皇冠梨糖度可见/近红外光谱在线检测模型传递研究

徐惠荣 李青青

(1.浙江大学生物系统工程与食品科学学院, 杭州 310058; 2.农业部农产品产地处理装备重点实验室, 杭州 310058)

皇冠梨糖度可见/近红外光谱在线检测模型传递研究

徐惠荣1,2李青青1

(1.浙江大学生物系统工程与食品科学学院, 杭州 310058; 2.农业部农产品产地处理装备重点实验室, 杭州 310058)

在水果内部品质检测分级实际生产中往往存在多通道测量,由于仪器不同或加工精度不同而存在多通道间检测模型不具通用性问题,应用多种模型传递方法研究了在线检测条件下两个不同可见/近红外光谱仪间的皇冠梨糖度预测模型传递及预测比较分析。结果表明:从仪器的光谱数据经直接校正算法(DS)和基于平均光谱差值校正的DS算法(MSSC-DS)转换后用于主仪器所建模型的预测结果相对较好,预测均方根误差小于0.5°Brix,可以满足实际生产。但通过模型转换后的预测结果均比利用从仪器数据直接建模的预测结果要差(预测均方根误差为0.381°Brix),因而在实际生产中,需要从成本和分级精度的要求来考虑选择建模的方式。

皇冠梨; 糖度; 在线检测; 可见/近红外光谱; 模型传递

引言

可见/近红外光谱分析技术已被广泛用于鲜果内部品质的无损检测[1-16],但在水果内部品质检测分级生产线实际应用中往往存在多通道测量,面临由于仪器不同或加工精度不同而存在多通道间检测模型不具通用性问题[17]。模型传递也称为仪器标准化,是指通过化学计量学方法,建立主、从仪器之间的数学关系,使主仪器上建立的校正模型,能够在从仪器上有效地预测新样品,从而减少重新建模所带来的工作量。模型传递最早由OSBORNE等[18]提出,并建立了斜率/偏差算法(Slope/bias,S/B),并由SHENK[19]、WANG等[20]相继提出了新的模型传递算法,即Shenk’s算法和分段直接校正算法(Piecewise direct standardization,PDS),之后,国内外学者在模型传递算法上进行了大量的研究[21-33]。近年来,已有少量文献报道用于水果糖度预测模型的传递研究。胡润文等[31]通过S/B算法和直接校正(Direct standardization,DS)算法实现了脐橙总糖模型在相同型号仪器间的传递。SALGUERO-CHAPARRO等[32]采用S/B算法、PDS算法和正交投影转换法将橄榄脂肪、游离酸含量以及含水率检测模型从静态仪器传递到了便携式仪器。吉纳玉等[33]采用DS算法实现了苹果糖度模型在相同型号便捷式近红外仪器之间的传递。

在水果品质在线实时检测分级中,对水果糖度无损检测模型稳健性影响的因素还来自样品相关因素和其他非样品相关因素[34],本文探讨在利用可见/近红外光谱进行梨糖度在线实时检测时不同小型光纤光谱仪之间模型传递的可行性。

1 材料与方法

1.1 材料

实验所用样本为河北省沧州皇冠梨,从杭州水果批发市场购买。选择大小与果形相近的皇冠梨,对其进行表面清洁并标号后,在实验室条件(温度约23℃、相对湿度约70%)下放置1 d,使样本内外温度一致,然后在线实时采集梨的可见/近红外半透射光谱,并测量糖度。

分别采用美国海洋光学公司生产的QE65Pro型和QE65000型微型光纤光谱仪采集同一批水果光谱,两款光谱仪都采用相同的滨松背照式CCD面阵探测器,可以合并同列垂直像素,大幅提高信噪比(>1 000),QE65Pro型光谱仪配置HC-1型光栅和OFLV-QE-400型滤波器,波长范围396.8~1 174.0 nm,共1 044像素,并安装有100 μm狭缝(入口孔径)。QE65000型光谱仪配置HC-1型光栅和OFLV-QE-250型滤波器,波长范围247.9~1 040.7 nm,共1 044像素,未安装狭缝(入口孔径即为光纤芯径1 000 μm)。

1.2 仪器与方法

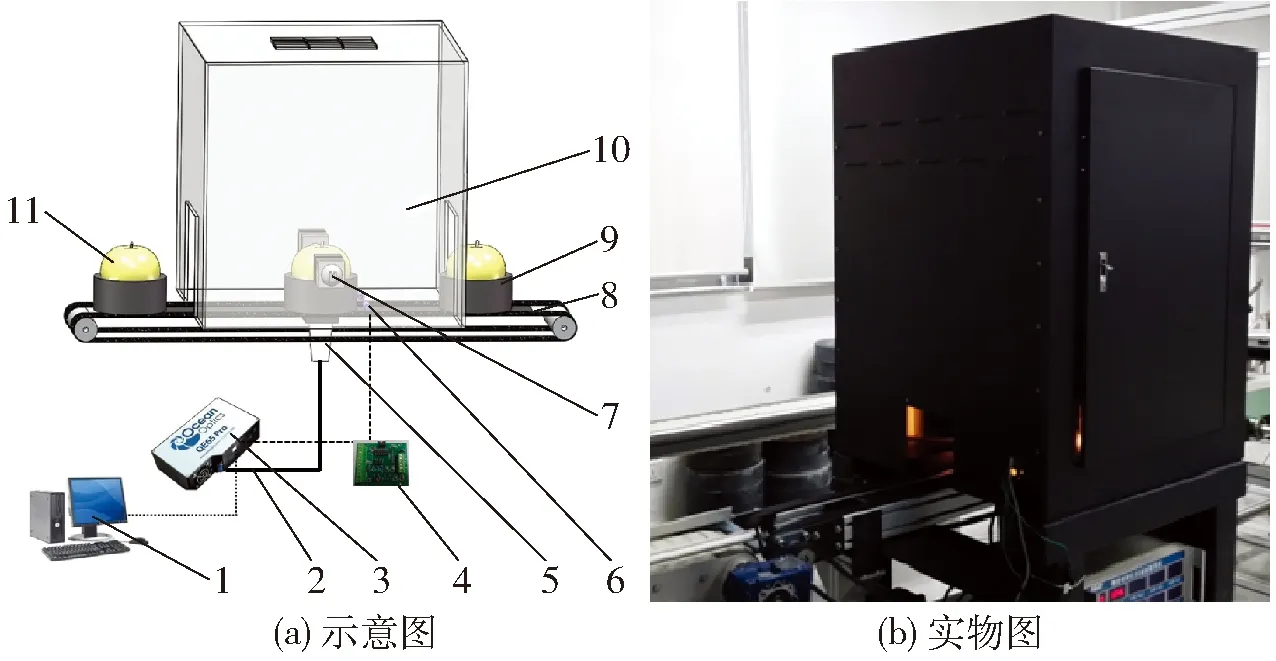

图1为自行设计的水果内部品质可见/近红外光谱在线实时检测系统,配置了基于C++语言自行开发的光谱数据采集记录软件。实验时,输送带速度为0.5 m/s。为了减少暗电流及光源随时间变化的影响,在采集样本光谱前,先采集暗场光谱(即在关闭光路的情况下采集暗电流值)以及参比光谱(参比采用直径为75 mm的Teflon球)。水果光谱采集时,水果放置在自由输送托盘上,由输送带传输至光照箱正中两侧光源(左、右两侧各装有一只150 W卤钨灯)之间,当托盘底座开口(直径35 mm)与准直镜大端接口(直径25 mm)刚接触时,光电传感器通过自行设计的控制电路触发光谱仪进行光谱采集,积分时间为100 ms。准直镜经光纤与光谱仪相连,光谱仪将得到的携带有水果信息的光谱信号通过USB数据线发送给计算机,进行实时处理并记录光谱数据。光谱记录时通过软件直接采用Boxcar平滑法(平滑点数为6)进行光谱平滑预处理。

图1 自由托盘输送的水果内部品质在线实时检测系统Fig.1 Free tray based on-line detection system for fruit internal quality1.计算机 2.光纤 3.光谱仪 4.控制电路 5.准直镜 6.位置传感器 7.卤钨灯 8.输送带 9.输送托盘 10.光照箱 11.皇冠梨

理化分析测定糖度时,参照NY/T 2637—2014,将水果去核切成小块,放入榨汁机中榨取果汁并进行过滤,用手持式糖量计(PR-101型数字式折射仪,日本ATAGO公司)进行测量,将2次测量平均值作为其糖度。

1.3 模型传递方法

1.3.1斜率/偏差算法

S/B算法是基于预测结果的校正,假设主仪器和从仪器上测得的预测值之间存在线性关系,其基本过程如下[18]:

(1)将主仪器上建立的校正模型T直接应用于从仪器,选择m个样品,在主仪器和从仪器上分别测得其光谱矩阵Xms和Xss,根据校正模型计算得到成分预测矩阵Cmp和Csp,计算公式为

(1)

(2)假设成分预测矩阵Cmp和Csp之间存在线性关系,并通过最小二乘法计算得到截距wbias和斜率sslop,公式为

Cmp=wbias+sslopCsp

(2)

(3)对于从仪器上测得的未知成分含量的样品光谱Xss,un,根据式(2)可直接预测成分含量Cpsp,un,即

Cpsp,un=wbias+sslop(Xss,unT)

(3)

1.3.2直接校正算法

DS算法是一种有标传递算法,其基本流程如下[20]:在主仪器和从仪器上测得的某一样品集光谱矩阵分别为Xms和Xss,其维数为m×p,p为波长点个数,可建立两者转换运算公式

Xms=XssF+B′s

(4)

式中F——维数p×p的转换矩阵B′s——维数p×1的背景校正矩阵的转置

若未知成分含量的样品在从仪器上测定的光谱为Xss,un,则根据式(4)可转换得到适合于主仪器所建模型T的光谱数据

Xpss,un=Xss,unF+B′s

(5)

1.3.3分段直接校正算法

PDS算法与DS算法的原理基本相同,不同之处在于,在DS算法中,从仪器样品光谱矩阵采用的是全波长数据Xss,all(下角标all表示所有波长)来拟合主仪器样品光谱矩阵Xms的每一个波长点数据Xms,i(下角标i表示第i个波长),而在PDS算法中,采用的是波长点附近一窗口大小为(j+k+1)的光谱段Xss,j+k+1来拟合Xms,i。

1.3.4平均光谱差值校正算法

平均光谱差值校正(MSSC)算法是一种运算简捷,且在实际应用中易于实现的光谱校正方法,最早被用于消除在线多通道近红外分析仪各通道间的光谱差异。操作过程如下[17]:

首先选取m个样本,在各个仪器(通道)上采集光谱,组成校正光谱阵Xi(i=1,2,…,n,n为仪器数或者通道数),每台仪器的平均光谱向量计算公式为

(6)

(7)

对第i台仪器(或者通道)测量的光谱进行修正的公式为

(8)

1.4 模型评价指标

在近红外光谱建模分析中,通常把样本分成校正集和预测集两部分,用校正相关系数rcal和校正均方根误差来评价校正精度,用预测相关系数rpre和预测均方根误差来评价预测精度,并用相对分析误差来判断模型的好坏,该指标是用标准偏差除以预测均方根误差得到的,MALLEY等[35]提出:高精度模型的相对分析误差在4以上;成功模型的相对分析误差在3~4范围内;比较成功模型的相对分析误差在2.25~3范围内;比较有用模型的相对分析误差在1.75~2.25范围内。

2 结果与讨论

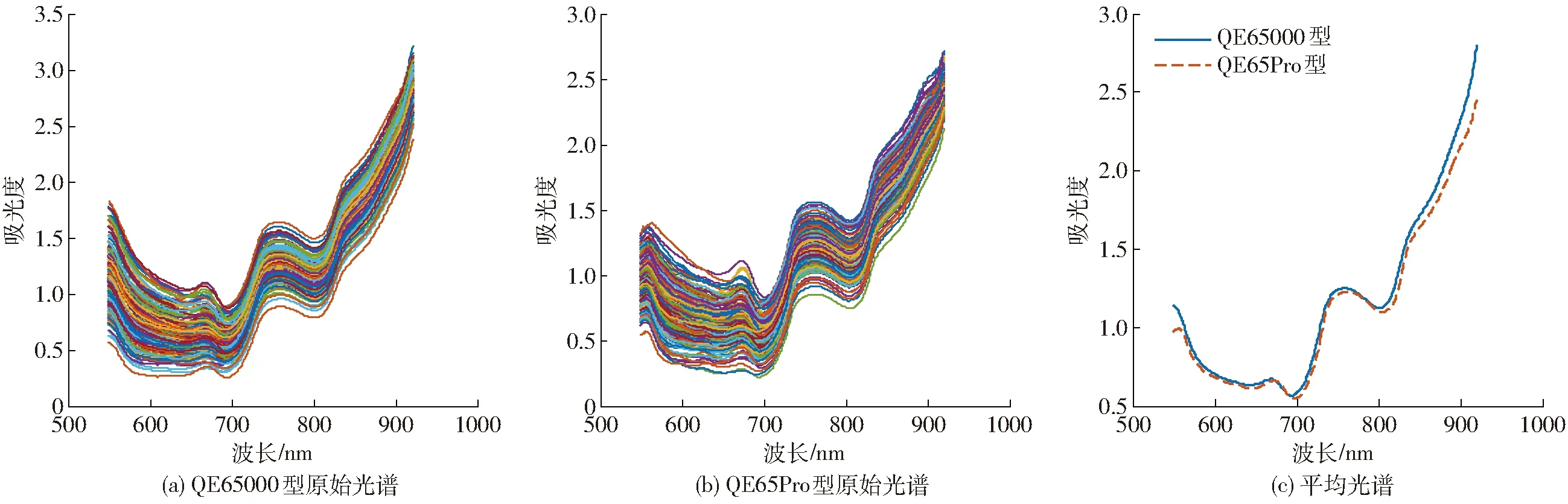

图2为皇冠梨样本通过QE65000型光谱仪和QE65Pro型光谱仪采集的550~920 nm波长范围内的原始光谱及平均光谱。总体上看,两台仪器采集的光谱相似,可看出微小的吸光度差异和波长漂移,QE65000型光谱仪采集的数据吸光度略大,且光谱数据噪声小。

2.1 PLSR建模分析

先对两个光谱仪各自采集的数据分别进行直接建模分析,剔除异常样本后,用于各自PLSR建模分析的样本数分别为199和200个(由于异常样本不同,两光谱仪数据并非严格一一对应),通过K-Stone算法将样本集按2∶1的比例划分为校正集和预测集,划分后的校正集和预测集样品外观形态和糖度检测结果如表1所示。表2为两光谱仪皇冠梨糖度PLSR模型校正和预测分析结果,从表中可以看出两光谱仪数据各自直接建模校正均方根误差都小于0.3°Brix,预测均方根误差都小于0.4°Brix,且相对分析误差大于2.2,所建模型较成功。图3为两光谱仪校正集和预测集样本真实值和预测值的对比分布图,QE65000型光谱仪模型的预测能力优于QE65Pro型。

2.2 模型传递分析

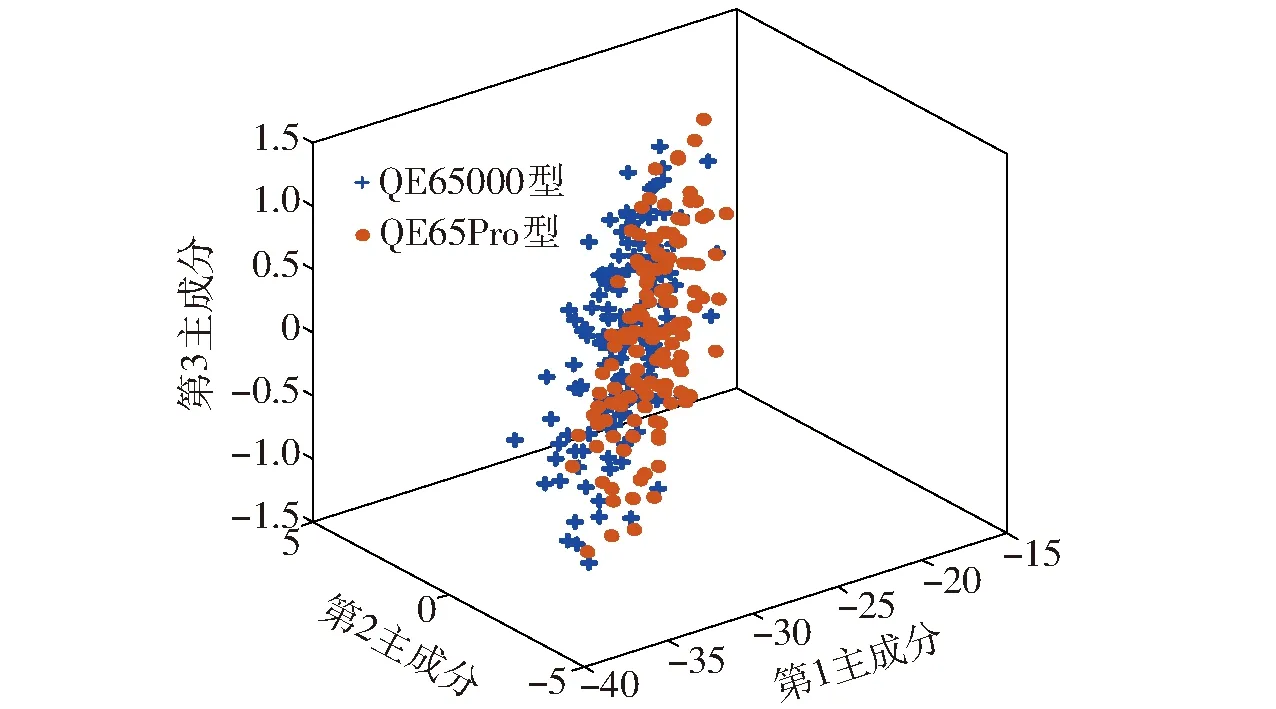

图4为两光谱仪采集的皇冠梨光谱数据校正集样本的前3个主成分分布图。从图4中可以看出,两组数据主成分空间分布有一定的偏差,但整体分布呈线性平移,可见两光谱仪采集的光谱数据差异有一定的规律可循。

图2 两台仪器采集的原始光谱及其平均光谱Fig.2 Raw and average spectra obtained by two spectrometers

光谱仪样本集样本数量参数数值最小值最大值平均值标准偏差质量/g222.00420.00309.9844.63校正集132横径/mm74.8892.7482.154.14纵径/mm65.3090.3377.735.17QE65000型糖度/°Brix9.5013.4011.240.81质量/g230.00420.00310.2542.06预测集67横径/mm76.0491.6882.463.80纵径/mm65.7489.0277.004.92糖度/°Brix9.8013.3011.320.84质量/g225.00420.00308.0944.33校正集133横径/mm74.8892.7481.934.08纵径/mm65.7390.3377.624.87QE65Pro型糖度/°Brix10.0014.0011.260.86质量/g233.00404.00309.1941.76预测集67横径/mm75.6190.6782.443.78纵径/mm65.3089.2376.745.41糖度/°Brix9.5013.4011.280.84

表2 两光谱仪检测皇冠梨糖度PLSR模型分析结果Tab.2 Calibration and prediction results of two spectrometers using PLSR model for sugar content of crown pear

图3 不同光谱仪皇冠梨可溶性固形物PLSR模型的检测结果Fig.3 Scatter plots of measured and predicted sugar contents obtained by PLSR model

图4 两光谱仪校正集样本的前3个主成分分布图Fig.4 Distribution diagram of the first three PCs of calibration set of two spectrometers

设QE65000型光谱仪为主仪器,QE65Pro型为从仪器,研究比较了DS、PDS、S/B、MSSC算法对两光谱仪间皇冠梨糖度在线检测模型的传递。模型传递前后的预测结果如表3所示,从表中可以看出,用主仪器所建的校正模型直接预测从仪器的预测集样本,所得预测均方根误差为8.482°Brix,而通过DS算法进行模型传递后,预测均方根误差下降到了0.473°Brix,经MSSC光谱差异校正后再进行DS传递,预测结果得到了进一步改善,预测均方根误差为0.453°Brix,已经达到一般生产实际的要求(小于0.5°Brix)。相比之下,其他模型传递算法没有得到明显的改善。可能原因是DS算法采用了所有波长点的数据进行转换,提高了光谱曲线的拟合精度,而MSSC算法更进一步减少了两台光谱仪数据间的光谱差异。

表3 模型传递前后预测结果Tab.3 Prediction results before and after calibration model transfer

3 结束语

应用多种模型传递方法(DS、PDS、S/B、MSSC、MSSC-DS、MSSC-PDS、MSSC-S/B)研究了在线检测条件下(速度0.5 m/s)两个不同可见/近红外光谱仪间皇冠梨糖度预测模型传递及预测比较分析,结果表明:从仪器的光谱数据经DS和MSSC-DS转换后用于主仪器所建模型的预测结果相对较好,可以满足实际生产,且通过光谱校正预处理(MSSC)消除或降低两光谱差异可以进一步提高预测精度。通过模型转换后的预测结果均比利用两光谱仪数据各自直接建模的结果要差,因而在实际生产中,需要从成本和分级精度的要求上来考虑选择建模的方式。

1 GOLIC M, WALSH K B. Robustness of calibration models based on near infrared spectroscopy for the in-line grading of stone fruit for total soluble solids content [J]. Analytica Chimica ACTA, 2006, 555(2): 286-291.

2 LU Huishan, JIANG Huanyu, FU Xiaping, et al. Non-invasive measurements of the internal quality of intact ‘gannan’ navel orange by VIS/NIR spectroscopy [J]. Transactions of the ASABE, 2008, 51(3): 1009-1014.

3 CAMPS C, CHRISTEN D. Non-destructive assessment of apricot fruit quality by portable visible-near infrared spectroscopy [J]. LWT—Food Science and Technology, 2009, 42(6): 1125-1131.

4 徐惠荣, 陈晓伟, 应义斌. 基于多元校正法的香梨糖度可见/近红外光谱检测[J]. 农业机械学报, 2010,41(12): 126-129, 147. XU Huirong, CHEN Xiaowei, YING Yibin. Multivariate approach to determinate sugar content of fragrant pears with temperature variation by visible/NIR spectroscopy [J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(12): 126-129, 147.(in Chinese)

5 XU Huirong, QI Bing, SUN Tong, et al. Variable selection in visible and near-infrared spectra: application to on-line determination of sugar content in pears [J]. Journal of Food Engineering, 2012, 109: 142-147.

6 刘燕德, 施宇, 蔡丽君, 等. 基于CARS算法的脐橙可溶性固形物近红外在线检测[J/OL]. 农业机械学报, 2013,44(9): 138-144. http:∥www.j-csam.org/jcsam/ch/reader/view_abstract.aspx?file_no=20130925&flag=1. DOI:10.6041/j.issn.1000-1298.2013.09.025. LIU Yande, SHI Yu, CAI Lijun, et al. On-line NIR detection model optimization of soluble solids content in navel orange based on CARS [J/OL]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(9): 138-144.(in Chinese)

7 LI Jiangbo, ZHAO Chunjiang, HUANG Wenqian, et al. A combination algorithm for variable selection to determine soluble solids content and firmness of pear [J]. Analytical Methods, 2014, 6(7): 2170-2180.

8 TRAVERS S, BERTELSEN M G, PETERSEN K K, et al. Predicting pear (cv. Clara Frijs) dry matter and soluble solids content with near infrared spectroscopy [J]. LWT—Food Science and Technology, 2014, 59(2): 1107-1113.

9 SHUXIANG F, ZHIMING G, BAOHUA Z, et al. Using vis/NIR diffuse transmittance spectroscopy and multivariate analysis to predicate soluble solids content of apple [J]. Food Analytical Methods, 2016, 9(5): 1333-1343.

10 MCGLONE V A, MARTINSEN P J, CLARK C J, et al. On-line detection of brownheart in Braeburn apples using near infrared transmission measurements [J]. Postharvest Biology and Technology, 2005, 37(2): 142-151.

11 韩东海, 刘新鑫, 鲁超, 等. 苹果内部褐变的光学无损伤检测研究[J]. 农业机械学报, 2006, 37(6):86-88, 93. HAN Donghai, LIU Xinxin, LU Chao, et al. Study on optical-nondestructive detection of breakdown apples [J]. Transactions of the Chinese Society for Agricultural Machinery, 2006, 37(6):86-88, 93.(in Chinese)

12 FU Xiaping, YING Yibin, LU Huishan, et al. Comparision of diffuse reflectance and transmission mode of VIS-NIR spectroscopy for detecting brown heart of pear [J]. Journal of Food Engineering, 2007, 83(3):317-323.

13 TEERACHAICHAYUT S, KIL K Y, TERDWONGWORAKUL A, et al. Non-destructive prediction of translucent flesh disorder in intact mangosteen by short wavelength near infrared spectroscopy [J]. Postharvest Biology and Technology, 2007, 43(2): 202-206.

14 SUBEDI P P, WALSH K B, OWENS G. Prediction of mango eating quality at harvest using short-wave near infrared spectrometry [J]. Postharvest Biology and Technology, 2007, 43(3): 326-334.

15 BLAKEY R J. Evaluation of avocado fruit maturity with a portable near-infrared spectrometer [J]. Postharvest Biology and Technology, 2016, 121: 101-105.

16 薛建新, 张淑娟, 孙海霞, 等. 可见/近红外光谱结合软化指标快速判定沙果货架期[J/OL].农业机械学报, 2013,44(8):169-173. http:∥www.j-csam.org/jcsam/ch/reader/view_abstract.aspx?file_no=20130828&flag=1. DOI:10.6041/j.issn.1000-1298.2013.08.028. XUE Jianxin, ZHANG Shujuan, SUN Haixia, et al. Detection of shelf life of malus asiatica using near-infrared spectroscopy and softening index [J/OL].Transactions of the Chinese Society for Agricultural Machinery,2013,44(8):169-173.(in Chinese)

17 褚小立, 袁洪福, 陆婉珍.一种消除在线多通道近红外分析仪各通道光谱差异的方法[J]. 分析化学, 2005, 33(6):745-750. CHU Xiaoli, YUAN Hongfu, LU Wanzhen. A method to eliminate spectral differences among multi-channels of an on-line near infrared spectroscopy analyzer [J]. Chinese Journal of Analytical Chemistry, 2005, 33(6): 745-750.(in Chinese)

18 OSBORNE B G, FEARN T. Collaborative evaluation of universal calibrations for the measurement of protein and moisture in flour by near-infrared reflectance [J]. Journal of Food Technology, 1983, 18(4): 453-460.

19 SHENK J S. Optical instrument calibration system:US 4,866,644[P]. 1989-09-12.

20 WANG Y D, VELTKAMP D J, KOWALSKI B R. Multivariate instrument standardization [J]. Analytical Chemistry, 1991, 63(23): 2750-2756.

21 BOUVERESSE E, MASSART D L, DARDENNE P. Calibration transfer across near-infrared spectrometric instruments using shenks algorithm-effects of different standardization samples [J]. Analytica Chimica ACTA, 1994, 297(3): 405-416.

22 BLANK T B, SUM S T, BROWN S D, et al. Transfer of near-infrared multivariate calibrations without standards [J]. Analytical Chemistry, 1996, 68(17): 2987-2995.

23 YOON J G, LEE B W, HAN C H. Calibration transfer of near-infrared spectra based on compression of wavelet coefficients [J]. Chemometrics and Intelligent Laboratory Systems, 2002, 64(1): 1-14.

24 褚小立, 袁洪福, 陆婉珍. 普鲁克分析用于近红外光谱仪的分析模型传递[J]. 分析化学, 2002, 30(1): 114-119. CHU Xiaoli, YUAN Hongfu, LU Wanzhen. Calibration transfer of spectra from near infrared spectrometers by procrustes analysis [J]. Chinese Journal of Analytical Chemistry, 2002, 30(1): 114-119.(in Chinese)

25 KRAMER K E, MORRIS R E, ROSE-PEHRSSON S L. Comparison of two multiplicative signal correction strategies for calibration transfer without standards [J]. Chemometrics and Intelligent Laboratory Systems, 2008, 92(1): 33-43.

26 KALIVAS J H, SIANO G G, ANDRIES E, et al. Calibration maintenance and transfer using Tikhonov regularization approaches [J]. Applied Spectroscopy, 2009, 63(7): 800-809.

27 邢志娜, 王菊香, 申刚, 等. 近红外光谱分析模型传递简易方法研究[J]. 分析科学学报, 2011, 27(1): 128-130. XING Zhina,WANG Juxiang, SHEN Gang, et al. A simple and practical model transfer method for the homotype near infrared spectrometers [J]. Journal of Analytical Science,2011, 27(1): 128-130.(in Chinese)

28 王菊香, 李华, 邢志娜, 等. 小波多尺度分段直接校正法用于近红外光谱模型传递的研究[J]. 分析化学, 2011, 39(6): 846-850. WANG Juxiang, LI Hua, XING Zhina, et al. Application of wavelet multi-scale piecewise direct standardization on near infrared analysis calibration [J].Chinese Journal of Analytical Chemistry, 2011, 39(6): 846-850.(in Chinese)

29 史新珍, 王志国, 杜文, 等. 近红外光谱结合新型模型传递方法用于糖料的在线质量监控[J]. 分析化学, 2014, 42(11): 1673-1678. SHI Xinzhen, WANG Zhiguo, DU Wen, et al. On-line quantitative monitoring and control of tobacco flavors by near infrared spectroscopy combined with advanced calibration transfer method [J].Chinese Journal of Analytical Chemistry, 2014, 42(11): 1673-1678.(in Chinese)

30 张晓羽, 李庆波, 张广军. 基于稳定竞争自适应重加权采样的光谱分析无标模型传递方法[J]. 光谱学与光谱分析, 2014, 34(5): 1429-1433. ZHANG Xiaoyu, LI Qingbo, ZHANG Guangjun. Calibration transfer without standards for spectral analysis based on stability competitive adaptive reweighed sampling[J]. Spectroscopy and Spectral Analysis,2014, 34(5): 1429-1433.(in Chinese)

31 胡润文, 夏俊芳. 脐橙总糖近红外光谱模型传递研究[J]. 食品科学, 2012, 33(3): 28-32. HU Runwen, XIA Junfang.Transfer of NIRS calibration model for determining total sugar content in navel orange [J]. Food Science, 2012, 33(3): 28-32.(in Chinese)

32 SALGUERO-CHAPARRO L, PALAGOS B, PENA-RODRIGUEZ F, et al. Calibration transfer of intact olive NIR spectra between a pre-dispersive instrument and a portable spectrometer [J]. Computers and Electronics in Agriculture, 2013, 96: 202-208.

33 吉纳玉, 韩东海. 苹果近红外预测模型的传递研究[J]. 食品安全质量检测学报, 2014, 5(3): 712-717. JI Nayu, HAN Donghai.Study on near-infrared prediction model transfer for apples [J]. Journal of Food Safety and Quality, 2014, 5(3): 712-717.(in Chinese)

35 MALLEY D F, MCCLURE C, MARTIN P D, et al. Compositional analysis of cattle manure during composting using a field-portable near-infrared spectrometer[J]. Communications in Soil Science and Plant Analysis, 2005, 36(4-6): 455-475.

CalibrationModelTransferbetweenVisible/NIRSpectrometersinSugarContentOn-lineDetectionofCrownPears

XU Huirong1,2LI Qingqing1

(1.CollegeofBiosystemsEngineeringandFoodScience,ZhejiangUniversity,Hangzhou310058,China2.KeyLaboratoryofOnSiteProcessingEquipmentforAgriculturalProducts,MinistryofAgriculture,Hangzhou310058,China)

With the development of social economy and growth of people’s living standand, the demond of fruit quality is ever increasing. Quality detection and grading of postharvest fruit is an integral part of commoditization processing, which is also an effective way to achieve high price with good quality. Visible/NIR spectroscopy with the advantages of rapid, nondestructive and being on-line analyzing, has been widely used in agriculture. In the actual application of visible/NIR spectroscopy for on-line detection of fruit internal quality, multi-channels measurement often exists, in which the prediction model is not universal among multi channels due to different spectrometers or their different manufacture precisions. Calibration model transfer is a key problem in visible/NIR spectral quantitative analysis. Comparative analysis of some calibration model transfer methods, such as direct standardization (DS), piecewise direct standardization (PDS), slope/bias (S/B) between two different visible/NIR spectrometers (master and slave spectrometers, model QE65000 and QE65Pro, Ocean Optics, Inc., USA) in the sugar content on-line detection of crown pears was carried out at conveyor speed of 0.5 m/s. The results showed that the prediction values by DS algorithm and DS algorithm based on the mean spectra subtraction correction (MSSC-DS) were relatively good with low root mean square error of prediction (RMSEP) of less than 0.5°Brix, which can satisfy the industry application. And pre-processing method of MSSC can improve the prediction accuracy of calibration model transfer by eliminating and mitigating the differences between the spectra acquired on master and slave spectrometers. However, the best prediction result on salve instrument after calibration model transfer (RMSEP was 0.453°Brix) was still inferior to that predicted by the model developed directly using slave data (RMSEP was 0.381°Brix). Thus, in the actual application, appropriate modeling selection should be considered from the cost and the accuracy of classification.

crown pears; sugar content; on-line detection; visible/NIR spectroscopy; calibration transfer

O657.33; S661.2

A

1000-1298(2017)09-0312-06

10.6041/j.issn.1000-1298.2017.09.039

2017-03-16

2017-07-02

国家自然科学基金面上项目(31571562)

徐惠荣(1973—),男,教授,博士生导师,主要从事农产品品质无损检测技术与装备研究,E-mail: hrxu@zju.edu.cn