越南领美亚丝绸的历史和发展

杜凯丽

(浙江理工大学 材料与纺织学院、丝绸学院,杭州310018)

Generally speaking,the silk industry plays an important role for economic and cultural aspects in the society of Vietnam.Although it is not a leading major in economy,silk industry brings income for thousands of farmers,and for the sericulture zones.Itmakes significant profits.Moreover,for Vietnamese manufacturers and traders,silk and textile product is valuable foreign currency income.Besides,silk industry promotes rural economic restructuring of Vietnam to industrialization and modernization,reduces the proportion of agriculture,and increases the proportion of services and handicrafts.

Lanh My A silk created in Tan Chau,An Giang Province is a popular and well-known material of Vietnam that has a development history through decades.With the comfortable characteristics for wearing,time-consuming dyeing process and glossy black colour from persimmon extract,Lanh My A is rated as high-class silk fabric of Vietnam.Until present,there are very few journals about Lanh My A silk,such as An GiangHandicraft and Industry by Professor Le Minh Tung,The lastartist ofLanh My A by journalist Nguyen Quynh Huong.However,they just focus on analyzing the weaving and dyeing technology of Lanh My A.On the basis of historical documents and data collected through research process,this article provides an overall knowledge about the history of Lanh My A silk,and its revival after difficult time and also recommends some application ways formodern textiles.

1 概 况

1 Introduction

1.1 越南丝绸业对领美亚丝绸的影响

1.1 Effect of history of Vietnam silk industry on Lanh My A silk

From the 15thcentury,silk industry had contributed positively to economy of Vietnam.From 1858,the Vietnam-France war started.The French government appreciated the potential resources of sericulture and textiles in Vietnam.In 1886,French army established the Department of Silk in Ha Noi,and prepared the plans and strategies to raise and collect themulberry leaves,silkworm eggs and cocoon in Northern Vietnam.From 1905,French government implemented the tax-free policies for textile products and built large silk centers in the whole country.By 1923,Indochina budgeted by French army for silk industry was divided as follows:Northern Vietnam 702.000 francs(125.200 USD),Central Vietnam 123.000 francs(21.900 USD),and Southern Vietnam 129.000 francs(23.000 USD).This capital boosted the development of silk industry throughout Vietnam,and especially the new sericulture areas such as Tan Chau(An Giang Province)in Southern Vietnam,where the typical productwas Lanh My A silk[1].

In the 1930s,factors of capital goods helped numerous traders in Tan Chau,An Giang whomade good benefits from textile products and opened private textile workshops.Except domestic manufacture resources,farmers imported silkworm eggs and cocoon from England,France, Brasil and China.In 1945, Vietnam Revolution was successful,and the war ended.Silk industry was concerned and invested by government.

1.2 潭州养蚕业的发展

1.2 Developed period of Tan Chau sericulture zone Located in the northwestern An Giang Province,Tan Chau Silk Town has been well known for long-known silk weaving.In July 1908,the very first Vietnam Silk Institute was established by French army in An Giang Province.Tan Chau was considered as the trade center of Southern Vietnam and Cambodia,located on the islet with suitable land and climate for growingmulberry and raising silkworm,which ensured the quality ofmanufacturematerial.In the most developed period of sericulture in Tan Chau, there were 60 textile workshops,250 weavingmachines and 120 incubation houses in the area of 300 acres which occupied a half of total mulberry plant acreage of Southern Vietnam.Annual fiber output reached 4-6 thousand tons.

In the early 20thcentury,Tan Chau Silk Town was regionally famous for two famous silkworm brands.The first one is a company founded in 1909 in Long Hung ward,producing fine mulberry varieties for the whole region.The second company was founded in 1912,and destroyed in 1945 by the war.Until1963,this firm was officially named Tan Chau Department of Sericulture[2].Currently,Vietnam silk industry has benefited from ASEAN Free Trade Area(AFTA)and Trans-Pacific Partnership Agreement(TPP)which remove the tax barriers for Vietnam textiles and garments,create conditions for these commodities to penetrate the broadermarket, integrate into the world economy, and contribute significantly to the import-export turnover and average income of Tan Chau.

2 领美亚丝绸的发展线

2 Timeline of Lanh My A silk

2.1 领美亚丝绸的制造

2.1 Manufacture of Lanh My A silk

From 1930 to 1937,with the support from Vietnam Silk Institute built and operated by French army in Tan Chau, An Giang Province, Lanh My A silk was created by Tan Chau silk farmers as the outstanding and expensive product line.

Primarymanufacturematerial of Lanh My A silk is fila-ment of the Bao Loc Plateau(Lam Dong Province).Each meter of silk consists of 12.550 warp threads,weaved by themethod ofweaving satin silk,and put into the machine, large tubes, and looms.According to the requirements of the Vietnam Silk Institute in Tan Chau,silkwormswere selected for propagation and technology dissemination to regional farmers for the sake of high yield and quality.At the same time,the Government also exempted land for planting areas and provided supportive policies.Originally,farmers cultivated the yellow pods, but later on, with the advancement of technology,they switched to white-grained silkworms and hybrid pairs.These silkworms produced cocoon with higher yield and quality.However,silkworm raising was very hard especially at feeding step.

Cocoon treatment step is followed by incubation stage.Previously,traditional weaving technology was applied:putting cocoon into boiling water,then pulling the silk thread and attaching to the spinning wheel;stirring the chopsticks simultaneously,curling the silk threads...Later,the French experts from Vietnam Silk Institute instructed farmers to improve silkworm incubation technology bymechanism to enhance productivity and quality.The coarse silk was then removed from the bundles to form a large thread,and then they were weaved into fabric sheets(Fig.1)[3].

Lanh My A is a kind of hand weaving silkmadewith very unique formulas.Advantages of Lanh My A silk include:glossy black colour that never fades under any washing condition; fabric notwrinkled; no need of ironing before using; its inability to stretch and not absorb moisture,suitable for variable climate condition in Asia.

However,the shortcoming of Lanh My A silk is 100%hand-weaving, time-consuming, and use of natural herbal dyeing materials,so it is impossible to produce with high quantity at the same time,which makes the price very high.

2.2 柿子提取物的染色技术2.2 Dyeing technology from persimmon extract

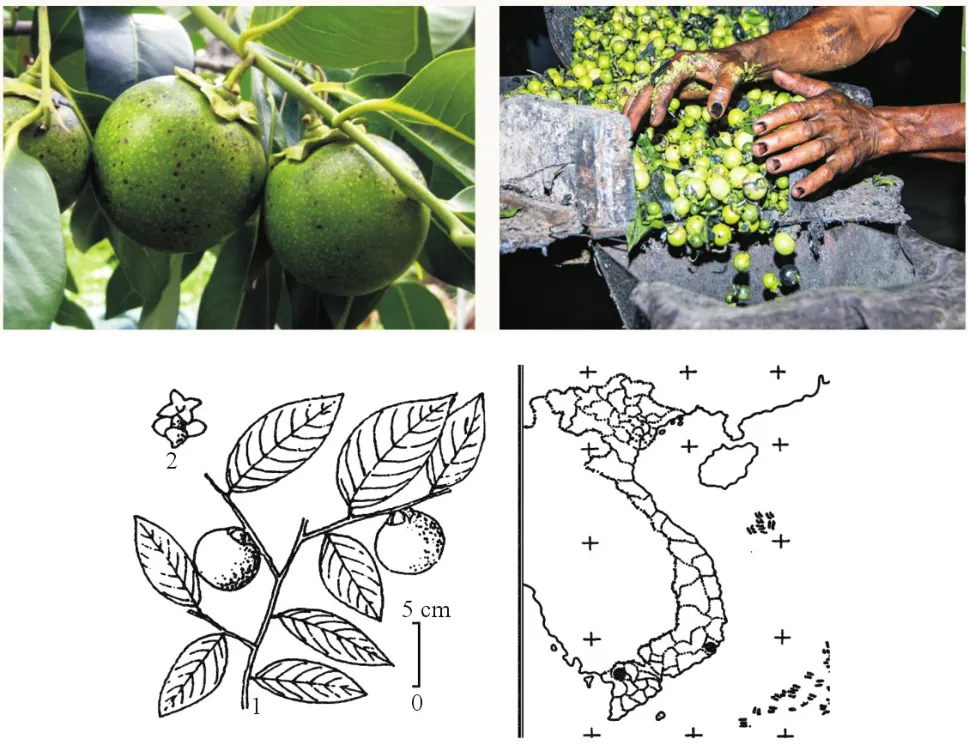

Characteristics of persimmon:medium hardness;diameter 30 -40 cm; white or gray boughs; sprouting leaves;oval shape;5-8 cm×3-3.5 cm;no feather.Colour of fruit:green; smooth, spherical,1 - 2 cm in diameter.Biology and ecology:flower blooming season in January, September to April(next year); productivity:100-500 kg fruit/tree/year.Leaves and fruits contain polyquinone which is used to dye black silk and nylon;beautiful and durable color;Fruit and seeds are also used in traditionalmedicine in Cambodia and Vietnam for hookworm and tapeworm(Fig.2)[4].

图2 领美亚丝绸的染色水果Fig.2 Persimmon fruit(Vietnamese:mǎc n'a)

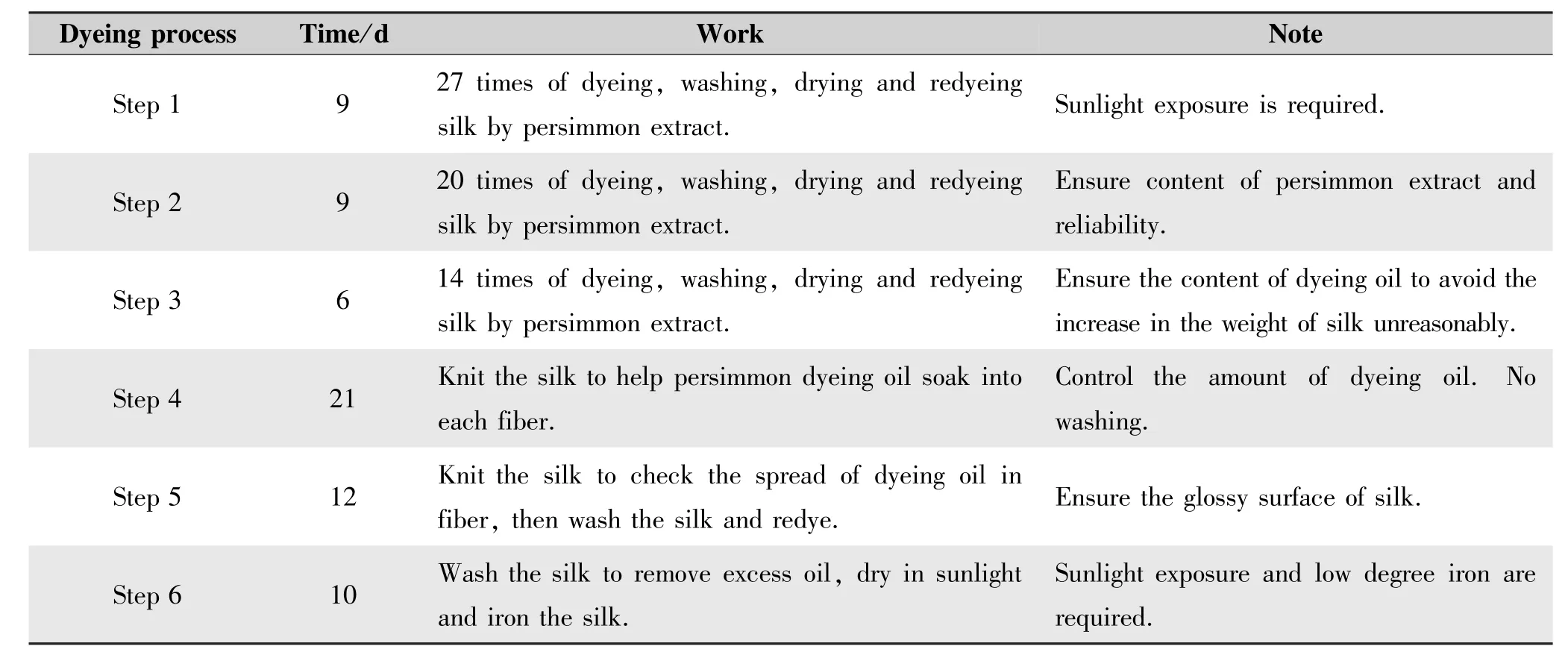

After been harvested,persimmon fruits are classified to collect fruit sap.Farmers use stonemortar or grinder to crush this fruit which is then mixed with water to form very nice yellow extract that turns black when exposed to air and heat.The extract is applied in dyeing process of Lanh My A silk(Tab.1).

Dyeing process is followed by silk drying stage on drying yards or grass fields with 20 meters in length.Fabrics are dipped in persimmon extract and then dried in natu-ral sunlight.They can be dyed for several times each day and then dried.The blackness of extract oil is permeated into the silk.This work is repeated for 40-45 days under the condition of normal weather.Meanwhile, every 5 -7 days, farmers knit the fabric to create the gloss for silk bymechanical force.

表1 领美亚丝绸的染色过程Tab.1 Dyeing process of Lanh My A silk

2.3 领美亚丝绸的消失2.3 Disappearance of Lanh My A silk

From 1975,farmers in Tan Chau stopped importing persimmon from Cambodia and started to plant it by seeds in hometown.With good capital and the great passion for Lanh My A silk and ambition to share experiences with local farmers,Mr.Tam Lang setup the largest textile workshop in Tan Chau(Fig.3).He was also the last artistwho tried tomaintain Lanh My A silk in Vietnam.However, due to consequences of the war, with the demands of variable styles of textile products and affordable price for every class of consumers,polyester and nylon fiber gradually dominated domestic market,which led to hard competitions for Lanh My A Silk with high requirement of design and purchase.Due to labour effort for economy and society recovery after the war,satin silk like Lanh My A became a luxurious product line that could not be popular in the general market.90%of farmers in Tan Chau pursued other agricultural professions to make living.Textile workshops were closed.Mulberry yards were cut to expand planting lands for fruits and cereals.Some of the last textile firms produced the nilon fabric for themarket instead of traditional Lanh My A silk.Like the captain of a cruise who would never leave the shipwreck even when all the passengers and crew had left, until1996, Mr.Tam Lang still continued tomaintain the textile profession,although he had to accept to close the very lastworkshop in 1984.

图3 Tam Lang-领美亚丝绸的最后的艺术家Fig.3 Tam Lang-The last artist of Lanh My A silk

3 领美亚丝绸的复兴

3 Revival of Lanh My A silk

In 1990,Rose Morant-French fashion designer came to Tan Chau tomake research about potential textilematerials.At that time,nearly 1 000 weaving looms in the sericulture zone were applied for nilon fiber textiles.Rose Morantwith the passion for Vietnam silk,created a private project with Tam Lang to revive and preserve Lanh My A silk with higher quality than ever before.Tam Langmade efforts formanufacture,while Rose Mo-rant ensured the output.

Rose Morant had strict requirements for silk quality.In the first year, during all stages including weaving,dyeing and finishing,only 5 errors are allowed for every 20 m silk.According to this request,Tam Lang had to change the material land to Bao Loc,Lam Dong Province,thanks to the appropriate climate for raising silkworms originating from Fuji Mountain of Japan.Each good silkworm could produce 700 m white cocoon.High-quality cocoon must be used to make the smooth surface of Lanh My A.At the textile workshop of Tam Lang, each cocoon was spun by professional workers,and weft yarn was folded from 8 silkworms,and twisted yarn from 10 silkworms.During the weaving stage,artistsmust always keep an eye on themachine in order to remove the cocoon in case of error and avoid wrinkled yarn for everymilimet,then put the silk into boiled water to remove silkworm sap and started the dyeing stage(Fig.4).

图4 领美亚丝绸的新染色工艺Fig.4 Dyeing process of Lanh My A silk

Rose Morant also had very hard requirements for dyeing process because this is the primary factor affecting directly the beauty of Lanh My A silk.Every 100 kg persimmon fruits provided extract oil to dye 20 m silk.

Totalmanufacture time of Lanh My A silk is 4 months,and meanwhile the dyeing process is themost important stage.

In 1991,textile workshop of Tam Lang produced the first500 m Lanh My A silk under the instruction and control of Rose Morant and French textile experts,but the quality of fabric was still not appreciated for tailor products.In 1992,1000 m Lanh My A silk was produced,and the quality reached 70% of requirements.From 1995,aftermany years of labour training forworkers and artists,the perfect Lanh My A silk was created successfully,due to the analysis of Rose Morant.Itwas suitable for high-class textile and tailor products for French market[5].

4 领美亚丝绸在休闲纺织品上的应用

4 Application of Lanh My A silk in casual textiles

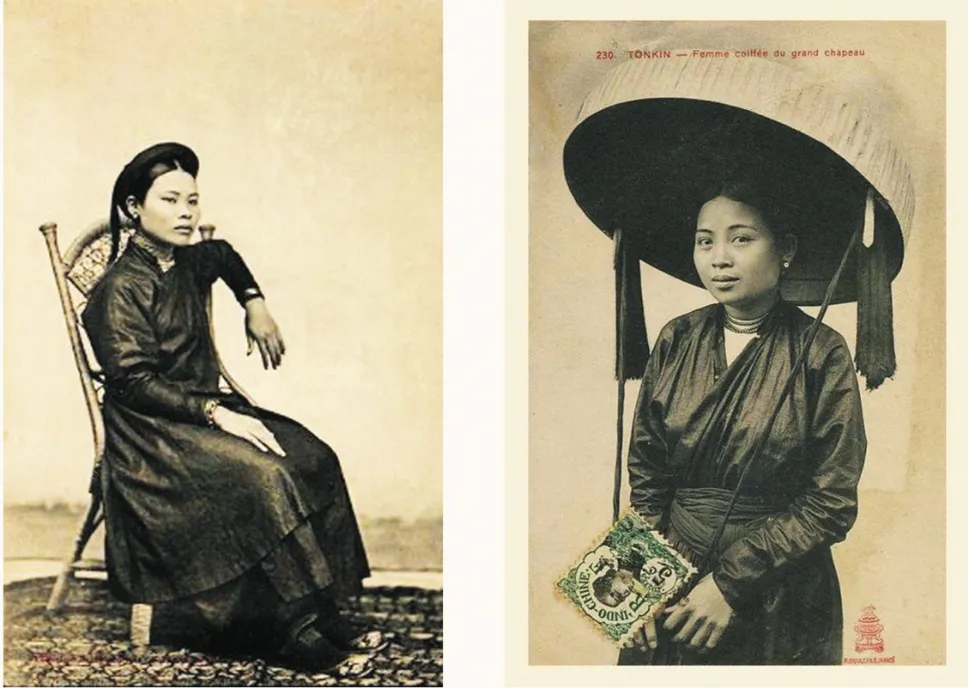

In the 20thcentury,Lanh My A silk was applied for only the pants of traditional dress in Vietnam(Fig.5).This was considered as ‘luxurious’ item for high-class women because of high price and hard washing condition.The pants made of Lanh My A silk created the beauty of fashion for women in Southern Vietnam in 1960s.

图5 领美亚古代衣服Fig.5 Ancient clothes of Vietnam made of Lanh My A silk

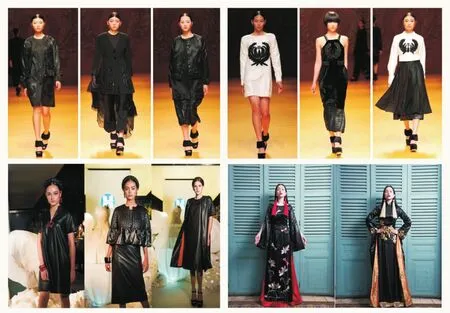

In modern fashion,Lanh My A silk is also an idealmaterial.In the 20thcentury,women in Southern Vietnam used to wear the farming clothes named ‘ao ba ba’ to work hard in the wheal fields(Fig.6).This image has become powerful inspiration for professional designers and theme formodern fashion collections.Based on the free-shape style of ‘ao ba ba’ with raglan sleeves,round neckline, two split lappets and two front pockets,casual items such as dresses, pants, skirts and dresses can be formed.Accordingly,90%of the textile materials are Lanh My A silk which is handmade completely.The remaining 10% of textile materials belong to other materials due to tailoring techniques.

图6 领美亚丝绸的现代时尚Fig.6 Vietnam fashion from Lanh My A silk

Besides the traditional glossy black colour,casual items made of Lanh My A Silk can bemixed with othermaterials such as pearl, purl, embroidery patterns and gemstone to make the clothes become younger and more flexible.

According to demands of market in fashion design,glossy black colour of Lanh My A silk is sometimes difficult to apply for young customers.Therefore,dyeing process from natural herbalmaterials is able to be applied for dyeing stage of Lanh My A silk.Dyeing extract oil from green tea, coffee bean, mangosteen, gac fruit…is ideal for Lanh My A silk.

5 结 语5 Conclusion

This article summarizes the history of Vietnam silk industry,and then provides the detailed knowledge of the development through decades of Lanh My A silk,its manufacture technology and its revival after recession period.Dyeing technology and persimmon extract are analyzed in order to conclude the special characteristics of Lanh My A silk.Moreover,this article suggests some application ways of Lanh My A silk fabric for casual products tomake it become a popularmaterial of textile and garment industry.

In the upcoming journals,the research looks forward to collectingmore detailed technology information about Lanh My A silk fabric and focusing design on thismaterial.

Reference:

[1]LE T H.Vietnam Textiles History[M].Ha Noi:Fine Art Publishing House,2017:11.

[2]LE M T.An Giang Handicraft and Industry[M].An Giang Province:An Giang Newspapers Publishing House,2003:31-32.

[3]NGUYEN V K.Tan Chau 1870-1964[M].Ho Chi Minh City:Vietnam Youth Publishing House,1966:26.

[4]Botany Research and Development Group of Vietnam.Vietnam Industrial Plants[M].Ho Chi Minh City:Botany Research and Development Group of Vietnam,2014:50.

[5]NGUYEN Q H.The Last Artist of Lanh My A[M].Ho Chi Minh City:Vietnam Youth Publishing House,2016:2.