含水率对羊粪堆肥腐熟度及污染气体排放的影响

李丹阳,马若男,亓传仁,袁 京,李国学,孙少泽,刘 燕

含水率对羊粪堆肥腐熟度及污染气体排放的影响

李丹阳1,马若男1,亓传仁1,袁 京1,李国学1※,孙少泽2,刘 燕1

(1. 中国农业大学资源与环境学院,农田土壤污染防控与修复北京市重点实验室,北京 100193;2. 中国科学院化学研究所综合处,北京 100190)

为了优化羊粪好氧堆肥的工艺条件,研究初始含水率对羊粪堆肥腐熟度及污染气体排放的影响。该研究以高湿新鲜羊粪为堆肥原料(含水率为75%),添加玉米秸秆调节初始物料含水率分别为70%、65%、60%和55%,堆肥在60 L密闭发酵罐中共持续35 d。结果表明:75%含水率羊粪堆体单独不能顺利启动升温,且在试验期间释放了大量的甲烷和氧化亚氮等温室气体,在所有处理中产生的总温室效应最大(41.4 g/kg)。玉米秸秆与羊粪联合均能成功启动堆肥过程,且堆肥产品均可以达到无害化卫生要求和腐熟标准。其中初始含水率为65%时,堆体不仅高温期持续时间长,且有机质降解程度高,物料干质量降解率达45%,同时比其他处理可降低4.81%~16.99%的总氮损失和7.56%~48.62%的总温室气体排放量。因此,在羊粪和玉米秸秆联合堆肥时,初始含水率65%左右为最佳条件。

含水率;粪;堆肥;腐熟度;污染气体

0 引 言

随着中国羊产业向规模化、集约化和专业化方向发展,羊粪污排放量也迅速增加。羊粪中有机质、总氮及磷含量远高于牛粪和猪粪,且铜、锌含量低于其他畜禽粪便[1],同时新鲜羊粪中一般含有大量病原菌、微生物、寄生虫卵等有毒有害的物质。利用好氧堆肥技术可有效减少畜禽粪便污染、转化生成可利用的有机肥,是目前关注度最高、应用最广泛的资源化处理途径。

不同地区羊养殖环境及饲养方式的不同,羊粪的含水率差异很大。前期实地调研发现,以漏缝地板为羊场圈舍地面、用刮粪板收集的羊粪污含水率较高(可达75%)。在堆肥过程中,物料的初始含水率是影响堆肥进程及有机质降解率的主要因素[2],它会影响物料堆体的氧气运输量,还可以调节发酵温度、物料孔隙率以及微生物活性等[3]。过高的含水率不仅不利于空气扩散,造成堆体局部厌(缺)氧环境,从而产生大量CH4、N2O、H2S等污染气体[4],且有机质降解速率减小,增加堆肥腐熟时间。而当含水率不足时,微生物活性降低,发酵过程受到抑制,导致堆肥腐熟延后,甚至不能腐熟[5]。腐熟度是后续有机肥农田利用中首要考虑的因素,未腐熟的畜禽粪污施用于土壤中,可能对种子发芽和作物生长有毒害作用[6]。另外,污染气体的排放也是一个值得关注的问题,这些气体排放不但会造成堆肥过程中养分大量损失,从而影响堆肥产品的肥效,且会给周围环境带来严重的危害,降低堆肥的环境效益[7]。研究表明适宜的含水率可以提高堆肥的腐熟度,减少堆肥过程中污染气体的排放。Tamura和Osada[8]通过对不同含水率的堆肥试验研究发现,物料含水率越高,温室气体排放量越高。Petrica等[9]研究表明,鸡粪和麦秸联合堆肥时的最佳初始含水率为69%,过高的含水率会造成NH3大量挥发。蔡海森[10]研究了3种初始含水率(55%、60%和70%)对鸡粪与稻壳堆肥腐熟度的影响,结果表明,只有含水率60%的处理可达到无害化要求和堆肥腐熟标准。

目前,对好氧堆肥的研究主要集中于以猪粪、鸡粪或牛粪为原料[11-13],而对于氮磷含量较高的羊粪好氧堆肥的研究相对较少。因此,本文以羊粪为堆肥原料,系统研究不同初始含水率对堆肥产品腐熟度及污染气体排放的影响,从而为羊粪堆肥产品的应用及污染气体减排提供一定的理论依据。

1 材料与方法

1.1 试验材料

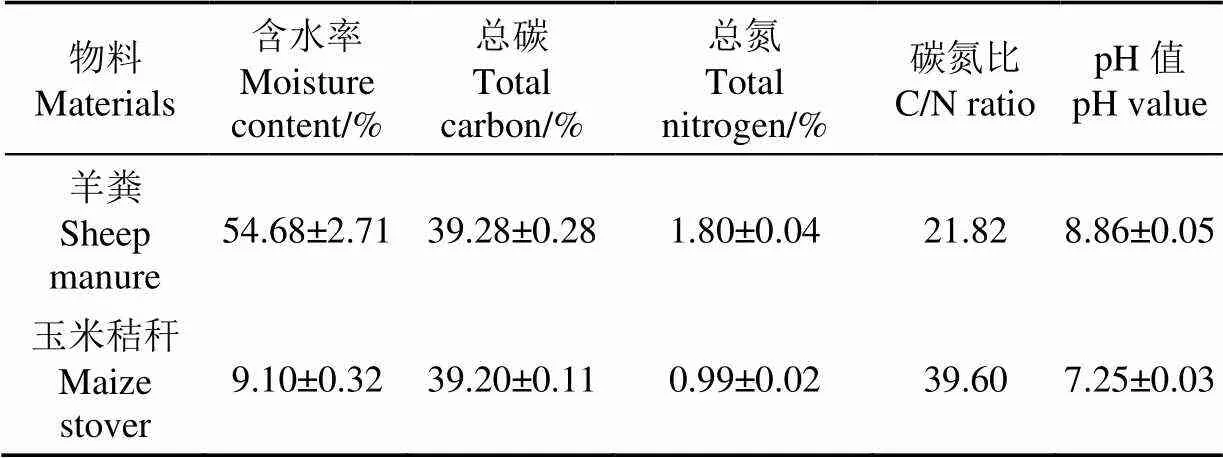

试验所用羊粪取自北京市奥鑫牧业有限公司。玉米秸秆取自中国农业大学上庄试验站,用粉碎机将其切割为长度为3 cm的段状秸秆,物料基本理化性状见表1。

表1 初始物料的基本理化性质

注:含水率以湿基计算;总碳和总氮均基于干基计算。

Note: Moisture was calculated based on wet basis; Total carbon and total nitrogen were acquired based on dry basis.

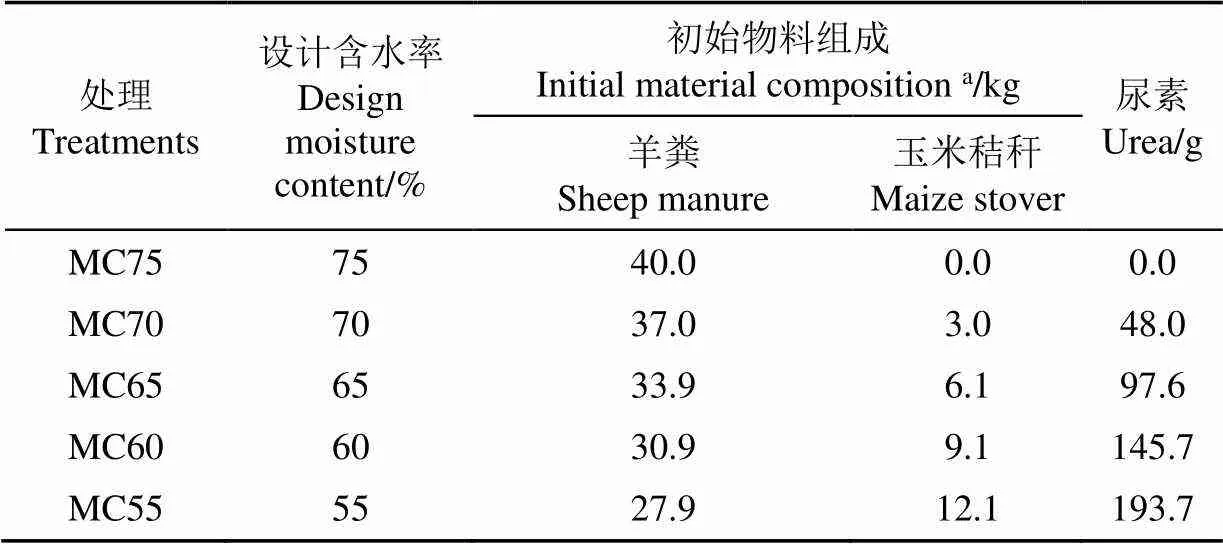

1.2 试验设计

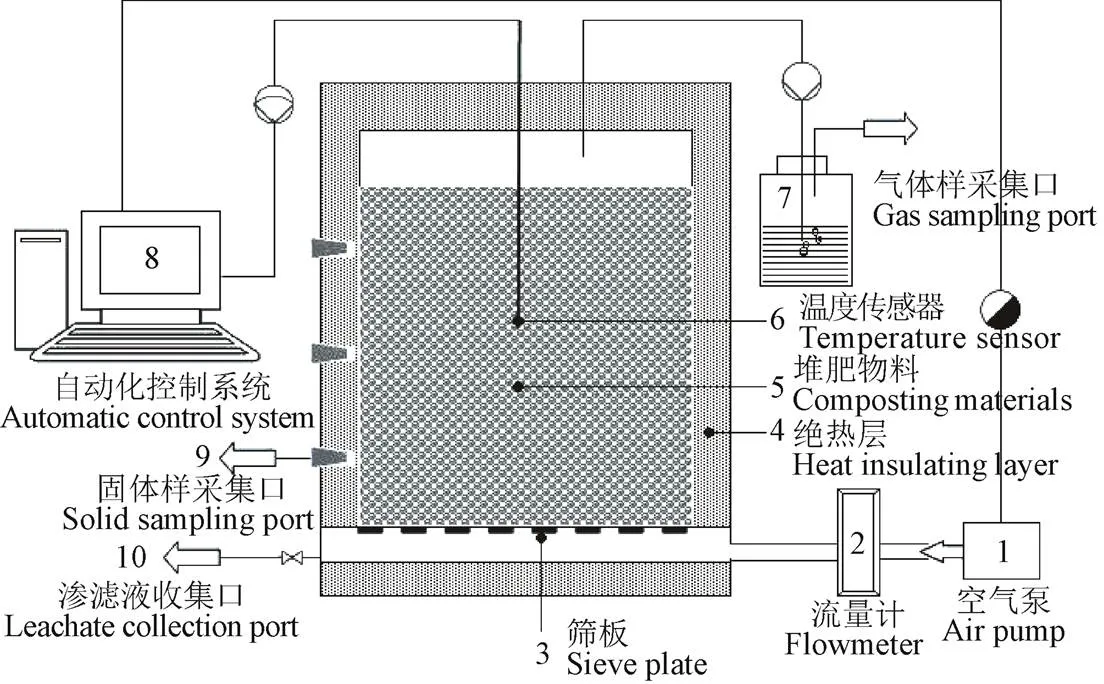

试验共设5个处理,初始含水率分别设为75%、70%、65%、60%和55%,设计方案如表2所示。为了在室内模拟高含水率羊粪堆肥,将从奥鑫公司所取羊粪(含水率约55%)按照1∶1(质量比)加水混合调节含水率至75%,再分别加入不同质量的玉米秸秆调节物料初始含水率到相应的设定值,用尿素调节各堆料初始C/N为22左右。试验装置为60 L密闭发酵罐(图1),通风方式为机械强制连续通风,通风速率为0.2 m3/h,堆肥周期为35 d,每周翻堆一次,翻堆后取样约300 g左右,样品分为2份,一份(约200 g)为新鲜样品冷冻保存,用于测定含水率、pH值、电导率(EC, Electrical Conductivity)、种子发芽率指数(GI,seed Germination Rate Index)、铵态氮(NH4+-N)、硝态氮(NO3--N);另一份(约100 g)经自然风干、粉碎、过100目筛后用于测定总碳(TC)和总氮(TN)。

表2 试验设计

注:a为基于鲜质量。

Note: a is based on wet weight.

图1 密闭式堆肥发酵罐示意图

1.3 测定指标及分析方法

堆肥温度,通过连接电脑的温度传感器直接读取,每半小时自动记录一次;堆肥积温计算方法见参考文献[14]。含水率的测定在105 ℃的烘箱中烘干至恒定质量。有机质的测定是将样品使用马弗炉灼烧(600 ℃±20 ℃)3h至恒重。利用元素分析仪(Vario Micro Cube,德国)测定样品中的TC、TN含量。pH值、EC、GI测定:用水浸提鲜样,固液比为1∶10,振荡30 min,静置10 min后过滤取滤液,使用多参数分析仪(DZS-706-A,中国)测定pH值、EC值。GI的测定方法参考文献[15]。NH4+-N、NO3--N的测定用2 mol/L的KCl溶液,按照1∶10(质量体积比)同样品混合,震荡30 min,静置10 min,过滤后取滤液经流动分析仪(Auto Analyzer 3,Seal,德国)测定。温室气体(CH4和N2O)用安装有火焰电离检测器、电子捕获检测器的气相色谱(SP-3420A,北京北分瑞利分析仪器有限责任公司,中国)测定。NH3通过发酵罐顶部装有质量分数为2%的硼酸吸收瓶吸收后,用0.02 mol/L标准浓度的稀硫酸滴定测得。O2和CO2由泵吸式沼气分析仪(Biogas 5000,Geotech,英国)直接读数测定。堆肥气体一天一测。

作图采用origin 8.5软件完成;统计分析采用Microsoft Excel和SPSS 20.0软件完成。

2 结果与分析

2.1 温度的变化

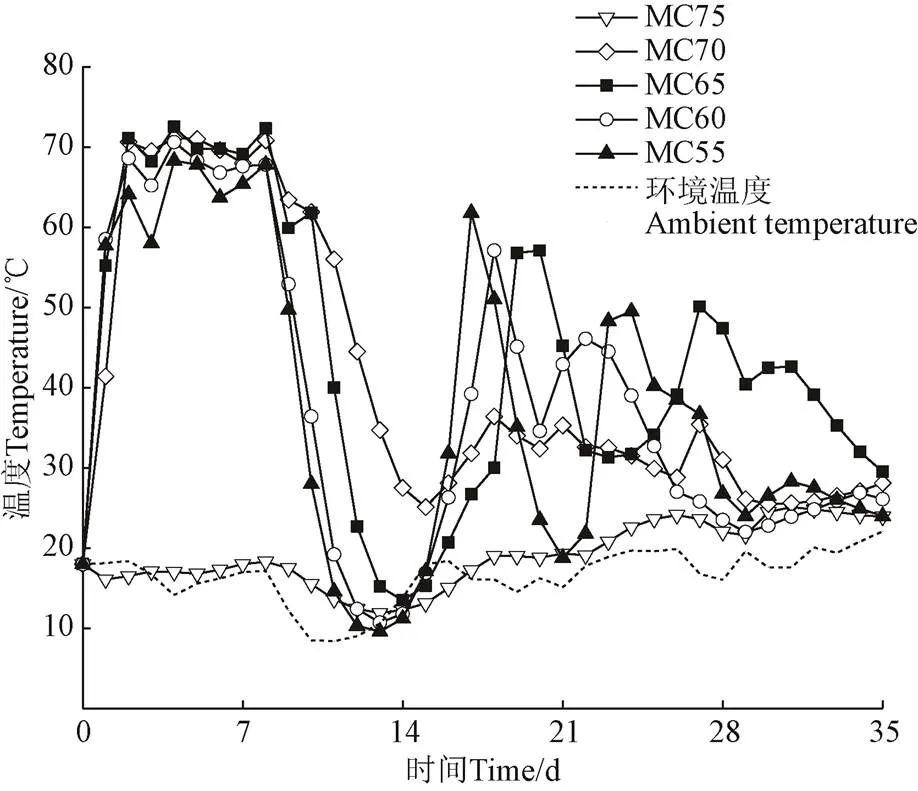

温度是表征堆体中微生物对有机物降解状况的重要指标,也可判断堆肥的无害化和稳定性[16]。各处理的堆体温度变化如图2所示。统计分析表明,MC75处理的温度与其他处理均存在极显著差异(<0.001),而其他4个处理的温度之间无显著差异(=0.480)。处理MC75的堆温在堆肥周期内始终与环境温度相近,最高温度仅为25.1 ℃,表明75%含水率的高湿羊粪无法成功启动堆肥过程,这主要是由于该处理羊粪结构致密,造成了堆体紧实,透气性差,不利于微生物的生长繁殖。在堆肥初期(第0~7天),连续通风使得堆体中氧气含量充足,微生物代谢活动旺盛,堆肥物料被快速分解并产生大量热量,使得T2~T5 4个处理的堆温迅速升高,在第2天均进入了高温期(>50 ℃),在第4天均达到温度峰值,最大值分别为71.1、72.5、70.6 ℃和68.3 ℃。在高温期的维持时间分别为10、10、9和8 d,可以有效杀灭羊粪中的病原菌、微生物及有害虫卵,均达到中国粪便无害化卫生标准(GB 7959—2012)。试验第8~14天,由于前期有机物降解消耗了大量氧气,供气不足,且高温使水分大量蒸发,所以温度逐渐下降。在第14天翻堆后各处理温度又有所回升,这是因为翻堆可提高物料之间的孔隙度,从而增加了物料与氧气的接触面积,未降解的有机质得到充分降解,产生热量导致温度增加,这一现象在Szanto等[17]的研究中也有所发现。堆肥后期,可被降解的有机物不断减少,微生物活动减弱,堆体温度逐渐降低至室温。

在5个处理中,MC65处理达到高温期所需时间短、温度峰值最高、高温期持续时间最长且有效积温最大(24 472.8oC·h),这是由于物料初始含水率为65%时,堆料具有足够的自由空域,更有利于微生物的新陈代谢,使得有机质降解更加充分。

图2 堆肥过程中温度变化

2.2 氧气含量的变化

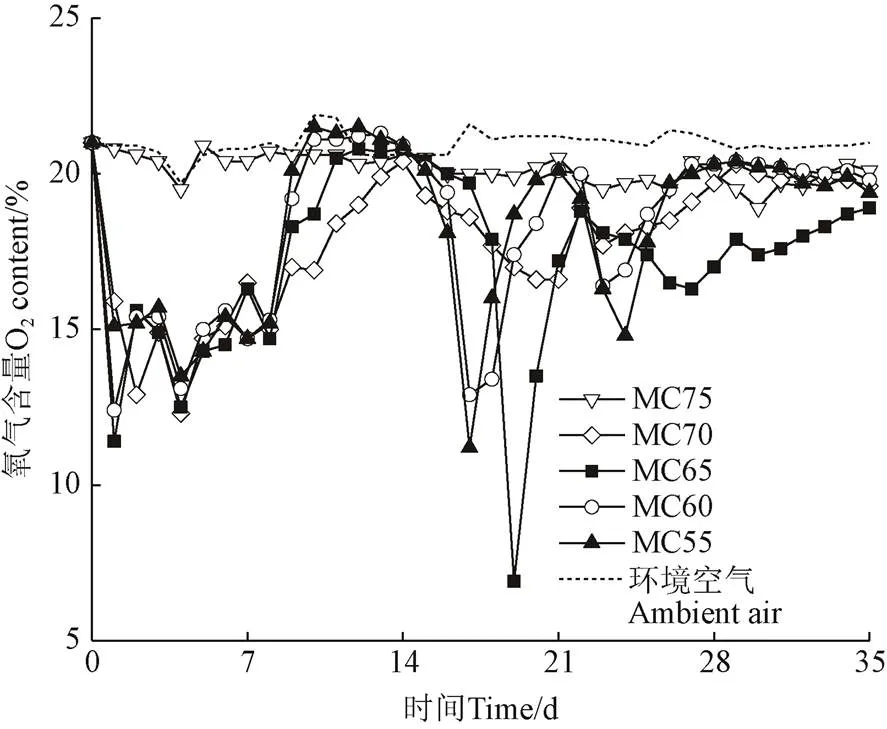

O2含量变化可以反映堆体中微生物的活性和有机物的降解情况。O2含量与温度呈极显著负相关关系(=-0.844,<0.001),这与陈是吏等[18]的研究结果一致。由图3可知,在堆肥前7 d,羊粪中的易降解性有机物质被微生物快速分解,消耗大量O2,导致O2含量降低。随着堆肥反应的进行,微生物分解有机质速度变缓,对O2需求量减少,O2含量逐渐上升。从第14天开始,每次翻堆后O2含量均呈先下降后升高的趋势。在第28天后,随着堆体温度逐渐接近室温,所有处理的O2含量逐渐趋近于环境本底值,说明堆肥已达到腐熟、稳定。研究表明,堆料中微生物生理活动的适宜O2含量为10%~18%[19]。整个堆肥过程中,只有MC65处理在堆肥第19天的O2含量较低,其余各处理在堆肥过程中O2含量均大于10%,较适宜微生物代谢活动。5个处理中,总体以MC65处理O2含量最低,这是因为初始含水率为65%更有利于微生物消耗大量O2降解有机质。

图3 堆肥过程中氧气含量变化

2.3 堆肥物理化学性质和物料腐熟指标变化

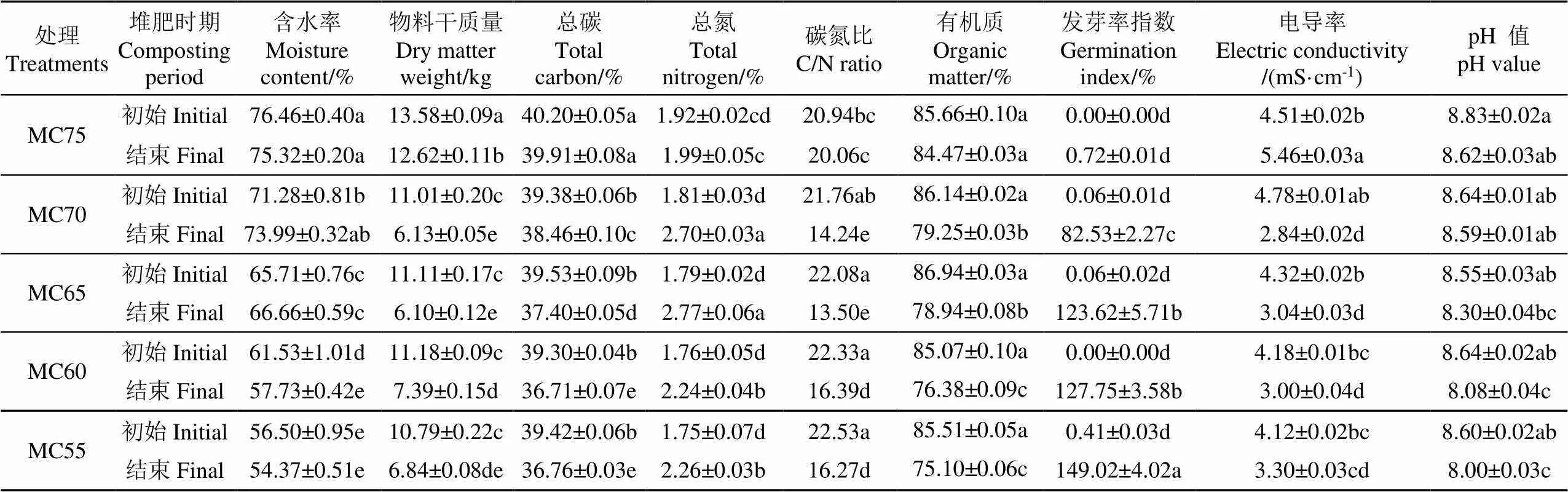

各处理初始及结束时的物理化学和物料腐熟指标如表3所示,堆肥前后各处理的含水率变化幅度较小。T1~T5各处理的物料干质量降解率分别为7.07%、44.32%、45.09%、33.90%和36.61%,高含水率组(70%和65%)比低含水率组(60%和55%)的干质量降解率高,这表明高含水率会增大有机质的降解程度,这可从温度、CO2和NH3的排放规律中进一步得到反证[9]。物料的TC和TN随着堆肥进行而不断降解损失,当TN的损失速率小于TC的降解速率时,TN含量由于被浓缩而增加,这与杨帆等[20]的研究结果一致。同时,T1~T5处理的C/N比均随着有机质的降解而呈下降趋势,在堆肥结束时比初始值分别降低了4.20%、34.56%、38.86%、26.60%和27.79%。其中,MC65处理下降幅度最大,这是因为其TC含量高,分解较快,而TN损失较少所致。

堆肥结束时,T1~T5处理有机质的降解率分别为1.39%、8.00%、9.20%、10.22%和12.17%。55%初始含水率的堆料疏松,有利于好氧微生物生长,使有机质的降解程度最大,但可能会增加污染气体排放。GI值是评价堆肥腐熟程度和植物毒性最敏感也是最佳的指标[21],当GI值超过80%时,可以认为堆肥已经腐熟或对植物没有毒性[22]。EC的变化能表示堆肥浸提液中可溶性盐含量,是评判堆肥产品对植物造成盐害作用的重要参数。在堆肥结束时,除了MC75处理的GI值未发生明显改变且EC值有所增加外,其他处理最终堆肥产品的GI>80%且EC<4 mS/cm,达到堆肥腐熟标准[23]。另外,所有处理在堆肥结束时的pH值在8~9范围内[24],满足堆肥产品呈弱碱性的要求。堆肥结束时各处理pH值的大小与堆体初始含水率呈正比,这是因为初始含水率越低,即玉米秸秆占比越多,其对羊粪堆肥pH的增大有一定的抑制能力[25]。

2.4 铵态氮和硝态氮含量的变化

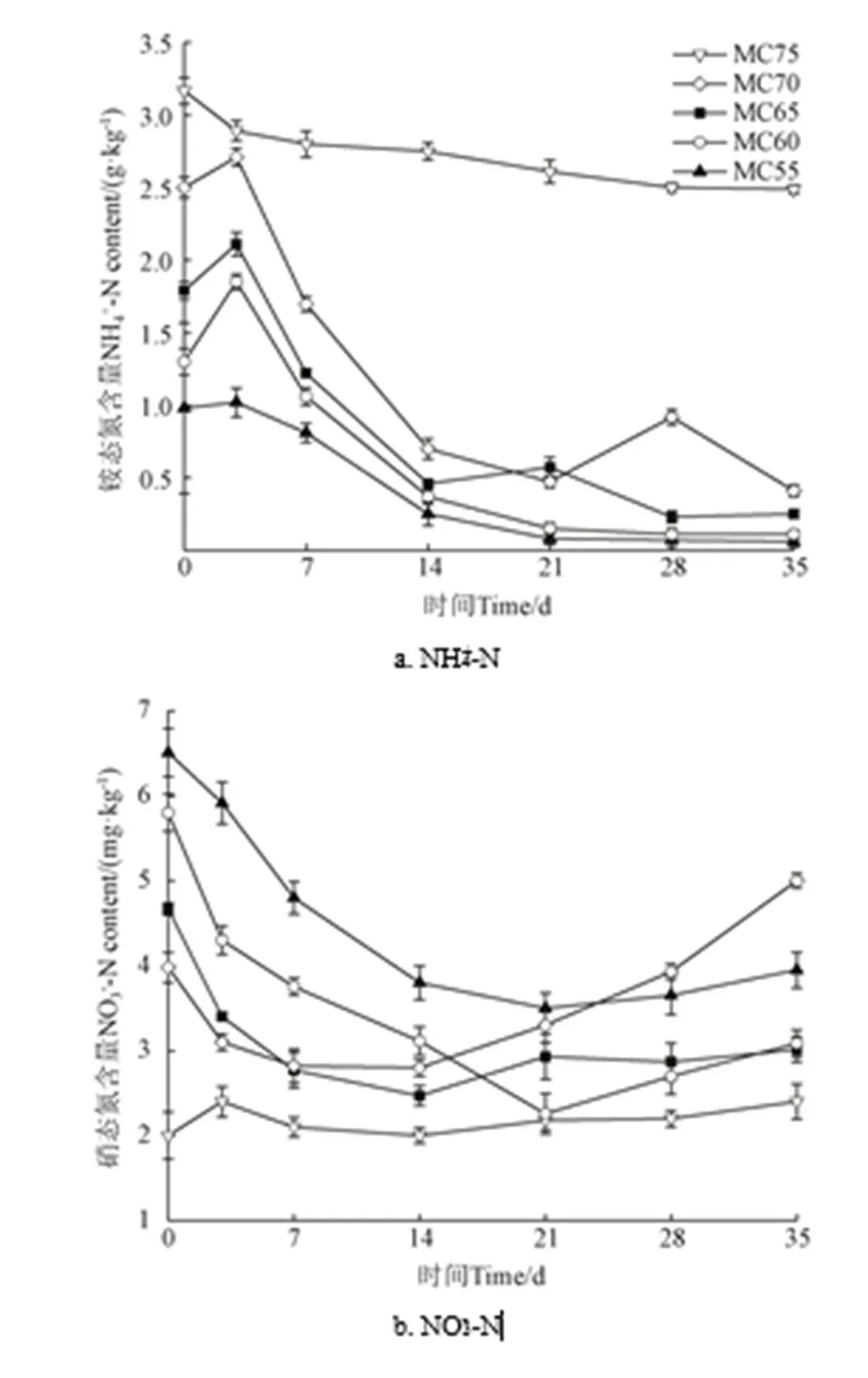

堆肥过程中铵态氮(NH4+-N)和硝态氮(NO3--N)含量变化如图4所示。统计分析表明,各处理间NH4+-N含量差异显著(<0.001),同样地,各处理间NO3--N含量差异显著(=0.001)。初始物料中秸秆添加量越大,NH4+-N含量越低,这是因为添加膨松剂会稀释物料中NH4+-N的浓度。除MC75处理外,在有机氮的矿化分解和微生物的氨化作用下,各处理NH4+-N都有所增加,在第3天均达到最大值。之后随着堆肥进入高温期,部分NH4+-N被微生物固定,部分以NH3形式挥发损失,堆肥中NH4+-N含量逐渐降低最后趋于稳定,堆肥结束时T2~T5处理NH4+-N含量下降至0.06~0.41 g/kg。

在堆肥前14 d,各处理的温度较高且反硝化作用较为剧烈,NO3--N作为底物被大量消耗,另外由于高温抑制了硝化细菌的活性[26],所以NH4+-N不能通过硝化作用转化为NO3--N,使NO3--N含量总体呈下降趋势。在第21天后,堆肥逐渐进入降温期,堆体O2含量增高,硝化细菌活性增强,NH4+-N转化为NO3--N,各处理的NO3--N含量逐渐升高[27]。其中,MC70处理由于在后期温度明显下降,硝化细菌活动相对比较剧烈,该处理从第14天到堆肥结束,NO3--N含量上升幅度可达78%。整个堆肥过程中各处理物料的NO3--N含量始终维持在较低水平,均在7 mg/kg以下,说明堆肥过程中各处理的硝化作用都较弱。

表3 堆肥物理化学性质和物料腐熟指标

注:同一列不同小写字母代表同一指标在<0.05水平上具有显著性差异。

Note: Different lowercase letters in the same column indicated significant difference in same index at<0.05.

图4 堆肥过程中NH4+-N和NO3--N含量的变化

2.5 气体排放

2.5.1 CH4排放

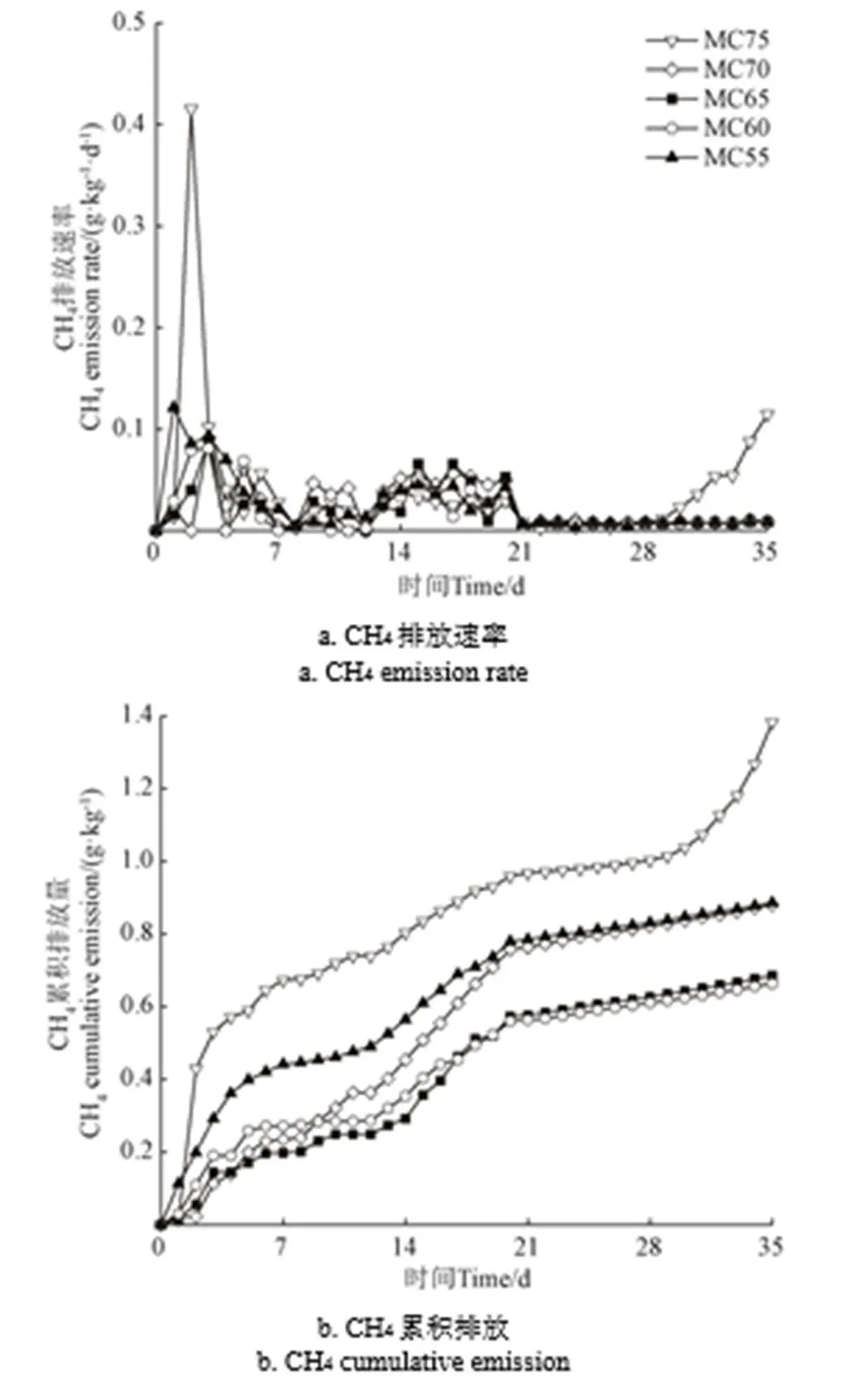

堆肥期间CH4日排放速率及累积排放量如图5所示。各处理的CH4排放高峰主要集中在堆肥高温期(图5a),与之前学者研究结果相似[28]。这是因为堆肥中的微生物消耗大量氧气降解有机质,使得堆体温度升高,并造成堆体中出现局部缺氧环境,导致CH4产生。MC75处理在堆肥第2天达到CH4日排放速率最大值,为0.415 g/(kg·d),T2~T5处理均在第3天达到排放高峰,排放率分别为0.091、0.089、0.081 g/(kg·d)和0.093 g/(kg·d)。在堆肥第2周翻堆后,各处理的CH4排放速率又明显增加,这是因为堆体温度回升,且在翻堆后,堆体内的CH4得以释放[29]。在第21天后,T2~T5四个处理CH4的日排放速率趋近于0,而MC75处理在第28~35天的CH4日排放速率又逐渐增加,最大值可达0.114 g/(kg·d),这可能与该处理长期处于高湿环境且第28天后温度随着室温小幅度增加有关。由图5b可知,堆肥结束时,MC75处理的CH4累积排放量最大(1.38 g/kg),以其为对照,T2~T5处理可明显减排CH4(0.001),减排率分别为36.35%、50.43%、52.01%和35.92%,其中初始含水率为60%~65%的减排效果较好。

2.5.2 N2O排放

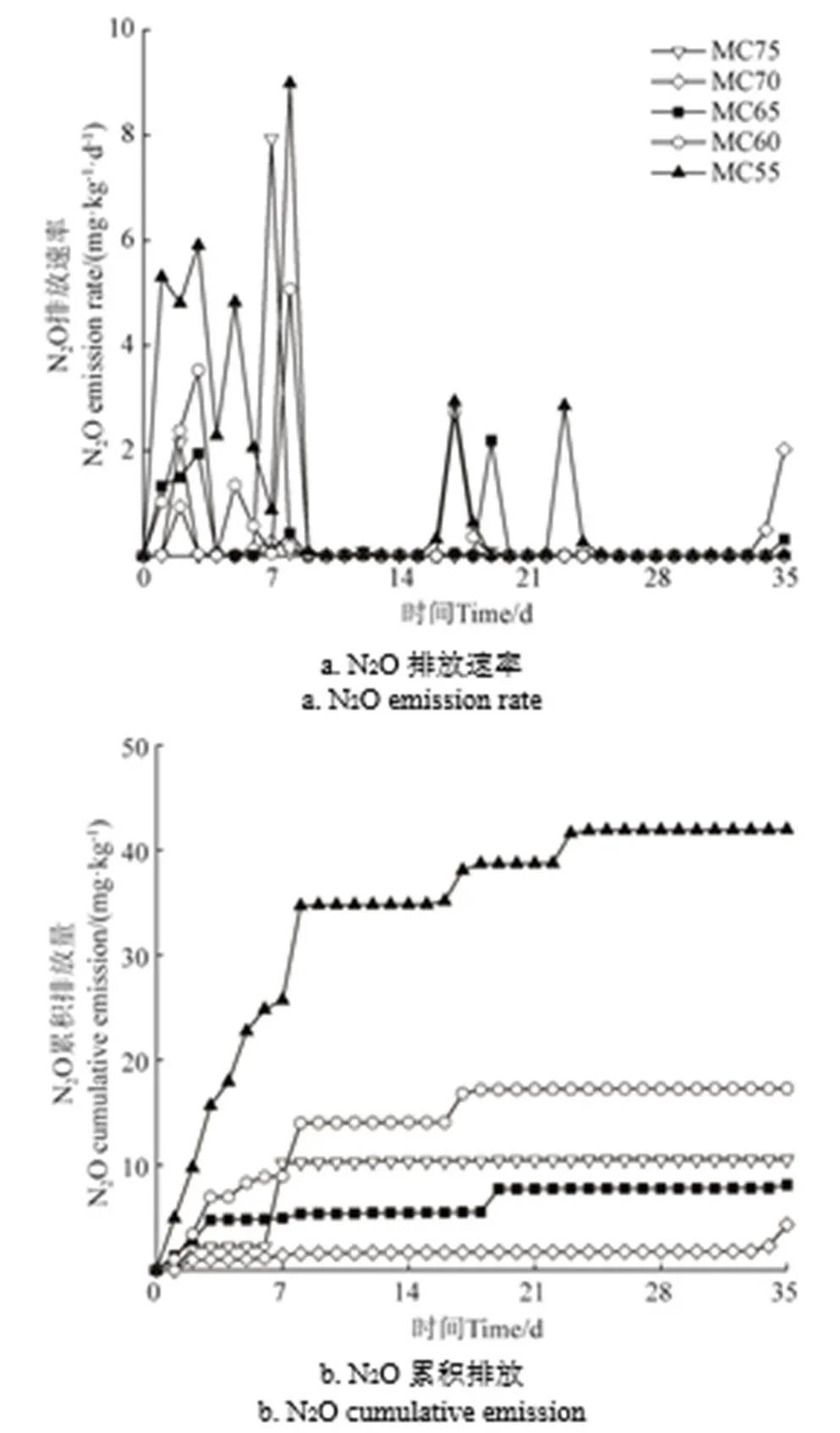

堆肥过程中铵态氮硝化与硝态氮反硝化作用均会导致N2O的产生[30],各处理的N2O排放规律如图6所示。从图6a可知,各处理的N2O排放主要集中在堆肥初期,排放高峰大约持续8 d,这是由于初始物料中NO3--N含量较高,在反硝化作用下产生N2O[31]。除了MC75处理外,其他处理在堆肥初期有机质剧烈降解,O2消耗量大,堆体内部易出现厌氧或缺氧情况,从而使得N2O大量排放并达到峰值。T1~T5处理的N2O排放峰值分别为7.93、0.94、1.95、5.07和8.98 mg/(kg·d)。MC65、MC60和MC55处理在第二周翻堆后会出现N2O排放小高峰,对比温度(图2)及O2含量变化规律(图3),可知这3个处理在翻堆后温度迅速上升,O2含量均有明显的下降,部分NO3--N通过反硝化作用产生N2O,这与周谈龙等[29]的研究结果类似。之后随着物料孔隙度的增大及通气状况的改善,N2O排放速率均趋于0,沈玉君等[32]用鸡粪、秸秆和干草皮为堆肥原料进行好氧堆肥也得到了类似的N2O排放规律。统计分析数据表明,初始含水率能显著影响N2O的排放(=0.000)。堆肥结束时,T1~T5处理的N2O累计排放量分别为10.51、4.32、8.12、17.29 mg/kg和41.96 mg/kg(见图6b),除了未发酵的MC75处理外,初始含水率越高,N2O峰值和累积排放量越低。

图5 堆肥过程中CH4排放速率及累积排放的变化

2.5.3 NH3排放

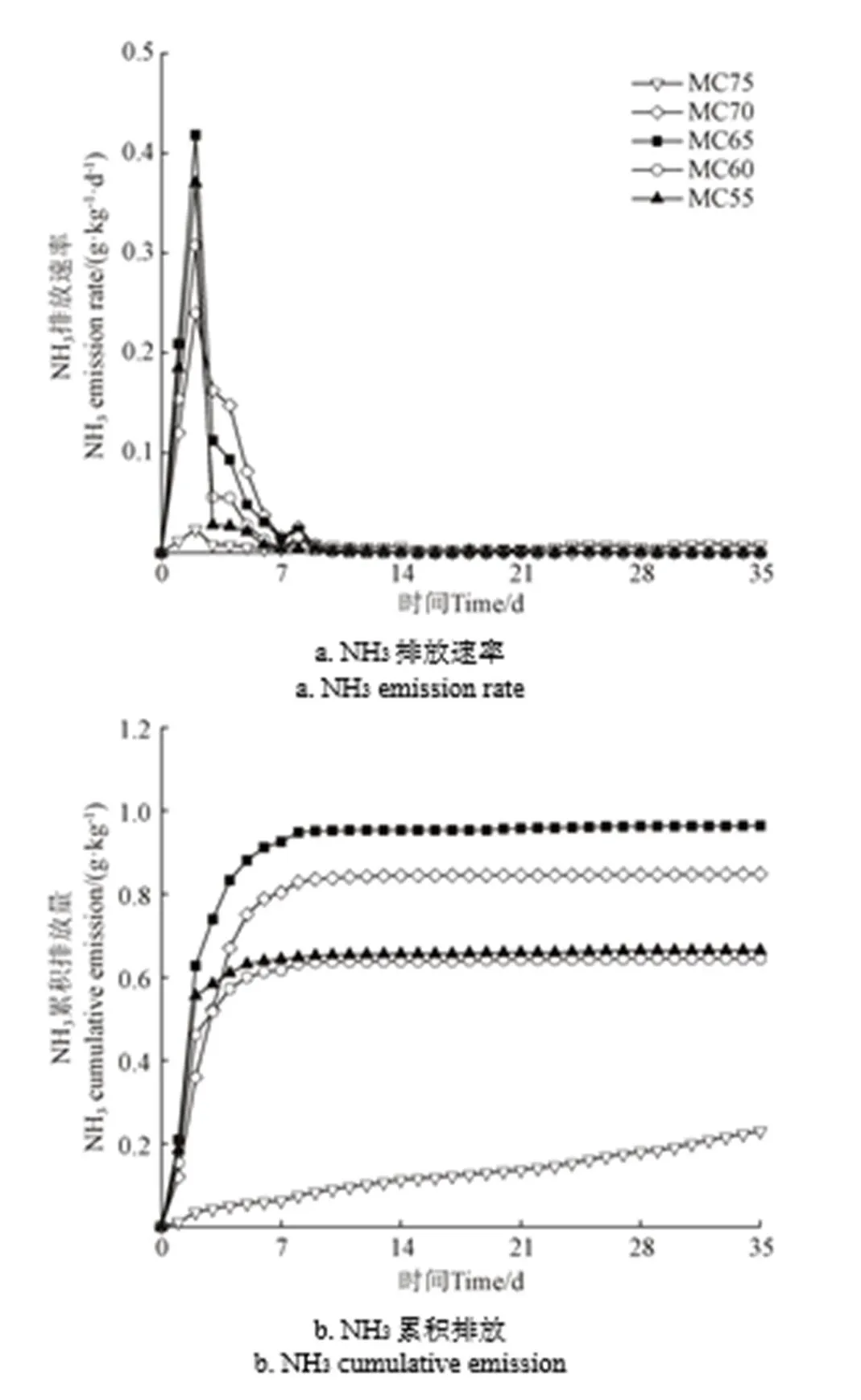

堆肥期间NH3平均排放速率和累积排放规律如图7所示。由图7a可知,5个处理NH3排放速率变化趋势基本相同,均呈现先快速上升后迅速下降再趋于稳定的过程。NH3排放主要发生在高温期,与其他学者的研究结果一致[33-34],这是因为有机质降解产生的NH4+-N在高温和高pH条件下迅速转化为NH3,使各处理的NH3排放速率在第2天均达到峰值,T1~T5处理NH3排放峰值分别为0.02、0.24、0.42、0.31和0.37 g/(kg·d)。在第7天翻堆后NH3排放率有小幅上升,这是因为一方面处于厌氧区的物料通过翻堆转移到氧气充足的区域,发生了进一步的降解。另一方面翻堆使堆料更加疏松,内部呈游离状态的部分NH4+-N和NH3暴露于堆体表层[35],进一步提高了NH3的排放。堆肥前8 d,T2~T5处理的NH3累积排放量占整个堆肥周期的97%以上。之后随着堆肥温度的降低,NH4+-N含量减少,NH3释放率逐渐下降几乎为0。而MC75处理因为没有经历高温期,NH3平均排放速率很低,在第21天后,由于其堆体温度随着室温略有增加,可检测到少量NH3排放。

图6 堆肥过程中N2O排放速率及累积排放的变化

到堆肥结束时,T1~T5处理的NH3累积排放量分别为0.23、0.85、0.96、0.64 g/kg和0.66 g/kg(图7b),高含水率组(70%和65%)的NH3挥发量显著高于低含水率组(60%和55%)(<0.0001),这是因为一方面高含水率组在整个试验期间的pH较大,从而促进NH3挥发。另一方面提高初始物料的含水率可促进物料中有机质的降解,提高堆体的温度,而温度是影响NH3释放的最主要因素[36]。统计分析结果表明,温度与NH3累积排放量呈极显著正相关关系(=0.359,<0.001),与Pagans等[37]的研究结果一致。

2.6 碳氮平衡及温室效应分析

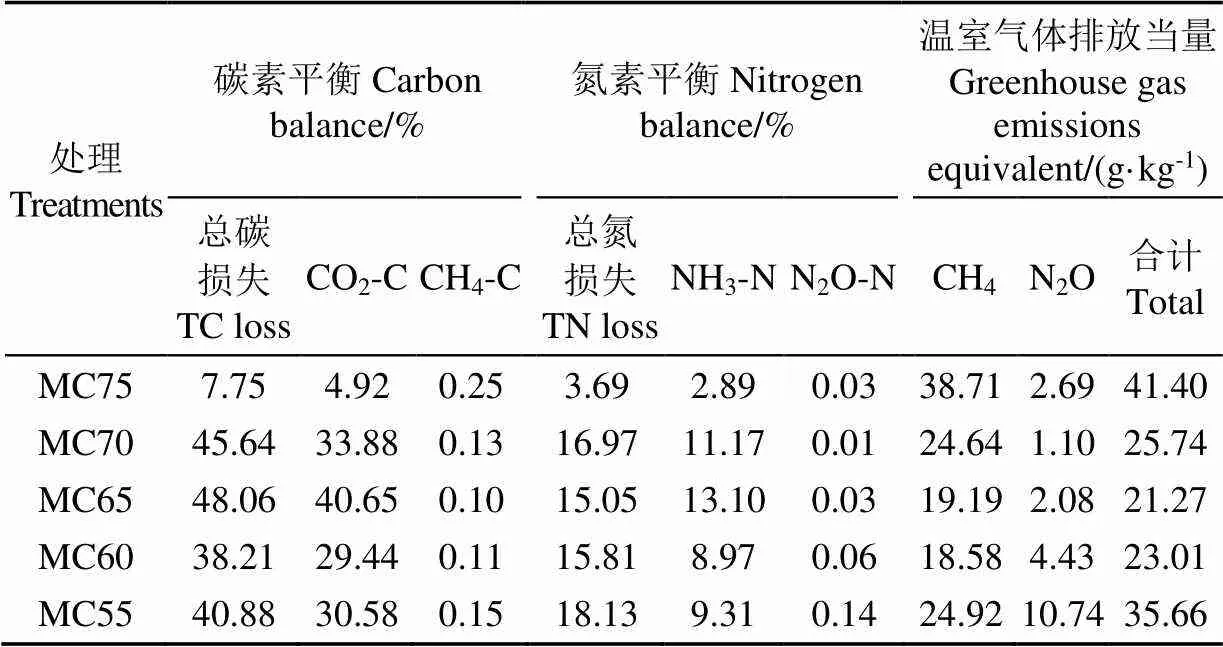

各处理碳氮平衡及温室效应分析如表4所示。虽然MC75处理因含水率太大未能成功启动堆肥过程,有机质降解缓慢,但也有7.75%的TC损失。其他4个处理TC损失率为38.21%~48.06%,TC主要以CO2-C形式损失,占初始TC的29.44%~40.65%;CH4排放贡献率较小,占初始TC的0.10%~0.15%。除了MC75处理的TN损失较低之外(3.69%),其他各处理TN损失率为15.05%~18.13%,MC65处理比其他3个成功启动堆肥的处理减少4.81%~16.99%的TN损失,保氮效果最好。NH3-N是TN主要的损失形式,占TN损失的51.35%~87.04%,N2O-N形式损失仅占初始TN的0.01%~0.14%,这与Jiang等[38]的研究结果相似。以其他形式损失的碳和氮可能是被微生物利用合成细胞组织[35]。

图7 堆肥过程中NH3排放速率及累积排放的变化

堆肥过程中CO2是微生物新陈代谢的产物,故在废弃物管理过程中不作为温室效应的贡献因子[39]。堆肥过程中温室气体的排放以CH4和N2O为主,各处理温室气体的CO2排放当量如表4所示。由表可知,CH4排放对总温室效应贡献率均在65%以上。MC75处理尽管未经过高温期来实现物料无害化,但在试验期间仍会产生大量温室气体,总温室效应在所有处理中最高(41.40 g/kg)。这表明在羊场实际生产活动中,若对高湿羊粪未能进行及时的收集及不合理堆置,在自然通风条件下,堆体内部很容易缺氧,产生的大量温室气体不仅会威胁动物及工作人员的健康,同时还会造成严重的大气污染。加入适量秸秆可调节物料的水分含量,明显降低温室气体排放当量,其中初始含水率为65%的处理在堆肥过程中产生的总温室效应最低(21.27 g/kg),比其他处理降低7.56%~48.62%。

表4 碳氮平衡及温室效应分析

注:碳、氮素平衡为碳、氮损失占初始总碳、氮的百分比;温室气体排放当量值以物料的干基计算;N2O和CH4对温室效应的贡献率分别为CO2的256和28倍[40]。

Note: The balance of carbon and nitrogen is the percentage of carbon and nitrogen loss in the initial total carbon and nitrogen; The greenhouse gas emissions equivalent was calculated based on dry basis; The global warming potentials of N2O and CH4are 256 and 28 times higher than that of CO2, respectively[40].

3 结 论

1)75%含水率的高湿羊粪无法成功启动堆肥过程,未能实现物料的无害化,堆肥产品也未能达到腐熟标准,但在试验期间可排放大量的CH4和N2O温室气体,总温室效应在所有处理中最高。

2)添加秸秆一方面能降低初始物料的含水率,另一方面能调节堆体的通气状况。本文中添加秸秆与高湿羊粪联合堆肥均能成功启动堆肥过程,满足堆肥高温无害化卫生标准,且堆肥产品均可达到腐熟。其中,初始物料含水率为65%时,堆体不仅升温快、有效积温最大,有机质分解程度高,物料干质量降解率达45%,且比其他3 个成功启动堆肥的处理减少了4.81%~16.99%的总氮损失。

3)初始含水率对N2O、CH4和NH3排放有显著影响。在成功升温的堆肥处理中,初始含水率越大,N2O峰值和累积排放量越低,适宜的含水率可显著降低CH4排放。由于初始物料含水率为65%的堆肥高温期持续时间最长,导致NH3累积排放量最高,但堆肥过程产生的总温室效应比其他4个处理降低了7.56%~48.62%。综上,在羊粪和玉米秸秆联合好氧堆肥时,初始含水率65%左右为最佳条件,后续也可使用部分添加剂来控制氨气排放。

[1] 李书田,刘荣乐,陕红. 我国主要畜禽粪便养分含量及变化分析[J]. 农业环境科学学报,2009,28(1):179-184. Li Shutian, Liu Rongle, Shan Hong. Nutrient contents in main animal manures in China[J]. Journal of Agro-Environment Science, 2009, 28(1): 179-184. (in Chinese with English abstract)

[2] 李红霞,蔡禄,季祥,等. 羊粪好氧堆肥最佳工艺参数的优化研究[J]. 中国农机化学报,2019,40(6):215-220. Li Hongxia, Cai Lu, Ji Xiang, et al. Optimization of optimum process parameters for aerobic composting of sheep manure[J]. Journal of Chinese Agricultural Mechanization, 2019, 40(6): 215-220. (in Chinese with English abstract)

[3] Guo Rui, Li Guoxue, Jiang Tao, et al. Effect of aeration rate, C/N ratio and moisture content on the stability and maturity of compost[J]. Bioresource Technology, 2012, 112(58): 171-178.

[4] 齐鲁. 污泥处置过程含氮气体的排放特征及其协同控制研究[D]. 北京:首都经济贸易大学,2015. Qi Lu. Study on the Discharge Characteristics of Nitrogen-Containing Gas and Its Cooperative Control During the Process of Sludge Disposal[D]. Beijing: Capital University of Economics and Business, 2015. (in Chinese with English abstract)

[5] 樊迎春. 羊粪无害化处理技术[J]. 兽医导刊,2020,11(6):67. Fan Yingchun. Harmless treatment technology of sheep manure[J]. Veterinary Orientation, 2020, 11(6): 67. (in Chinese with English abstract)

[6] Gao Mengchun, Li Bing, Yu An, et al. The effect of aeration rate on forced-aeration composting of chicken manure and sawdust[J]. Bioresource Technology, 2010, 101(6): 1899-1903.

[7] Onwosi C O, Igbokwe V C, Odimba J N, et al. Composting technology in waste stabilization: On the methods, challenges and future prospects[J]. Journal of Environmental Management, 2017, 190(4): 140-157.

[8] Tamura T, Osada T. Effect of moisture control in pile-type composting of dairy manure by adding wheat straw on greenhouse gas emission[J]. International Congress, 2006, 1293(7): 311-314.

[9] Petrica I, Šestan A, Šestan I. Influence of initial moisture content on the composting of poultry manure with wheat straw[J]. Biosystems Engineering, 2009, 104(1): 125-134.

[10] 蔡海森. 鸡粪与稻壳堆肥影响因素的研究[D]. 哈尔滨:东北农业大学,2015. Cai Haisen. Research on Composting of Chichen Manure and Rice Husk[D]. Harbin: Northeast Agricultural University, 2015. (in Chinese with English abstract)

[11] 尹晓明,王荣江,徐潇潇,等. 猪粪堆肥过程中养分和重金属含量的动态变化[J]. 植物营养与肥料学报,2019,25(2):92-101. Yin Xiaoming, Wang Rongjiang, Xu Xiaoxiao, et al. Dynamic changes of nutrient and heavy metal concentrations during swine composting[J]. Journal of Plant Nutrition and Fertilizers, 2019, 25(2): 92-101. (in Chinese with English abstract)

[12] 吴晓东,邢泽炳,何远灵,等. 添加生物炭对鸡粪好氧堆肥过程中养分转化的研究[J]. 中国土壤与肥料,2019(5):141-146. Wu Xiaodong, Xing Zebing, He Yuanling, et al. Nutrient transformation during chicken manure composting with biochar under aerobic conditions[J]. Soil and Fertilizer Sciences in China, 2019(5): 141-146. (in Chinese with English abstract)

[13] 郜斌斌,王选,王珏,等. 化学和黏土矿物钝化剂对牛粪秸秆堆肥磷形态转化的影响[J]. 农业工程学报,2019,35(2):250-257. Gao Binbin, Wang Xuan, Wang Jue, et al. Effects of chemical and clay mineral additives on phosphorus transformation during cow manure and corn stover composting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(2): 250-257. (in Chinese with English abstract)

[14] 陈同斌,黄启飞,高定,等. 城市污泥好氧堆肥过程中积温规律的探讨[J]. 生态学报,2002,22(6):911-915. Chen Tongbin, Huang Qifei, Gao Ding, et al. Accumulated temperature as an indicator to predict the stabilizing process in sewage sludge composting[J]. Acta Ecologica Sinica, 2002, 22(6): 911-915. (in Chinese with English abstract)

[15] Ren Limei, Schuchardt F, Shen Yujun, et al. Impact of struvite crystallization on nitrogen losses during composting of pig manure and cornstalk[J]. Waste Management, 2010, 30(5): 885-892.

[16] 勾长龙,高云航,娄玉杰,等. 微生物菌剂对堆肥发酵影响的研究进展[J]. 湖北农业科学,2013,52(6):1244-1248. Gou Changlong, Gao Yunhang, Lou Yujie, et al. Investigation and application progress of inoculating microbes on aerobic composting of manure[J]. Hubei Agricultural Sciences, 2013, 52(6): 1244-1248. (in Chinese with English abstract)

[17] Szanto G L, Hamelers H V, Rulkens W H, et al. NH3, N2O and CH4emissions during passively aerated composting of straw-rich pig manure[J]. Bioresource Technology, 2007, 98(14): 2659-2670.

[18] 陈是吏,袁京,李国学,等. 过磷酸钙和双氰胺联用减少污泥堆肥温室气体及NH3排放[J]. 农业工程学报,2017,33(6):199-206. Chen Shili, Yuan Jing, Li Guoxue, et al. Combination of superphosphate and dicyandiamide decreasing greenhouse gas and NH3emissions during sludge composting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(6): 199-206. (in Chinese with English abstract)

[19] Magalhaes A, Shea P J, Jawson M D, et al. Practical simulation of composting in the laboratory[J]. Waste Management & Research, 1993, 11(2): 143-154.

[20] 杨帆,欧阳喜辉,李国学,等. 膨松剂对厨余垃圾堆肥CH4,N2O和NH3排放的影响[J]. 农业工程学报,2013,29(18):226-233. Yang Fan, Ouyang Xihui, Li Guoxue, et al. Effect of bulking agent on CH4, N2O and NH3emissions in kitchen waste composting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(18): 226-233. (in Chinese with English abstract)

[21] 蔡娟,张应虎,张昌勇,等. 牛粪堆肥过程中的物质变化及腐熟度评价[J]. 贵州农业科学,2018,46(10):72-75. Cai Juan, Zhang Yinghu, Zhang Changyong, et al. Material change and rotten degree evaluation in cattle dung composting process[J]. Guizhou Agricultural Sciences, 2018, 46(10): 72-75. (in Chinese with English abstract)

[22] Ko H J, Kim K Y, Kim H T, et al. Evaluation of maturity parameters and heavy metal contents in composts made from animal manure[J]. Waste Management, 2008, 28(5): 813-820.

[23] 鲍士旦. 土壤农化分析[M]. 北京:中国农业出版社,2000.

[24] 张倩倩. 抗生素菌渣的堆肥处理研究[D]. 郑州:郑州大学,2019. Zhang Qianqian. Research on the Composting Treatment for Antibiotic Fermentation Dregs[D]. Zhengzhou: Zhengzhou University, 2019. (in Chinese with English abstract)

[25] 宋春,徐锋,赵伟,等. 羊粪-玉米秸秆高温堆肥优化配比研究[J]. 四川农业大学学报,2018,36(2):17-23. Song Chun, Xu Feng, Zhao Wei, et al. Research on the optimum ratio of sheep manure and maize straw for high temperature compost[J]. Journal of Sichuan Agricultural University, 2018, 36(2): 17-23. (in Chinese with English abstract)

[26] Thompson A G, Wagner-Riddle C, Fleming R. Emissions of N2O and CH4during the composting of liquid swine manure[J]. Environmental Monitoring and Assessment, 2004, 91(1-3): 87-104.

[27] 高伟,郑国砥,高定,等. 堆肥处理过程中猪粪有机物的动态变化特征[J]. 环境科学,2006,27(5):986-989. Gao Wei, Zheng Guodi, Gao Ding, et al. Transformation of organic matter during thermophilic composting of pig manure[J]. Environmental Science, 2006, 27(5): 986-989. (in Chinese with English abstract)

[28] Sánchez-Monedero M A, Serramiá N, Civantos C G O, et al. Greenhouse gas emissions during composting of two-phase olive mill wastes with different agroindustrial by-products[J]. Chemosphere, 2010, 81(1): 18-25.

[29] 周谈龙,尚斌,董红敏,等. 低碳氮比条件下猪粪堆肥氨气和温室气体排放[J]. 中国农业气象,2017,38(11):689-698. Zhou Tanlong, Shang Bin, Dong Hongmin, et al. Emission characteristics of ammonia and greenhouse gas during the low C/N ratio swine manure composting[J]. Chinese Journal of Agrometeorology, 2017, 38(11): 689-698. (in Chinese with English abstract)

[30] Yang Fan, Li Guoxue, Yang Qingyuan, et al. Effect of bulking agents on maturity and gaseous emissions during kitchen waste composting[J]. Chemosphere, 2013, 93(7): 1393-1399.

[31] El Kader N A, Robin P, Paillat J M, et al. Turning, compacting and the addition of water as factors affecting gaseous emissions in farm manure composting[J]. Bioresource Technology, 2007, 98(14): 2619-2628.

[32] 沈玉君,李国学,任丽梅,等. 不同通风速率对堆肥腐熟度和含氮气体排放的影响[J]. 农业环境科学学报,2010,29(9):1814-1819. Shen Yujun, Li Guoxue, Ren Limei, et al. The impact of composting with different aeration rates on maturity variation and emission of gas concluding N[J]. Journal of Agro-Environment Science, 2010, 29(9): 1814-1819. (in Chinese with English abstract)

[33] Wang Xuan, Selvam A, Chen Manting, et al. Nitrogen conservationand acidity control during food wastes composting throughstruvite formation[J]. Bioresource Technology, 2013, 147(8): 17-22.

[34] Luo Wenhai, Yuan Jing, Luo Yiming, et al. Effects of mixing and covering with mature compost on gaseous emissions during composting[J]. Chemosphere, 2014, 117(1): 14-19.

[35] 张地方,袁京,王国英,等. 木本泥炭不同添加比例对猪粪堆肥腐熟度和污染及温室气体排放的影响[J]. 农业工程学报,2016,32(增刊2):233-240. Zhang Difang, Yuan Jing, Wang Guoying, et al. Effects of woody peat addition on maturity and gaseous emissions during pig manure composting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(Supp. 2): 233-240. (in Chinese with English abstract)

[36] Guardia A D, Petiot C, Rogeau D, et al. Influence of aeration rate on nitrogen dynamics during composting[J]. Waste Management, 2008, 28(3): 575-587.

[37] Pagans E, Barrena R, Font X, et al. Ammonia emissions from the composting of different organic wastes: Dependency on process temperature[J]. Chemosphere, 2006, 62(9): 1534-1542.

[38] Jiang Tao, Ma Xuguang, Yang Juan, et al. Effect of different struvite crystallization methods on gaseous emission and the comprehensive comparison during the composting[J]. Bioresource Technology, 2016, 217(10): 219-226.

[39] Rabl A, Benoist A, Dron D, et al. How to account for CO2emissions from biomass in an LCA[J]. International Journal of Life Cycle Assessment, 2007, 12(5): 617-619.

[40] IPCC. Climate change 2013: the physical science basis. Contribution of working group I to the fifth assessment report of the intergovernmental panel on climate change[R]. New York: Cambridge University Press, 2013.

Effects of moisture content on maturity and pollution gas emissions during sheep manure composting

Li Danyang1, Ma Ruonan1, Qi Chuanren1, Yuan Jing1, Li Guoxue1※, Sun Shaoze2, Liu Yan1

(1.,,,100193,; 2.,,,100190,)

With the development of intensive and large-size livestock farming, a large amount of livestock manure has brought environmental pollution in some areas. Aerobic composting is a widely-used and efficient technology for the treatment and utilization of organic waste, which realizes harmless treatment, quantity reduction, stabilization and reutilization. However, there are several issues such as low maturity degree of compost product and emission of polluting gases during the process of composting, moisture content (MC) is one of the most important factors of composting. In order to study the effects of initial MC on maturity and pollution gas emissions during the sheep manure composting and optimize the process conditions, an experiment was carried out in 60 L sealed fermenters for 35 days. In this research, sheep manure and cornstalk were used as raw composting materials. According to the different initial MC, high-humidity sheep manure without any cornstalk was set as MC75 treatment, cornstalks were thoroughly mixed with sheep manure in certain proportions to adjust the initial MC to be 70%, 65%, 60% and 55%, respectively. C/N ratio of the composting mixture of five treatments was adjusted to 22 approximately by adding urea. The chemical and physical characters and maturity indicators such as temperature, germination index, electric conductivity, and pH value were analyzed, and continuous monitoring of pollution gases (CH4, N2O, and NH3) were conducted. The results demonstrated that the sheep manure composting pile with the MC of 75% could not be activated successfully, the compost product still had the risk in farmland utilization because it did not experience the thermophilic period (>50 ℃). However, lots of greenhouse gases such as CH4and N2O were released and the greenhouse gas emissions equivalent was the largest among all treatments during the experiment (41.4 g/kg). While the co-composting process could be started effectively for all treatments with sheep dung and cornstalks. MC70%, 65%, 60% and 55% treatments all entered into thermophilic stage and reached the peak values of temperature on the 2nd and 4th day, respectively. The thermophilic phase lasted for 8-10 d to reach the compost sanitary requirements. Moreover, the germination index of all treatments under the addition of cornstalks were higher than 80%, the electric conductivities were below 4 mS/cm and the pH values were in the range of 8 to 9 at the end of composting, which could be biologically non-toxic and meet the maturity standard completely. The treatment with the initial MC of 65% had long thermophilic phase (10 d) and high biodegradation degree, whose degradation rate of dry material reached 45%. Meanwhile, compared to the other treatments, the total nitrogen loss and the total greenhouse effects were decreased by 4.81%-16.99% and 7.56%-48.62%, respectively. Consequently, sheep manure with high moisture content should be collected and disposed frequently in sheep farming, and it is not environmentally friendly to pile up without any bulking agent. The optimal initial moisture content is about 65% in this study during the aerobic co-composting of sheep manure and cornstalk. In addition, the control of ammonia emissions by adding additives could be taken into account in future research.

moisture content; manure; composting; maturity; pollution gas

李丹阳,马若男,亓传仁,等. 含水率对羊粪堆肥腐熟度及污染气体排放的影响[J]. 农业工程学报,2020,36(20):254-262.doi:10.11975/j.issn.1002-6819.2020.20.030 http://www.tcsae.org

Li Danyang, Ma Ruonan, Qi Chuanren, et al. Effects of moisture content on maturity and pollution gas emissions during sheep manure composting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(20): 254-262. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.20.030 http://www.tcsae.org

2020-07-05

2020-10-10

国家现代农业产业技术体系建设专项(CARS-39-19)

李丹阳,博士生,从事固体废弃物资源化利用研究。Email:lidanyang@cau.edu.cn

李国学,教授,博士生导师,从事固体废弃物资源化利用研究。Email:ligx@cau.edu.cn

10.11975/j.issn.1002-6819.2020.20.030

X713

A

1002-6819(2020)-20-0254-09