仉家骅:毕生的爱国情怀

孙侃

杭州钢铁集团半山钢铁基地(曾称浙江钢铁厂、半山钢铁厂、杭州钢铁厂,本文统一简称杭钢)已经关停的厂区内,不少生态项目正在实施,杭钢人当年艰苦创业的故事依然在流传,高级工程师仉家骅在平凡中显崇高的事迹便是其中之一。日前,笔者应《文化交流》独家之邀,连续采访了这位正住院的老人,倾听他的人生经历,感受他的赤诚情怀。毫无疑问,仉家骅正是新中国第一代知识分子为祖国为人民奉献一生的生动典范。

立志报国,刻苦攻读

接受采访,仉家骅从大哥仉家驹谈起。仉家驹,即新中国初期培养的电影演员张平,出演过《钢铁战士》《怒潮》等许多有影响的影片。

“大哥对我的引领意义很大。1949年我高中毕业,得到在东北电影制片厂当演员的大哥的帮助,于次年考取了东北工学院。刚到沈阳时,大哥曾提议让我去长春、跟着他当演员,我没有答应。其实我从小也爱好文艺,年轻时的模样也英俊。”80余岁的仉家骅个子高高的,腰杆直直的,一脸老来的清朗。

“我之所以没听大哥的话,一是因为我非常渴望成为工程师,认定做实业更能体现爱国心;二是因为我怯于进入演艺界,拍电影免不了男男女女搂搂抱抱,于我实在不适应。”

仉家骅籍贯天津,1931年出生在上海,家境贫寒。他4岁时,在旅馆当差的父亲积劳去世,母亲靠做佣人勉强养活五个孩子。稍长,仉家骅知道了生活的艰辛,产生了求学改变命运的渴望。他是回族人,上学得到过上海回民商人社团“清寒回族子弟助学金”的支助:每学期都能考到全班第一、第二名,从而取得资格。这同时也促使他养成了珍惜机会、刻苦学习的品质。

经历内战带给国统区之凋敝的仉家骅,在东北老解放区,感受到了一派朝气蓬勃、万象更新的景象,对新中国美好前途的向往,让他内心深处的爱国情怀得以释放。多年前即投身革命文化事业的大哥的思想引导,更促使仉家骅立志报效祖国,以贡献自己的才华乃至生命为荣。在东北工学院机械制造专业,他如饥似渴地攻读,学业生涯从无虚度。

由于国家实施第一个五年计划的需要,仉家骅这一届学生提前到1954年1月毕业。让他绝对没想到的是,在全系几百名同学中,只有他被分配到清华大学机械制造系机械设计教研组担任助教!这可是百里挑一的事,证明他学业成绩之优异!在清华,他这个大四毕业生一进课堂,就给大四学生讲授起重运输机课程,人生灿烂美好的前景正在展现。

然而让别人绝对没想到的是,3年后,当仉家骅听说浙江正在筹建钢铁厂、亟需人才时,毅然决然地放弃相对优裕的工作和生活条件,主动要求到杭钢,投入生产建设第一线。

发挥专长,结下丰硕科技成果

笔者问,您能讲讲当初选择来杭钢的原因吗?仉家骅明确地答道,教学科研最终应当转化为生产实践。

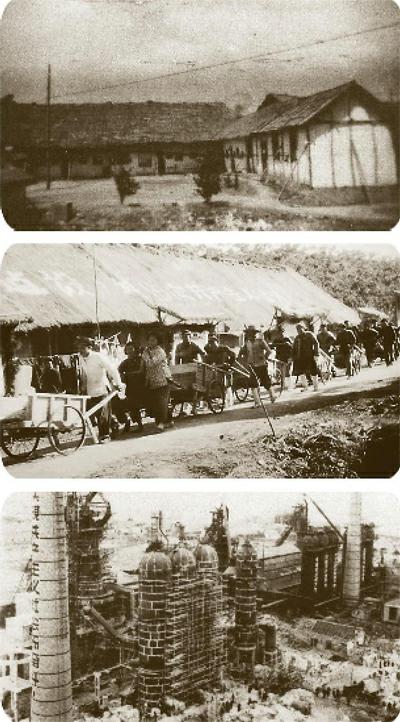

1958年初,仉家骅携在冶金部钢铁研究院工作的新婚妻子翁季蕓,从北京来到杭州城郊半山脚下,开启自己为之奉献一生的历程。那时,整个厂只有两座传统小转炉在生产,他被分配到铸造车间筹备组当技术员,同时兼车间团支部书记,组织并负责青年突击队。他既和工程人员安装设备,又率领突击队员搞基建,经常连日连夜苦干。由于工作出色,次年12月他加入了中国共产党。

仉家骅在融入杭钢发展、壮大的历程中,倾注了自己的情怀和心血。

1964年,杭钢以仉家骅为项目牵头人,对传统转炉进行氧气顶吹改造。其时,该技术已在国外应用,但在国内并不成熟。仉家骅和技改小组成员凭借部分参考图纸,埋头钻研,攻克诸多难题,终于改造出4吨氧气顶吹转炉。

“在我们那个技改小组中,有机械、电器、仪表、冷却水、土建等各专业的‘高人,大家都发挥了智慧。氧气顶吹转炉里机器设备很多,负责机械设计的我,好好地露了一手,所以它是我的得意之作。”仉家骅得意的原因是,这座转炉在多年运行中,至少有10年被冶金部评为生产成绩最好的“红旗炉”。

改革开放后,来杭钢考察的外国同行很多。一次,澳大利亚冶金专家组来到这座氧气顶吹转炉前,被它独创的设计所折服——土洋结合,又科学合理!当他们得知杭钢在设计建造30吨氧气顶吹转炉时,更为钦佩,因为这意味着杭钢炼钢设备的设计建造技术已与国际先进水平相比肩。仉家骅真挚地说:“每当看到国外同行对我们科技进步的肯定和羡慕,就油然升起一股民族自豪感,就觉得所有艰辛的付出都是值得的。”

采用液压驱动255m?高炉炉顶装料设备,是杭钢在上世纪70年代的重点技术革新项目。仉家骅指出,“当时全国各大钢铁公司都有255m?高炉,听说杭钢第一家应用了炉顶液压设备,纷纷来参观取经,冶金院校的学生也来实习。后来,鞍山钢铁设计院编写《钢铁工业液压设备使用实例》一书,把杭钢这一系统的应用和运行情况,列为第一个范例。”

牢记使命,不惧人生厄运

仉家骅曾提到他十分喜爱一套“大炼钢铁”的邮票,那是邮电部于1959年发行的“纪58—钢铁生产大跃进”。他说,那热烈喜庆的画面反映了他的一部分心情,可惜在“文化大革命”期间丢失了。

仉家骅平静地述说往事:那时候我被分配做电工,“能及时调整心态的原因是工人的友善和照顾。作为外线电工,我得系好皮带,穿上工作鞋,带上各种工具,爬上架子去登高作业。可我第一次准备作业就被一位老师傅阻止了,他说我们是经过培训并考核的,你没有,所以不能爬架子,也爬不上去。他分明是在暗中救我的命,因为像我这样一点操作技能都没有的人,登高而上,真的就是去送命。我心里十分感激,也明白大家还需要我在合适的岗位。”

和工人在一起,仉家骅觉得很随和、很融洽。他有一件谈资,工人们起初对他的姓“仉”不认识,以为是“倪”的简写,便叫他“倪工”。他幽默地回答:“我不是泥工,我是铁匠,专门对付铁家伙的!”谈笑间,他仍对“遗弃”科研不能释然,一有机会就与同事开展技术探讨,一些实践经验丰富的老师傅也来帮助解决具体技术问题。endprint

上世纪80年代,中国特色的现代化进程加紧展开,仉家骅专注于科技研究,成果迭出。讲到这里,他拿起枕头旁的《设备泄漏防治技术》《工业管道泄漏防治》两书,说,出版之后业内重视,同行视作不可缺少的技术用书,现在自己正抽空作修订。

1983年,仉家骅当选为浙江省第七次党代会代表。他异常欣喜,觉得这份荣誉同时也是给杭钢乃至全省冶金系统所有的科技人员的,说:“党和人民信任知识分子,期待知识分子发挥应有作用,自己当更努力。”

“我妻子翁季芸工作的劲头也更大了。她是晚清大臣翁同龢的曾孙女,家学渊源,毕业于浙江大学化工系。我俩来到杭钢后,她一直在中心试验室工作,活跃在杭钢各个发展阶段的化验技术人员大都是她的学生!”

1986年,仉家骅被評定为高级工程师,是杭钢首批6人之一。不久后,他担任杭钢总工程师,并为省冶金局高工评审委员会成员,又担任杭钢技术开发处处长、科学技术协会首任主席。

有一分热,发一分光

仉家骅的事迹其实平凡普通,但所体现的敬业奉献精神却留在人们的记忆中。

上世纪80年代,某国钢铁专家参观杭钢,座谈会上省冶金局的年轻翻译把“转炉”译成了“回转窑”,仉家骅当场举手,及时予以更正。

仉家骅多次说,“打好基础,潜心专业,心无旁骛,努力工作。”他深知,只有掌握知识,特别是精深地学会一门技能、运用一项技术,才能为国家建设事业添砖加瓦,实现自己的人生理想。他熟练掌握三种外语:上高中,学英语;上大学,学俄语;上讲台后,清华专门从北大请来德国籍女教授,教青年教师和研究生德语。“本以为从事机械设计制造,外语不太用得上,其实后来都用上了,还发挥了很大作用。”

多年来,仉家骅一直坚持温习外语,这一专长得到了多方器重,成为他在机械设计专业之外、为杭钢发展做出较大贡献的领域。担任总工和科协主席后,他又以一己之力倡导企业内部学习外语,并形成氛围。他还翻译了不少国外重要专业资料,以供大家及时了解国外冶金业发展动态。

1991年,仉家骅退休了。那时,杭钢周边有不少乡镇企业主营钢铁后期加工,发展较快,于是有人便找仉家骅,希望他去任职、兼职。对此,他一概谢绝,但技术方面的解惑释疑,始终热心而无偿地提供。“我最感兴趣、最擅长的是搞技术,能在晚年发挥余热,为企业发展助一点点力,是我的荣幸。”

与笔者相熟悉的仉家骅一位邻居告诉笔者,仉工退休后的很长一段时间里,前来咨询讨教的人络绎不绝,而他总十分热情,那种中国老一代知识分子执着、严谨、谦逊、淡泊的作风令人钦佩。

仉家骅声音洪亮,很健谈,但也有让笔者稍息的片刻。他在回想。

“我承认,如果留在清华,自己将拥有另一种生活。可我选择了一家从零起步、逐步发展,能直接为国家产生经济效益的工厂,并且亲身感受了它的整个发展历程。尽管我在这里吃了很多苦,经历了很多的曲折,但我从来没有后悔过。甘于清寒本来就是中国知识分子的品格,何况我在这里贡献了自己的才华,为杭钢、为国有企业的发展出了力,这就够了。”这便是仉家骅的肺腑之言。

环境保护,晚年的关切

仉家骅“甘于清寒”,耐得住朴素生活的秉性一生没有改变。比如,他坚守“够吃够用就行”的原则。当年,他去省冶金局办事,坚持用餐自费,那便是去吃一碗最便宜的阳春面。

仉家骅向笔者说起一件小事。数年前的一天,他在杭州市区延安路上行走,发现身后有人喊着追赶他,回头却是几位头发也已花白的老人,急切地问他是不是仉老师。原来他们是毕业于清华、就教于浙大的教授,都是当年仉家骅的学生。师生相见,分外动情。攀谈中,教授们得悉了老师的退休金,不由得感慨万端。他们拿出身边的超市购物卡相送,以示对老师的敬意。仉家骅再三推辞。

也许朴素的生活会锻造人格精神,影响终生。

2015年底,杭钢将全线关停,为杭钢发展贡献一生的仉家骅感慨万千,当年筚路蓝缕的艰苦历程重现眼前。正式关停前的几天里,杭钢的老人,也有很多中年人、年轻人,不约而同地绕走厂区,看看最后运转的杭钢。仉家骅说,那时他的眼泪止不住往下流。“走一圈要近半天时间,而我正好犯病,只走了一半。熟悉的厂房、高炉、机器,都让我留恋,特别是那些由我设计的机械设备,似乎是活的、有血有肉的。它们寄托了我的感情。我默声说,老伙计,拜拜了!”

然而,“拜拜”音未了,2016年初,仉家骅就住进了杭钢医院,直到今天。他对笔者说,杭钢有它的历史功绩,如今关停也肯定正确。理性地分析,杭州这样的世界著名旅游城市,距西湖不太远的地方,居然有座钢铁厂,布局上确实不够科学合理,尤其在高度重视生态环保的当下。日内瓦湖旁边会有钢铁厂么?所以,把杭钢作为去产能的目标之一、还杭州一片洁净清新的蓝天白云,还是值得的。

身在病榻,仉家骅心里牵挂着杭钢:可利用的设备运到了哪里?哪座高炉成了工业遗存?科技资源该怎样发挥作用?住院期间,身体稍有恢复,老人又闲不住了,不仅抽时间阅读相关专业书籍,而且经常与前来看望的老同事探讨科技问题。他欣喜地告诉笔者,现在,哪怕躺在病床上,或者在附近散步,都能感觉出空气在变好,环境在变好,心情越来越舒畅了。

仉家骅毕生的情怀都在杭钢,在祖国的建设事业上。

(本文照片由仉家骅和作者提供)

Engineers Lifelong Dedication to Steelworks in Hangzhou

By Sun Kan

Hangzhou Iron & Steel Group Company, now a huge conglomerate in Zhejiang Province, has grown up from an iron & steel factory in the northeastern part of Hangzhou. A company listed at Shanghai Stock Exchanges, it reported 57.3 billion yuan in assets and 70.2 billion yuan in sale revenue by the end of 2016.endprint

Zhang Jiahua, now 86, is a retired engineer who contributed a great deal to the prosperity of the giant steel works. Born in Shanghai in 1931, he was one of the five siblings of the family. The father died when Zhang Jiahua was only 4 years old. The mother worked as a maid to raise the five children. He was a good student. With the financial assistance from a Hui Charity foundation, he was able to graduate with top scores from high school in 1949 in Shanghai. In 1950, he entered Northeast College of Technology as a student of machinery manufacturing.

It was a major life choice he made. His elder brother Zhang Yong, a film actor, was working in a film studio in Northeast and advised Zhang Jiahua to follow his footsteps. The younger brother chose another career. He wanted to be an engineer and make physical contributions to the countrys modernization.

He proved to be a top student again in January 1954 when the students graduated one year ahead of schedule as the country started its first Five Year Plan and needed engineers urgently. Of all the hundreds of graduates of the college, the prestigious Qinghua University picked him to be a teacher of machinery manufacturing. At his first class, he gave a lecture on hoist transporters to students in their senior year.

Three years later, Zhang Jiahua made another big decision and this decision has changed his life totally. After learning in 1957 that Hangzhou Iron & Steel Works needed engineers badly, he asked to be transferred to the new project in Zhejiang. Asked about his motivation back then in an interview with the author of this article 60 years later, he said he wanted to turn theories into practice.

In early 1958, he arrived in Hangzhou, with his newly married wife Weng Jiyun, a great granddaughter of Wen Tongsu, a key minister of the Qing Dynasty and tutor to Emperor Guangxu. They immediately settled down at the foot of Banshan, in the northeastern suburb of the city. His wife, a graduate of chemistry of Zhejiang University, worked at the steelworks central lab. Back then, the steelworks had only two small Bessemer converters in operation. He soon plunged himself in the setup of the foundry at the steelworks, working as a technician installing equipment at the workshop and heading a taskforce composed of young enthusiasts working overtime at infrastructure.

As an engineer, Zhang Jiahua contributed substantially. In 1964, he headed a four-tonnage oxygen blowing upgrade project. The technology had been mature and widely used in foreign countries, but in China, the technology was yet to be fully mastered. Zhang and his team of experts in different technological fields worked out quite a few innovative solutions. Even now Zhang still feels proud about the part he played as a machinery designer in the project. In its operation history, the converter was recognized by the Ministry of Metallurgical Industry as a “Red Banner Converter” for its excellent productivity for ten consecutive years. In the 1980s while the country turned anew in full force to modernization and opened to the outside world, the innovative converter amazed visiting foreign engineers.endprint

Another big success in Zhangs engineer career was the hydraulic charging equipment for the 255-m2 blast furnace. It was a key technological innovation project at Hangzhou Iron & Steel Works. Zhang was the mastermind of the innovation. Many steelmaking companies across the country had same-size blast furnaces, but they didnt have the hydraulic charging equipment. “After learning that we had it, they sent their experts to take a look. Many senior students from metallurgy colleges came to work as interns at the steelworks in Hangzhou in a bid to be close to it. The hydraulic charging solution was later written into a textbook by Anshan Steelmaking Design Institute.

Zhangs achievement was widely recognized. In 1983, he attended the CPC Zhejiang Congress as a representative of the science and technology circles. He considers the experience as an honor. In 1986 he became a state-accredited senior engineer. Soon he was appointed Chief Engineer of the Hangzhou Iron & Steel Works. During these years, he wrote books on technological innovation and did technical translations (he has working knowledge of English, Russian and German). In 1991, he retired. Though some new businesses in the field of steel making and processing wanted to engage him as an advisor, he turned down all the offers, but was willing to solve technological problems for these businesses.

He has never regretted the decisions he made in the 1950s. “I would have a different life had I chosen to continue working as a teacher at Qinghua. But I chose a steelworks and started from scratch. The factory contributed directly to our nations growth. I participated in and witnessed the whole history of the steelworks. Though I suffered hardships and setbacks, I have never regretted. Moreover, Chinese intellectuals are willing to contribute to the nation. I have contributed my talent to Hangzhou Iron & Steel Works and to the nation. Thats enough,” said Zhang after a long and hard look at his own life.

The site of Hangzhou Iron &Steel Works was shut down toward the end of 2015 as the conglomerate shifted its operations to other places across Zhejiang and diversified further into other industries. Former and current employees visited the facilities and couldnt tear themselves away. Zhang Jiahua took a tour, too. But he wasnt able to finish the goodbye trip because he was weak and ill. In particular, he looked at the machines he had designed. For a moment, he felt they were alive with blood and flesh. “I put my heart and soul into them. I said silent farewell to them,” recalled Zhang in the interview.

He understands the reason of the shutdown. After all, Hangzhou as an international tourism city needs a sky free of pollution. And he doesnt need to worry about the steelmaking business. It has long since grown into a multiple conglomerate continuing its contribution to the countrys bright future. Though he has been in hospital since early 2016, he is still concerned with the future of the steelworks to which he has dedicated his whole life.endprint