪,其重要性也进一步凸显,直接影响飞行器研制进程,决定飞行试验的成败。超高温材料因具有高熔点、高比强度、高热导、高电导、耐腐蚀以及较好的化学稳定性等众多优异特性,使其成为可以应用于极端环境下飞行器的高温结构材料。目前常用的超高温材料有C/C复合材料、陶瓷基复合材料,碳化物超高温陶瓷、硼化物超高温陶瓷及氮化物超高温陶瓷。本文综述了近年来在超高温材料领域的研究进展和突破,同时对未来研究的重点进行了展望。

2超高温材料

2.1C/C复合材料

C/C复合材料具有高比强、高比模、低膨胀系数、耐烧蚀和耐冲刷的优异特性,尤其是C/C复合材料的强度随着温度的升高不降反升的独特性能,使得其用作飞行器热防护系统具有其他材料难以比拟的优势。在2014年国际新材料发展趋势高层论坛上,航天材料及工艺研究所的李仲平院士强调了C/C复合材料在临近空间高超声速飞行器热结构材料体系中的重要作用,西北工业大学的李贺军教授介绍了C/C复合材料抗氧化抗烧蚀方面的最新研究成果,航天动力研究院的侯晓研究员详细介绍了C/C复合材料扩张段的发展情况,中南大学的黄启忠教授总结了C/C复合材料化学气相沉积工艺的研究进展,航天材料与工艺研究所的冯志海研究员分析了C/C复合材料中碳纤维的结构与性能。

2.1.1C/C复合材料的组织形成机理

通过调控C/C复合材料的热解炭织构可优化其力学性能、热物理性能和氧化烧蚀性能,从而保证C/C复合材料在实际服役环境中综合性能最优化,因此研究热解炭织构的形成机理具有重要的意义[1-2]。

Bokros[3-4]以甲烷作为气源沉积热解炭,系统研究了沉积温度(1 000~2 400 ℃)、气体组成、滞留时间、颗粒表面积等因素对热解炭结构的影响。Lieberman和Pierson[5-6]首次建立起热解炭的织构与气相化学组分的联系,对热解炭的织构形成机理研究具有重要意义。Féron等[7-8]采用丙烷为前驱气体进行研究,发现了热解炭织构由中织构(MT)-高织构(HT)-中织构(MT)的转变规律。Bourrat[9]和Bouchard[10]等在高定向热解石墨表面沉积了热解炭,测试了热解炭的结构及热解炭和高定向热解石墨表面的接触角,发现随着气体滞留时间的延长,热解炭织构发生MT-HT的转变,同时接触角变小,认为转变是由于气氛中的大分子芳香烃比例增加引起的。Zhang等[11]采用化学气相渗透(CVI)工艺,以甲烷为前驱体,在更大的压力范围内研究了热解炭织构的变化规律,提出了Particle-filler模型。黄启忠等[12]对热解碳点状织构的形核和生长机理进行了深入研究,丰富了热解碳的织构种类,开辟了热解碳沉积机理的新领域。作者所在课题组深入细致研究了化学气相沉积过程中温度、压力和滞留时间等因素对热解碳组织的影响规律,较为全面地解释了不同类型热解碳组织的形成机理,在此基础上实现了基体组织控制,制备出室温弯曲强度超过500 MPa,800 ℃弯曲强度超过700 MPa的高性能C/C复合材料,并成功应用于喷管实验件(图1)、导向叶片等构件的制备。

图1 C/C复合材料喷管实验件Fig.1 C/C composite nozzle sample

2.1.2C/C复合材料的疲劳行为

C/C复合材料在循环加载后出现剩余强度升高的现象,即“疲劳强化”现象,目前的研究主要集中于C/C复合材料疲劳增强机理和疲劳后材料物理性能(如热学、电学和内耗性能)的变化规律。

Ken等[13]研究了层压C/C复合材料循环加载后的剩余强度,提出“界面损伤”有助于提高C/C复合材料强度。Yang[14]和Zaman[15]等的研究发现C/C复合材料经循环加载之后,纤维/基体界面显著弱化,认为界面弱化是造成C/C复合材料疲劳增强的主要原因。关于疲劳实验参数对C/C复合材料疲劳性能的影响,Liao等[16]发现3D-C/C复合材料经过拉拉循环加载后,剩余强度随循环周次的增加而增加;Xue等[17]发现高的疲劳应力水平会使材料内部产生较多损伤,只有当应力水平低于疲劳极限时才出现疲劳增强现象。针对C/C复合材料构件局部区域的应力集中问题,Ken等[18]对缺口C/C试样进行了拉-拉疲劳测试,发现试样的剩余强度随疲劳应变的增加而增加;Anggit等[19]进一步指出缺口C/C试样的疲劳极限受纤维方向、缺口形状和应力比的影响,而对缺口深度不敏感。有关C/C复合材料热物理性能在循环加载后的变化规律,文献[20-22]进行了深入研究,典型的不同循环加载次数之后的热膨胀系数变化曲线如图2所示。此外,通过对材料在循环加载过程中电学[15,23]和内耗性能[24]进行监控,可以间接评价材料内部缺陷积累和性能衰变规律。

2.1.3C/C 复合材料的基体改性

C/C复合材料在高于450 ℃的有氧环境下极易氧化,超高温极端环境下烧蚀严重,导致力学性能急剧下降。基体改性技术是提升C/C复合材料抗氧化抗烧蚀性能的有效手段之一。目前的基体改性材料主要有ZrC、ZrB2、HfC、HfB2等。

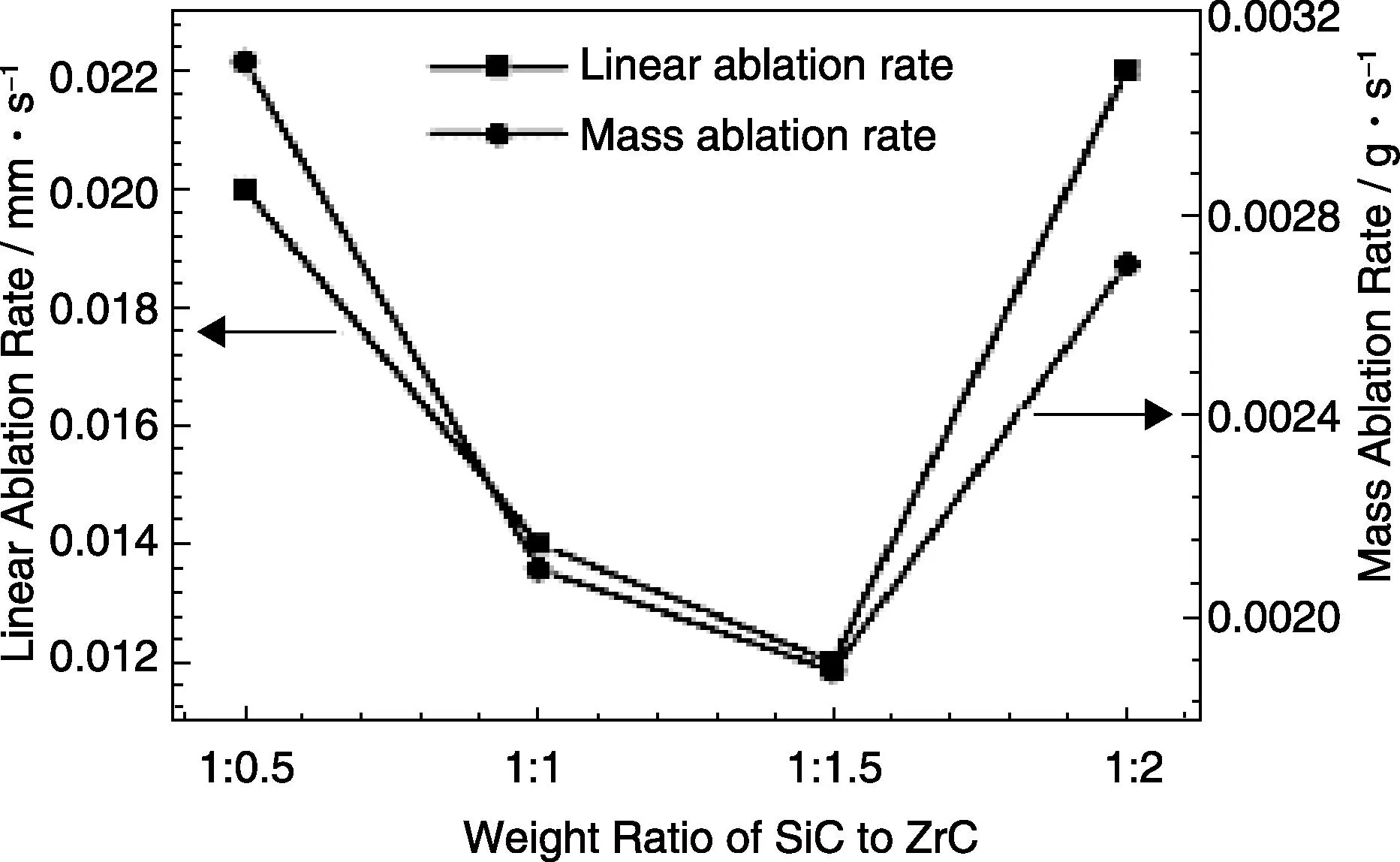

针对ZrC改性C/C复合材料,Liu等[25]通过先驱体高温裂解工艺制备出C/C-ZrC复合材料。Wang等[26]分别以酚醛树脂和沥青为碳源,得到多孔C/C预制体,再采用反应熔体浸渗法制备了3D-C/ZrC复合材料。Li等[27]在聚合有机锆和PCS的质量比为1∶1,热处理温度及热处理时间分别为1 500 ℃和120 s的前提下,通过聚合物浸渍裂解(PIP)工艺制备3D Cf/SiC-ZrC复合材料。Wang等[28]采用反应熔渗(RMI)工艺制备出C/C-SiC-ZrC复合材料。Feng等[29]研究了SiC/ZrC 的质量比对C/C-SiC-ZrC复合材料力学及抗烧蚀性能的影响(图3)。 针对ZrB2改性C/C复合材料,Tong等人[30]采用反应熔体渗透法向C/ZrC预制体中浸渗Zr-B合金,原位反应后得到ZrB2改性的C/ZrC复合材料。Huang等[31]将ZrB2颗粒喷涂在每层织物上,随后将织物叠层采用针刺法缝合,最终得到Cf/ZrB2预制体,再通过PIP工艺得到C/C-ZrB2-ZrC-SiC复合材料。Hu等[32]采用CVI技术和PIP技术相结合的方法制备出了以Cf/SiC-ZrB2-ZrC为外层包夹Cf/SiC内层的“三明治”结构复合材料。Liu等[33]采用PIP技术制备出了C/C-ZrB2-ZrC-SiC与C/C-ZrB2-ZrC复合材料。针对HfC改性C/C复合材料,Xue 等[34]采用PIP工艺,将HfC陶瓷前驱体引入到低密度C/C预制体中,经过高温裂解得到C/C-HfC复合材料。Li等[35]以八水氧氯化铪为铪源制备出HfC-C/C复合材料。针对HfB2改性C/C复合材料,Yao等[36]分别以氯化铪和氧化硼为铪源及硼源,制备出HfB2改性的C/C复合材料。

图2 不同循环加载次数后2D-C/C复合材料的热膨胀曲线[21] Fig.2 Thermal expansion curves of 2D-C/C composites underdifferent cyclic loading times[21]

图3 不同质量比SiC/ZrC改性C/C复合材料的质量烧蚀率及线烧蚀率[33]Fig.3 Mass and linear ablation rates of the C/C-ZrC-SiC composites with different SiC/ZrC wight ratios[33]

2.1.4C/C 复合材料的抗氧化

基体改性技术的防氧化温度与保护时间有限[37-40],高温长寿命防氧化必须依赖涂层技术。

目前开发的防氧化涂层体系主要有玻璃涂层、金属涂层和陶瓷涂层。玻璃涂层可以用于密封层材料[41-45]或刹车盘非摩擦面的防氧化(图4)[46-48]。

图4 涂覆磷酸盐玻璃涂层的C/C复合材料飞机刹车盘Fig.4 C/C composite brake disc with phosphate glass coating

金属涂层采用高熔点和低氧扩散系数的Ir、Hf、Cr、Mo等金属,对C/C复合材料进行防护,起到了较好的效果[49-50]。而陶瓷涂层是目前研究得最为深入、高温防护效果最好的抗氧化涂层体系。陶瓷涂层通常利用硅化物的高温氧化产物(玻璃态SiO2)填充涂层中的裂纹,阻挡氧气渗入[51]。陶瓷涂层中的SiC-HfC多层复合涂层已经应用于X43A飞行器的C/C复合材料前缘(图5)[52]。

为进一步提高陶瓷涂层的性能,缓解陶瓷与C/C之间热膨胀系数的差异,研究人员相继开发了多相镶嵌、梯度、第二相增韧等陶瓷涂层体系。多相镶嵌涂层利用大量的相界面来松弛应力,缓解热失配。Zhao等[53]制备的Si-MoSi2/SiC涂层经1 400 ℃氧化100 h后失重0.36%。Ran等[54]制备的MoSi2/SiC涂层可在1 500 ℃对C/C复合材料有效保护52 h。Ren等[55]开发的TaxHf1-xB2-SiC/SiC涂层在1 500 ℃下的防氧化寿命达到1 480 h。梯度涂层使涂层与基体及多层涂层之间的组成呈连续分布,可消除界面应力,缓解了涂层开裂趋势。国外学者制备的(SiC/Si3N4)/C梯度涂层[56],可用于1 500~1 550 ℃抗氧化。Zhang等[57-58]在C/C复合材料表面引入C-SiC梯度涂层,有效缓解了涂层与基体的热失配。将小尺寸的第二相引入陶瓷涂层中也可以提高韧性,减少涂层中裂纹。文献[59-64]报道通过引入SiC、ZrO2纳米颗粒和SiC晶须,或将SiC、HfC纳米线引入涂层中,通过纳米线拔出、桥联以及裂纹偏转等增韧机理有效地抑制了涂层的开裂(图6)。

图5 涂覆SiC-HfC多层复合涂层的C/C复合材料前缘[52]Fig.5 C/C composite engine leading edge with SiC-HfC multi-layer composite coating[52]

2.2超高温陶瓷

目前常用的超高温陶瓷主要有陶瓷基复合材料、碳化物陶瓷、硼化物陶瓷和氮化物陶瓷。在2014年国际新材料发展趋势论坛上,李仲平院士强调加快发展高性能低成本SiC前驱体和 SiC纤维研发工作,推动SiC/SiC陶瓷基复合材料基础研究和应用基础研究。论坛上,西北工业大学成来飞教授介绍了SiCw/SiC层状结构陶瓷的研究进展,中国科学院上海硅酸盐研究所的董绍明教授介绍了原位反应法制备碳化物和氮化物陶瓷基复合材料。

2.2.1陶瓷基复合材料

陶瓷基复合材料的研究主要集中在Cf/SiC及SiCf/SiC复合材料。西北工业大学张立同院士课题组采用CVI、PIP以及RMI等方法制备出Cf/SiC陶瓷基复合材料并提出界面区的概念,建立了Cf/SiC内基体裂纹与界面区相互作用的物理模型,并对其服役性能进行了系统性的评价[65-66]。中国科学院上海硅酸盐研究所的董绍明等尝试在PIP制备Cf/SiC、SiCf/SiC复合材料的过程中加入硼、铝等添加剂,达到了缩短PIP致密化时间、提高抗氧化能力和力学性能的效果[67-68]。另外,该研究组还通过液相渗硅(LSI)的方法制备出新型Cf/SiC复合材料,在干摩擦条件下主要表现为磨粒磨损,磨损率仅为5.87 μg/m MPa[69]。

图6 SiC纳米线在抗氧化涂层中的拔出 (a)、桥联 (b) 以及裂纹偏转 (c)[62]Fig.6 SiC nanowire in anti-oxidation coating: (a) pullout or debonding; (b) bridging; (c) microcrack deflection[62]

2.2.2碳化物超高温陶瓷

碳化物超高温陶瓷具有高熔点、高强度、高硬度以及良好力学性能、良好的化学稳定性,是应用广泛的超高温陶瓷材料[70],目前常用的碳化物超高温陶瓷主要包括SiC、ZrC、TaC和HfC。

针对SiC陶瓷的研究,成来飞等结合流延成型、反应热压烧结和CVI的方法,发展出结构、抗冲击和超高温等针对不同应用领域的层状陶瓷。例如,通过结合流延成型和CVI的方法,成功制备出层状SiCw/SiC复合陶瓷,与SiC块体陶瓷相比,SiCw/SiC层状结构陶瓷具有较高的断裂位移和断裂功,与SiCf/SiC和C/SiC复合材料相比,SiCw/SiC层状结构陶瓷具有较高的弯曲模量[71];通过流延成型和反应热压烧结的方法,制备出Zr/SiC和Zr/Si3N4等层状复合材料,这些陶瓷都具有优异的动态压缩性能和高的冲击能量吸收率[72-74];采用结合流延成型和反应热压烧结的方法,制备出ZrB2-SiC以及HfC-SiC层状复合陶瓷,其在短时烧蚀的条件下具有极低的线烧蚀率,表现出优异的抗烧蚀性能[75-76]。Wang等[77]研究了VC、NbC和TaC掺杂对ZrC陶瓷的影响。Ma等[78]采用热压烧结法制备的含20% SiC及10%石墨的ZrC-SiC-C陶瓷,其室温下弯曲强度达到了425 MPa,并且在300 ℃热震后仍能保持约63.5%的原始强度。Ljiljana等[79]通过放电等离子烧结法制备出ZrC-SiC陶瓷,其两相分布均匀,室温下维氏显微硬度和断裂韧性分别达到了20.7 GPa和5.07 MPa·m1/2。Liu等[80]利用放电等离子烧结法制备了TaC陶瓷,研究了SiC添加剂对TaC陶瓷显微组织及力学性能的影响。Wang等[81]采用浆料浸渗结合CVI工艺制备出碳纤维增强SiC-TaC复合材料,结果表明添加TaC有助于提高C/SiC复合材料的抗烧蚀性能。Pienti等[82]加入15%体积分数的MoSi2作为烧结助剂,制备了HfC和TaC基复合材料,并对比基于HfC和TaC复合材料的烧蚀模型发现,HfC和TaC复合材料具有更佳的耐烧蚀性。Liu 等[83]等用流延法和热压法制备了含有BN和石墨两种中间层的层压 HfC-SiC陶瓷,氧乙炔烧蚀测试发现层压HfC-SiC陶瓷比单层HfC-SiC具有优异的热氧化稳定性和构型稳定性。

2.2.3硼化物超高温陶瓷

硼化物超高温陶瓷与碳化物和氮化物相比,拥有更加优异的抗氧化性能,因此吸引了世界各国学者广泛的关注[84-87]。近年来关于硼化物超高温陶瓷的研究主要集中在致密化工艺、力学性能的提高以及抗氧化行为等方面。硼化物超高温陶瓷主要包括ZrB2,TaB2和HfB2。

Zou等[88]使用热压法制备了ZrB2-SiC复合材料,并研究了WC和ZrC作为添加剂对试样的影响,结果表明WC的添加可以显著增加试样的弯曲强度,而ZrC的添加降低了试样的弯曲强度,ZrB2-20SiC-5WC陶瓷在1 600 ℃下的弯曲强度约为675±33 MPa,是室温下其弯曲强度的1.115倍。Sciti等[89]选用MoSi2和TaSi2作为烧结助剂,采用放电等离子烧结法制备了HfB2-MoSi2和HfB2-TaSi2陶瓷,二者的硬度约为20~22 GPa,HfB2-3% MoSi2(体积分数)复合材料具有较高的强度,在室温下和1 500 ℃下的弯曲强度分别为760 MPa和480 MPa。Wang等[90]使用原位反应热压法制备了ZrB2-SiC-ZrC复合材料,并研究了试样在1 750 ℃下的静态等温氧化性能。Lee等[91]以Ta,B4C和Si为前驱物采用反应热压法制备了TaB2-SiC复合材料,其弹性模量、弯曲强度、维氏硬度及断裂韧性分别为487 GPa,542 MPa及17.9 GPa以及3.63 MPa·m1/2,试样在1 500 ℃的氧化条件下表现出抛物线规律的被动氧化行为。Lin等[92]研究了ZrO2纤维增韧相对ZrB2-SiC复合材料的影响,采用热压法在1 850 ℃下制备的ZrB2-SiC-ZrO2f陶瓷的弹性强度和断裂韧性分别为1 086±79 MPa和6.9±0.4 MPa·m1/2。Silvestroni[93]以MoSi2作为添加剂采用热压法制备了相对密度达到90%~95%的TaB2-MoSi2复合材料,试样的硬度为18 GPa,断裂韧性为4.6 MPa·m1/2。Talmy等[94]通过无压烧结方法制备了TaC-TaB2-C陶瓷,发现TaB2的存在可以抑制TaC晶粒生长并增加TaC陶瓷的硬度。Ni等[95]通过热压烧结技术制备了HfB2-SiC(HS)陶瓷以及HfB2-HfC-SiC (HHS)陶瓷。发现在添加HfC后,复合材料的晶粒尺寸得到了优化,HHS陶瓷的断裂韧性和弯曲强度值分别为5.09 MPa·m1/2和863 MPa,明显优于HS陶瓷的3.95 MPa·m1/2和654 MPa。

2.2.4氮化物超高温陶瓷

氮化物超高温陶瓷的化学性质稳定,多以共价键为主,结构单元为四面体的M4N,类似于金刚石,也称为类金刚石化合物。应用较广泛的氮化物超高温陶瓷主要有Si3N4,BN和HfN等。

Escobar等[96]用磁控溅射技术在钢表面沉积多层体系HfN/VN层,发现HfN/VN多层涂层在面心立方(111)晶体结构方向优先生长。Huang等[97]用第一性原理计算了HfN向Hf3N4陶瓷相转变时电子性质的变换。Zhou等[98]等用单源前驱体的氨化作用制备了新型非晶态聚合物衍生的Si-Hf-N陶瓷。Matsuoka等[99]研究发现HfO2促进了Si3N4的致密化。Guo等[100]发现在烧结助剂MgO-Lu2O3的作用下,在1 500℃或低于1 500℃的Ar气环境中可得到密实的Si3N4-ZrB2陶瓷。Ahmad等[101]发现气氛类型、退火温度和含氮量对Si3N4-Al2O3-SiO2-Y2O3玻璃陶瓷的微观结构和转变温度都有很大影响。Li等[102]采用热压法以Si3N4粉末和CeO2为添加剂制备了致密的Si3N4陶瓷。董绍明等[103]将Si3N4陶瓷引入到Cf/SiC复合材料中,提高了陶瓷的产率,降低了体积收缩和线收缩,改善了复合材料的界面结合状态,使得其弯曲强度提高近一倍。

3结语

世界航空航天技术的发展对超高温材料的性能提出了苛刻的要求,尤其是高性能航空发动机热结构件与空天飞行器热防护系统,其在服役过程中要承受严重的烧蚀、高速气流的强冲击和大梯度的热冲击,因而对超高温材料的发展提出了新的挑战。目前,我国在超高温材料的研究方面已取得了较大的突破性进展,然而该材料的研究仍然有诸多问题悬而未决,今后对于超高温材料的研究,认为应重点加强以下几方面:

(1)开发宽温区抗氧化C/C复合材料。目前已开发的抗氧化涂层的有效防护温度范围较窄,难以满足低温至高温的宽温区范围抗氧化,构建功能梯度涂层,避免涂层开裂或减少涂层中裂纹尺寸,是实现宽温区抗氧化的有效途径;

(2)针对应用构件的C/C复合材料基体改性研究。目前的C/C复合材料基体改性研究大多针对微小试样进行,针对具体的应用构件,尚需研究由微小试样到应用构件转变过程中,制备工艺的稳定性、基体改性措施的可移植性以及构件综合性能的协调性等问题;

(3)探索提高超高温陶瓷材料韧性的措施,如将纳米线、纳米带、纳米棒引入碳化物、氮化物和硼化物及其复合陶瓷中,有望显著提高超高温陶瓷的韧性;

(4)解决超高温陶瓷材料的缺陷控制问题。缺陷是超高温陶瓷材料中难以避免的组成部分,而缺陷对超高温陶瓷材料的性能又有十分显著的影响,因此探索缺陷的形成原因、检测、表征与控制是未来研究的方向之一;

(5)完善超高温材料的性能测试规范。目前缺乏针对超高温材料的性能测试统一标准。各个研究机构的性能测试结果难以实现横向对比,急需建立和完善超高温材料的性能指标和评价体系数据库。

参考文献References

[1]Guellali M, Oberacker R, Hoffmann M J. Influence of the Matrix Microstructure on the Mechanical Properties of CVI-Infiltrated Carbon Fiber Felts[J].Carbon, 2005, 43(9): 1 954-1 960.

[2]Xu Guozhong, Li Hejun, Bai Ruicheng,etal. Influence of the Matrix Texture on the Fracture Behavior of 2D Carbon/Carbon Composites[J].MaterialsScienceandEngineering:A, 2008, 478(1-2): 319-323.

[3]Bokros J C. The Structure of Pyrolytic Carbon Deposited in a Fluidized Bed[J].Carbon,1965,3(1): 17-29.

[4]Price R J, Bokros J C, Koyama K. Structure and Properties of Pyrolytic Carbons Prepared in a Fluidized Bed between 1900℃ and 2400℃[J].Carbon, 1966, 4(2): 263-272.

[5]Lieberman M L, Pierson H O. Effect of Gas Phase Conditions on Resultant Matrix Pyrocarbons in Carbon/Carbon Composites[J].Carbon, 1974, 12(3): 233-241.

[6]Pierson H O, Lieberman M L. The Chemical Vapor Deposition of Carbon on Carbon Fibers [J].Carbon, 1975,13(3): 159-166.

[7]Féron O, Langlais F, Naslain R,etal. On Kinetic and Microstructural Transitions in the CVD of Pyrocarbon from Propane[J].Carbon,1999,37(9): 1 343-1 353.

[8]Lavenac J, Langlais F, Feron O,etal. Microstructure of the Pyrocarbon Matrix in Carbon/Carbon Composites[J].CompositesScienceandTechnology, 2001, 61(3): 339-345.

[9]Bourrat X, Lavenac J, Anglais F,etal. The Role of Pentagons in the Growth of Laminar Pyrocarbon[J].Carbon, 2001, 39(15): 2 376-2 380.

[10]Bouchard E, Lavenac J, Roux J C,etal. Pyrocarbon Deposits on a Graphite Surface Observed by STM[J].ChemicalVaporDeposition, 2001, 7(3): 125-130.

[11]Zhang W G, Hu Z J, Hüttinger K J. Chemical Vapor Infiltration of Carbon Fiber Felt: Optimization of Densification and Carbon Microstructure[J].Carbon, 2002, 40(14): 2 529-2 545.

[12]Fan Z Q, Tan R X, He K J,etal. Preparation and Mechanical Properties of Carbon Fibers with Isotropic Pyrolytic Carbon Core by Chemical Vapor Deposition [J].ChemicalEngineeringJournal, 2015, 272(1): 12-16.

[13]Goto Ken, Hatta Hiroshi, Katsu Daisuke,etal. Tensile Fatigue of a Laminated Carbon-Carbon Composite at Room Temperature[J].Carbon, 2003, 41 (6):1 249-1 255.

[14]Yang Xi, Li Hejun, Yu Kuahai,etal. Effect of Stress Level on Fatigue Behavior of 2D C/C Composites[J].TransactionsofNonferrousMetalsSocietyofChina, 2013, 23(7): 2 135-2 140.

[15]Wajed Zaman, Li Kezhi, Li Wei,etal. Flexural Strength and Thermal Expansion of 4 D Carbon/Carbon Composites after Flexural Fatigue Loading[J].NewCarbonMaterials, 2014, 29(3): 169-175.

[16]Liao Xiaoling, Li Hejun, Xu Wenfeng,etal. Effects of Tensile Fatigue Loads on Flexural Behavior of 3D Braided C/C Composites[J].CompositesScienceandTechnology, 2008, 68(2): 333-336.

[17]Xue Lizhen, Li Kezhi, Jia Yan,etal. Flexural Fatigue Behavior of 2D Cross-Ply Carbon/Carbon Composites at Room Temperature[J].MaterialsScienceandEngineering:A, 2015, 634: 209-214.

[18]Goto Ken, Furukawa Yuko, Hatta Hiroshi,etal. Fatigue Behavior of 2D Laminate C/C Composites at Room Temperature[J].CompositesScienceandTechnology, 2005, 65 (7): 1 044-1 051.

[19]Murdani A, Makabe C, Fujikawa M,etal. Fatigue and Fracture Behavior in Notched Specimens of C/C Composite with Fine-Woven Carbon Fiber Laminates[J],Carbon, 2009, 47 (14): 3 355-3 364.

[20]Liao Xiaoling, Li Hejun, Xu Wenfeng,etal. Study on the Thermal Expansion Properties of C/C Composites[J].JournalofMaterialsScience, 2007, 42 (10): 3 435-3 439.

[21]Yang Xiaohui (杨晓辉), Lu Jinhua (卢锦花), Li Kezhi (李克智),etal.弯-弯疲劳加载对2D-C/C复合材料热膨胀性能的影响[J].JournalofSolidRocketTechnology(固体火箭技术), 2012, 05: 665-669.

[22]Luo Wenfei, Fu Yewei, Zhang Shouyang,etal. Effects of Different Loading Methods on Thermal Expansion Behaviors of 2D Cross-Ply Carbon/Carbon Composites from 850°C to 2300°C[J].CeramicsInternational, 2014, 40(8,Part A): 12 545-12 551.

[23]Xue Lizhen, Li Kezhi, Zhang Shouyang,etal. Monitoring the Damage Evolution of Flexural Fatigue in Unidirectional Carbon/Carbon Composites by Electrical Resistance Change Method[J].InternationalJournalofFatigue, 2014,68: 248-252.

[24]Cheng Jing, Li Hejun, Zhang Shouyang,etal. Internal Friction Behavior of Unidirectional Carbon/Carbon Composites after Different Fatigue Cycles[J].MaterialsScienceandEngineering:A, 2014, 600:129-134.

[25]Liu Chunxuan, Chen Jianchun, Su Zhean,etal. Pyrolysis Mechanism of ZrC Precursor and Fabrication of C/C-ZrC Composites by Precursor Infiltration and Pyrolysis[J].TransactionofNonferrousMetalsSocietyofChina, 2014, 24(6):1 779-1 784.

[26]Wang Song, Zhu Yulin, Chen Hongmei,etal. Effects of Carbon Matrix on Microstructure and Properties of 3-D C/ZrC Composites Prepared by Reactive Melt Infiltration[J].CeramicsInternational, 2014, 40(5):7 307-7 314.

[27]Li Q G, Zhou H J, Dong S M,etal. Fabrication and Comparison of 3D Cf/ZrC-SiC Composites Using ZrC Particles/ Polycarbosilane and ZrC Precursor/Polycarbosilane[J].CeramicsInternational, 2012, 38(6):5 271-5 275.

[28]Wang Yiguang, Zhu Xiaojuan ,Zhang Litong,etal. C/C-SiC-ZrC Composites Fabricated by Reactive Melt Infiltration with Si0.87Zr0.13Alloy[J].CeramicsInternational, 2012, 38(5):4 337-4 343.

[29]Feng Bo, Li Hejun, Zhang Yulei,etal. Effect of SiC/ZrC Ratio on the Mechanical and Ablation Properties of C/C-SiC-ZrC Composites[J].CorrosionScience, 2014, 82:27-35.

[30]Tong Yonggang, Bai Shuxin, Ye Yicong,etal. Reactive Melt Infiltration of a ZrB2Modified C/ZrC Composite by a Eutectic Zr-B Alloy[J].MaterialsLetters, 2015,138(1):208-211.

[31]Huang Dong, Zhang Mingyu, Huang Qizhong,etal. Ablation Mechanism of C/C-ZrB2-ZrC-SiC Composite Fabricated by Polymer Infiltration and Pyrolysis with Preform of Cf/ZrB2[J].CorrosionScience,2015,19(2):22-27.

[32]Hu Chenglong, Pang Shengyang, Tang Sufang,etal. Ablation and Mechanical Behavior of a Sandwich-Structured Composite with an Inner Layer of Cf/SiC between Two Outer Layers of Cf/SiC- ZrB2-ZrC[J].CorrosionScience,2015,80:154-163.

[33]Liu Lei, Li Hejun, Feng Wei,etal. Ablation in Different Heat Fluxes of C/C Composites Modified by ZrB2-ZrC and ZrB2-ZrC-SiC Particles[J].CorrosionScience,2013,74:159-167.

[34]Xue Liang, Su Zhean, Yang Xin,etal. Microstructure and Ablation Behavior of C/C-HfC Composites Prepared by Precursor Infiltration and Pyrolysis[J].CorrosionScience,2015,94:165-170.

[35]Li Shuping, Li Kezhi, Du Hongying,etal. Effect of Hafnium Carbide Content on the Ablative Performance of Carbon/Carbon Composites as Rocket Throats[J].Carbon,2013,51(4):437-438.

[36]Li Hejun, Yao Dongjia, Fu Qianggang,etal. Anti-Oxidation and Ablation Properties of Carbon/Carbon Composites Infiltrated by Hafnium Boride[J].Carbon,2013,52:418-426.

[37]Corral E L,Loehman R E. Ultrahigh-Temperature Ceramic Coatings for Oxidation Protection of Carbon-Carbon Composites[J].JournalofAmericanCeramicSociety,2008,91(5):1 495-1 502.

[38]Jcobson N S, Curry D M. Oxidation Microstructure Studies of Reinforced Carbon/Carbon[J].Carbon, 2006, 44(7):1 142-1 150.

[39]Li Hejun(李贺军), Xue Hui(薛 晖), Fu Qiangang(付前刚),etal. C/C复合材料高温抗氧化涂层的研究现状与展望[J].JournalofInorganicMaterials(无机材料学报), 2010, 25(4):337-342.

[40]Fu Qiangang(付前刚), Zhang Jiaping(张佳平), Li Hejun(李贺军). 抗烧蚀C/C复合材料研究进展[J].NewCarbonMaterials(新型炭材料), 2015, 30(2):97-105.

[41]Smeacetto F, Ferraris M, Salvo M. Multilayer Coating with Self-Sealing Properties for Carbon-Carbon Composites[J].Carbon, 2003, 41(11):2 105-2 111.

[42]Fu Qiangang, Li Hejun, Li Kezhi,etal. A SiC/Glass Oxidation Protective Coating for Carbon/Carbon Composites for Application at 1173K[J].Carbon, 2007, 45(4):892-894.

[43]Fu Qiangang, Li Hejun, Shi Xiaohong,etal. Double-Layer Oxidation Protective SiC/Glass Coatings for Carbon/Carbon Composites[J].Surface&CoatingsTechnology, 2006, 200(11):3 473-3 477.

[44]Fu Qiangang, Li Hejun, Shi Xiaohong,etal. Oxidation Protective Glass Coating for SiC Coated Carbon/Carbon Composites for Application at 1773K[J].MaterialsLetters,2006,60(3):431-434.

[45]Huang Jianfeng, Zhang Yulei, Zhu Kongjun,etal. Microstructure and Oxidation Protection of Borosilicate Glass Coating Prepared by Pulse Arc Discharge Deposition for C/C Composites[J].CeramicsInternational, 2015, 41(3):4 662-4 667.

[46]Fu Qiangang(付前刚), Li Hejun(李贺军), Huang Jianfeng(黄剑锋),etal. 炭/炭复合材料磷酸盐涂层的抗氧化性能研究[J].MaterialsProtection(材料保护), 2005, 38(3):52-54.

[47]Fang Haitao, Zhu Jingchuan, Yin Zhongda,etal. A Si-Mo Fused Slurry Coating for Oxidation Protection of Carbon-Carbon Composites[J].JournalofMaterialsScienceLetters, 2001, 20(2):175-177.

[48]Zhang Yulei, Li Hejun, Fu Qiangang,etal. A Si-Mo Oxidation Protective Coating for C/SiC Coated Carbon/Carbon Composites[J].Carbon, 2008, 45(5): 1 130-1 133.

[49]Fu Qiangang, Li Hejun, Li Kezhi,etal. A Si-Mo-W Coating to Protect SiC-Coated Carbon/Carbon Composites against Oxidation[J].JournaloftheAmericanCeramicSociety, 2009, 92(9):2 132-2 135.

[50]Zhang Yulei, Li Hejun, Yao Xiyuan,etal. Oxidation Protection of C/SiC Coated Carbon/Carbon Composites with Si-Mo Coating at High Temperature[J].CorrosionScience, 2011, 53(6):2 075-2 079.

[51]Zhang Yulei, Li Hejun, Hu Zhixiong,etal. Microstructure and Oxidation Resistance of Si-Mo-B Coating for C/SiC Coated Carbon/Carbon Composites[J].CorrosionScience, 2013, 72:150-155.

[52]http://blog.sina.com.cn/s/blog_4e66996d0100bcll.html

[53]Zhao Juan, Guo Quangui, Shi Jingli,etal. SiC/Si-MoSi2Oxidation Protective Coatings for Carbon Materials[J].Surface&CoatingsTechnology,2006,201(3/4):1 861-1 865.

[54]Ran Liping(冉丽萍),Yi Maozhong(易茂中),Jiang Jianxian (蒋建献),etal. 炭/炭复合材料MoSi2/SiC高温抗氧化复合涂层的制备及其结构[J].NewCarbonMaterials(新型炭材料),2006,21(3):231-236.

[55]Ren Xuanru, Li Hejun, Fu Qiangang,etal. TaxHf1-xB2-SiC Multiphase Oxidation Protective Coating for SiC-Coated Carbon/Carbon Composites[J].CorrosionScience, 2014, 87:479-488.

[56]Zhu Y C, Ohtani S, Sato Y,etal. Formation of a Functionally Gradient (Si3N4+SiC)/C Layer for the Oxidation Protection of Carbon-Carbon Composites[J].Carbon, 1999, 37(9):1 417-1 423.

[57]Zhang Yulei, Li Hejun, Fu Qiangang,etal. A C/SiC Gradient Oxidation Protective Coating for Carbon/Carbon Composites[J].Surface&CoatingsTechnology, 2006, 201(6):3 491-3 495.

[58]Li Hejun, Zhang Yulei, Fu Qiangang,etal. Oxidation Behavior of SiC Nanoparticle-SiC Oxidation Protective Coating for Carbon/Carbon Composites at 1773K[J].Carbon, 2007, 45(13):2 704-2 707.

[59]Zhang Yulei, Li Hejun, Fu Qiangang,etal. High Performance SiC Oxidation Protective Coating with ZrO2Particle Dispersion for Carbon/Carbon Composites[J].AdvancedEngineeringMaterials,2008, 10(10):986-989.

[60]Li Hejun, Fu Qiangang, Shi Xiaohong,etal. SiC Whisker-Toughened SiC Oxidation Protective Coating for Carbon/Carbon Composites[J].Carbon, 2006, 44(3):602-605.

[61]Fu Qiangang, Li Hejun, Li Kezhi,etal. SiC Whisker-Toughened MoSi2-SiC-Si Coating to Protect Carbon/Carbon Composites against Oxidation[J].Carbon, 2006, 44(9):1 866-1 869.

[62]Chu Yanhui, Fu Qiangang, Li Hejun,etal. Effect of SiC Nanowires on the Mechanical and Oxidation Protective Ability of SiC Coating for C/C Composites[J].JournaloftheAmericanCeramicSociety, 2012, 95(2):739-745.

[63]Chu Yanhui, Li Hejun, Li Lu,etal. Oxidation Protection of C/C Composites by Ultra Long SiC Nanowire-Reinforced SiC-Si Coating[J].CorrosionScience, 2014,84:204-208.

[64]Zhang Yulei, Ren Jincui, Tian Song,etal. HfC Nanowire-Toughened TaSi2-TaC-SiC-Si Multiphase Coating for C/C Composites against Oxidation[J].CorrosionScience, 2015, 90:554-561.

[65]Li Houbu, Zhang Litong, Cheng Laifei,etal. Polymer-Ceramic Conversion of a Highly Branched Liquid Polycarbosilane for SiC-Based Ceramics[J].JournalofMaterialsScience,2008,43(8): 2 806-2 811.

[66]Hui Mei, Laifei Cheng. Thermal Cycling Response Behavior of Ceramic Matrix Composites under Load and Displacement Constraints[J].MaterialsScienceandEngineeringA-StructuralMaterialsPropertiesMicrostructureandProcessing,2008,486(1-2): 235-240.

[67]Wang Zhen, Dong Shaoming, He Ping,etal. Fabrication of Carbon Fiber Reinforced Ceramic Matrix Composites with Improved Oxidation Resistance Using Boron as Active Filler[J].JournaloftheEuropeanCeramicSociety,2010,30(9): 1 971-1 972.

[68]Zhu Yunzhou, Zhu Shuzhen, HuangZhengren,etal. Properties and Microstructure of KD-I/SiC Composites by Combined Process of CVI/RB/PIP[J].MaterialsScienceandEngineeringA-StructuralMaterialsPropertiesMicrostructureandProcessing,2008,477(1-2): 198-203.

[69]Zhou Haijun, Dong Shaoming, DingYusheng,etal. Friction and Wear Properties of 3D Carbon/Silicon Carbide Composites Prepared by Liquid Silicon Infiltration[J].TribologyLetters, 2010,37(2): 337-341.

[70]Ma Yan, Wang Song, Chen Zhaohui. Effects of High-Temperature Annealing on the Microstructures and Mechanical Properties of Cf/SiC Composites Using Polycarbosilane[J].MaterialsScienceandEngineeringA-StructuralMaterialsPropertiesMicrostructureandProcessing,2011,528(7-8): 3 069-3 072.

[71]Xie Yupeng, Cheng Laifei, Li Liangjun,etal. Fabrication of Laminated SiCw/SiC Ceramic Composites by CVI[J].JournaloftheEuropeanCeramicSociety,2013,33(10): 1 701-1 706.

[72]Li Liangjun, Cheng Laifei, Fan Shangwu,etal. A Novel Fabrication Approach for Impact Resistance Laminated Ceramics[J].Materials&Design,2015,79: 26-31.

[73]Li Liangjun,Cheng Laifei, Fan Shangwu,etal. Fabrication and Properties of Zr/SiC and Zr/Si3N4Laminated Composites[M]. 2014: 99-103.

[74]Li Liangjun, Cheng Laifei, Fan Shangwu,etal. Fabrication and Dynamic Compressive Response of Laminated ZrO-Zr2CN/Si3N4Ceramics[J].CeramicsInternational, 2015,41(7): 8 584-8 591.

[75]Zuo Fengjuan, Cheng Laifei, Xiang Liuyi ,etal. Ablative Property of Laminated ZrB2-SiC Ceramics under Oxyacetylene Torch[J].CeramicsInternational,2013,39(4): 4 627-4 631.

[76]Xiang Liuyi, Cheng Laifei, Fan Xiaomeng,etal. Effect of Interlayer on the Ablation Properties of Laminated HfC-SiC Ceramics under Oxyacetylene Torch[J].CorrosionScience,2015,93: 172-179.

[77]Wang Xingang, Liu Jixuan, Kan Yanmei,etal. Effect of Solid Solution Formation on Densification of Hot-Pressed ZrC Ceramics withMC (M= V, Nb, and Ta) Additions[J].JournaloftheEuropeanCeramicSociety,2012,32(8): 1 795-1 802.

[78]Ma Baoxia, Han Wenbo. Thermal Shock Resistance of ZrC Matrix Ceramics[J].JournalofRefractoryMetalsandHardMaterials,2010, 28: 187-190.

[79]Kljajevic L, Nenadovic S, Nenadovic M,etal. Spark Plasma Sintering of ZrC-SiC Ceramics with LiYO2Additive[J].CeramicsInternational, 2013, 39: 5 467-5 476.

[80]Liu Han(刘 晗).EffectsofSiliconCarbideAdditiononMicrostructureandMechanicalPropertiesofTantalumCarbideCeramics(碳化硅添加剂对碳化钽陶瓷显微组织及力学性能的影响) [D]. Harbin: Harbin Institute of Technology,2013.

[81]Wang Yi(王 毅),Xu Yongdong(徐永东),Xie Chongbo(谢翀博),etal. 三维针刺 C/(SiC -TaC)复合材料的烧蚀性能及烧蚀机理[J].JournaloftheChineseCeramicSociety(硅酸盐学报),2009,37(10): 1 718-1 723.

[82]Pienti L,Sciti D,Silvestroni L,etal. Ablation Tests on HfC-and TaC-Based Ceramics for Aeropropulsive Applications[J].JournaloftheEuropeanCeramicSociety,2015,35:1 401-1 411.

[83]Liu Yixiang,Cheng Laifei,Fan Xiaomeng,etal. Effect of Interlayer on the Ablation Properties of Laminated HfC-SiC Ceramics under Oxyacetylene Torch[J].CorrosionScience,2015,93:172-179.

[84]Shugart K, Patterson B, Lichtman D,etal. Mechanisms for Variability of ZrB2-30vol% SiC Oxidation Kinetics[J].JournaloftheAmericanCeramicSociety, 2014,97(7): 2 279-2 285.

[85]He Rujie, Zhang Xinhong, Han Wenbo,etal. Effects of Solids Loading on Microstructure and Mechanical Properties of HfB2-20vol% MoSi2Ultra High Temperature Ceramic Composites through Aqueous Gel Casting Route[J].Materials&Design,2013,47: 35-40.

[86]Peng F, Laningham G V, Speyer R F. Thermogravimetric Analysis of the Oxidation Resistance of ZrB2-SiC and ZrB2-SiC-TaB2-Based Compositions in the 1 500~1 900 ℃ Range[J].JournalofMaterialsResearch, 2011, 26(01): 96-107.

[87]Zapata S E, Jayaseelan D D, Lin H T,etal. Mechanical Properties of ZrB2-and HfB2-Based Ultra-High Temperature Ceramics Fabricated by Spark Plasma Sintering[J].JournaloftheEuropeanCeramicSociety,2013,33(7): 1 373-1 386.

[88]Zou Ji, Zhang Guojun, Hu Chufeng,etal. Strong ZrB2-SiC-WC Ceramics at 1 600 ℃[J].JournaloftheAmericanCeramicSociety,2012,95(3): 874-878.

[89]Sciti D, Bonnefont G, Fantozzi G,etal. Spark Plasma Sintering of HfB2with Low Additions of Silicides of Molybdenum and Tantalum[J].JournaloftheEuropeanCeramicSociety,2010,30: 3 253-3 258.

[90]Wang Zhi,Wu Zhanjun,Shi Guodong.The Oxidation Behaviors of a ZrB2-SiC-ZrC Ceramic[J].SolidStateSciences,2011,13(3): 534-538.

[91]Lee S J, Baek S S, Kang E S,etal. Fabrication and Oxidation Behavior of Reactively Hot Pressed TaB2-SiC Ceramics [J].ReviewsonAdvancedMaterialsScience,2011,28: 21-25.

[92]Lin Jia, Zhang Xinghong, Wang Zhi,etal. Microstructure and Mechanical Properties of Hot-Pressed ZrB2-SiC-ZrO2fCeramics with Different Sintering Temperatures[J].MaterialsandDesign, 2012,34: 853-856.

[93]Silvestroni L, Guicciardi S, Melandri C,etal. TaB2-Based Ceramics: Microstructure,Mechanical Properties and Oxidation Resistance[J].JournaloftheEuropeanCeramicSociety,2012,32(01): 97-105.

[94]Talmy I G, Zaykoski J A, Opeka M M. Synthesis, Processing and Properties of TaC-TaB2-C Ceramics[J].JouranaloftheEuropeanCeramicSociety,2010,30 (11): 2 253-2 263.

[95]Ni Dewei, Liu Jixuan, Zhang Guojun. Microstructure Refinement and Mechanical Properties Improvement of HfB2-SiC Composites with the Incorporation of HfC[J].JournaloftheEuropeanCeramicSociety,2012,32(10): 2 557-2 563.

[96]Escobar C, Villarreal M, Caicedo J C,etal. Mechanical Properties of Steel Surfaces Coated with HfN/VN Superlattices[J].JournalofMaterialsEngineeringandPerformance, 2014,23(11):3 963-3 974.

[97]Huang H H, Fan Xiaofeng, Hu C Q,etal. Transformation of Electronic Properties and Structural Phase Transition from HfN to Hf3N4[J].JournalofPhysics-CondensedMatter,2015,27(22):1-7.

[98]Zhou C, Gao X, Xu Y,etal.Synthesis and High-Temperature Evolution of Single-Phase Amorphous Si-Hf-N Ceramics[J].JournaloftheEuropeanCeramicSociety,2015,35(7): 2 007-2 015.

[99]Matsuoka M,Yoshio S,Tatami J,etal. Development of CNT-Dispersed Si3N4Ceramics by Adding Lower Temperature Sintering Aids[J].JournaloftheKoreanCeramicSociety,2012,39(4):333-336.

[100]Guo Weiming, Wu Lixiang, Ma Ti,etal. Chemical Reactivity of Hot-Pressed Si3N4-ZrB2Ceramics at 1500-1700 ℃[J].JournaloftheEuropeanCeramicSociety,2015,35(11):2 973-2 979.

[101]Ahmad S,Ludwig T,Herrmann M,etal. Crystallisation Studies of Si3N4-Al2O3-SiO2-Y2O3Glass-Ceramics under Different Heat-Treatment Conditions[J].JournaloftheEuropeanCeramicSociety,2015,35(8):2 261-2 268.

[102]Li Y X, Han W B, Chen G Q,etal. Influence of CeO2Addition on Si3N4Ceramics[J].MaterialsResearchInnovations, 2015,19 (1):339-342.

[103]Wu B, Wang Z, Dong S M. Improved Oxidation Resistance of SiC-Based Ceramic Matrix Composites by In-Situ Reaction with Si3N4Filler [J].KeyEngineeringMaterials, 2012,512 (1):775-778.

(编辑惠琼)

Research State and Prospect of Ultra-HighTemperature Materials

ZHANG Leilei, FU Qiangang, LI Hejun

(Science and Technology on Thermostructural Composite Materials Laboratory,

Northwestern Polytechnical University, Xi’an 710072,China)

Abstract:The ultra-high temperature materials (UHM) are essential materials used for the long-time flight , reentry flight and crossover flight of aerosphere, which influence the research process of the flight and play an important role in the success or failure of the flight tests. The research state and prospect of UHM, including carbon/carbon composites, ceramic-based composites, carbide UHM, boride UHM and nitride UHM are summarized. The close attention is paid to the formation mechanism of texture, fatigue property, matrix modification and oxidation behavior of carbon/carbon composites as well as the preparation technology, mechanical property, oxidation and ablation resistance of ceramic-based ceramic composites and ultra-high temperature ceramic.The merits and drawbacks as well as the research keynotes of the UHM are discussed. The present problems and potential development direction of the UHM are also proposed.

Key words:carbon/carbon composites; carbide; boride; nitride; ultra-high temperature ceramic

中图分类号:TB332

文献标识码:A

文章编号:1674-3962(2015)09-0675-09

DOI:10.7502/j.issn.1674-3962.2015.09.05

通讯作者:付前刚,男,1979年生,教授,博士生导师,Email:

收稿日期:2015-07-20