Mechanical property and deformation mechanism of gold nanowire with non-uniform distribution of twinned boundaries:A molecular dynamics simulation study∗

Qi-Xin Xiao(肖启鑫), Zhao-Yang Hou(侯兆阳), Chang Li(李昌), and Yuan Niu(牛媛)

School of Science,Chang’an University,Xi’an 710064,China

Keywords: twin nanowire,gold,non-uniform distribution,mechanical property,molecular dynamics simulation

1. Introduction

Metallic nanowires have been widely studied due to their unique physicochemical and mechanical behaviors.[1,2]Particularly,gold nanowire usually displays excellent chemical stability and good biocompatibility,which makes it possess some potential applications in biosensor,nanoscale electric and mechanical devices,and energy conversion.[3–5]One special type of grain boundary, twin boundary (TB), is a kind of planar stacking fault whose lattice structure exhibits a mirror symmetry across the boundary. The metallic nanowires with high density of TBs always display a remarkable enhancement of strength and considerable plasticity.[6–9]

The metallic nanowires with uniform distribution of TBs have been studied extensively.[10–18]Some studies[10–13]showed that the TBs can lead the nanowire to be strengthened.Furthermore, it has been revealed that the TBs provide a repulsive force for dislocation nucleation and it increases with twin boundary spacing (TBS) decreasing, so that the yielding stress is enhanced with TBS decreasing.[10,14]Meanwhile,some studies[15–18]have shown that the TBs provide a dislocation source,which gives rise to the softening effect of TBs.

The nanowires with non-uniform distribution of TBs are often obtained experimentally.[19–21]Wang et al.[19]observed the plastic deformation and fracture of twinned gold nanowires by the in-situ tensile tests. They claimed that the nanowire with ultrahigh-density twin (UDT) has better strength than that with low-density twin(LDT),but the UDT nanowire has worse plasticity. Moreover,the bimodal twin distribution with a mixture of UDT and LDT spacings was often observed experimentally. The bimodal structure leads to a compromise in strength and semibrittle fracture. However, the effects of the distributions of different TBSs on the mechanical property and deformation mechanism of twinned gold nanowire have not been systematically studied. Recently,the distribution effects of different TBSs in twinned Cu nanofilms were studied by Sun et al.[22]using the MD method. They found that the distributions of different TBSs remarkably affect the ductility of Cu nanofilms but have almost no contribution to strengthening. The initial dislocations always appear in the larger TBS region. The failure usually occurs at or near the TBs adjacent to the larger TBS. While many researches have shown that the mechanical property and deformation mechanism of two-dimensional nanofilms are quite different from those of the one-dimensional nanowires.[1,23,24]

Accordingly, the mechanical property and deformation mechanism of twinned gold nanowires with non-uniform TBs are investigated by the MD method in this work. Meanwhile,these results are compared with those of the twinned gold nanowires with the uniform distribution of TBs.

2. Computational method

The MD method is used to simulate the tensile process of twinned gold nanowires by using the large-scale atomistic/molecular massively parallel simulator (LAMMPS).[25]The embedded atom model (EAM) potential developed by Sheng et al.[26]for gold is used in this study. The velocity-Verlet integrator in time steps of 2 fs is used in the entire simulations.

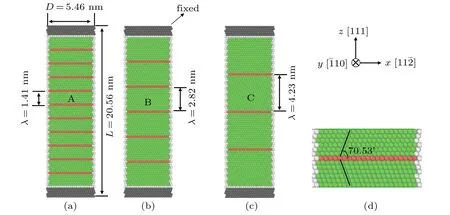

To investigate the effect of TBS, the cylindrical gold nanowires with uniform distribution of TBs are constructed as shown in Fig.1. Three types of nanowires with ultrahighdensity twin (UDT, λ = 1.41 nm), medium-density twin(MDT, λ =2.82 nm), low-density twin (LDT, λ =4.23 nm)are constructed to compare with the experimental results by Wang et al.[19]The initial configuration of cylindrical Au twinned nanowires is constructed by repeating Σ3 coherent twins along the[111]axis orientation. The length and diameter of each nanowire are 20.65 nm and 5.46 nm,respectively.

Fig.1. Configurations of cylindrical twinned gold nanowires with uniform distributions of TBSs,showing(a)twinned nanowire with TBS λ =1.41 nm,(b)twinned nanowire with TBS λ =2.82 nm,(c)twinned nanowire with TBS λ =4.23 nm,and(d)close-up view of the configuration of a TB,where TBs(HCP atoms)are shown in red color, FCC atoms are shown in green color, black color represents the fixed atoms, and cross-section diameter of nanowire is D=5.46 nm.

To investigate the effects of distributions of different TBSs, cylindrical gold nanowires with non-uniform twin(NUT) are constructed as shown in Fig. 2. Non-uniform distributions of three TBSs in the LDT (λ = 4.23 nm), MDT(λ =2.82 nm), and UDT (λ =1.41 nm), marked as A, B,and C respectively,are constructed. There are six distribution models of the three TBSs,and they are denoted as ABCCBA,ACBBCA, BACCAB, BCAACB, CABBAC, and CBAABC.The diameter of each NUT nanowire is 5.46 nm,which is the same as that in the uniform case. The length of each NUT nanowire is 20.41 nm, which is very close to that of the uniform cases. To characterize the degree of non-uniform of TBs in the NUT nanowires,the non-uniform parameter introduced in the Ref.[22]is used in this work. The degree of local asymmetry is defined as the ratio between the TBSs on both sides of a TB,and the smaller TBS is often divided by the larger one.The smaller local symmetry ratio means the larger degree of local asymmetry. In the following analysis of the plastic deformation mechanism,it is found that the plastic deformations and fractures of the six NUT samples all occur in the second or third TBS regions,thus the local symmetry ratio for the second TBs is considered in this work.

Fig.2. Six structural models of twinned gold nanowires with different spatial distributions of three TBSs. A,B,C refer to TBS of λ =1.41 nm,TBS of λ =2.82 nm, and TBS of λ =4.23 nm, respectively. (a)–(f)Samples are labelled as ABCCBA,ACBBCA,BACCAB,BCAACB,CABBAC,and CBAABC,respectively.

The crystallographic orientation of each nanowire in the x, y, and z axes are taken to be in the direction of [11¯2],[¯110], and [111], respectively. Free boundary conditions are imposed in the x, y, and z axes. Firstly, each sample is relaxed at 273 K for 100 ps to reach equilibrium state under a Nose–Hoover thermostat.[27,28]Then,these nanowire samples are axially tensioned at a constant velocity of 0.056 ˚A·ps−1along the [111] direction at 273 K under the NVT ensemble.The resulting strain rate is 1.0×108s−1. This strain rate is higher than those in usual experiments,and serves as the limitation of computational ability. To make the simulation close to the tensile loading process in experiment,[19]both ends of nanowires are fixed in this work, consisting of five atom layers. Virial stress is used to calculate the atomic stress.[29]

The microstructures of the nanowires are identified by the common neighbor analysis (CNA).[30,31]In this work, FCC and HCP are colored in green and red, respectively. Other atoms which are often located at the surface of nanowire or dislocation core are colored in grey.The TB is a single layer of HCP atoms.Two adjacent layers of HCP atoms are regarded as an intrinsic stacking fault (ISF). Two adjacent layers of HCP atoms with one layer of FCC atoms are identified as an extrinsic stacking fault (ESF).[32]The visualization software of OVITO is used to visualize the microstructure of nanowire.

3. Results and discussion

3.1. Mechanical property of twinned gold nanowire

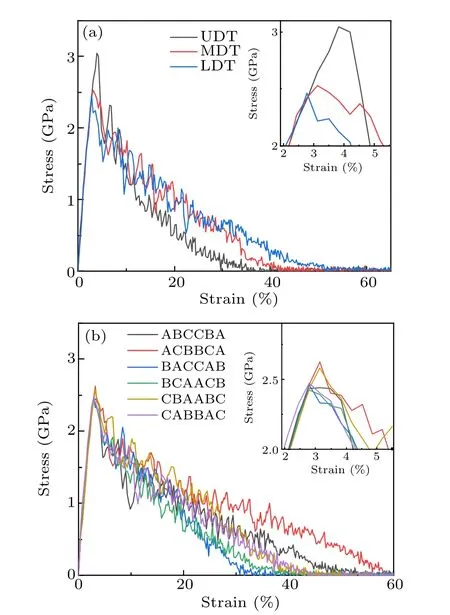

The mechanical properties of gold nanowires with different distributions of TBs are presented in Fig. 3. And some mechanical parameters obtained from the stress–strain curves are shown in Table 1. As shown in Fig. 3(a), the slopes of different stress–strain curves are the same in the elastic stage.This means that the effects of TBS and its distribution on the Young’s modulus of twinned gold nanowire are very slight.While many reports have shown that the TBS has little effect on the Young’s modulus of nanowires.[18,19,32]

From Fig. 3(a) and Table 1, it can be found the UDT nanowire has the largest yield stress but the lowest fracture strain; while the LDT nanowire shows the lowest yield stress but the largest fracture strain. This means that the strength of nanowire is enhanced with the decrease of TBS, but the plasticity is reduced. This relationship is consistent with some experimental and simulation results.[12,19]

From Fig. 3(b) and Table 1, it can be seen that six NUT nanowires change in a narrow range of 2.51 GPa–2.71 GPa,which is between the minimum value(2.47 Gpa in LDT)and the maximum value (3.07 GPa in UDT) of nanowires with uniform distribution of TBs. This indicates that the compromise in strength appears in the NUT nanowires, comparing with the case of uniform distribution of TBs. The strength of the twinned gold nanowire is mainly determined by the TBS,but the effect of its distribution is very weak. This strength compromise in NUT nanowires has also been found in the experiment on twinned gold nanowire,[19]and the simulation of twinned Cu nanofilm.[22,33]

Fig.3.(a)Stress–strain curves(a)for nanowires with UDT,MDT,and LDT,and (b) for NUT nanowires with different TBS distributions of ABCCBA,ACBBCA,BACCAB,BCAACB,CABBAC,and CBAABC,with insets indicating magnified segment of the stress–strain curves for clarity.

Table 1. Yielding stress–strains and fracture strains of twinned gold nanowires.

From Fig.3(b)and Table 1,it can also be found that the fracture strain of six NUT nanowires is in a large range of 36.9%–59.3%.The fracture strain of ABCCBA and ACBBCA nanowires with local symmetry ratio 2/3 are higher than the maximum value (55.7% in LDT) of the nanowires with uniform distribution of TBs. The fracture strain of BACCAB and BCAACB nanowires with a local symmetry ratio 1/3 are lowest, but still higher than the minimum value (35.9% in UDT)of the nanowires with uniform distribution of TBs. The fracture strain of CABBAC and CBAABC nanowires with a local symmetry ratio 1/2 are moderate among these NUT nanowires.These results indicate that the spatial distributions of different TBSs remarkably affect the plasticity of nanowires. The higher the local symmetry ratio of TBS,the better the plasticity of the nanowires will be. This is different from the case of twinned Cu nanofilm,[22]where the samples with uniform distribution of TBs have the best ductility,and the brittle fracture occurs in the NUT nanofilm.

3.2. Deformation mechanism of twinned gold nanowire

3.2.1. Effect of TBS on the deformation mechanism of gold nanowires

Figure 4 shows the evolution of microstructures of twinned gold nanowire with LDT (λ = 4.23 nm) in the uniaxial tensile process. As shown in Fig. 4(a), a dislocation nucleates at the intersection between the free surface and TBs at a strain of 2.58%, accompanied by an ISF behind, which has been observed in earlier experiments and simulations.[10–13,15,19]This dislocation spreads in the nanowire with the increase of strain and is hindered by the TBs at a strain of 2.74%as shown in Fig.4(b). At the same time,some new dislocations nucleate.When the strain is 3.01%[see Fig.4(c)],the stacking faults slide and the ISF transforms into an ESF.Due to the interaction between dislocations and TBs,the TBs are distorted and many disordered atoms form near the TBs [see Fig. 4(c)], in which the nanowire breaks when the strain reaches 55.7%.

Figure 5 shows the evolution of microstructures of gold with UDT (λ =1.41 nm) in the uniaxial tensile process. As shown in Fig.5(a),some dislocations form at a strain of 3.9%.During the interaction between dislocations and TBs,shear localization forms at a strain of 4.2% [see Fig. 5(b)], in which the nanowire breaks when the strain reaches 35.9%.

According to the above microstructure analysis of gold nanowires with LDT and UDT, it can be found that the dislocations can propagate and annihilate in the LDT nanowire and the stacking faults glide in it,due to the large space to accommodate their movement. However, there is limited space for the movement of dislocations and stacking faults in the UDT nanowire,thus resulting in the shear localization. So the twinned gold nanowire with larger TBS has better plasticity.

Fig.4. Microstructures of gold nanowire with LDT(λ =4.23 nm)in deformation and fracture process at different strains of(a)2.58%,(b)2.74%,(c)3.01%,(d)55.7%.

Fig. 5. Microstructures of gold nanowire with LDT (λ =1.41 nm) in deformation and fracture process at different strains of (a) 3.9%, (b) 4.2%, (c)35.9%,with part of Fig.5(b)magnified for displaying distribution of the shear strain.

3.2.2. Effect of distribution of TBs on deformation mechanism of gold nanowire

As the above analyses, the six NUT nanowires can be classified as three categories according to their mechanical properties and local symmetry ratios,respectively. Moreover,the nanowires belong in the same category have similar mechanical properties and deformation mechanisms, so we discuss only one case in each category to clarify their deformation mechanisms for clarity.That is,the ACBBCA,BACCAB,and CBAABC nanowires are selected. Figure 6 shows the microstructural evolutions of the three typical NUT nanowires.For the ACBBCA nanowire as shown in Fig. 6(a), the dislocation first forms in the TBS of C, and then some new dislocations form in the TBS of B. During the interaction of dislocations and TBs,many disordered atoms form near the TBs between the TBS of C and TBS of A at a strain of 15.2%. Finally,the nanowire breaks near the TBs between the TBS of C and the TBS of A.

For the BACCAB nanowire as shown in Fig.6(b),all dislocations nucleate and spread in the TBS of C. At a strain of 14.3%, many disordered atoms are formed near the TBs between the TBS of C and the TBS of A,and remarkable necking appears in the TBS of C.Finally,the nanowire breaks near the TBs between the TBS of C and the TBS of A at a strain of 38.5%.

For the CBAABC nanowire as shown in Fig. 6(c), some dislocations first form in the TBS of C,and then they gradually annihilate at a strain of 15.5%.Meanwhile,many new dislocations form in the TBS of B,and many disordered atoms form near the TBs between the TBS of B and the TBS of A.Finally,the nanowire breaks near the TBs between the TBS of B and the TBS of A at a strain of 44.8%.

Fig. 6. Microstructures of gold nanowires with NUT in deformation and fracture process, showing (a) ACBBCA nanowire at different strains, (b)BACCAB nanowire at different strains,and(c)CBAABC nanowire at different strains.

According to the above microstructure analysis of gold nanowires with NUT, it can be found that the initial dislocation always forms in the largest TBS of C. This is due to the smaller nucleation stress required to form the dislocation in the larger TBS of C.[10,17]This result is in agreement with the experimental result of twinned gold nanowire[19]and simulation result of twinned Cu nanofilm.[22,33]

A comparison of the dislocation characteristics among the three NUT nanowires shows that the dislocations move in the TBS of C and the TBS of B for the ACBBCA nanowire with a local symmetry ratio of 2/3,in the TBS of B and the TBS of C for the CBAABC nanowire with a local symmetry ratio of 1/2,and only in the TBS of C for the BACCAB nanowire with a local symmetry ratio of 1/3. And most of dislocations appear in the second or third TBS region in the plastic deformation and fracture process. The NUT nanowires with higher local symmetry ratio have larger space to accommodate the dislocation motion, so the plasticity of ACBBCA, CBAABC, and BACCAB nanowires decrease in turn.

It can also be found that the fractures of three NUT nanowires always appear at or near the TBs adjacent to the smallest TBS of A.This may be due to the larger resistance to the propagation of dislocations when they spread toward the TBs with smaller TBS.[14,22]So many disordered atoms form at or near the TBs adjacent to the smallest TBS of A,thus the necking always appears in this region.

4. Conclusions

The mechanical property and deformation mechanism of twinned gold nanowires with non-uniform TBs are investigated by the MD method. The evolutions of dislocations in the deformation process are analyzed by the structural characterization method of CNA.

It is found that both the TBS and its spacing distribution have little effect on the Young’s modulus of twinned gold nanowire. The TBS has a great effect on the strength and plasticity of nanowires, while the distribution of TBs has little effect on the strength of nanowire,but it has a remarkable effect on its plasticity. For gold nanowire with uniform distribution of TBs, its strength is enhanced with the decrease of TBS,while its plasticity declines,which is consistent with the experimental and simulation results. For twinned gold nanowire with non-uniform distribution of TBs, the compromise in strength appears,which is also consistent with the experimental and simulation results. Moreover, the nanowire with higher local symmetry ratio has better plasticity, which is different from Cu nanofilm.

It is also found that the initial dislocation always forms in the largest TBS of non-uniform twin gold nanowires,which is in agreement with the experimental result of twinned gold nanowire. The fracture always appears at or near the TBs adjacent to the smallest TBS. Few dislocations appear in the second or third TBS region of NUT nanowires in plastic deformation and fracture process. The non-uniform twin gold nanowires with higher local symmetry ratio have larger space to accommodate the dislocation motion,thus they have better plasticity.

- Chinese Physics B的其它文章

- Corrosion behavior of high-level waste container materials Ti and Ti–Pd alloy under long-term gamma irradiation in Beishan groundwater*

- Degradation of β-Ga2O3 Schottky barrier diode under swift heavy ion irradiation*

- Influence of temperature and alloying elements on the threshold displacement energies in concentrated Ni–Fe–Cr alloys*

- Cathodic shift of onset potential on TiO2 nanorod arrays with significantly enhanced visible light photoactivity via nitrogen/cobalt co-implantation*

- Review on ionization and quenching mechanisms of Trichel pulse*

- Thermally induced band hybridization in bilayer-bilayer MoS2/WS2 heterostructure∗