Effect of Adding Heat-Moisture Treated or Dry-Heat-Treated Highland Barley Flour on the Quality of Noodles

XU Hanshan, LI Lin,2, CHEN Ling,*, ZHENG Bo,*

(1.Guangdong Province Key Laboratory for Green Processing of Natural Products and Product Safety, Engineering Research Center of Starch & Protein Processing, Ministry of Education, School of Food Science and Engineering, South China University of Technology,Guangzhou 510640, China; 2.School of Chemical Engineering and Energy Technology,Dongguan University of Technology, Dongguan 523808, China)

Abstract: In this study, the effect of partial replacement of wheat flour with native and thermally processed whole grain highland barley flour on the quality of noodles was investigated by scanning electron microscopy and texture analyzer.Further, we examined the effect of addition of wheat gluten on improving the quality of noodles incorporated with highland barley flour.The results showed that the resistant starch content of highland barley flour was increased from 21.95% to 39.17% and 34.08% after heat moisture treatment and dry heat treatment, respectively.Decreasing the substitution level from 70% to 30% increased the microstructure compactness of noodles incorporated with native, heat-moisture-treated or dry-heat-treated highland barley flours, reduced the cooked breaking rate, and improved the cooking and texture properties.The cooking and texture properties of noodles incorporated with 50% highland barley flour and 5% wheat gluten were comparable to those of pure wheat flour noodles, confirming the feasibility of partially replacing wheat flour with heat-moisture-treated or dry-heat-treated highland barley flours in noodle making.This study provides a theoretical basis and basic data for developing high-quality, nutritious noodles incorporated with highland barley flour.

Keywords: highland barley flour; thermal processing; wheat gluten; noodle quality

With the improvement of living standards, many chronic metabolic diseases, such as obesity, diabetes, hyperlipidemia and cardiovascular diseases, become serious problems threatening human health.This phenomenon is closely related to the inappropriate dietary structure consisting of high fat and sugar content and low dietary fiber content[1-2].Therefore,needs for nutritional and healthy food are increasingly urgent.A growing number of people hope to prevent or help to treat diseases through a reasonable diet.Noodles are one of the traditional staple foods in Asia.After over 4 000 years of development, noodles have been characterized by diversified varieties and simple processing methods.Noodles occupy an important position in the dietary structure of Asian residents and its consumption has increased worldwide due to good palatability and convenience[3-4].According to the raw materials, noodles can be classified into traditional noodles and coarse cereals noodles[5].However, traditional noodles are out of line with the modern needs of nutrition and health because of lacking mineral elements, vitamin B and dietary fiber.Coarse cereals noodles have attracted increasing attention due to the unique nutritional functions.

Coarse cereals refer to cereals other than wheat and rice.These cereals are laden with dietary fiber, isoflavones,polyphenols, saponins and other functional components[6-7],which benefit the treatment and prevention of some chronic diseases, such as stroke, cardiovascular disease, cancer,obesity and type II diabetes mellitus[8-9].Applying coarse cereals to traditional noodles should be capability to produce nutritional food.However, the rough taste and low gluten content made it difficult to prepare high quality noodles from coarse cereals flour.Wheat gluten (also known as active gluten) is a natural plant protein extracted from wheat bran,which mainly consists of gliadin and glutenin.It is one of the ideal noodles modifiers that can strengthen noodle gluten network and finally improve the product quality.

Whole grain highland barley is one of the special coarse cereals in the plateau of China.Compared with other grains,highland barley has attracted growing attention because of its unique composition and high nutritional value, including high content of protein, fiber and vitamin, and low content of fat and sugar.Especially the content ofβ-glucan is the highest among all barley varieties, which is 50 times the average content of wheat[10-13].It has become one of the raw materials to process nutritional and healthy food.

The major component of highland barley flour (HBF)is starch (ca.70%).Starch can be classified into three major kinds according to the rate and extent of starch digestionin vitro: rapidly-digestible starch (RDS), slowly-digestible starch(SDS) and resistant starch (RS)[14].RS has many beneficial physiological effects, such as prevention of colonic cancer,hypoglycaemic effect, reduction of gall stone formation and hypocholesterolaemic effect[15-16].At present, various methods for starch modification had been used to enhance RS content[17-19].Heat moisture treatment (HMT) and dry heat treatment (DHT) are two efficient physical methods, which can increase the RS content significantly[20-21].However,few studies had been undertaken so far to investigate the processability and digestion of HBF, heat moisture treatment highland barley flour (HMT-HBF) or dry heat treatment highland barley flour (DHT-HBF), much less studies on quality evaluation of noodles prepared from these flours.

This study aimed at evaluating the qualities of noodles prepared from HBF, HMT-HBF and DHT-HBF with gradient addition of wheat flour (WF).Meanwhile, the effect of wheat gluten (WG) on the quality of highland barley noodles (HBN)was further investigated.The findings from the present study may provide theoretical basis and reference data for developing high quality, nutritional and healthy HBN.

1 Materials and Methods

1.1 Materials and reagents

Highland barley was purchased from Qinghai Gaojian Biotechnology Co.Ltd..HBF was self-made in laboratory.The moisture, protein, and ash content of HBF were 12.14,10.10 and 0.39 2 g/100 g, respectively.WF was purchased from Henan Jinyuan Grain and Oil Co.Ltd..The moisture,protein, and ash content of HBF were 11.14, 9.87 and0.412 g/100 g, respectively.WG was purchased from Shandong Shengxie Biotechnology Co.Ltd..The moisture and protein content of WG were 11.66 and 85 g/100 g, respectively.

The Porcine pancreaticα-amylase (8 U/mg),amyloglucosidase (> 300 U/mL) Sigma-Aldrich Inc.(USA); The glucose oxidase-peroxidase (GOPOD) assay kit Megazyme Inc.(Ireland).

1.2 Instruments and equipments

EVO18 scanning electron microscopy (SEM)Germany Carl Zeiss Inc.; TA-XT PLUS with stable micro systems UK Surrey Inc.; MTD-168/140 electric noodle machine Beijing Dongfu Jiuheng Instrument Technology Co.Ltd.; BPS-1000CL temperature and humidity chamber Shanghai Yiheng Scientific Instrument Co.Ltd.; HM750 doughmaker Qingdao Hauswirt Co.Ltd..

1.3 Methods

1.3.1 HMT and DHT of HBF

HMT: the moisture content (MC) of HBF was adjusted to 35% and the samples were equilibrated at 4 ℃ for 24 h.After that, they were placed in HMT reactor and heated at 100 ℃ for 4 h, and then cooled to room temperature.Subsequently, the treated samples were dried in an oven at 40 ℃, ground and screened through an 80-mesh sieve.The treated samples were coded as HMT-HBF.

DHT: 20 mL of 10% (m/m) sodium hydroxide solution was evenly sprayed on 200 g of HBF and the samples were equilibrated at 4 ℃ for 24 h.Then, they were placed in DHT reactor and heated at 160 ℃ for 4 h, followed by cooling to room temperature.The treated samples were coded as DHT-HBF.

1.3.2In vitrodigestibility

In vitrostarch digestibility was analyzed according to the previous studies[22]with some modifications.The enzyme solution was prepared as follows: 6 g porcine pancreatic was dissolved in 40 mL distilled water and magnetically stirred for 30 min.After that, the suspension solution was centrifuged for 20 min at 4 000 r/min.The supernatant was transferred into a beaker, 1.4 mL amyloglucosidase and 3.6 mL distilled water were added into the beaker.

1 g Sample was placed into a 100 mL conical flask.Several glass beads (simulated gastrointestinal peristalsis environment) were added to the flask.Sodium acetate buffer solution (20 mL, pH 5.2) was added to the flask,then gelatinized in boiling water for 30 minutes.5 mL mixed enzyme solution was added to the flask after the sample cooled to 37 ℃, and then incubated in a shaking bed(180 r/min) at 37 ℃.0.5 mL supernatant was taken after 20 min and 120 min respectively, and the enzyme was deactivated by adding 20 mL of 70% ethanol.

1.3.3 Preparation of highland barley noodle

HBF, HMT-HBF and DHT-HBF were mixed with WF in the mass proportion of 7:3, 6:4, 5:5, 4:6 and 3:7,respectively.HBN were coded as NX-Y.N meant noodle,Xmeant HBF, HMT-HBF and DHT-HBF respectively whenXwas 1, 2 and 3,Ymeant the proportion of WF in noodle.Control was noodles without highland barley flour.

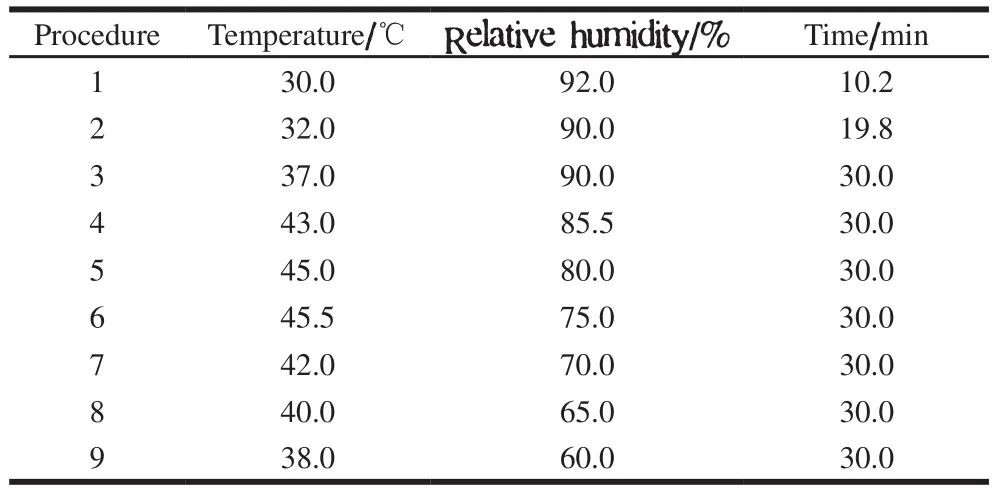

Based on the method of Yoo et al[23]with some modifications.According to the above proportion, 200 g mixed flour was placed in doughmaker and pre-mixed for 1 min, then distilled water (44% of the recommended water absorption obtained from farinograph) was added and mixed for 18 min.The blended dough was sealed with a freshkeeping film and fermented at room temperature for 60 min.After that, the blended dough was passed through the rollers of a noodle machine at a 1-mm gap, the dough sheet was cut into strips (300 mm × 2 mm × 1 mm)[24], followed by drying in a drying constant temperature and humidity box according to the procedure in Table 1.

Table 1 Drying parameters for noodles

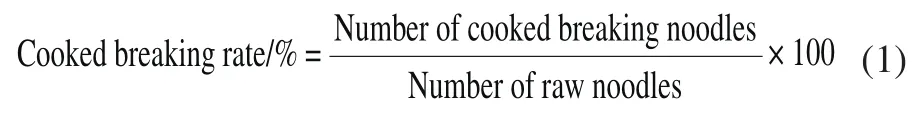

1.3.4 Determination of cooked breaking rate and cooking loss rate

The cooking methods followed the previous studies[25]with some modifications.Dried raw noodles (10 g) were placed in a beaker (beaker weighed) equipped with a lid with 200 mL boiling water for 5 min until the white core disappeared.The cooked breaking rate was calculated as equation (1).

After cooking, the remaining noodle soup was further boiled to evaporate most of the water, and then dried in a 105 ℃ blast drying oven until constant mass.The cooking loss rate was calculated as equation (2).

1.3.5 Determination of cooked noodles texture

The textural properties of cooked highland barley noodles were measured by using a TA-XT Plus texture analyzer.The methods followed the previous studies[26-27]with some modifications.

For compression tests, two cooked noodles were evenly placed in the middle of the test platform and the HDP/PFS probe was used to test.Pre-test speed was 2.0 mm/s, test and post-test speeds were 0.8 mm/s.Compression ratio was 70%.The trigger force was 5.0 g.Interval between two compression tests was 2 s.For each group more than five times was tested and average was taken as the result.

For tensile tests, the spaghetti/noodle tensile grips(A/SPR) were used.Two ends of noodles were wound on the hook of A/SPR probe respectively.Make sure the noodles under test was in a natural straightening state without slackness or tightness.Pre-test speed was 2.0 mm/s, test and post-test speeds were 3 mm/s.Distance was 100 mm.The trigger force was 5.0 g.Five measurements were taken for each sample.

1.3.6 Microstructure observing

SEM was used to observe the microstructure of noodles.Dried raw noodles were broken to a growth of about 2 - 4 mm,fixed on the loading stage with double-sided glue, and coated with gold particles under vacuum[28].

1.3.7 Sensory evaluation

The sensory evaluations were performed by 15 food professionals.Dried raw noodles were placed in boiling water for 5 min and then the cooked noodles were transferred into a soup-free bowl.Samples were scored as follows: color (1 =extremely dull, 10 = extremely bright), flavor (1 = extremely dislike, 5 = extremely like), palatability (1 = extremely low,20 = extremely high), smoothness (1 = extremely poor, 5 =extremely good), toughness (1 = extremely non-elastic, 25 =extremely elastic), viscosity (1 = extremely low, 25 =extremely high), and appearance (1 = extremely rough, 10 =extremely intact).During the evaluation process, samples were randomly numbered and placed, and only one sensory index was evaluated at a time.

1.3.8 Effect of wheat gluten (WG) on cooking properties,texture, sensory evaluation and microstructure of HBN

The HBN were prepared by methods of section 1.3.3.The proportion of HBF in NX-50 formula was kept unchanged.HBN were coded as NX-YG, N meant noodles,Xmeant HBF, HMT-HBF and DHT-HBF respectively whenXwas 1,2 and 3,Ymeant addition level of WF, G meant addition of 5% WG.Cooking properties, texture, sensory evaluation and SEM were determined as described by 1.3.4 to 1.3.7.

1.4 Statistical analysis

All results were expressed as mean ± standard deviation.IBM SPSS Statistics 22.0 software was used to analyze the statistical significance of experimental data.The comparison between the two groups was made by One-way analysis of variance (ANOVA) with Duncan’s test at the level of 0.05.

2 Results and Analyses

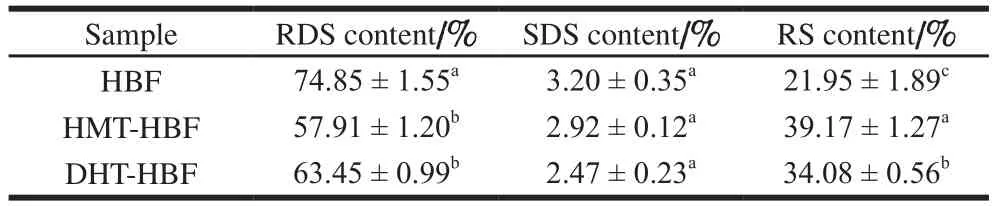

2.1 In-vitro carbohydrate digestibility of HBF

Digestibility of HBF, HMT-HBF and DHT-HBF were showed in Table 2.After heat moisture treatment and dry heat treatment, the RDS content of HBF were decreased from 74.85% to 57.97% and 63.45%, and the RS content of HBF were increased from 21.95% to 39.17% and 34.08%,respectively, which indicated that HMT and DHT could reduce starch digestion rate by transforming some fractions of RDS into RS.This mainly due to the change of the aggregate structure and chain structure of the highland barley starch under heat energy and the migration of water molecules.Meanwhile, the starch molecules formed complexes with lipids, proteins and some small molecule compounds such as polyphenol combining effects of aggregation, entanglement,static electricity and hydrogen bonding, which resulted in the increase of resistant starch and dietary fiber[20,29].

Table 2 Carbohydrate digestibility of HBF, HMT-HBF and DHT-HBF

2.2 Cooking loss rate and cooked breaking rate of HBF,HMT-HBF and DHT-HBF

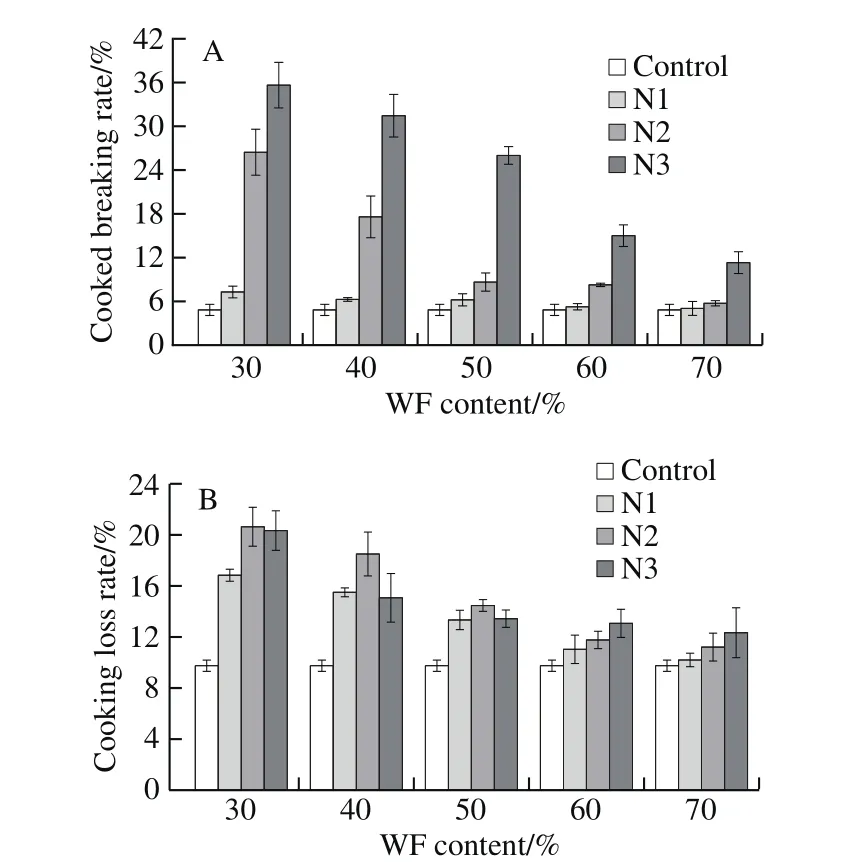

In order to maintain the integrity of high-quality noodles, the solids which were lost in water should be minimized during cooking.Cooking loss rate and cooked breaking rate are important indexes for evaluating cooking characteristics of noodles, and the former related to the loss of solids from noodles during cooking[30].Noodle with higher cooking loss rate and cooked breaking rate tasted soft and sticky, which resulted in turbidity of noodles soup[31].The cooking loss rate and breaking rate of noodles obtained with various HBF are showed in Fig.1.The cooked breaking rate was 4.83% for control, and it increased to 5.03% - 7.28% for addition of 30% - 70% HBF,5.74% - 26.44% for addition of 30% - 70% HMT-HBF and 11.31% - 35.64% for addition of 30% - 70% DHT-HBF(Fig.1A).The cooking loss rate was 9.75% for control noodle,and it was increased to 10.20% - 16.83% for addition of 30% - 70% HBF, 11.21% - 20.63% for addition of 30% - 70% HMT-HBF, 12.33% - 20.33% for addition of 30% - 70% DHT-HBF (Fig.1B).The results indicated that HMT and DHT had negative effect on the cooking properties of HBN, but the cooking loss rate and cooked breaking rate could be reduced by increasing WF addition.

Fig.1 Breaking rate (A) and cooking loss rate (B) of HBN

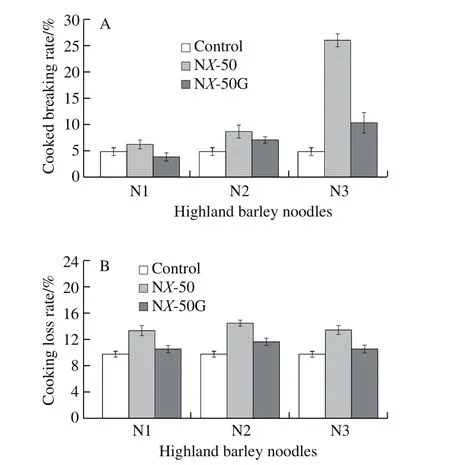

WG is one of the ideal noodles modifiers in strengthening the noodle gluten network and improving the product quality.Effects of WG on the cooking properties of HBN are showed in Fig.2.The cooked breaking rate were 6.21%,8.65% and 26% for N1-50, N2-50 and N3-50, respectively,and it was decreased to 3.83%, 7.06% and 10.33% for 5% WG addition, respectively (Fig.2A).The cooking loss rate were 13.33%, 14.46% and 13.43% for N1-50,N2-50 and N3-50, respectively, and it was decreased to 10.52%, 11.63% and 10.53% for 5% WG addition,respectively (Fig.2B).The results indicated that addition of WG increased the gluten content of noodles and it formed a denser network structure, encapsulated starch granules and other components more compactly, and reduced their dissolution and migration during cooking.Therefore,the cooking properties of three HBN were significantly improved by adding WF and WG, especially for N3-50 with looser structure.

Fig.2 Effect of WG on cooked breaking rate (A) and cooking loss rate (B) of HBN

2.3 Compression and tensile tests results of HBN

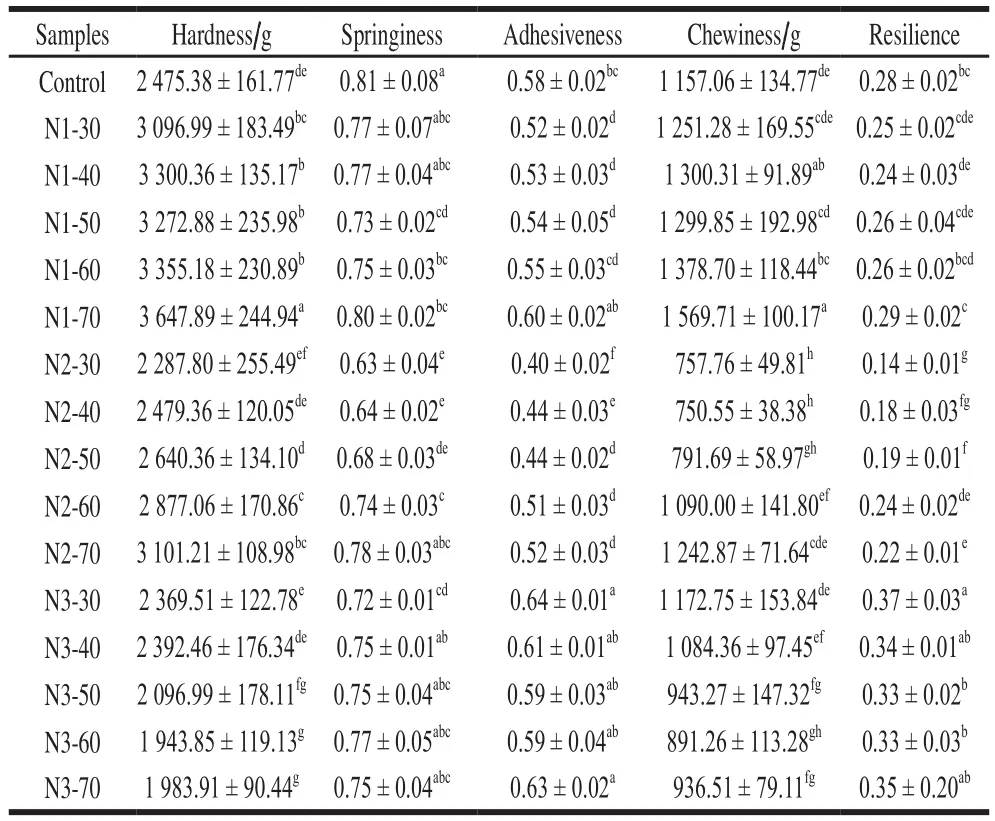

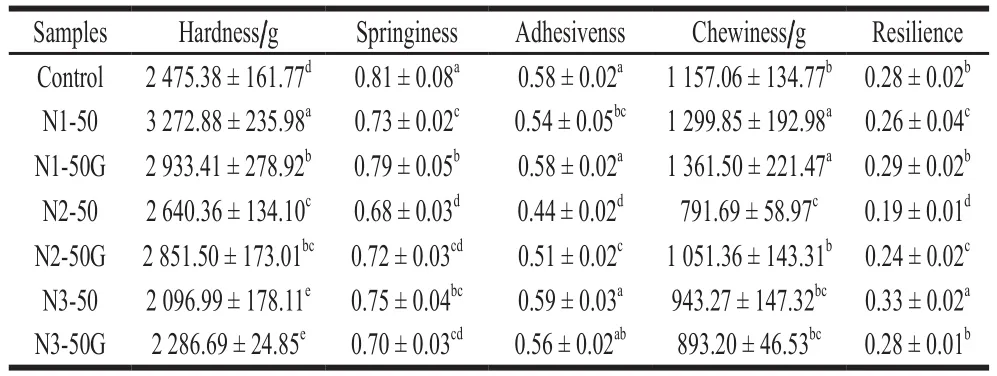

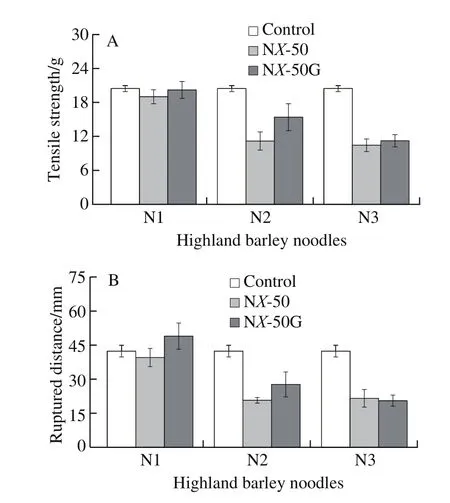

Texture was an important quality of noodles that consumers care about[32-33].Effect of WF addtion on texture properties of three HBN were showed in Table 3 and Fig.3.It could be seen from Table 3 that at the same addition level(e.g.30%) of WF, the hardness, springiness and chewiness of N1 were higher than that of N2 and N3.The adhesiveness and resilience of N3 were higher than that of N1 and N2,and N2 was the lowest of the three groups.The results indicated HMT-HBF and DHT-HBF could result in loose internal structure of noodles, poor densification of gluten network structure and worse quality of noodle, which was consistent with the conclusions of cooking properties.The negative effect of HMT on texture quality of noodles was more significant than that of DHT.As addition levels of WF increased, all texture parameters of N1 and N2 basically showed an increased trend.As shown in Fig.3, at the same addition level (e.g.30%) of WF, the tensile strength and ruptured distance of N1 were slightly larger than those of N2 and N3, indicating that HMT and DHT had negative effect on the tensile properties, but WF had positive effect on it.

Effects of WG on the tension properties of HBN are showed in Table 4 and Fig.4.As shown in Table 4, with addition of WG, springiness, adhesiveness, chewiness and resilience of N1-50G increased, and hardness showed theopposite trend.All texture parameters of N2-50G increased compared with N2-50.While the springiness, adhesiveness,chewiness and resilience of N3-50G were decreased, and hardness showed the opposite trend.The results indicated that texture properties of N1-50 and N2-50 were improved by adding WG, but it was not significant for N3-50.

Table 3 Effect of substitution levels on texture properties of noodles

Fig.3 Tension properties of highland barley incorporated noodles:tensile strength (A) and ruptured distance (B)

Table 4 Effect of WG on texture properties of highland barley incorporated noodles

Fig.4 Effect of WG on tensile strength (A) and ruptured distance (B)of highland barley incorporated noodles

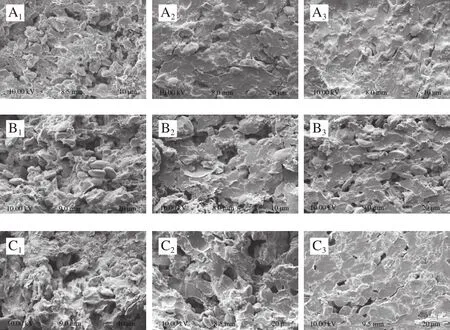

2.4 Microstructure of HBN

Fig.5 Scanning electron micrographs of highland barley incorporated noodles with different substitution levels

In order to explore the effect of WG and addition level of WF on the quality of dried highland barley noodles, the cross-sectional microstructure of HBN was observed by SEM.As shown in Fig.5, the gluten network structure of N1-30 was sparse and many starch granules were embedded worse.With the addition level of WF increased, the gluten network structure gradually formed, starch granules were embedded better in the continuous gluten network, and the whole structure of noodles was more compact.Compared to N1-30, the gluten network structure of N2-30 and N3-30 were looser, which indicated that HMT and DHT could lead to poor process ability of HBF.But WF could reduce thisdeficiency.It could be seen from Fig.6 that gluten network structure of HBN was smoother with additional WG, more continuous and compact than the noodles without WG.This was consistent with the results of cooking properties.

Fig.6 Effect of WG addition on microstructure of highland barley incorporated noodles with different substitution levels

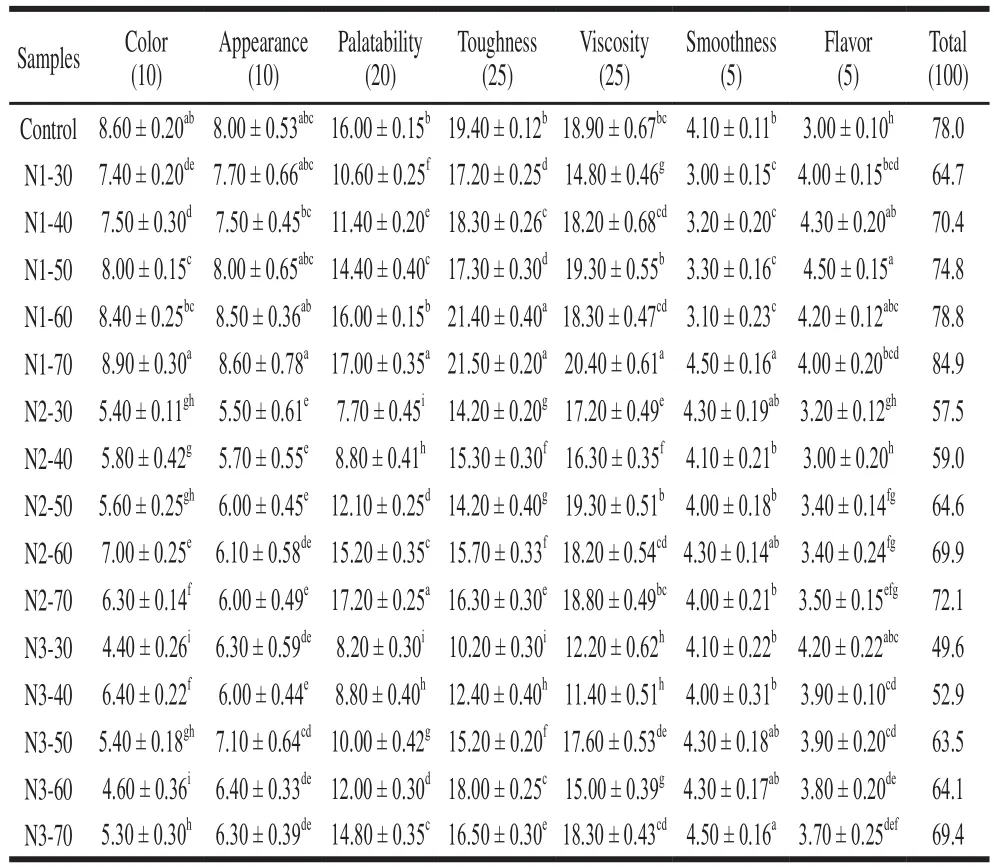

2.5 Sensory analysis results of HBN

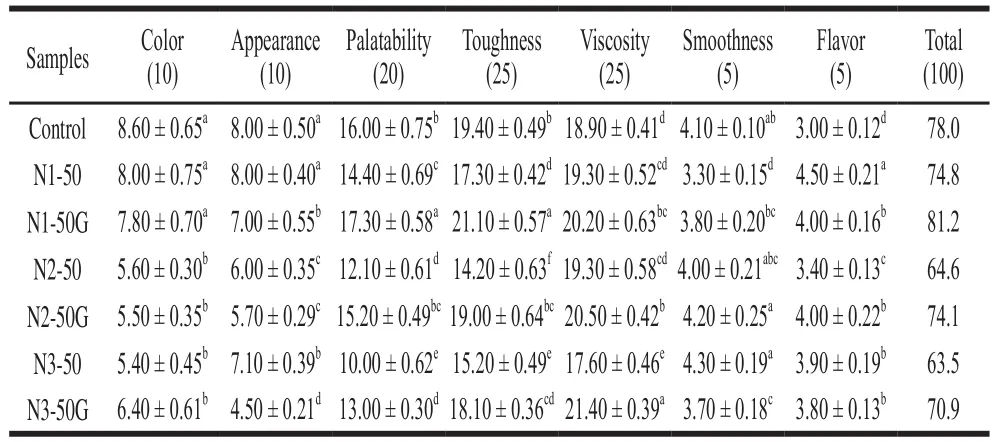

Sensory evaluation directly reflects the views of consumers on noodle quality, so it is an important evaluation index of noodle quality[34].As shown in Table 5, with the increase of WF content, the sensory scores of N1 increased continuously.At addition level 70% of WF, N1 had higher scores on all aspects than control noodle.The scores of N2 and N3 got closer to control noodle with the addition of WF increased.In addition, the flavor scores of N1, N2 and N3 were basically higher than those of the control, especially N1 with different additional WF had higher flavor scores, which indicated that the unique aroma of highland barley was more pleasant and more popular than that of ordinary wheat noodles.

It could be seen from Table 6 that addition of WG could increase the sensory scores of HBN.In particular, after the addition of WG, scores of N2-50 increased from 64.6 to 74.1.There were significant effect on flavor of N1-50,N2-50, N3-50, but with the addition of WG, there were no significant differences among N1-50G, N2-50G, N3-50G.But the appearance got worse with additional WG.This may be related to the uniformity of the distribution of WG.In addition, it could be seen from Table 5 and Table 6, N1-50G had higher sensory scores than control noodle and N1-60.N2-50G had higher sensory scores than N2-70 and N3-50G had higher sensory scores than N3-70.The results indicated that the quality of HBN prepared from combinations of WG and WF was better.This provides a feasibility for increasing the proportion of HBF in noodles on the premise of guaranteeing sensory quality, and has an important guiding significance for the development of healthy and nutritional HBN with higher addition level HBF.

Table 5 Sensory analysis of highland barley incorporated noodles

Table 6 Effect of WG addition on sensory quality of highland barley incorporated noodles

3 Conclusion

This study investigated the effect of thermal processing on the carbohydrate digestibility, cooking properties, texture,and microstructure of HBN.Digestion analysis reflected redistribution of starch components (reduction of RDS and increase of RS).Both HMT and DHT increased cooked broken rate and cooking loss, reduced hardness, chewiness of HBN.Microstructure results showed that HMT and DHT reduced compactness of gluten network structure of HBN.Sensory analyses suggested that HMT and DHT had negative effects on sensory attributes such as appearance, palatability and toughness.But WF and WG improved all of the aboveproperties, and with addition of WF increasing, the positive effects were more obvious.The noodles prepared from combinations of WG and WF with enhanced cooking and texture properties as well as a better flavor than conventional wheat noodles were endowed.This study may provide a potential approach for applying whole grain highland barley and corresponding thermally processed products in traditional fresh noodles.