鱼豆腐冻藏过程中的品质变化

宁云霞 马俪珍 梁丽雅 李玲

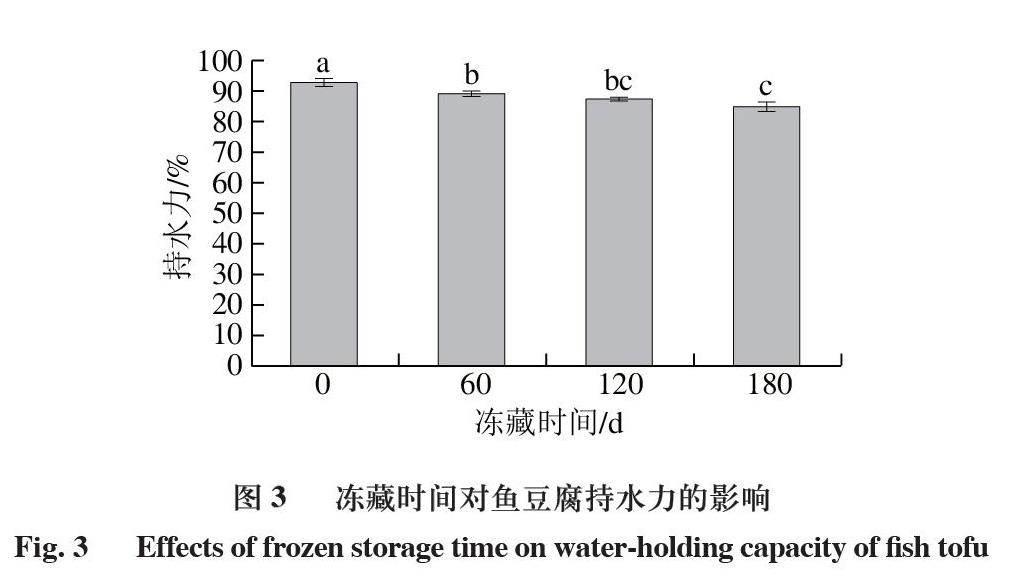

摘 要:以革胡子鲶鱼(Clarias gariepinus)为原料,不经过漂洗制成鱼糜,然后加工成鱼糜制品(鱼豆腐),取冻藏0、60、120、180 d(分别标记为FTF0、FTF60、FTF120和FTF180组)的样品进行测定,研究鱼豆腐-18 ℃冻藏过程中的品质变化。结果表明:随冻藏时间的延长,FTF60、FTF120和FTF180组鱼豆腐水分含量分别比FTF0组降低1.37%、1.76%和5.16%;FTF0、FTF60和FTF120组鱼豆腐凝胶强度差异不显著,持水力为86%~92%,均大于85%,感官评分均显著高于FTF180组;4 组鱼豆腐的白度为59.83~63.03,符合市场需求;鱼豆腐含丰富的谷氨酸、赖氨酸和牛磺酸,FTF180组鱼豆腐的鲜味氨基酸含量显著低于其他3 组,苦味氨基酸含量最高且显著高于FTF0、FTF60组。综合以上指标可知,鱼豆腐冻藏0~120 d品质良好。

关键词:革胡子鲶鱼;鱼糜制品;凝胶特性;游离氨基酸;品质变化

Abstract: Unwashed surimi was made from Clarias gariepinus and then used to prepare fish tofu. The quality changes of fish tofu during frozen storage at ?18 ℃ were studied by measuring samples taken after 0, 60, 120 and 180 days of storage (marked as FTF0, FTF60, FTF120 and FTF180, respectively). The results showed that the water content of FTF60, FTF120 and FTF180 respectively decreased by 1.37%, 1.76% and 5.16%, compared with that of FTF0. There was no significant difference in gel strength among FTF0, FTF60 and FTF120. The water-holding capacity of FTF0, FTF60 and FTF120 was 86%–92%, greater than 85%, and their sensory scores were significantly higher than that of FTF180. The whiteness of fish tofu in the four groups were 59.83–63.03, which were in line with the market demand. Fish tofu was rich in glutamate, lysine and taurine. The content of umami amino acids in FTF180 was significantly lower than that in the other three groups, and the content of bitter amino acids was the highest and significantly higher than that in FTF0 and FTF60. Based on the above results, it can be seen that the frozen fish tofu can remain good quality for up to 120 d.

Keywords: Clarias gariepinus; surimi products; gel properties; free amino acid; quality changes

DOI:10.7506/rlyj1001-8123-20200518-124

中图分类号:TS254.5 文獻标志码:A 文章编号:1001-8123(2020)08-0078-06

引文格式:

宁云霞, 马俪珍, 梁丽雅, 等. 鱼豆腐冻藏过程中的品质变化[J]. 肉类研究, 2020, 34(8): 78-83. DOI:10.7506/rlyj1001-8123-20200518-124. http://www.rlyj.net.cn

NING Yunxia, MA Lizhen, LIANG Liya, et al. Quality changes of fish tofu during frozen storage[J]. Meat Research, 2020, 34(8): 78-83. DOI:10.7506/rlyj1001-8123-20200518-124. http://www.rlyj.net.cn

水产品深加工的主要方式是将鱼糜加工成鱼糜制品,鱼糜制品具有营养价值高、易消化和风味鲜美等特点,深受广大消费者青睐[1]。市场上的鱼糜制品一般均以经过采肉、漂洗、脱水、精滤、冷冻等工序制得的海水鱼糜或淡水鱼糜为原料[2]。漂洗是通过水溶液将鱼肉进行洗涤,除去鱼肉中的可溶性蛋白、色素、脂肪及无机离子(如Ca2+、Mg2+)等成分[3],能够延长鱼糜及鱼糜制品的保藏期。但是,漂洗过程需要投入大量的人力和物力,成本高,排放的污水又容易造成环境污染,并且漂洗出的可溶性蛋白和脂肪会使鱼糜营养成分流失、产率降低。为了突破此瓶颈,本实验鱼糜的制作过程不包含漂洗工序。近几年海水资源捕捞过于频繁,资源短缺导致海水资源压力剧增,为了缓解海水资源的压力,迫切需要开发和利用淡水产品资源。革胡子鲶鱼(Clarias gariepinus,CG)属于优质淡水鱼之一,肉多刺少、肉质鲜美、生长迅速、适应性强、经济实惠,易去皮和采肉,是制作鱼糜制品的最佳原料之一[4-5]。