Developing ISO International Standards for the Animal and Vegetable Fats and Oils Sector (英文原文)

Gretel BESCOBY

(1. The Federation of Oils, Seeds and Fats Associations Ltd (FOSFA), London EC2N 2DL, United Kingdom; 2. The secretariat of ISO/Food Products/ Animal and vegetable fats and oils(ISO/TC34/SC11), London EC2N 2DL, United Kingdom)

Abstract: Increasing volumes of oils and fats are produced annually with a large section that are traded internationally. The International Organization for Standardization (ISO) body develops international standards covering almost all aspects of technology and manufacturing with 23,882 standards currently published. Standards in the animal and vegetable fats and oils sector is developed by Technical Committee ISO/TC 34, Food products, Subcommittee SC 11, Animal and vegetable fats and oils. Standards are developed through consensus by national members that represent ISO in their country. Each Standard is developed within a determined timeframe and goes through various pre-determined stages such as project proposal, development, national voting and commenting on the draft Standard to final publication. ISO TC34/SC11 Standards range from sampling of oils and fats, sample preparation to analysis of its composition,the minor components, and quality and identity parameters as well as contaminants. The analysis results are used by industry for product development, labelling, research and to provide peace of mind for consumers on its safety. An important future trend is the focus on the safety concerns from either environmental contamination (e.g. mineral oils) or processing contaminants such as esters of 3-MCPDs (3-monochloropropane-1,2-diol or 3-chloropropane-1,2-diol).

Key words: animal and vegetable fats and oils; International Organization for Standardization (ISO); National Standard Bodies; time frame; standard development stages; review

1. INTRODUCTION

1.1 The animal and vegetable fats and oils industry

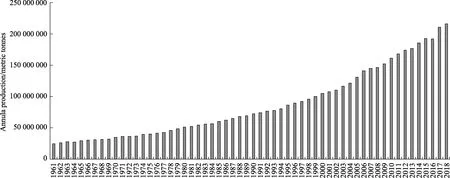

The international trade in food and agriculture has more than doubled in real terms since 1995 where the exports by emerging economies and developing countries in global agricultural and food markets have grown to more than one-third of the world total[1]. Animal and vegetable oils and fats are one of the major agricultural commodities traded internationally. Starting from low levels, exports in especially middle- and low-income countries increased, amongst others, in fats and oils with an approximate fivefold increase in lower middle-income countries and a threefold increase in low-income countries[1]. In fact, vegetable oil has one of the highest trade shares of all agricultural commodities where more than 40% of vegetable oil produced is traded internationally[2]. The growth in animal and vegetable fats and oils can be seen in Fig. 1. The total amount produced in 2018 was around 215,470,225 tonnes with 88,876,480 tonnes traded.

Fig.1 Global vegetable and animal fats and oils production since 1961

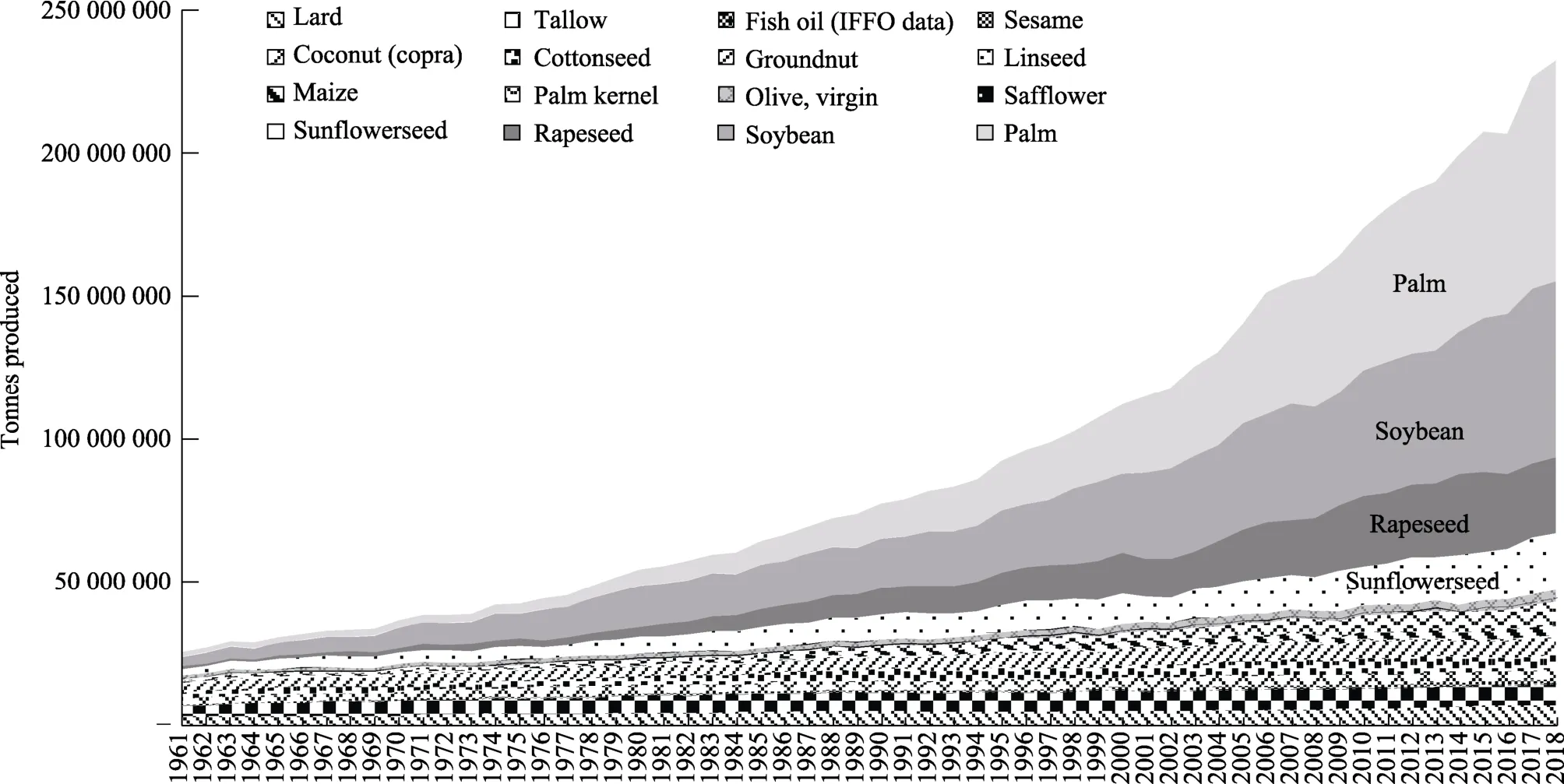

The largest increase in production volumes over the last few years are in the “Big 4” namely palm oil, soyabean oil, rapeseed oil and sunflowerseed oil (Fig. 2).

Fig. 2 Increase in global production of major animal and vegetable oils and fats since 1961

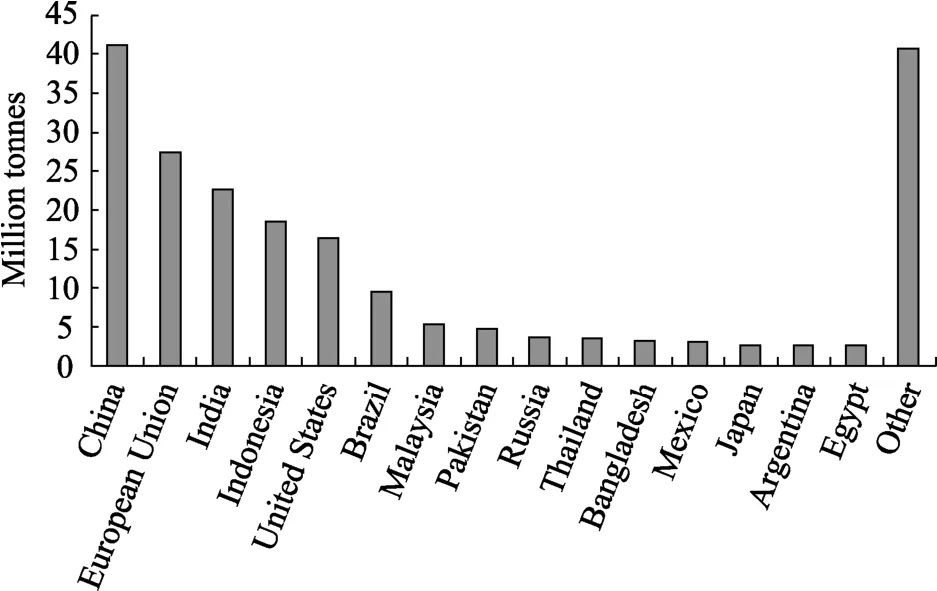

The major vegetable oil producing countries are shown in Fig. 3.

Fig. 3 Major vegetable oil producing countries (February 2020/21)

The largest vegetable oil producers are not necessarily the largest consumers of oils and fats.Countries that consume the most vegetable oils are seen in Figure 4 where China is the largest consumer of vegetable oils. The variation in volumes between countries that produce and consume fats and oils indicate significant movement of the commodity globally.

Fig.4 Domestic consumption of vegetable oils in various countries (Feb 2020/21)

1.2 International Organization for Standardization

Reliable chemical analysis of this valuable commodity is crucial for trade, producers and consumers and this is where ISO Standards are of importance. The International Organization for Standardization (ISO) develops and publishes International Standards (ISs) covering almost all aspects of technology and manufacturing and is an independent, non-governmental international organization with a membership of 165 national standards bodies. There are more than 250 Technical Committees (TCs) that represent all sectors of industry such as TCs that deal with screw threads, spacecraft, and marine technology,furniture, footwear and many more. Technical Committees may have Sub-Committees (SCs) that focusses on more specific topics within the TCs with currently up to 541 Sub-Committees within the Technical Committees.

National Standard Bodies (NSB) are members of ISO and each NSB such as SAC in China, DIN in Germany, AFNOR in France etc can select whether they would like to participate in a particular Technical Committee and/or Sub-Committee, and what their level of involvement would be.Participating-members (P-members) are actively involved and participate by voting on the standard at various stages of its development whereas Observer-members (O-members) are not actively involved and observes the standards that are being developed, offering comments and advice. ISO Standards are developed by people who use them and experts in the subject field that they work in are registered by the National Standard Body to participate in the development of ISO Standards in a specific sector. The experts have a good understanding of the needs and challenges of their sector and this helps to develop international standards that will be of benefit to everyone.International Standards ensures that consumers can have confidence that their products are safe, reliable and of good quality.

There are different types of ISO publications with the main publication types described in brief within the animal and vegetable fats and oils sector context:

•International Standards (IS):These are analysis methods that have been validated internationally to give assurance that the correct result is achieved.

•Technical Specification (TS):The method may still need additional technical work to qualify as an IS such as international validation data and may in future be published, once completed, as an International Standard. It is useful when the industry needs a method for immediate use which will be validated in future.

•Technical Report (TP): The information it contains is different from that of the previous two publications and may include data obtained from a study or an informative report.

•Publicly Available Specification (PAS): It is published to respond to an urgent market need and as with Technical Specifications,are published for immediate use and also serve as a means to obtain feedback for an eventual transformation into an International Standard.

The standards for methods of analysis of animal and vegetable fats and oils are developed under Technical Committee number “34” on “Food Products” in Sub-Committee number “11” “Animaland vegetable fats and oils” (ISO/TC34/SC11).ISO/TC34/SC11 currently has 26 Participating Members (P-members) and 31 Observing Members(O-members). Apart from the National Standard Organisation members, the sub-committee also have 11 Category A liaison members with other industry organisation such as the AOCS (American Oil Chemist’s Society); IOC (International Olive Council); FOSFA (Federation of Oils, Seeds and Fats Associations) and others who have an interest in the development of Standards in Fats and Oils and actively contribute to projects. The three categories of liaison members are Category A(active participation and contribution), Category B(observe development of work) and Category C(participate in a specific Working Group only).

The Sub-Committee is managed by the committee secretariat that consists of the Chair, who should have good technical knowledge of the subject field as well as general understanding of current developments in the subject, and the Committee Manager, who should be familiar with the ISO processes and procedures. Support is also given by the ISO/TC34 Technical Programme Manager and Committee Manager as well as by ISO Central if necessary.

ISO/TC34/SC11 currently have 85 published International Standards and four Technical Specifications with five projects currently actively under development and two projects at the preliminary stage.

Typically, a new Standard is developed when there is a request from industry or other stakeholders such as consumer groups who communicate the need for a standard to their National Member Body who then contacts the relevant Committee or Sub-Committee in ISO and the process to develop a new Standard starts. It usually takes about 3 years to develop a standard from first proposal to final publication.

2. THE PRINCIPLE AND REQUIREMENTS FOR DEVELOPMENT OF STANDARDS

Any new work proposed in ISO/TC34/SC11 should be relevant to the market, and therefore,either solve a problem experienced in the industry or respond to a specific need in the market. The proposer (typically the National Standards Body)must complete a new work item proposal form which includes justification of why the market needs the standard and in whose interest development of the standard will be. Stakeholders such as industry and commerce; governments;consumers; academic and research bodies who have an interest in the development of the Standard and who may be affected by it should be approached about the relevance of the proposed work and if it would bring value to the end users. In addition, it is important to know if stakeholders may be willing to participate in the development of the new work.

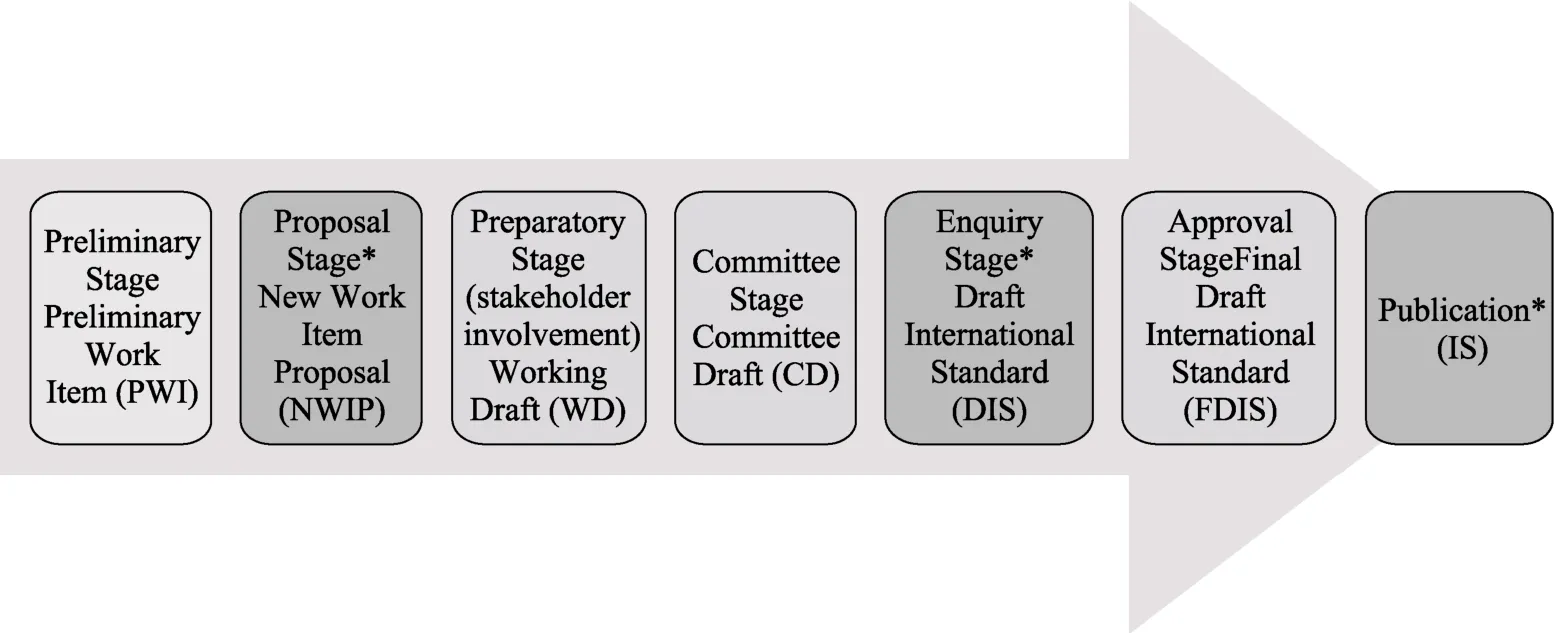

At the start of the project (or development of a standard) the period of time needed to complete the work is agreed. ISO has three set timeframes for the development of a standard, namely, 18, 24 or 36 months. Within the agreed timeframe, the project passes through various process stages with target dates for each stage to publication. A project leader is appointed by the committee for each standard development project, often as per the nomination of the project leader made by the proposer of the new work item proposal.

The process stages to develop a standard is illustrated in Fig. 5.

Fig.5 Stages in ISO standard development

2.1 Preliminary stage

A work item that is still an idea and is not yet sufficiently developed to start and go through the various stages can be registered as a Preliminary Work Item (PWI) as agreed by a simple majority vote of the P-members. This stage will give time for initial development work, the elaboration of the new work item proposal and the preparation of an initial draft. A preliminary work item must progress to the proposal stage within 3 years or it will be cancelled.

2.2 Proposal stage

The first step in the development process is to confirm that a new International Standard in the subject area is needed. The proposer of the project submits the new work item proposal (NP) to the committee for vote using the specified form (Form 4). The nominated project leader (PL) named on the proposal should act in purely neutral capacity and is responsible for the development of the project. The committee is generally given 12 weeks to return their votes on approval or disapproval of the new proposed project via the ISO electronic balloting portal.

The new work is approved if 2/3 majority of the P-members of the SC11 subcommittee votes their agreement on the development of the standard.There must also be commitment to actively participate in the development of the project where at least 5 P-members nominated technical experts to contribute to the preparation stage and to comment on the working drafts. Member bodies who voted against the development of the project should give a reason why they did not approve it.

The ISO/TC34/SC11 Committee Manager reports the result of voting to the ISO Central Secretariat (using Form 6). Once a proposed new work item is accepted it is registered in the ISO/TC34/SC11 work programme as a new project with the decided timeframe and agreed target dates for each stage within the timeframe.

2.3 Preparatory stage

During the preparatory stage the working draft(WD) is prepared with collaboration of the experts/stakeholders until they are satisfied that the WD is complete to the best of their knowledge.Once the WD has been finalised the project leader may recommend to the committee which stage to go to next, either Committee stage or directly to the Enquiry stage. The committee decide by vote,through a ballot, if they are confident that the WD does not need further development and that the ballot on the Committee Draft can be skipped and consequently the WD is submitted directly to the Enquiry stage.

A very important part of ISO/TC34/SC11’s Standard development is the validation of the method. The international validation study can be undertaken at any stage once the method procedure has been finalised. Validation is essential to demonstrate that the method is fit for purpose,results are consistent and that the analytical results are comparable between analysts, laboratories and countries. It is also important to make sure that the written method procedure is clear to all users.

It is not within the scope of this article to discuss the details of the validation studies but generally more than 8 laboratories should participate (preferably 10~12) from various locations and if possible, around 5 or more countries to demonstrate the international suitability of the method. At least 5 samples representing different matrixes or oil types should be included in such a study. Guidance on the performance of validation studies can be found in Horwitz, 1995 and ISO 5725-2:2019-Part 2: Basic Method for the Determination of Repeatability and Reproducibility of a Standard Measurement Method[3-4]. The project timeframe will be paused while the validation study is in progress. The validation data can be included in the WD or CD stage but should be included at the time of the Enquiry stage (DIS).

2.4 Committee stage

This is an opportunity for the members of the ISO/TC34/SC11 subcommittee to comment on the Working Draft and agree whether the draft is ready to move to the next stage for publication. The Working Draft is circulated to all P-members and O-members via an 8 week long ballot who then comment and vote using the ISO Electronic Balloting Portal.

The CD stage is optional and may be skipped if the Project Leader decides to do so following a consultation with the nominated experts. The committee takes the final decision through an internal ballot.

It is also important to keep in mind that any graphics such as chromatograms and illustrations need to be submitted to ISO in a specific format.Obtaining the images with the correct format should be started early on in the development stage to ensure there are no delays once it gets to the publication stage. The most important factor is to provide revisable (vectorized) image files.

All comments received during the CD Ballot must be addressed and the action taken on each of the comments must be indicated and the draft Standard revised accordingly. The Committee Manager along with the Chair of the committee and,if necessary the Project leader, decide on the next stage depending on the outcome of the ballot. If the draft is not quite ready for publication and many technical comments had been received it may be best to circulate a revised committee draft for consideration or discuss the draft and comments at the next meeting. Should the committee decide by consensus that the draft is ready for the next stage,the draft can be prepared for submission for the Enquiry stage.

2.5 Enquiry stage

The enquiry draft, Draft International Standard(DIS), is submitted to the ISO office of the Central Secretariat (ISO/CS) by the Committee Manager for circulation to all ISO National Member Bodies who then have 12 weeks to vote and comment on it.Votes submitted by the National Member Bodies shall be specific on the question “Do you approve the draft for publication?” and can be either “approval;disapproval or abstention”. An “Approve” vote may be accompanied by editorial or technical comments and a “Disapprove” vote must be accompanied by the technical reasons for the negative vote.

The DIS is approved for publication if two-thirds of the P-members of the subcommittee are in favour and not more than one-quarter of the total number of votes cast are negative.

If the DIS is approved and no technical changes are required in the draft, it will go straight to publication. However, if technical changes are needed, the Final Draft International Standard(FDIS) stage is mandatory.

A full report is prepared by the secretariat and circulated to the National Member Bodies which includes the voting result, the decision made by the Chair whether to proceed to publication, or not, as well as the comments received along with the observation by the secretariat on the comments. If the DIS does not meet requirements for publication it can also be published as a Technical Specification(TS) or Publicly Available Specification (PAS) after agreement by the committee.

2.6 Approval stage

The Approval Stage will be automatically skipped if the DIS has been approved and there were no technical changes required. Technical changes would be amendments to the method and how the method is performed.

If there were technical changes required following the DIS stage, the FDIS Stage would be mandatory. In that case, the Final Draft International Standard (FDIS) is submitted to ISO/Central Secretariat (ISO/CS) by the Committee Manager who circulates it to ISO’s National Members for an 8 week vote. Similar to the DIS, the standard is approved if two-thirds of the P-members of the subcommittee are in favour and not more than one-quarter of the total number of votes cast are negative. Similar rules apply for the voting as for the DIS stage and votes submitted by the National Member Bodies shall be either “approval; disapproval or abstention” in response to the question “Do you approve the draft for publication?”. Comments may be submitted on the FDIS although no technical changes can be made at this stage.

The approval stage ends with the circulation of the voting report stating the decision of the committee. The decision could be that the FDIS has been approved for publication as an International Standard, or needs to be resubmitted, either as a modified committee draft, an enquiry or a final draft,or alternatively to be published as a Technical Specification or a Publicly Available Specification.In the worst case scenario, the project should be cancelled.

2.7 Publication stage

The Committee Manager submits the final documents of the DIS, or FDIS if performed, to ISO/CS for publication. Only editorial corrections can be made to the final text. Committee Managers and project leaders have the opportunity for a final two review period before the standard is published.Once approved, the standard is published by the ISO/CS as an International Standard.

2.8 Review

Standards are reviewed every five years after publication to ensure that they remain up-to-date and globally relevant through an automatically generated Systematic Review process. ISO/CS asks National Member Bodies in the Systematic Review ballot whether the Standard is still used and is relevant in their country and if it should be updated or even possibly withdrawn. The P-members of a committee or subcommittee (such as TC34/SC11)are required to vote on all systematic review ballots.Any outstanding technical comments received on the Standard during the final publication or afterwards is reviewed and addressed if necessary.

All comments obtained at the Systematic Review are reviewed by the secretariat as well as the project leader and, if necessary, may result in the revision of the standard if agreed by the P-members of the sub-committee. In case a revision is necessary, the committee will pass a resolution containing the target dates, confirmation that the scope will not be expanded, and identify the project leader after which a project would be registered to initiate the work.

3. STRUCTURE OF ISO INTERNATIONAL STANDARDS

The drafting of ISO International Standards is made easier by the provision of a template that is a document “skeleton” which incorporates predefined stylistic and structural rules. A Model document of an International Standard, namely the “Rice model”(not a real standard), is also available which provides notes, examples and guidance at each section of the standard.

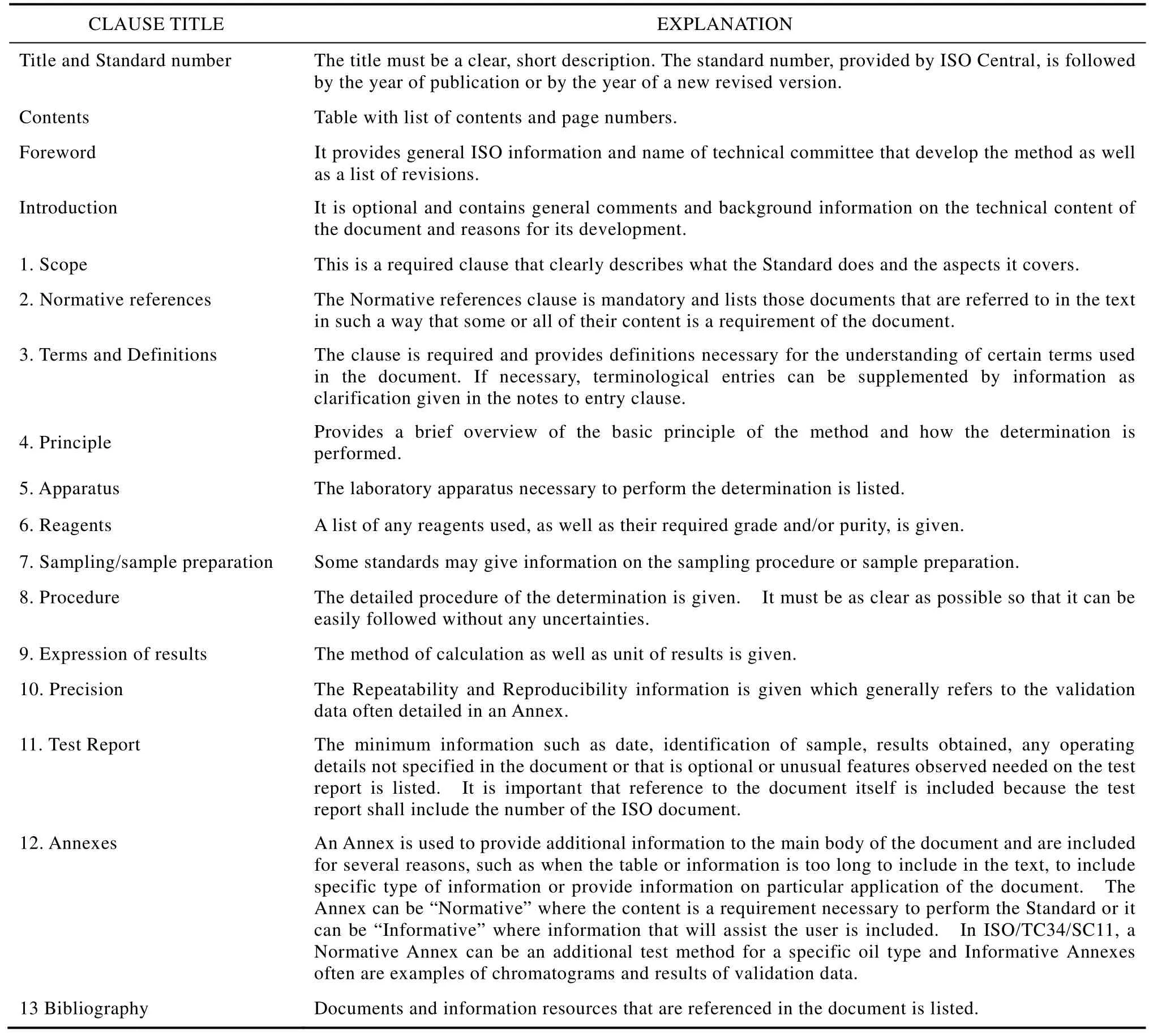

The basic structure of standards under ISO/TC34/SC11 are shown below in Table 1. There may be variations on the format and only the structure generally used within ISO/TC34/SC11 is described.

Table 1 Basic structure of International Standards developed under ISO/TC34/SC11

These details give an example of the structure of a standard in TC34/SC11 but not all the clauses are necessarily included in each standard. The Title and Standard number; Contents; Foreword; Scope;Normative References and the Terms and Conditions are required and the clauses after that may vary depending on the standard.

4. THE APPLICATION OF STANDARDS

The world population is continuing to grow and it is a challenge to meet the rising demand for safe food. As indicated in the section above, the trade of food and agriculture has more than doubled since 1995 and fats and oils is one of the food commodities that has one of the highest trade shares of production of all agricultural commodities. The large trade in fats and oils means that the commodity repeatedly crosses national borders from initial extraction to consumption in the final product and needs to meet various safety and quality standards along the way. For instance, it is important to ensure that crude soybean oil shipped from the USA to Rotterdam arrives in the agreed quality and safety condition. The oil is then sent to another country for production in, for instance margarine, and needs to comply with specified composition requirements such as fatty acid composition and once processed and incorporated into the final product must be safe without processing contaminants and the amount of sterols and/or antioxidants added must be known.Producers also want good quality raw material to ensure a long shelf life of their final product.Traders, producers, consumers and regulators in all countries that trade and consume and produce products from oils and fats need reliable methods specifically for fats and oils.

A standard is not a law and is generally voluntary but can become compulsory when it is required by law or legislation, in trade contracts or is part of certification as illustrated in the scheme in Figure 6[5].

Fig. 6 The status of standards for different purposes (Cantrill, 2020)

International trade organisations such as FOSFA International (Federation of Oils, Seeds and Fats Associations) use ISO Standards in their standard contracts for the shipping of Oils and Fats.FOSFA contracts are used for around 85% of oils and fats shipped internationally. There are specific contractual methods to determine specifications of the cargo and most of the methods are ISO Standards as it is considered to be reliable internationally validated methods that will ensure consistent results independent of the location and laboratory who performs the analysis. Traders often require certain quality parameters on a shipment such as free fatty acids or impurities content in their trade contracts. Another very important parameter is the determination of conventional mass per volume as this provides the basis for the weight determination of the traded cargo. Using reliable internationally developed standards in conjunction with accredited laboratories give confidence that the results are trustworthy.

ISO standards are developed independently by the industry internationally and is therefore impartial and perfectly suited to assist producers to meet legal and regulatory requirements. For example, the levels of environmental contaminants such as polycyclic aromatic hydrocarbons (PAH),heavy metals, benzo[a]pyrene, dioxins and polychlorobiphenyls (PCBs) needs to be monitored and the formation of processing contaminants such as trans fatty acids, 3-monochloropropanediol(3-MCPDs) and glycidyl esters needs to be controlled. There is often more focus on specific oil types as some environmental contaminants are more common in oils such as grapeseed oil, coconut oil,pomace olive oil and sunflower oil that are more likely contaminated by PAHs because of the way that the raw materials are dried often at too high temperatures[6].

Determining the authenticity of high value oils and fats such as olive oils and some fish oils containing high levels of eicosapentaenoic acid(EPA) and docosahexaenoic acid (DHA) is very valuable to the trade and consumer. For instance,there are various designations for olive oil such as extra virgin olive oil, virgin olive oil, refined olive oil, olive pomace oil and various methods have been developed specifically for olive oil to be able to differentiate between these various olive oil types.ISO/TC 34/SC11 works closely together with the International Olive Council (IOC) and have adopted and incorporated many of the IOC methods into the ISO format as ISO/TC34/SC11 Standards.

ISO standards in animal and vegetable fats and oils also address issues relevant to consumers such as nutritional labelling where the saturated fat content or omegas-3 fatty acids contents are labelled as well as the amount of food additives such as antioxidants added and more. They give consumers the peace of mind that comes with knowing the food they consume meets high standards for safety and quality and contains what it says on the packaging.

Regulators also need to know that reliable test methods are available should they implement maximum limits for contaminants or list certain quality parameters as part of their regulation. The contaminant methods need to be able to accurately determine the contaminant content at the level required according to the regulation.

More than 40% of the ISO/TC34/SC11 standards are related to the quality of fats and oils and around 30% of the standards are relevant to the composition and characteristics of the product. The composition and characteristics are often used in the authentication of fats and oils. Currently, 17% of the standards determine industrial, environmental and processing contaminants in fats and oils and a few standards are on procedures such as sampling of oils and fats, which is extremely important to obtain a representative sample for contractual and contamination purposes.

5. TRENDS OF FUTURE WORKS IN ANIMAL, MARINE AND VEGETABLE FATS AND OILS

The increasing focus on health and well-being and more discerning consumers that demand authentic, good quality food that is safe increases the need for reliable international standards to determine the required health, quality, safety and authenticity parameters. ISO/TC34/SC11 will focus on developing methods as required by the industry amongst them the characterisation of oils by determining the fatty acids in the sn-2 position of triglycerides. Olive oil is a high value product and methods are constantly evolving to differentiate between categories of olive oils and its quality.

At the same time consumers prefer natural foods and are moving away from synthetic additives such as synthetic antioxidants which has been used for many years. Methodology to determine trace levels of synthetic antioxidants in vegetable oils will be improved.

In order to comply with the demand for safe food, the contamination of oils from environmental and external sources are constantly monitored. Fats and oils processing procedures are continuously modified and improved to ensure optimal reduction and removal of contaminants as well as to reduce the risk of formation of processing contaminants.Instrumentation and analyses have improved dramatically over the last few years where contaminants are now detected at increasingly low levels, in many instances much lower than was previously thought possible. The focus of future work will be on the emerging contaminants such as plasticisers (phthalates), mineral oil hydrocarbons and the processing contaminants 3-MCPD esters and glycidyl esters. These are not single component contaminants but rather a range of constituents in each contaminant group which poses challenges when it comes to mitigation and analysis. The methodology as well as the speed of analysis needs to improve to meet processing quality control conditions and once reliable internationally validated methods are in place, regulations may follow for those contaminants that do not already have regulations. Increasing awareness of the presence of possible naturally occurring contaminants such as aflatoxins in popular cold pressed oils such as peanut and sesameseed oils also require the development of a reliable analysis method.

ISO/TC34/SC11 will continue to develop standards when a need is highlighted by the industry as well as review current standards to ensure that they are relevant and up to date. The industry and stakeholders’ involvement are crucial to ensure that international standards are developed to serve the ever-changing landscape and demands of our industry.