汽车供应链质量风险智能预警系统的开发与应用

胡健斌

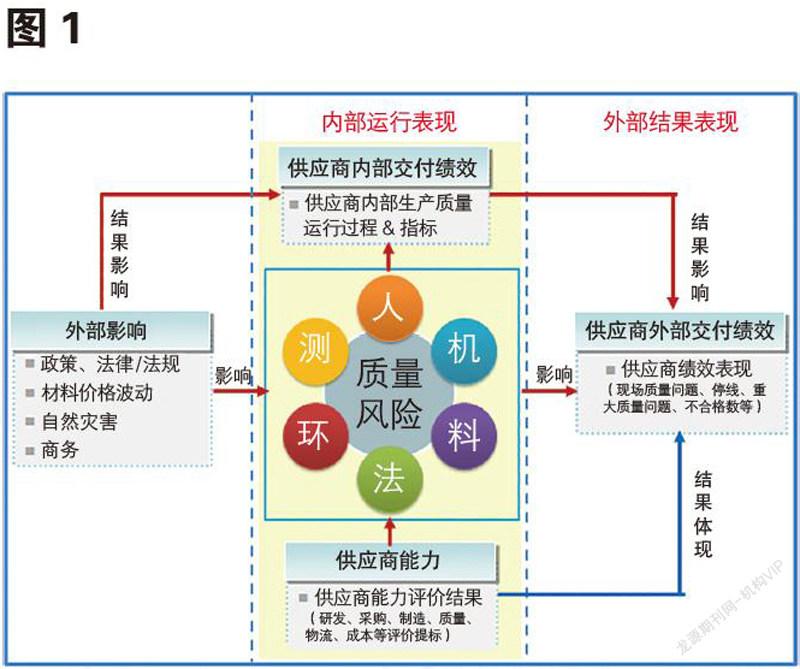

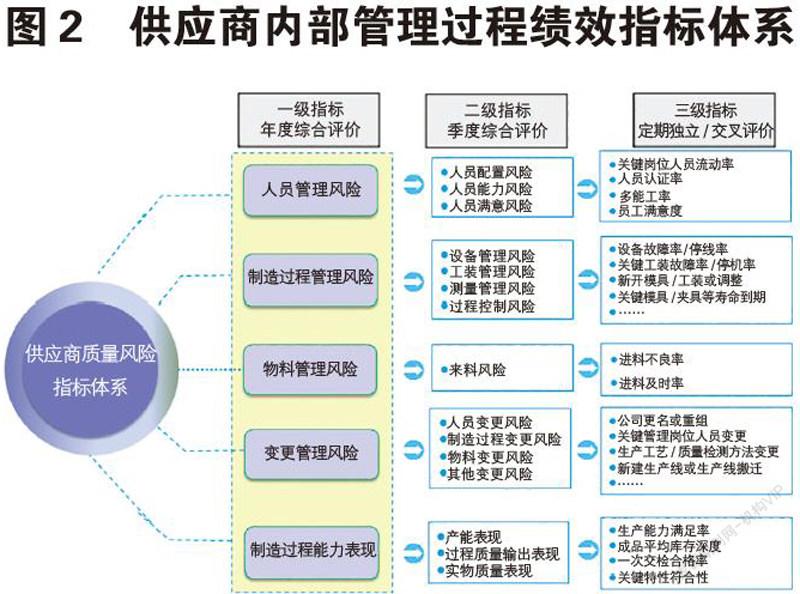

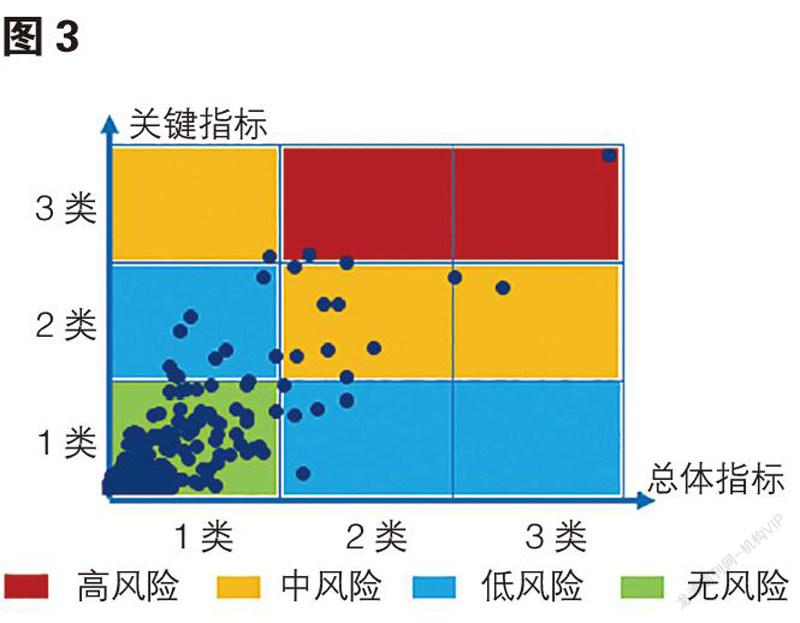

摘 要:针对汽车行业对质量风险普遍依托定性评价和考核管理,缺乏定量评估和动态监测的有效方法的痛点,开展供应链质量风险管控的研究。基于供应链链上节点企业运营过程的质量风险具有相关性、积累性和传递性等特点,形成一套集成风险定义、采集、分析、评估、预警、应对为一体的风险定向监测与准确预警的关键技术,包括质量风险指标体系、质量风险算法模型、风险预警法则;整合和挖掘供应链“产”、“销”、“存”全过程的内外部运行数据,建立供应链风险智能分析预测模型,开发汽车供应链质量风险智能预警系统,利用信息技术实现数据采集、分析计算、评估匹配、预警应对的自动化智能监测,突破原有的传统预警技术的局限,实现供应链质量风险数据定量分析与趋势预判,提高整车企业和零部件制造业的风险管控能力,降低质量损失,为汽车行业的质量风险管控提供经验借鉴。

关键词:汽车供应链 风险预测模型 风险控制方法集 风险定向监测 智能预警系统大数据

Development and Application of Intelligent Early Warning System for Quality Risk in Automobile Supply Chain

Hu Jianbin

Abstract:Aiming at the pain points that the automobile industry generally relies on qualitative evaluation and assessment and management of quality risks, and lacks effective methods for quantitative assessment and dynamic monitoring, research on supply chain quality risk management and control is carried out. Based on the characteristics of relevance, accumulation and transferability of quality risks in the operation process of node enterprises in the supply chain, a set of integrated risk definition, collection, analysis, evaluation, early warning, and response is formed to form a set of risk-oriented monitoring and accurate early warning. Key technologies include quality risk index system, quality risk algorithm model, and risk warning rules. The article integrates and mines the internal and external operating data of the entire supply chain "production", "sales" and "storage", and establishes a supply chain risk intelligent analysis and prediction model to develop an intelligent early warning system for quality risk in the automotive supply chain, and uses information technology to realize automatic intelligent monitoring of data collection, analysis and calculation, assessment matching, and early warning response, breaking through the limitations of the original traditional early warning technology, and realizing quantitative analysis and analysis of supply chain quality risk data, so as to improve the risk management and control capabilities of vehicle companies and parts manufacturing, reduce quality losses, and provide experience and reference for quality risk management and control in the automotive industry.

Key words:automotive supply chain, risk prediction model, risk control method set, risk-oriented monitoring, intelligent early warning system big data

在經济全球化的今天,汽车行业市场竞争激烈,而汽车整车零部件成本占到整车成本近85%,供应链的竞争力成为了主机厂的核心竞争优势,正如著名供应链管理专家马丁·克里斯托弗曾说:“市场上只有供应链而没有企业,21世纪的竞争不是企业和企业之间的竞争,而是供应链与供应链之间的竞争”。每个主机厂均拥有着庞大的供应链体系,供应链在主机厂经营活动中的作用及影响越来越大,零部件质量成为影响整车质量水平的关键因素。汽车供应链链上节点企业运营过程的不确定质量风险,会对企业获利、生存及发展产生影响。由于汽车制造业典型的供应链式结构使得供应链链上节点企业的质量风险具有相关性、积累性和传递性等特点,因此汽车供应链风险不仅指产品质量本身,更指供应商的制造能力、管理水平、变更控制等风险,而国内外汽车领域对供应链质量风险的研究集中在某个特定风险或供应链管理过程的某个阶段,普遍依托定性评价和考核管理,缺乏定量评估和动态监测的有效方法,对供应链质量风险的综合研究较少,如何有效控制供应链的质量风险,确保产品质量稳定输出,成为整车企业共同关注的课题。