样本量估计及其在nQuery和SAS软件上的实现*——均数比较(十一)

南方医科大学生物统计学系(510515)

徐 莹 高培纯 徐笑寒 陈平雁△

1.2.2.11 基于比值高阶交叉设计的非劣效性检验

Chen(1997)[1]和Chow and Liu(2009)[2]给出的高阶交叉设计的样本量估计方法是建立在近似服从自由度为vk的t分布上,当指标为高优指标时,其检验效能计算公式为:

(1-59)

当指标为低优指标时,对应的检验效能计算公式为:

(1-60)

在计算样本量时,一般先设定样本量初始值,然后迭代样本量直到所得的检验效能满足条件为止。此时的样本量,即研究所需的样本量。

【例1-32】某公司欲验证一种治疗风湿病的仿制药非劣于标准药。拟采用2×4设计。研究者决定将非劣界值设置为0.2。根据以往研究,已知标准药CV为0.4。假设仿制药与标准药真实比值为1。检验水准为0.05,试估计检验效能为90%所需的样本量。

nQuery Advanced 8.2实现:设定检验水准为α=0.05,检验效能取90%。由题意知,μ2/μ1=1,NIM=0.2,CV=0.4。在nQuery Advanced 8.2主菜单选择:

方法框中选择:Higher-order Cross-Over Design for Two Means- Non-Inferiority-using Ratios

在弹出的样本量计算窗口将各参数键入,如图1-75所示,结果为N=29。

图1-75 nQuery Advanced 8.2 关于例1-32样本量估计的参数设置与计算结果

SAS9.4软件实现:

proc IML;

start MTE91(Designtype,Better,a,Ratio,NIM,CV,power);

error=0;

if(Designtype=1|Designtype=2|Designtype=3|Designtype=4)then do;

error=0;end;

else do;error=1;print"error" "Designtype must be 1 or 2 or 3 or 4";end;

if(Better=1 | Better=0)then do;

error=0;end;

else do;

error=1;print"error" "Higher means better(1)/worse(0)";end;

if(a>0.2 | a<0) then do;

error=1;print"error" "Test significance level must be in 0-0.2";end;

if(Ratio<0) then do;

error=1;print"error" "True Ratio of means must be>0";end;

if(NIM<0) then do;

error=1;print"error" "Non-Inferiority margin must be>0";end;

if(Better=1) then do;

if(Ratio<= 1-NIM)then do;

error=1;print"error" "True Ratio should be>1 - Non-Inferiority margin if higher means better";end;

end;

if(Better=0) then do;

if(Ratio>= 1+NIM)then do;

error=1;print"error" "True Ratio should be<1+Non-Inferiority margin if higher means worse";end;

end;

if(CV<0) then do;

error=1;print"error" "Coefficient of variance must be>= 0";end;

if(power>100 | power<1) then do;

error=1;print"error" "Power(%) must be in 1-100";end;

if(error=1) then stop;

if(error=0) then do;

if(Designtype=1) then do;n=1;b=2;end;

if(Designtype=2) then do;n=2;b=3/4;end;

if(Designtype=3) then do;n=1;b=11/20;end;

if(Designtype=4) then do;n=1;b=1/4;end;

Sw=sqrt(log(CV**2+1));

if(Better=1) then do;

do until(pw>=power/100);

if(Designtype=1) then do;df=4*n-3;end;

if(Designtype=2) then do;df=4*n-4;end;

if(Designtype=3) then do;df=6*n-5;end;

if(Designtype=4) then do;df=12*n-5;end;

t=(-log(Ratio)-log(1-NIM))/(Sw*sqrt(b/n))-tinv(1-a,df);

pw=probt(t,df);n=n+0.01;

end;

end;

if(Better=0) then do;

do until(pw>=power/100);

if(Designtype=1) then do;df=4*n-3;end;

if(Designtype=2) then do;df=4*n-4;end;

if(Designtype=3) then do;df=6*n-5;end;

if(Designtype=4) then do;df=12*n-5;end;

t=tinv(1-a,df)-(log(Ratio)+log(1+NIM))/(Sw*sqrt(b/n));

pw=probt(t,df);n=n+0.01;

end;

end;

if(Designtype=1) then do;N=ceil((n-0.01)*4);end;

if(Designtype=2) then do;N=ceil((n-0.01)*2);end;

if(Designtype=3) then do;N=ceil((n-0.01)*2);end;

if(Designtype=4) then do;N=ceil((n-0.01)*4);end;

if(Designtype=1) then do;Design_type="1. 4*2";end;

if(Designtype=2) then do;Design_type="2. 2*3";end;

if(Designtype=3) then do;Design_type="3. 2*4";end;

if(Designtype=4) then do;Design_type="4. 4*4";end;

if better=1 then Better_="better";else Better_="worse";

Design_type

Better_[label="Higher Mean Values are"]

a[label="Test Significance Level"]

Ratio[label="True Ratio of Means,u2/u1"]

NIM[label="Non-Inferiority Margin"]

CV[label="Coefficient of Variance,CV"]

power[label="Power(%)"]

N[label="N"];

end;

finish MTE91;

run MTE91(3,1,0.05,1,0.2,0.4,90);

quit;

SAS运行结果:

图1-76 SAS 9.4 关于例1-32样本量估计的参数设置与计算结果

1.2.2.12 基于均差高阶交叉设计的优效性检验

Chen(1997)[1]和Chow and Liu(2009)[2]给出的高阶交叉设计的样本量估计方法是建立在近似服从自由度为vk的t分布上,当指标为高优指标时,其检验效能计算公式为:

(1-61)

当指标为低优指标时,对应的检验效能计算公式为:

(1-62)

在计算样本量时,一般先设定样本量初始值,然后迭代样本量直到所得的检验效能满足条件为止。此时的样本量,即研究所需的样本量。

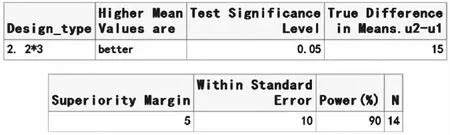

【例1-33】某公司欲验证一种治疗风湿病的仿制药非劣于标准药,拟采用2×3设计。研究者决定将优效界值设置为5。根据以往类似研究,已知均方误为100。假设仿制药于标准药真实差值为15。检验水准设置为0.05,试估计检验效能为90%所需的样本量。

nQuery Advanced 8.2 实现:设定检验水准为α=0.05,检验效能取90%。由题意知,μ2-μ1=15,SM=5,=10。在nQuery Advanced 8.2主菜单选择:

方法框中选择:Higher-order Cross-Over Design for Two Means- Superiority by Margin-using Differences

在弹出的样本量计算窗口将各参数键入,如图1-77所示,结果为N=14。

图1-77 nQuery Advisor 8.2 关于例1-33样本量估计的参数设置与计算结果

SAS 9.4软件实现:

proc IML;

start MTE71(Designtype,Better,a,Delta,SM,Sw,power);

error=0;

if(Designtype=1|Designtype=2|Designtype=3|Designtype=4)then do;

error=0;end;

elsedo;error=1;print"error" "Designtype must be 1 or 2 or 3 or 4";end;

if(Better=1 | Better=0)then do;

error=0;end;

else do;

error=1;print"error" "Higher means better(1)/worse(0)";end;

if(a>0.2 | a<0) then do;

error=1;print"error" "Test significance level must be in 0-0.2";end;

if(Better=1) then do;

if(Delta<= abs(SM))then do;

error=1;print"error" "True difference in means must>superiority margin if higher means better";end;

end;

if(Better=0) then do;

if(Delta>= -abs(SM))then do;

error=1;print"error" "True difference in means must end; if(Sw<0) then do; error=1;print"error" "Within standard error must be>=0";end; if(power>100 | power<1) then do; error=1;print"error" "Power(%) must be in 1-100";end; if(error=1) then stop; if(error=0) then do; if(Designtype=1) then do;n=1;b=2;end; if(Designtype=2) then do;n=2;b=3/4;end; if(Designtype=3) then do;n=1;b=11/20;end; if(Designtype=4) then do;n=1;b=1/4;end; if(Better=1) then do; do until(pw>=power/100); if(Designtype=1) then do;df=4*n-3;end; if(Designtype=2) then do;df=4*n-4;end; if(Designtype=3) then do;df=6*n-5;end; if(Designtype=4) then do;df=12*n-5;end; t=(Delta-abs(SM))/(Sw*sqrt(b/n))-tinv(1-a,df); pw=probt(t,df);n=n+0.01; end; end; if(Better=0) then do; do until(pw>=power/100); if(Designtype=1) then do;df=4*n-3;end; if(Designtype=2) then do;df=4*n-4;end; if(Designtype=3) then do;df=6*n-5;end; if(Designtype=4) then do;df=12*n-5;end; t=tinv(1-a,df)-(-Delta-abs(SM))/(Sw*sqrt(b/n)); pw=probt(t,df);n=n+0.01; end; end; if(Designtype=1) then do;N=ceil((n-0.01)*4);end; if(Designtype=2) then do;N=ceil((n-0.01)*2);end; if(Designtype=3) then do;N=ceil((n-0.01)*2);end; if(Designtype=4) then do;N=ceil((n-0.01)*4);end; if(Designtype=1) then do;Design_type="1. 4*2";end; if(Designtype=2) then do;Design_type="2. 2*3";end; if(Designtype=3) then do;Design_type="3. 2*4";end; if(Designtype=4) then do;Design_type="4. 4*4";end; if better=1 then Better_="better";else Better_="worse"; print Design_type Better_[label="Higher Mean Values are"] a[label="Test Significance Level"] Delta[label="True Difference in Means.u2-u1"] SM[label="Superiority Margin"] Sw[label="Within Standard Error"] power[label="Power(%)"] N[label="N"]; end; finish MTE71; run MTE71(2,1,0.05,15,5,10,90); quit; SAS运行结果: 图1-78 SAS 9.4 关于例1-33样本量估计的参数设置与计算结果 1.2.2.13 基于比值高阶交叉设计的优效性检验 Chen(1997)[1]和Chow(2009)[2]给出的高阶交叉设计的样本量估计方法是建立在近似服从自由度为vk的t分布上,当指标为高优指标时,其检验效能计算公式为: (1-63) 当指标为低优指标时对应的检验效能计算公式为: (1-64) 在计算样本量时,一般先设定样本量初始值,然后迭代样本量直到所得的检验效能满足条件为止。此时的样本量,即研究所需的样本量。 【例1-34】某公司欲验证一种治疗风湿病的仿制药非劣于标准药,拟采用2×4设计。研究者决定将优效界值设置为0.2。根据以往研究,已知标准药CV为0.4。假设仿制药与标准药真实比值为1.4。检验水准设置为0.05,试估计检验效能为90%所需的样本量。 nQuery Advanced 8.2 实现:设定检验水准为α=0.05,检验效能取90%。由题意知,μ2/μ1=1.4,SM=0.2,CV=0.4。在nQuery Advanced 8.2主菜单选择: 方法框中选择:Higher-order Cross-Over Design for Two Means- Superiority by Margin- using Ratios 在弹出的样本量计算窗口将各参数键入,如图1-79所示,结果为N=60。 图1-79 nQuery Advanced 8.2 关于例1-34样本量估计的参数设置与计算结果 SAS 9.4软件实现: proc IML; start MTE101(Designtype,Better,a,Ratio,SM,CV,power); error=0; if(Designtype=1|Designtype=2|Designtype=3|Designtype=4)then do; error=0;end; elsedo;error=1;print"error" "Designtype must be 1 or 2 or 3 or 4";end; if(Better=1 | Better=0)then do; error=0;end; else do; error=1;print"error" "Higher means better(1)/worse(0)";end; if(a>0.2 | a<0) then do; error=1;print"error" "Test significance level must be in 0-0.2";end; if(Ratio<= 0) then do; error=1;print"error" "True Ratio of means must be>0";end; if(SM<0) then do; error=1;print"error" "Superiority margin must be>0";end; if(Better=1) then do; if(Ratio<= 1+SM)then do; error=1;print"error" "True difference in means must>1+superiority margin if higher means better";end; end; if(Better=0) then do; if(Ratio>= 1-SM)then do; error=1;print"error" "True difference in means must<1 - superiority margin if higher means worse";end; end; if(CV<0) then do; error=1;print"error" "Coefficient of variance must be>= 0";end; if(power>100 | power<1) then do; error=1;print"error" "Power(%) must be in 1-100";end; if(error=1) then stop; if(error=0) then do; if(Designtype=1) then do;n=1;b=2;end; if(Designtype=2) then do;n=2;b=3/4;end; if(Designtype=3) then do;n=1;b=11/20;end; if(Designtype=4) then do;n=1;b=1/4;end; Sw=sqrt(log(CV**2+1)); if(Better=1) then do; do until(pw>=power/100); if(Designtype=1) then do;df=4*n-3;end; if(Designtype=2) then do;df=4*n-4;end; if(Designtype=3) then do;df=6*n-5;end; if(Designtype=4) then do;df=12*n-5;end; t=(abs(log(Ratio))-log(1+SM))/(Sw*sqrt(b/n))-tinv(1-a,df); pw=probt(t,df);n=n+0.01; end; end; if(Better=0) then do; do until(pw>=power/100); if(Designtype=1) then do;df=4*n-3;end; if(Designtype=2) then do;df=4*n-4;end; if(Designtype=3) then do;df=6*n-5;end; if(Designtype=4) then do;df=12*n-5;end; t=-(abs(log(Ratio))+log(1-SM))/(Sw*sqrt(b/n))+tinv(1-a,df); pw=probt(t,df);n=n+0.01; end; end; if(Designtype=1) then do;N=ceil((n-0.01)*4);end; if(Designtype=2) then do;N=ceil((n-0.01)*2);end; if(Designtype=3) then do;N=ceil((n-0.01)*2);end; if(Designtype=4) then do;N=ceil((n-0.01)*4);end; if(Designtype=1) then do;Design_Type="1. 4*2";end; if(Designtype=2) then do;Design_Type="2. 2*3";end; if(Designtype=3) then do;Design_Type="3. 2*4";end; if(Designtype=4) then do;Design_Type="4. 4*4";end; print Design_Type a[label="Test Significance Level"] Ratio[label="True Ratio of Means,u2/u1"] SM[label="Superiority margin"] CV[label="Coefficient of Variance(non-logarithmic),CV"] power[label="Power(%)"] N[label="N"]; end; finish MTE101; run MTE101(3,1,0.05,1.4,0.2,0.4,90); quit; SAS运行结果: 图1-80 SAS 9.4 关于例1-34样本量估计的参数设置与计算结果