Prediction Study of Niger-Delta Brown Fields Using Simulation Horizontal Wells Technology

S. I. Onwukwe; N. C. Izuwa; E. E. Ileaboya; K. K. Ihekoronye

[a] Petroleum Engineering, Federal University of Technology Owerri, Nigeria.

Abstract Developing brown fields by horizontal drilling is one of the most valuable technologies employed nowadays since it can maximize matured field's benefits. Using re-entry horizontal wells in brown oil fields is essential for potential successful high oil recovery. The re-entry horizontal in this research was represented by a virtual horizontal well to study the potentials of producing from brown field reservoir. The simulation paradigm studied was Black oil with light oil type variation (32 ° API). This scenario was proposed to reproduce a possible real field situation,where more oil and less water was produced. This paper compared the anticipated cumulative recoveries of the existing vertical wells to that of re-entry horizontals well in brown fields and provide a simulation prediction results for the next 4 years (2018-2022). Based on the result of this study, oil recovery can be optimized using re-entry horizontal wells.

Key words: Brown fields, Reservoir simulation, Horizontal wells

1. INTRODUCTION

Today, horizontal drilling of brown fields offers multiple advantages such as, high production rates, better drainage, lower drawdown and delay water production. Horizontal wells also provide the ability to drill more wells from a single platform in offshore fields. Many oil and gas industries applied horizontal drilling for driving better results especially in matured fields by enhancing ultimate recovery because of reaching the bypassed oil away from the offshore existing jackets reducing the needed vertical wells number and minimizing offshore and infrastructures which could effectively reduce costs and time needed for exploiting oilfields.

1.1 Literature Review

Brown fields are representing the backbone of global oil production. Brown fields produce about two thirds of global daily average oil production and this percentage is increasing with time Syed (2012). Kabir et al (2008)stated that developing brown fields having a thin oil column using horizontal wells improve hydrocarbon recovery from water and or gas-cap drive reservoirs. They confirmed that it has been widely used in recent years.Papatzacos et al (1989) observed that larger capacity to produce oil at the same drawdown and a longer breakthrough time at a given production rate as some of the advantages of using a horizontal well. Joshi (1991)noted that the purpose of the horizontal wells was to enhance well productivity, reduce water and gas coning,intersect natural fractures and to improve well economics. Applying horizontal wells in brown fields has the potential to maximize their oil recovery and improve the performance index of the wells.

1.2 Objective of the Study

· Converting the existing vertical wells of these brown fields into re-entry horizontal wells;

· Investigate horizontal well efficiency using re-entry horizontal technology;

· Compared vertical wells in the past and future of the brown reservoirs and their main controlling factors such as suitable well length, well placement, water movements and field production network capabilities.

2. METHODOLOGY

2.1. Reservoir Modelling Using Eclipse as the Simulator

ECLIPSE software was used to simulate the oil production behavior of the reservoir with vertical wells and re-entry horizontal wells. ECLIPSE is an oil and gas reservoir simulator originally developed by Exploration Consultants Limited and currently owned and maintained by Schlumberger. ECLIPSE uses the finite volume method to solve material and energy balance equations modeling. The reservoir has an area of 37, 000 feet and thickness of 40 feet. A Horizontal well was drilled in the first layer at a depth of 10040 feet and a minimum length of 200 feet. The procedures applied in this study are summarized as follows:

i. Model existing vertical well, evaluate its production performance with the aid of the ECLIPSE simulator.

ii. Model re-entry horizontal well in order to reduce draw down, water or gas coning and to improve production performance with the aid of the ECLIPSE simulator.

iii. Compare the cases of vertical wells with re-entry horizontal wells.

vi. Provide re-entry horizontal wells simulation prediction results for the next 4 years (2018-2022).

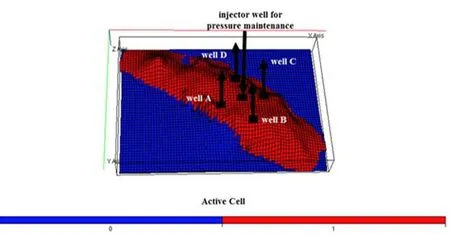

Figure 1: Reservoir model showing grids

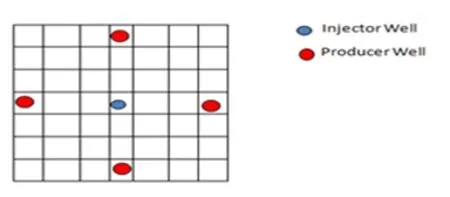

Figure 2: 5 spot pattern used in the well configuration

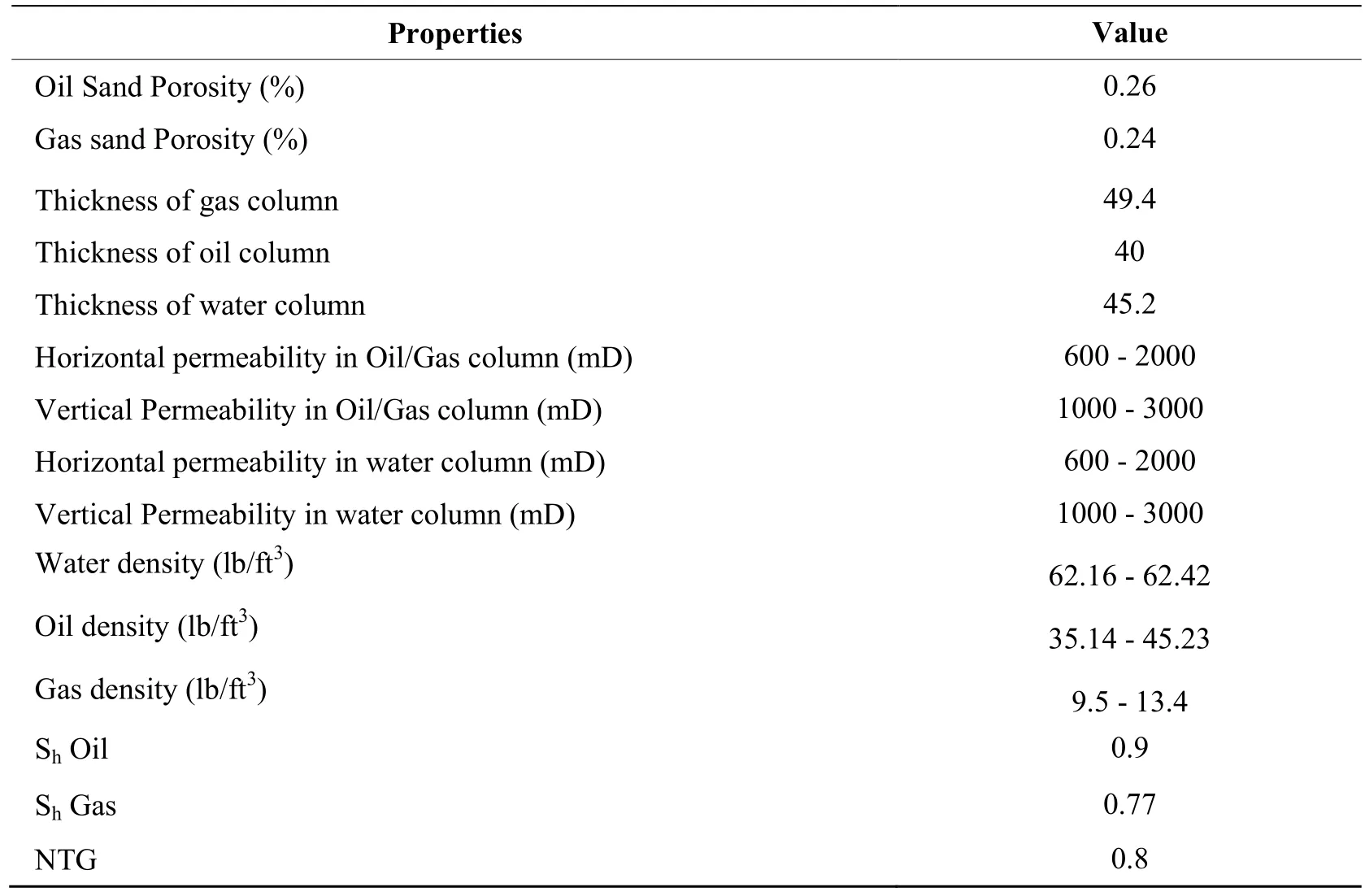

Table IRock and fluid properties of the reservoir

Continued

3. RESULTS AND DISCUSSION

3.1 Result Presentation

Figure 3: Well-X performance before re-entry work-over

Figure 3 showed the prediction study of the well from 2012-2016; it can be observed from figure 3 that the oil rate was 2000 BOPD in 2012. However, it dropped to 1500 BOPD in 2013. Oil production rate increases to 1800 BOPD in 2014. Furthermore, there was a sharp decline in oil production rate from 2014-2016. This showed that the reservoir needs to be revived in order to improve oil production rate. Water-cut was 90% in 2016 which is very high.

Figure 4: Well-X performance after re-entry work-over

The oil recovery from the new re-entry horizontal well was about 2500 BOPD in 2018 and water cut was 60%in 2022 showing a decrease in water-cut (that is well X performance before work over). The oil gain from Well-X was about 500 BOPD after re-entry horizontal well. This explains the importance of converting the vertical wells to horizontal wells as shown in figure 4.

Figure 5: Simulation Performance plot of Converting existing vertical well to re-entry horizontal well

Figure 5 showed the conversion of vertical wells to re-entry horizontal well. It can be showed from the graph that the introduction of the re-entry horizontal well helped to improve oil recovery of the thin oil rim reservoir from 2500 BOPD to 2700 BOPD and water-cut greatly reduced.

Table 2 Summary of before and after re-entry wells

Figure 6: Comparison of oil production rate over time

Figure 7: Comparison of cumulative production over time

Figure 8: Comparison of water cut over time

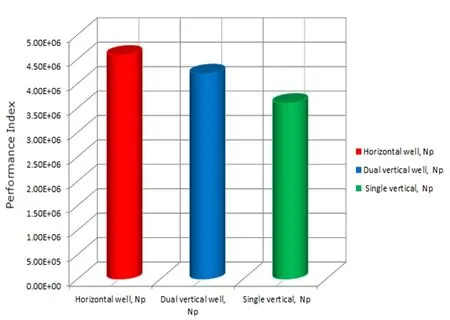

Figure 9: Cumulative oil produced (NP) performance index

Figure 10: Cumulative water produced (WP) performance index

4. DISCUSSION OF RESULT

4.1 Reservoir Simulation Model Before and After Re-Entry Horizontal Well

Table I is the reservoir rock and fluid data used in the simulation analysis to evaluate the production performance of the vertical and horizontal well technology used in brown oil reservoirs. The data are obtained from the Niger-Delta oil field. The horizontal well was not just placed arbitrarily but its optimum well placement was calculated and used. Figure 1 is the reservoir model used in the simulation work.

Figure 3 and 4 showed the results of the simulation model performance plot before and after re-entry horizontal well for existing Well-X. Figure 4 showed the conversion of vertical well to re-entry horizontal well. A good match for both oil production rate and water cut was shown on the left side part of Figure 4 from 2012 to 2016.Also, on the right side of Figure 6, the prediction period of 4 years (2018-2022) was illustrated.

However, many work-over operations were carried out to shut off the water but failed because the water was coming quickly from the bottom as conning through the high vertical permeability. The latest test conducted in July, 2015 showed an oil production rate of 1300 BOPD with about 60 % water cut, as shown in figure 3.

After a simulation conversion of the vertical Well-x to a horizontal well, the simulation prediction of the well was investigated and it was observed that Well-X was revived and oil production from the re-entry horizontal well was 2,700 BOPD and would drop to about 1,700 BOPD in 2022. Water cut was 30% till 2019 and started to increase gradually until it reached about 60%. The cumulative oil from the new re-entry horizontal well was about 4.52MMSTB and water cut only 60%. While the cumulative oil from the vertical well from the actual data was about 4.98 MMSTB and water cut about 90% as shown in figure 5. The cumulative oil gain from Well-x was about 1.34 MMSTB, and reduction in the cumulative water production was about 0.75 MMSTB (again see Table II).

4.2 Model Comparison for Re-Entry Horizontal and Vertical Wells

4.2.1 Oil Production Rate (STB/day)

Figure 6 showed the simulation result comparing the cases of re-entry horizontal well model, dual vertical wells model and single vertical well model in oil production rates over a time period of 4 years (1461 days). The result showed that horizontal well model had superior potential over vertical wells in producing oil reservoir subjected to water coning problems due to low draw-down pressure capability of horizontal well. This was responsible for the longer period of plateau production prior to water breakthrough. The horizontal well model produced at 3000 stb/day for close to 450days before showing a gradual sign of decline in production rate. The dual vertical well model delivered a combined total of 3000 stb/day (1500 stb/day each) and declined gradually almost immediately.The single vertical well model delivered 3000 stb/day liquid rate. As shown in the figure 6, the single vertical well model experienced water breakthrough rather early and so the production of oil declined sharply almost immediately. The figure showed that oil production rate for horizontal wells model may be comparable to that of equivalent number of vertical wells.

4.3 Cumulative Oil Recovery (STB)

Figure 7 showed the simulation result comparing the cases of re-entry horizontal well model, dual vertical wells model and single vertical well model for the cumulative oil recovery over a time period of 4 years (1461 days).The case models of dual vertical wells and single vertical well produced lesser cumulative amount of oil due to high draw-down pressure and the re-entry horizontal well model produced higher quotient of cumulative oil recovery over time due to the low draw-down and large surface area contact of the well with the hydrocarbon in the thin oil column.

4.4 Water Cut (Fractional Flow)

Figure 8 showed the simulation result comparing the cases of reentry horizontal well model, dual vertical wells model and single vertical well model for water cut over a time period of 4 years (1461 days). As showed in figure 9, the re-entry horizontal well model have superior performance over the dual vertical wells model and single vertical well model due to delayed water breakthrough. Very little water was produced for over 540 days before a gradual rise in the fraction of water cut as compared to the other two models which showed an almost immediate rise in the fraction of water cut. At the end of the simulation time, it was showed that the single vertical well model had the highest fraction of water cut of 70%, followed by the dual vertical well model with a with a water cut of 64%. The re-entry horizontal well model had water cut of 41%.

4.5 Performance Index

4.5.1 Cumulative Oil Produced, NP (STB)

Figure 9 showed the cumulative oil produced performance index, which was an estimate of the models capability during the simulations. Figure 10 indicated that the quotient of the re-entry horizontal well model was more capable of producing better output within the specification limits as to when compared with those of dual vertical well model and single vertical well model.

4.6 Cumulative Water Produced, WP (STB)

Figure 10 showed the cumulative water produced performance index, which was the simulation result, comparing the cumulative water produced in the reentry horizontal well model, dual vertical well model and single vertical well model. Figure 9 indicated that the quotient of the reentry horizontal well produced less water when compared with those of dual vertical well model and single vertical well model.

4.6.1 Contribution to Knowledge

A simulation approach to optimize oil production from vertical wells into re-entry horizontal wells was established in this study to revitalize the field.

CONCLUSIONS

Based on the simulation work carried out on this study, following conclusions have been drawn:

· Re-entry horizontal well technology is a proven technology.

· Re-entry horizontal well was successful in reducing the water production and increasing the oil production.

· Using re-entry horizontal wells technology in matured oil fields has a promising potential to improve oil production.

· Brown oil fields that have become thin oil reservoirs with column ranging between 20ft - 60ft should be considered for development using re-entry horizontal as against the existing vertical wells so as to revitalize the field.

· In prediction, faster water conning for vertical wells was noticed when compared with the horizontal wells.

Advances in Petroleum Exploration and Development2019年2期

Advances in Petroleum Exploration and Development2019年2期

- Advances in Petroleum Exploration and Development的其它文章

- Description of Shale Pore Fracture Structure Based on Multi-Fractal Theory

- Comparative Analysis of Abnormal Pore Pressure Prediction Models for Niger Delta Oil and Gas Fields Development

- Development of a New Model for Leak Detection in Pipelines

- Optimizing Production in Brown Fields Using Re-Entry Horizontal Wells

- Economic Analysis of Low Salinity Polymer Flooding Potential in the Niger Delta Oil Fields

- Using Shallow Platform Drilling Technology to Tap the Reserves of the Below Constructed Area of Fuyu Oilfield:Taking Chengping Block 12 as an Example