A Novel Mechanism for TRF of Plant-wide Material Flows in Process Industry MES*

A Novel Mechanism for TRF of Plant-wide Material Flows in Process Industry MES*

ZHU Wei (朱炜)1,2, ZHU Feng (朱峰)1and RONG Gang (荣冈)1,**

1State Key Laboratory of Industrial Control Technology, Institute of Cyber-System and Control, Zhejiang University, Hangzhou 310027, China

2Quzhou University, Quzhou 324000, China

This paper is standing on the recent viewpoint originated from relevant industrial practices that well organized tracing, representing and feedback (TRF) mechanism of material-flow information is crucial for system utility and usability of manufacturing execution systems (MES), essentially, for activities on the side of multi-level decision making and optimization mainly in the planning and scheduling. In this paper, we investigate a key issue emphasized on a route of multi-level information evolution on the side of large-scale feedback, where material-flow states could evolve from the measuring data (local states) to networked event-type information cells (global states) and consequently to the key performance indicators (KPI) type information (gross states). Importantly, with adaptabilities to frequent structural dynamics residing in running material flows, this evolving route should be modeled as a suit of sophisticated mechanism for large-scale dynamic states tracking and representing so as to upgrade accuracy and usability of the feedback information in MES. To clarify inherent complexities of this evolving route, the investigated issue is demonstrated from extended process systems engineering (PSE) point of view, and the TRF principles of the multi-level feedback information (states) are highlighted under the multi-scale methodology. As the main contribution, a novel mechanism called TRF modeling mechanism is introduced.

extended process systems engineering, manufacturing execution systems, material flow, modeling method

1 INTRODUCTION

The competitive business climate and the serious energy circumstances, as well as environmental concerns have posed significant challenges to manufacturers in the petrochemical industry and, especially, to refineries during the last two decades. Meanwhile, for facing these challenges and for overcoming problems derived from various sections (purchasing, manufacturing, distribution, sales, etc.), there has been remarkable progress in academic research regarding multilevel decision making and optimizing strategies that serve to planning, scheduling and controlling activities [1] as well as to integrations and inter-operations between them [2]. On the other hand, commercial systems for plant- and/or enterprise-wide application have become much more indispensable. Particularly, with the guidance of ANSI/ISO 95 [3], a category of systems for collaborative production management (CPM) named manufacturing execution systems (MES) have been widely applied to realize profits and also to lower costs while the large-scale multi-product and multi-purpose production has to be carried out [4]. Undoubtedly, the activities of multi-level decision and optimization must been converted and constructed as a series of dominating functionalities in MES to drive and evaluate most of the plant-wide production behaviors under an integrated information environment.

In general, above efforts can be categorized as the researches and practices in the field of extended process systems engineering (PSE) [5]. With roots dating back to 1950s, PSE has progressed to a specialized discipline at the interface between chemical engineering, applied mathematics and computer science with specific model-based methods and tools, as its core competencies to deal with the inherent complexity of chemical processes and multi-objective nature of decision-making during the lifecycle of manufacturing process of chemical products. And, it has been clear that the main methodologies of extended PSE have their roots in traditional PSE with expansions of scopes or scales of relevant problems. Typically, with the scalability, the methods of modeling, simulation and optimization (MSO) that have been employed usually for designing, controlling and operating individual units are now tailored and applied accordingly for the large-scale process systems, such as the single plant but networked with multiple processes and the enterprise with distributed sites, as well as the supply chain in which various enterprises or plants are involved [6]. However, while regarding extended PSE as a set of strategies, problems solving methods and tools subject to a global feedback-control loop towards the running of a plant- or enterprise-wide system, it is also clear after extensive investigations that most of recent efforts in the community have concentrated rather on the side of multi-level production decision making and optimization [7-10] than on the side of global production information tracking, representation and feedback (TRF) while the effectiveness of the later side are far from being revealed.

In this paper, relevant problems of plant-wideinformation TRF are regarded as residing in a multi-level evolving route, where production states should be evolved from the measuring data (local states) to the event-type but networked information cells (global states) and consequently to the key performance indicators (KPI) type information (gross states). The evolving steps in this route are closely linked to the strategic, tactical and operational levels on the side of decision course respectively. Along this line, the key issue of TRF is illustrated firstly within a global feedback-control loop from the systematic perspective. Thereafter, the integration principles of the leveled feedback information (states) of material flows are highlighted under multi-scale methodology. Finally, as the main contribution, a novel mechanism we call it TRF modeling mechanism is introduced.

2 BACKGROUND AND THE KEY ISSUE

Extended PSE has been successfully adapted and refined to address the needs of designing, controlling and operating the large-scale process systems in a holistic manner. As researches have been developing along many lines, there are too many outstanding to be covered in a mini-review. Overall, from the perspective of the object, the major achievements may include methodologies and tools to support and improve operations against the strategic, tactical or operational level of a whole enterprise respectively, usually including the planning, scheduling and controlling.

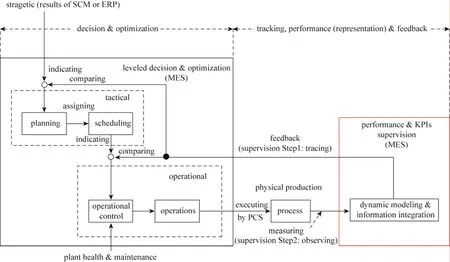

As the most important trend, the integration issues have received a considerable amount of attentions in the last decade. The integrated planning and scheduling as well as the integrated scheduling and controlling are addressed to ensure the inter-operation capabilities, flexibilities, and consistencies for global production optimizations. In the field of planningscheduling integration, since the resulted integrated models may be hard to solve, several solution strategies have also been proposed [11]. The strategies can be broadly classified into: (1) hierarchical methods, (2) iterative methods, and (3) full-space methods. The first two decompose the integrated problem into a master and several slave sub-problems, while the last considers the integrated problem as a whole using mixed integer programming (MIP) decomposition approaches. Correspondingly, the integration of scheduling and controlling is commonly regarded as a field with increasing amount of contributions but still leaving lots of opportunities unexploited [12]. Most of the recent researches are concentrated on the issues about avoiding sub-optimal results or working against each other while solving the global scheduling problems and trying to locally increase the controlling performance simultaneously. Therefore, the above efforts have initiated the key requirement of a model-centered and information-integrated system environment [13] which can be denoted briefly from a systematic perspective. Fig. 1 denotes a global feedback-control loop towards a plant-wide production system (such as a refinery) in the process industry. Although numerous members might be included, components in the loop can be mainly classified as the following two categories: (1) the ones constituting the multi-level decision course at the left side; and (2) the others constituting the production information feedback course at the right side. Moreover, this figure is also equivalent to a feedback-control view of a conceptual construction map of the process industry MES.

Figure 1 The global feedback control loop (SCM: supply chain management, ERP: enterprise resource plan)

Inevitably, the information availabilities for activities on the left side in Fig. 1 have become important keywords [12]. While focusing on the bi-side inter-relationships, information availability is mainly composed of the leveled and variously scaled feedback requirements of the following real-time information, which have to be derived from running processes and be organized by the right side of the loop: (1) the measured variable-type states (local-states) correspond to operational setting-values; (2) the tracked and networked event-type states (global states) occurring on the units and devices correspond to production tasks produced by scheduling; and (3) the merged KPI-type states (gross states) correspond to related production plans. Commonly, the first always reflects transient situations and the leaving two reflect steady of a running plant with relevant time- and spatial-scales respectively. And, the most importantly, various kinds of dynamics are also included as the essential parts in the reflection for inherent complexities of process productions, for example the transient trajectory fluctuations in ‘local states’, as well as the steady dynamics of structural changes of material flows in ‘global states’while productions are carried out in a multi-purpose and frequently switching manner. Especially, inherent structural dynamics in running plant-wide material flows would seriously impact on and overfill out of the stationary entity-relation (E-R) relationships that are usually pre-built and used to reflect global states and to organize feedback information in MES.

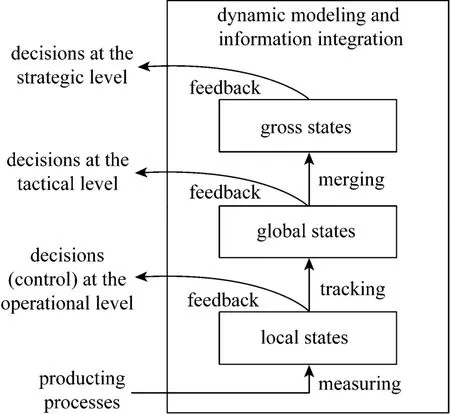

Also seen from the systematic perspective, above requirements can be further generalized as a key issue: how the feedback course should be constructed as an online mechanism so that the multi-scale and leveled states could be tracked and represented in real time together with various dynamics for permanently fulfilling the requirements of the information availabilities of the multi-level decision course. As set forth, we call this key issue as the TRF problem of the large-scale process systems and illustrate it generally in Fig. 2.

Figure 2 the multi-level feedback course

However, this problem is rarely addressed both in the extended PSE community and in relevant application areas, especially, when the relative difficulties emerge at the global (plant-wide) level of Fig. 2. It is seemingly convinced in most of the discussions and practices that the prevalent IT tools for information integrations such as database and ethernet have already been sufficient to cope with this problem. Nevertheless, while investigating more deeply into the decision course, both dynamic situations and the leveled nature of the problem are really far from being acknowledged comprehensively. The current bottleneck in applications of MES is how to construct dynamic models (such as material flows) and then match them to networked production processes with frequent structural dynamics. Answers to this problem might help to open unrevealed domains in extended PSE. Crucially, the TRF problem is the most challenging one related to the information availabilities in the global feedbackcontrol loop.

3 DIFFICULTIES AND PRINCIPLES

3.1 Modeling difficulties at the plant-wide level

The ultimate goal of the productions is to transform raw materials to semi-finished products and consequently to final products with supports of devices, energy supplying systems and computer integrated manufacturing systems (CIMS). In other words, states of material flows constitute the core information that can be used as stem-states for organizing other production states together, including data of energy, device health, manpower and so forth. Therefore, in this paper, the TRF problem of material flows is focused in order to simplify the discussion.

Briefly, the process operations (processing, moving, storing, retrieving, discarding, etc.) inevitably lead to complexities and dynamics of plant-wide material flows while numerous categories of materials and recipes are involved. So, based on the previous research, modeling difficulties of plant-wide material flows can be further identified as following questions according to the fore-mentioned multi-level division: (1) how to clarify the TRF principles among the leveled states; (2) how to track the global and networked structural dynamics; and (3) how to represent the global and dynamical information (global states). Importantly, the first is the most general so that its answer could be seen as the key to the rest two.

3.2 TRF principles

Figure 3 The model of a plant with spatial scales

Figure 4 The model of CIMS with temporal scales

To answer question (1), it is necessary to decompose the global feedback-control loop (shown as Fig. 1) into a much more detailed construction with reference to the information flows [12] in the decision course as well as in the feedback course. For this purpose, as considering the multi-scale methodology has penetrated in many areas for systems modeling and designing with principles of decomposition and aggregation from the temporal or spatial perspective [14, 15], we decompose and denote a plant as Fig. 3 and CIMS as Fig. 4 under this methodology. The model of a plant could be decomposed and aggregated based on the spatial scales, including the process control loop, the unit and device as well as the plant scales as shown in Fig. 3. These levels could be regarded as objects that are under control of relative systems on the respective temporal scales consisted of ERP, MES and PCS (process control systems), as shown in Fig 4.

In general, multi-scale methods can be employed to meet the demands on the depth of revealing the characteristics of a system so that various and leveled mathematical models may involve relations of properties at different scales of the system [14-16]. Regarding the relationships between the plant and CIMS as denoted in Figs. 3 and 4, the given parameters and the measured variables as well as the tracked structural states may constitute the properties at the respective scales. From the feedback-control perspective, these properties should be composed sophisticatedly into relative mathematical equations. Consequently, thousands of such equations would be involved in the detailed and multi-scale mathematical model in consideration of the hugeness of the large-scale process systems, which is beyond the scope of this paper.

Figure 5 The multi-scale view of Fig. 1 (KFP: key feedback parameter)

Briefly, the control and feedback information flows can be illustrated as Fig. 5 in light of the multi-scale relations and above concepts. In Fig. 5, the control information flow is composed of a multi-step procedure on the direction of left-to-right where the production plans are decomposed to scheduling tasks firstly and the tasks to set-points of the process control loop thereafter. On the opposite direction, the feedback information loop includes a multi-step aggregation procedure where the local states (variables) are aggregated to the global states firstly and to the gross states (KPIs) thereafter. Moreover, as considering the term of ‘Event’ has been widely used to substitute ‘Task’in the scheduling domain, such as the unit-specific scheduling [17], the term of ‘event-type states (Event)’is also appropriate to represent the result of the relevant executed task as the global feedback information (states) cell concretely.

Thus, the TRF principles of the global states (material flows) can be concluded as follows according to the multi-step aggregation procedure in Fig. 5:

(1) Firstly, before the global information is constructed, the measured variable-type should be collected and tracked as event-type information cells which are relative to the executed tasks both on units and on other devices such as the storage tanks. It is called the “tracking principle” in this paper.

(2) Secondly, considering the networked nature of processes and the multi-product nature with switchable processing recipes, the structural dynamics of material flows should be traced accurately by means of synthesizing the material flows from the involved events occurring on relevant units or devices. We call this the “synthesizing principle”.

(3) Thereafter, although the tracked events and synthesized movements constitute the unordered information sets, the global states (information) would only appear when the cells are represented as a global information net referring to the spatial and temporal orders during the processing. This is the “representing principle”.

(4) Finally, as considering the feedback of various sections or pieces of the represented information towards the different decision functionalities, it is necessary to provide a general tool that can be used to resolve the massive information efficiently and limberly. We call it the “resolving principle”.

Principles of above highlight the evolution route of global feedback information. Following these principles, the resulting TRF mechanism would have great advantages over the traditional means that merely employ information integration tools because of its adaptability to the structural dynamics and information availabilities to the decision functionalities. Nevertheless, novel mechanisms should be invented before the principles are implemented thoroughly. In the following sections, we will try to demonstrate a primary mechanism including the first three principles, and leave the last to future works for complete investigations related to more details of the decision course. Crucially, as the TRF is an extensive field characterized with nature of online systems, only the primary contents of the proposed mechanism are illustrated in the following sections, and system related issues are overleaped for the extent limitation of this paper.

4 THE MECHANISM

The following contents mainly comprise two primary parts of the mechanism: (1) several fundamental concepts which provide the bases of the mechanism; and (2) the multi-step modeling methods along the evolution route that has been identified with the TRF principles. In addition, only the unit and tank are considered in the device aspect in order to simply the description.

4.1 Fundamental concepts

4.1.1 General definitions

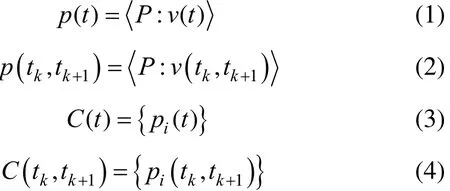

According to the general information theory, the time-variant information has the clear constitution commonly including cells and properties as well as measured data.

While considering the TRF principles and the compositions of plant-wide material flows, it can be defined generally that a property p is the pair of its name P and value v denoted as Eq. (1) or (2), as well as an information cell C comprises of a specific amount of properties as Eqs. (3) or (4). The alternative expressions could be selected for formulations according to the instantaneous properties or not, and parameters with other patterns such as counters and constants would be involved in the expression of the cell.

Thereafter, the grouped information J with type-specific cells (tasks, events or movements as introduced in the next section) can be denoted as Eq. (5) or (6):

where 〚•〛 is used to indicate that the amount of the included cells is variable.

Consequently, the global information I of plantwide material flows with spatial and temporal orders can be denoted as Eq. (7):

In addition, the expressions with the parameter of time-interval are dominating in the proposed mechanism because most of the properties are cumulative quantities in the MES domain.

4.1.2 Event-type information cells

To clarify the rational classification of event-type information cells of plant-wide material flows, a typically segmented part of a refinery is denoted in Fig. 6 that comprises of five components including three units (U1, U4 and U5) and two tanks (T2 and T3). Inevitably, the switches of recipes on units for multiproduct productions will cause structural dynamics, for example the structural changeovers as shown between Fig. 7 and 8 by the recipe-switching on U1 (supposing R1 to R2).

Whereas the global information is expected not only to aggregate necessary local states but also to reflect the dynamics, the types of information cells must be classified clearly. According to Figs. 6 to 8, the matters involved during the processing mainly include four types: (1) the tasks that are scheduled by the scheduling and then transmitted to executing on respective units; (2) the processing events on units relative to the executed tasks; (3) the storing events on storage devices motivated by relevant processing/storing events; and (4) the material-flow occurring between the respective event-pairs linked through physical pipelines. Therefore, these information cells can be defined as the task, processing event, storing event and flow event respectively, and they are all event-type with reference to the proceeding production. According to Eqs. (2) and (4), these cells can be denoted as the following expressions.

Figure 6 The typically segmented part of a refinery

Figure 7 The material-flow diagram during R1

Figure 8 The material-flow diagram during R2

Parameters in tasks with the apostrophe superscript such askt′ denote the intended beginning or ending time-points, and the relative parameters in events without the semicolon superscript such as tkdenote the real time-points. Therefore, real time-points should be tracked according to related tasks and production behaviors when recipe-switches occur during the production.

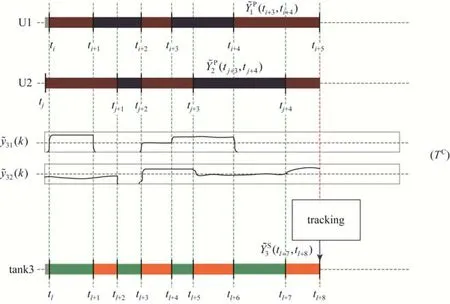

4.1.3 Timing of the event and transport

As denoted in Eqs. (8) to (11), production behaviors in a plant are motivated by scheduled tasks and then resulted with events as cells of the global information that needed to be tracked, represented and for feedback. For multi-product and other purposes related to higher profits and lower costs, recipe-switches are carried out frequently in the process production. On the other hand, uncertainties have become unavoidable factors in most production sections, such as device failures, raw material shortages and operational condition abnormalities. As a result of these reasons as shown in Fig. 9, the real time-parameters (tk) are usually so deflected to the intended values (kt′) that they have to be accurately estimated, especially, when the quantity-specific properties of material flows are calculated from them. Thus, the timing of beginning or ending time-points of the tracked cells is seriously desired when TRF of the global information is concerned. And, it really constitutes the primary base of the proposed mechanism that will be described in next sub-section.

However, the timing is difficult because relevant dependencies are usually complex and even unapparent, especially in the continuous production such as the oil refining. In this section, we introduce several approaches from the engineering perspective as follows. And, we believe that the more sophisticated approaches which combine with relevant mathematical methods usually working for uncertainties should be invented and introduced in the future.

(1) Timing the processing event

In most of the processing cases, a transition of two tasks on a unit is equivalent to a switch occurring between the relative recipes. While investigating the constitution of a recipe, this timing approach could be obtained with reference to the features during a recipe-switching. Usually, the changes of the following aspects would appear when a recipe-switching occurs on a unit: ① the types and proportions of the input materials; and ② the types and proportions of the output materials. Therefore, from the engineering perspective, it is possible to determine the time-interval in which the time-point resided with reference to the periodical data from the LIMS (laboratory information management system), and thereafter to determine the time-point exactly by searching the choppy changedegrees of the proportions during this time-interval.

This approach can be denoted concisely as the following conditional expression while supposing1kt+is the time-point to be determined andDD[,(1)] rTrT+ is the time-interval where1kt+is included. The relevant symbols in the expressions correspond with Eq. (9):

Therein,iσ andjϕ represent the referenced and rigid proportions belonging to the recipe that started atthe beginning time-point (tk) of the event.

Figure 9 The timing of events

The approach can be implemented circularly because the ending time-point of one event usually coincides with the beginning time-point of the next event in continuous productions. Nevertheless, for more adaptive solutions, the sophisticated mathematical methods and additional conditions should be considered relative to this concise edition.

(2) Timing the storing event and transport

Compared to the processing event, it is different that the storing events are mainly driven by the related processing or other storing events as needed during the processing and transporting. In other words, the timing of a storing event depends on the occurring events on its physically connected units or devices. On the other hand, as the storage devices in a plant are also used as the buffers besides their storage functionality, so the time-interval of the timed storing event commonly appear at the overlapping interval of bi-side events on the connected units or devices. Similar to but simpler than the storing event, a transport is driven by the bi-side events directly even without delays. So, the interval and time-points are easy to be timed when the bi-side events of the movement have been tracked accurately. For clarification, the visualized approaches for the timing of the two event-type cells will be illustrated in the next sub-section.

4.2 Modeling methods

Motivated by the promising prospects, the emphasis should be placed on several system-related issues mainly including: (1) the methods to model the leveled states to ordered information dynamically according to the TRF principles; (2) the software frameworks to sustain the outpouring information smoothly; and (3) the practical mathematical approaches to resolve the problems with respect to uncertainties, correctness, completeness and utilities that the large-scale feedback mechanism has to confront at relevant levels. Nevertheless, these issues comprise of many extensive fields beyond the extent of this paper. As the essential one among these issues, modeling methods constitute the core content of the future system. Because time-points and flow-rates are the two types of determining factors in tracking information cells and finally in organizing the global information of material flows, the introduced procedures of modeling methods could be illustrated under relevant time sequences via the elaborated diagrams as follows.

Step 1 Tracking

As shown in Fig. 10, the tracking of processing events on a unit can be denoted as a sequential circular timing and accumulating procedure synchronous to the production process.

In this procedure, the following sates are involved for timing an event: (1) the tasks assigned to the unit; (2) the LIMS data K(q) with sampling period TDfor determining the searched time-interval with reference to the situation of material-type changes; and (3) the measured input and output flow rates of the materials. In Fig. 11, while supposing5it+is the current time-point to be timed according to Eq. (12), so the output of the tracking method isexactly that is formulated as Eq. (9).

Similarly, while events on the bi-side units or devices are tracking sequentially, the storing events on a tank can be tracked synchronously with the procedure as shown in Fig. 11. As denoted in the diagram, time-points of the tracked event are determined by the bi-side events as well as the input and output flow rates of the tank are collected to calculate the quantity-specific properties denoted in Eq. (10).

Step 2 Synthesizing

As the processing and storing events are tracked through the procedures of above, the occurring transports between them should be synthesized synchronously to obtain construction relationships for the global information. Fig. 12 shows the procedure of the synthesizing, where time-points of the transportsdepend on the events of bi-side and the calculated quantity of the material flow also dictates the movement happening or not. This procedure can be used in all of the situations where movements would happen on the pipelines or transport routes.

Figure 10 Tracking the processing events

Figure 11 Tracking the storing events

Figure 12 Synthesizing the movements

Step 3 Representing

Finally, while all the types of information cells including events and movements are tracked and synthesized with the respective modeling methods, the global information containing the dynamically structured cells can be further represented in an information map shown as Fig. 13. As illustrated with the spatial and temporal elements of the space, it is possible to index the global information into specific numerical forms so that the information could be stored and fetched limberly for resolving, feedback and further analyzing with combination to the relevant mathematical approaches.

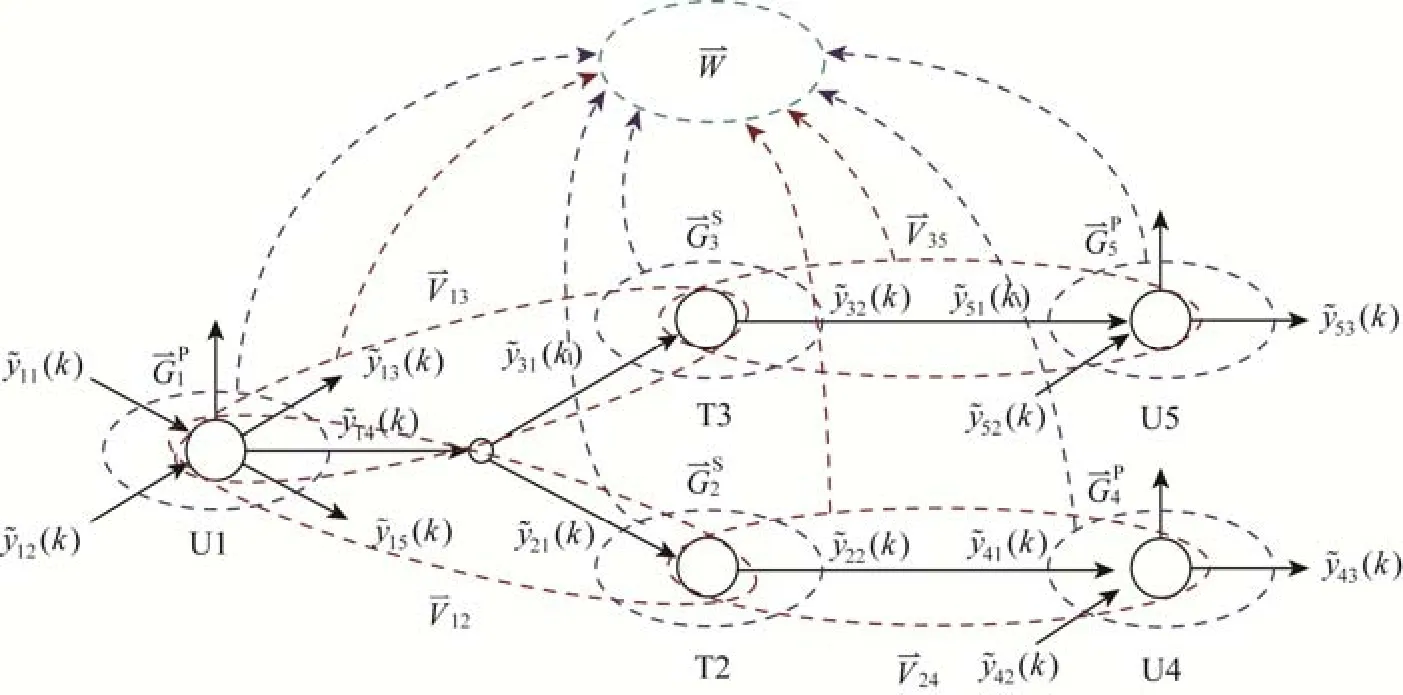

4.3 The construction relations

On the whole, each of the modeling methods introduced as above focuses on the level that is interested individually. While considering the practical aspect, the methods should be constructed as a whole framework from the system perspective. According to the TRF principles, the construction relations of these

Figure 13 Representing the global information

Figure 14 The construction relations

modeling methods regarding the application can be illustrated. The application scenario is taken from Fig. 6.

As dictated in Fig.14, the tracking methods (Gˉ⇀) are implemented to the units and tanks as the bottom layer. Then the synthesizing methods (Vˉ⇀) are installed upon the tracking layer to synthesize the movements depending on the information of the tracked events. Finally, the tracked events as well as the synthesized movements are all gathered by the represent method (Wˉˉ⇀). Consequently, it is sure that the local states can be tracked, synthesized and finally represented as the global information step by step. And, the construction relations also illustrate that these methods could further be constructed a complete and sophisticated TRF system.

5 CONCLUSIONS

Based on the previous research, a mechanism about information tracking, representing and feedback with respect to the large-scale process systems is introduced in this paper. With the modeling methods, this mechanism might help to constitute the multi-step feedback course that would serve to support the multilevel decision course more efficiently, as well as to construct a sophisticated feedback system that could cope with various challenges including the structural dynamics of plant-wide material flows. Because of the extent limitation of this paper, more details of the mechanism and the illustrative simulations will be introduced in recent papers.

As set forth, numerous issues should be addressed with the motivation of promising prospects in the future. Besides the mechanism and system issues, we believe that the combinatorial topics between the TRF framework and relevant mathematical methods to resolve the problems with respect to uncertainties, correctness, completeness and final utilities that the large-scale information feedback system has to be confronted with are the most important issues.

NOMENCLATURE

αicalculated parameter for comparing the input material proportion

βjcalculated parameter for comparing the output material proportion

σigiven parameter of the input material proportion for reference

φjgiven parameter of the out material proportion for reference

REFERENCES

1 Klatt, K.U., Marquardt, W., “Perspectives for process systems engineering—Personal views from academia and industry”, Comput. Chem. Eng., 33 (3), 536-550 (2009).

2 Shaik, M., Gudi, R.D., “A multilevel control-theoretic framework for integration of planning, scheduling, and rescheduling”, Ind. Eng. Chem. Res., 44, 4001-4021 (2005).

3 The Instrumentation Standard and Automation Society, Enterprise-control System Integration, Part 1: Models and Terminology, ANSI/ISA 95.00.01, North Carolina, USA (2005).

4 Kim, M., Lee, I.B., “Rule-based reactive rescheduling system for multi-purpose batch processes”, Comput. Chem. Eng., S1197-S1202 (1997).

5 Naraharisetti, P.K., Adhitya, A., Karimi, I.A., Srinivasan, R., “From PSE to PSE2—Decision support for resilient enterprises”, Comput. Chem. Eng., 33, 1939-1949 (2009).

6 Grossmann., I., “Enterprise-wide optimization: A new frontier in process systems engineering”, AIChE J, 51 (7), 1846-1857 (2005).

7 Li, Z., Ierapetritou, M.G., “Rolling horizon based planning and scheduling integration with production capacity consideration”, Comput. Chem. Eng., 65 (22), 5887-5900 (2010).

8 Shaik, M.A., Floudas, C.A., Kallrath, J., Pitz, H.J., “Production scheduling of a large-scale industrial continuous plant: Short-term and medium-term scheduling”, Comput. Chem. Eng., 33 (3), 670-686 (2009).

9 Shaik, M.A., Floudas, C.A., “Unit-specific event-based continuous-time approach for short-term scheduling of batch plants using RTN framework”, Comput. Chem. Eng., 32 (1), 260-274 (2008).

10 Floudas, C.A., Lin, X., “Continuous-time versus discrete-time approaches for scheduling of chemical processes: A review”, Comput. Chem. Eng., 28, 2109-2129 (2004).

11 Maravelias, C.T., Sung, C., “Integration of production planning and scheduling: Overview, challenges and opportunities”, Comput. Chem. Eng., 33 (12), 1919-1930 (2009).

12 Harjunkoski, I., Nyström, R., Horch, A., “Integration of scheduling and control—Theory or practice?”, Comput. Chem. Eng., 33, 1909-1918 (2009).

13 Muñoz, E., Elisabet, C.G., Marta, M.B., Espuña, A., Puigjaner, L.,“Scheduling and control decision-making under an integrated information environment”, Comput. Chem. Eng., 35 (5), 774-786 (2011).

14 Patel, M.P., Shah, N., Ashe, R., “Plant-wide optimisation and control of a multi-scale pharmaceutical process”, Comput. Chem. Eng., 29, 713-717 (2011).

15 Yang, A., Marquardt, W., “An ontological conceptualization of multiscale models”, Comput. Chem. Eng., 33, 822-837 (2009).

16 Li, J., Ge, W., Zhang, E.J., Kwauk, M., “Multi-scale compromise and multi-level correlation in complex systems”, Chem. Eng. Res. Des., 83 (A6), 574-582 (2005).

17 Shaik, M.A., Floudas, C.A., “Unit-specific event-based continuous-time approach for short-term scheduling of batch plants using RTN framework”, Comput. Chem. Eng., 32 (1), 260-274 (2008).

2012-05-30, accepted 2012-09-17.

* Supported by the National Basic Research Program of China (2012CB720500) and the National High Technology Research and Development Program of China (2012AA041102).

** To whom correspondence should be addressed. E-mail: grong@iipc.zju.edu.cn

Chinese Journal of Chemical Engineering2014年4期

Chinese Journal of Chemical Engineering2014年4期

- Chinese Journal of Chemical Engineering的其它文章

- An Approach to Formulation of FNLP with Complex Piecewise Linear Membership Functions

- Determination and Correlation of Solubility for D-Xylose in Volatile Fatty Acid Solvents*

- Impacts of Power Density on Heavy Metal Release During Ultrasonic Sludge Treatment Process*

- One Step Preparation of Sulfonated Solid Catalyst and Its Effect in Esterification Reaction*

- Effects of Assistant Solvents and Mixing Intensity on the Bromination Process of Butyl Rubber*

- Determination and Correlation of Solubilities of Four Novel Benzothiazolium Ionic Liquids with6PF−in Six Alcohols*