Study on Extraction of Tea Saponin from Camellia oleifera Cake Using Water as Extraction Solvent

Li MA, Yongzhong CHEN, Shaofeng PENG, Xiangnan WANG, Longsheng CHEN, Rui WANG, Xiaohu YANG, Jian LUO

1. Hunan Academy of Forestry, Changsha 410004, China;

2. National Engineering Technology Research Center of Camellia, Changsha 410004, China

Camellia oleifera cake is the residue of camellia seeds after oil extraction. Currently, China has an annual production of Camellia oleifera seeds cake of about 70 000 tons[1-2].Contain hydrophilic glycosome and hydrophobic coordination group,the tea saponin in the cake of Camellia oleifera seeds is a good surface active agent,which not only has the activities of emulsification, foaming, dispersion and penetration, but also has hemoly sis,antibacterial,insecticidal effects[3-5].With wide application, tea saponins can be used in pesticide, feed, aquaculture, textile, oil extraction, mining,building materials, highway construction and other fields to make emulsifier,detergent, pesticides, feed additives, crab and shrimp aquaculture protective agent, textile assistants, oil extraction flotation agent,mining lubricant oil, aerated concrete foam stabi lizer and express highway deicers[6-8].In this paper, we used water as the extraction solvent to study the optimal processing conditions for the extraction of tea saponin from the cake of Camellia oleifera seeds with the aim to improve the extraction rate of tea saponin and the added value of the cake of Camellia oleifera seeds.

Materials and Methods

Materials and reagents

The materials included the following: cake of Camellia oleifera seeds(provided by Hunan Academy of Forestry), standard tea saponin substances (including 90% of tea saponin), absolute ethyl alcohol, concentrated sulfuric acid,vanillin.

Main instruments

The main instruments used in this study included the following: UV-2550 UV visible spectrophotometer (Shimadzu Corporation), TDL-5Z multi frame automatic balancing centrifuge(Hunan Xingke Scientific Instrument Co., Ltd.), digital display electric thermostatic water bath (Shanghai Yuejin Medical Instrument Factory),9240MBE electric blast drying box(Shanghai Boxun Industrial Co., Ltd.),JJ-1 precise power boosting electric mixer (Changzhou Aohua Instrument Co. Ltd.), medicinal herb grinder(Tianjin Taisite Instrument Co.,Ltd.).

Test methods

The Kjeldahl method was used to determine the protein components in camellia cake based on theGB5009.4-2010; total soluble sugar was determined by the anthrone method; fat were measured according to GB/T5009.6-2003; crude fiber were measured by GB/T in 5515-2008; tea saponin was determined by vanillin sulfuric acid method.

First,50 g of the crushed camellia oil cake powder after screening was collected and put in a beaker, and the tea saponin was extracted according to the set single factor (temperature,liquid-solid ratio, time, pH value). And then after centrifugation, flocculation,and centrifugation, the liquid was collected to measure the tea saponin content of each group. Based on the measured test results of the 4 single factor (temperature,time,liquid-solid ratio,pH value),3 levels of each factor were determined to carry out the orthogonal experiment with the extraction ratio of tea saponin from the camellia oil cake as the measurement index.

Results and Analysis

Analysis of oil-tea-cake

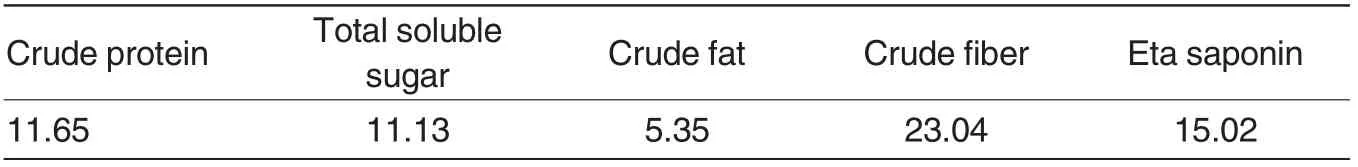

As shown in Table 1, the main compositions of the camellia oil cake included proteins, tea saponins, crude fiber, and soluble sugar, in which the tea saponin accounted for 15% of the total.

Table 1 The main chemical compositions of oil-tea meal %

Determination of process conditions

Effect of liquid to solid ratio on extraction ratio As shown in Fig.1,with the increase of liquid-solid ratio,the extraction rate of tea saponin increased. However, after the liquidsolid ratio reached 10 ∶1, the increase range of the extraction rate of tea saponin became much smaller. In the meantime, the increase consumption of water increased the production cost.Therefore, considering water saving and economic costs,the optimal liquidsolid ratio was 10∶1.

Effect of temperature on extraction ratio As shown in Fig.2, the extraction rate of tea saponin increased when the extracting temperature increased from 40 to 80 ℃, and when the temperature was 80 ℃,the extraction rate was the highest of 90.05%.The result indicated that the tea saponin was freely soluble in hot water. However, when the temperature continued to increase, the extraction rate of tea saponin decreased due to the excess high temperature,which resulted in the decomposition of tea saponin. In addition, the irreversible denaturation solidification of proteins and other impurities were intensified,resulting in the absorption and combination of some tea saponins.

Effect of time duration on extraction ratio As shown in Fig.3,with the extension of extracting time, the extraction rate of tea saponin continuously increased and reaching the highest of 91.3% after 8 h of extraction. When the extracting time reached 6 h,the increase of extraction rate of tea saponin became slowly, and the continuous extension of extracting time showed small influence on the increase of tea saponin extraction rate.

Effect of pH on extraction ratio As shown in Fig.4,when the pH value varied in the range of 6-10,the extraction rate of tea saponin increased with the increase of pH,and reached the highest of 91.3%when the pH reached 10,indicating that the extraction of tea saponin was more favorable in weak base condition.However,when the pH value went over 10,the extraction rate decreased,which was mainly because under high alkalinity,some alkaline soluble impurities would also digested out, which would absorb and combine some tea saponins.

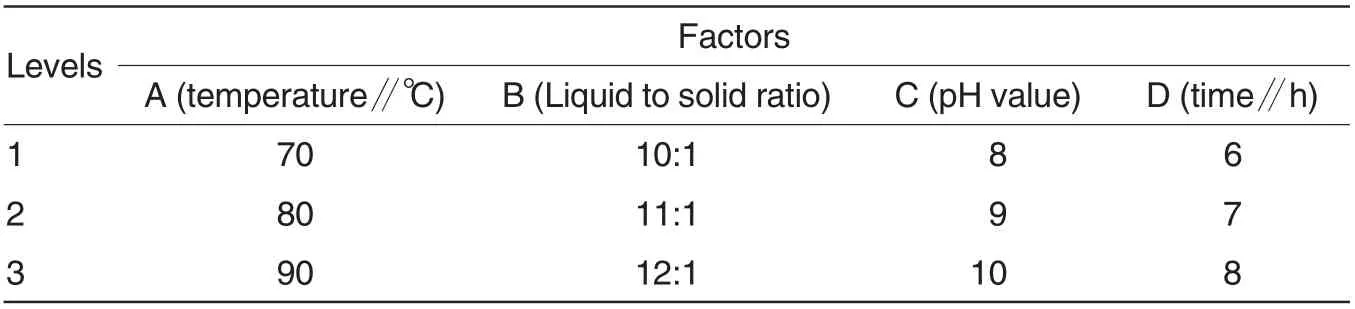

Selection of the optimal process conditions Based on the results of single factor tests,the L9(34)orthogonal test was designed and the levels of the designed factors were shown in Table 2.

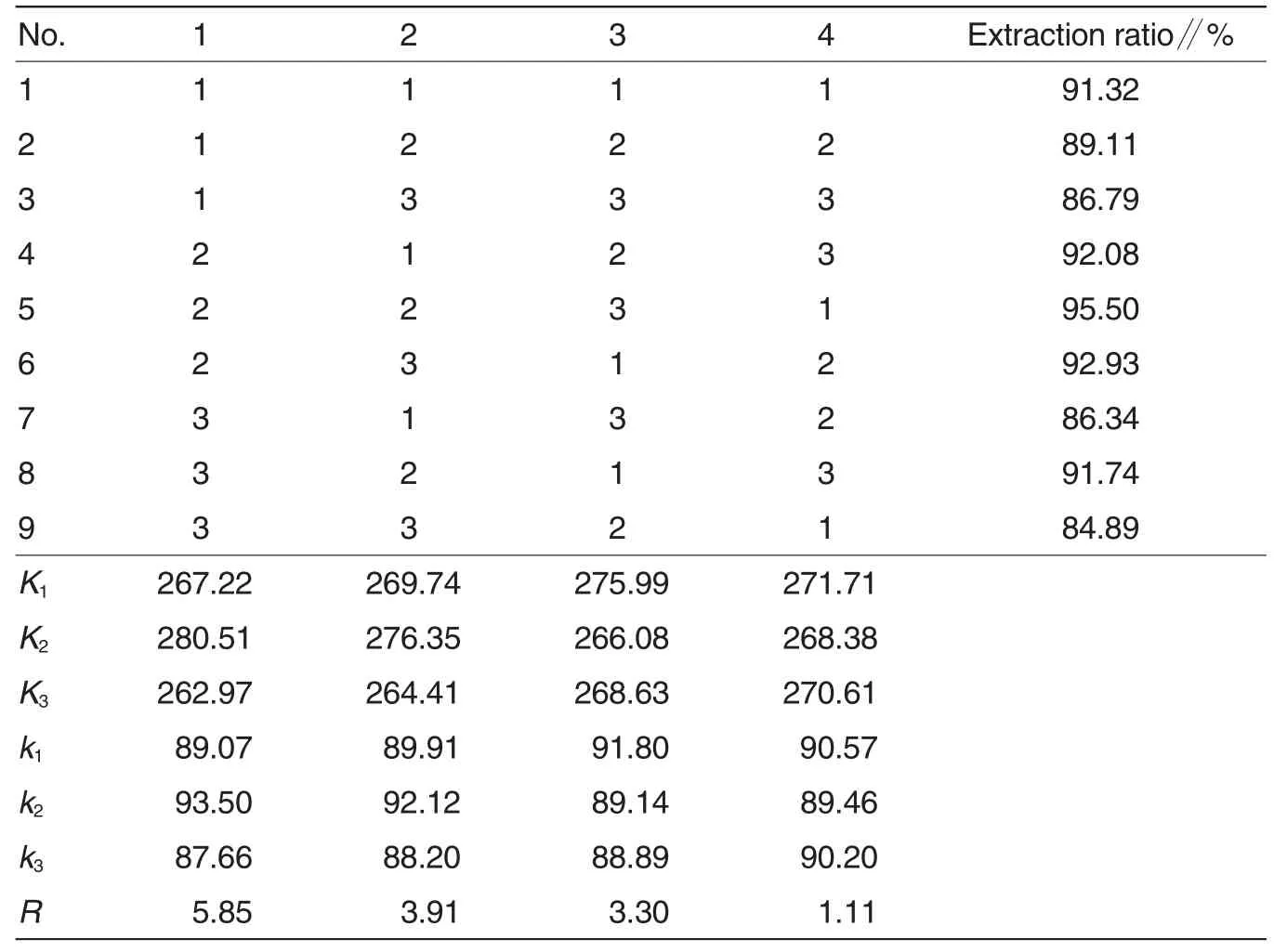

As shown in Table 3, the influences on the extraction rate of tea saponin from high to low were in the order of A,B,C,D,in which extracting time showed the most significant effect on the extraction rate of tea saponin,followed by liquid-solid ratio and pH value, while the extracting time showed the most insignificant influence on the extraction of tea saponin.The optimal extraction conditions for tea saponin was A2B2C3D1, that is, extraction temperature of 80, liquid-solidratio of 11∶1, extracting pH value of 9,extraction time of 6 h,when the extraction rate could reach up to 95.50%.

Table 2 Factors and levels of L9(34)orthogonal test

Table 3 The orthogonal test results of tea saponin extraction

Conclusion and Discussion

Camellia oleifera cake is mainly composed of proteins, tea saponins,crude fiber and soluble sugar,in which tea saponins accounted for 15%of the total, and therefore, the high-efficient extraction and purification of Camellia oleifera cake could improve its added value. The optimal processing parameters for the extraction of tea saponins from Camellia oleifera cake is liquidsolid ratio of 11∶1,extracting temperature of 80 ℃, extracting time of 6 h,and pH value of 9,when the extraction ratio of tea saponin could reach up to 95.5%. Currently, there still exist the problems of high production cost,difficult purification and poor economic benefits in the industrial production of tea saponins, and therefore, much research remains to be done to find out the way to extract the tea saponins of high purity to meet the requirements of industrial production.

[1]HOU RY(候如燕).Extraction,purification and antibacterial activities of teasaponins(茶皂素提取纯化及其抗菌活性研究)[D].Hefei:Anhui Agricultural University,2002.

[2]ZHONG HY(钟海雁), XIE BX(谢碧霞),WANG CN (王承南). Current research status and analysis on the processing and utilization of teasaponins in China(我国油茶加工利用研究现状及分析)[J].China Forestry Science and Technology,2001,15(4):6-8.

[3]ZHANG K(张可),QIAN H(钱和).Study on extraction of tea saponin from out cake of Camellia oleifera seeds(油茶饼粕中茶皂素提取工艺的研究)[J]. Food Science and Technology,2003(10):68-70.

[4]LIAO SJ(廖书娟),TONG HR(童华荣),JI DL(吉当玲).Study on extraction and application of teasaponin in Camellia cake (茶籽饼茶皂素提取及应用研究)[J].Cereals&Oils,2005(1):13-15.

[5]LU XY (卢向阳), TANG MY (唐明远).Surface activities of tea saponin and its washing efficiency to silk and wool(茶皂素表面活性性能及对丝毛织物的洗涤效果)[J]. Journal of Hunan Agricultural University: Natural Science Edition, 2000,26(3): 218-220.

[6]LU SZ(陆顺忠),LI QT(李秋庭).Study on the new extracting technology of teasaponin(茶皂素提取新工艺)[J].Guangxi Forestry Science, 2001, 30 (4): 186-188.

[7]PENG YS(彭阳生),XI RC(奚如春).Oiltea camellia cultivation and tea-seed oil extraction(油茶栽培及茶籽油制取)[M].Beijing:JinDun Publishing House,2006.

[8]TANG L(唐玲),FENG BM(冯宝民),LI HB (李红冰),et al.Research progress on oil-tea saponin (油茶皂素的研究进展)[J].Central South Pharmacy,2008,6(3):330-333.

Agricultural Science & Technology2015年5期

Agricultural Science & Technology2015年5期

- Agricultural Science & Technology的其它文章

- Effect of Meteorological Factors on Yield of Cotton in Different Years

- Breeding of Mycoplasmal pneumonia-negative Swine Population Using Combination Therapy,Segregated Early Weaning(SEW)and Three-point Production System

- Land Use Situation and Strategies under the Background of New Urbanization in Yunnan Province

- Analysis of Heavy Rainstorm in Dongting Lake on July 4,2014

- Regeneration Cultivation Technology of Flammulina velutipes in Factories

- Study on FTIR Spectra of Corn Germs and Endosperms of Three Different Colors Combining with Cluster Analysis