Achieving High Light Uniformity Laser-driven White Lighting Source by Introducing Secondary Phases in Phosphor Converters

DENG Taoli, CHEN Hexin, HEI Lingli, LI Shuxing, XIE Rongjun

Achieving High Light Uniformity Laser-driven White Lighting Source by Introducing Secondary Phases in Phosphor Converters

DENG Taoli1,2, CHEN Hexin1, HEI Lingli1, LI Shuxing1, XIE Rongjun1

(1. State Key Laboratory of Physical Chemistry of Solid Surfaces and Fujian Key Laboratory of Surface and Interface Engineering for High Performance Materials, College of Materials, Xiamen University, Xiamen 361005, China; 2. College of Chemistry and Chemical Engineering, Anshun University, Anshun 561000, China)

Laser-driven white lighting sources have great potential for applications with super-high brightness, high directionality and long distance illumination, but are usually limited by their poor uniformity due to mismatch between blue laser light and phosphor converted light. In this work, a secondary phase of TiO2, BN, Al2O3or SiO2was introduced as scattering media in the Y3Al5O12: Ce3+(YAG) phosphor-in-glass (PiG) film to regulate the light path, where the optimum concentration of the secondary phase was determined, respectively. The images of illumination and speckle, angular distributions of luminance and color temperature, as well as optical properties of the white light produced by the different secondary phases based-YAG PiG films were investigated. The light uniformity in luminance and color temperature is greatly improved by introducing secondary phases, among which TiO2is demonstrated as the best one as it has the largest relative reflective index. In addition, the YAG-TiO2PiG film has the largest luminance saturation threshold of 20.12 W/mm2and the highest luminous flux of 1056.6 lm under blue laser irradiation. This work paves an avenue to choose appropriate scattering media in PiG films for realizing more uniform and brighter laser-driven white lighting source.

light uniformity; laser-driven white lighting source; scattering; phosphor-in-glass film; optical properties

Given the laser diodes (LDs) can bear a much higher input power density than light-emitting diodes (LEDs), laser-driven solid state lighting by combining blue LDs with phosphor converters promises super-high-brightness[1-3]. Till now, extensive investigations have been devoted to optical performances of laser-driven lighting sources, such as luminous flux, luminous efficacy, correlated color temperature (CCT) and color rendering index (CRI)[4-7], but the light uniformity receives much less attentions. In fact, the uniformity of the lighting source is an extremely important parameter for the safety uses in some special fields, including high-beam headlamps and endoscopy[8-9].

Generally, laser light presents a Gaussian distribution (, high energy in the middle and low energy at the edge), and the phosphor converted light follows a Lambert curve (, a uniform spherical cosine emitter). This difference usually yields uneven spatial distribution of the emitted light when they are mixed. Moreover, the blue laser light has a strong emission intensity and high directionality, leading to much poorer angular color uniformity. Therefore, the “blue circle” or “yellow ring” is often observed in the laser-driven white light[10-11].

Many efforts have been made to improve the mixing uniformity in white LEDs, for example, SiO2or TiO2particles are used as the secondary phases in phosphor layers to enhance the light scattering, which then improves the uniformity of angular CCT[12-15]. Meanwhile, optical software simulations are applied to understand the effect of scattering media, such as CaCO3, CaF2, SiO2and TiO2, on the light uniformity of white LEDs[16]. As far as we know, there are still few studies on regulating the microstructure of the phosphor converter for obtaining a high uniformity laser-driven white lighting source. In addition, the methods for evaluating the light uniformity have not been systematically established.

In this work, we attempt to introduce a secondary phase (., TiO2, BN, Al2O3or SiO2) as scattering media in YAG-PiG films to improve the light uniformity of laser-driven white lighting source. Analyses of the illumination and speckle images, illuminance curve, luminance and CCT distributions of the different secondary phases based-YAG PiG films under blue laser irradiation have been done to evaluate the optical quality of the white light. This work lays a foundation for regulating the light path in phosphor converters that enable to create high performance laser-driven white lighting sources.

1 Experimental

1.1 Materials

Y3Al5O12: Ce3+(YAG, Rhonda Fluorescent Materials Co., Ltd., China), Al2O3(TAIMICRON, Japan), TiO2(Zhongnuo New Material Technology Co., Ltd., China), BN (AI LAN, China) and SiO2(Sinopharm Chemical Reagent, China) are commercially available. The glass powder SiO2-Al2O3-Na2O-CaO-TiO2(XinghaiGaoke Non- metallic Mining Material Ltd., China), used as the binder, has a particle size of 1.8 μm and a softening temperature of 650 ℃. A certain proportion of ethyl cellulose (Aladdin, China, CP), terpineol (Xilong Scientific Co., Ltd., China, AR) and 2-(2-butoxyethoxy) ethyl acetate (Aladdin, China, 98%) were fully mixed at 80 ℃ for 10 h to prepare the organic vehicle. The single crystal sapphire plates (SA) with a size of 10 mm×10 mm×0.3 mm are commercially available (Crystal-Optiech, China).

1.2 Fabrication of PiG Films

The YAG, YAG-TiO2, YAG-BN, YAG-Al2O3and YAG- SiO2PiG films were produced by using a blade-coating method. The phosphor slurry was prepared by fully admixing YAG, glass powders, organic vehicles, and the scattering medium (, Al2O3, TiO2, BN or SiO2) in an agate mortar. The weight ratio of the YAG phosphor to glass powder (PtG ratio) was fixed at 3:7, and the secondary TiO2, BN, Al2O3or SiO2was added with the optimal contents of 20%, 25%, 30% and 30% in mass relative to the phosphor, respectively (Fig. S1, Table S1). The evenly mixed slurry was blade-coated on the SA substrate with a film thickness of 35 µm. Finally, all films were heat-treated at 120 ℃ for 60 min to volatilize the organic glue, and then fired at 650 ℃for 10 min in a Muffle furnace.

1.3 Characterizations

The microstructure and elemental mappings were obtained by using a field-emission scanningmicroscope (SEM, SU70, Hitachi, Japan) equipped with an energy dispersive X-ray spectroscope (EDS, X-MaxN, Oxford

Instruments, UK). The emission spectra and decay curves were measured by using the fluorescence spectrometer (FLS980, Edinburgh Instruments Ltd, UK). The speckle images were captured by a CCD camera (ARTCAM- 0134AR-WOM Series) under the excitation of blue laser (em=445 nm). The luminance uniformity and the light spot diameter were measured in a transmissive configuration by using an imaging colorimeter (IC-PMI16- XBND3, Radiant Zemax, USA) under a laser power of 0.015 W. The optical properties of all PiG films under high power density laser irradiation were measured in a transmissive configuration by using a sphere-spectroradiometer system. This system specially consists of a high-power blue laser light source (LSR445CP-FC-48W,Lasever, Ningbo, China) and an integrating sphere (diameter of 30 cm, Labsphere) that is connected to a CCD spectrometer (HR4000, Ocean Optics). The incident laser spot has a nearly circular area of 0.5 mm2. The optical power of the blue laser, controlled by the input current, was measured with a laser powermeter (LP-3C, Physcience Opto- Electronics, Beijing, China). The uniformity of color temperature was tested by using an optical test platform from different angles in the range of 10°~170°. The measurement platform consists of an incident blue laser, a sample stand, a semicircular protractor with a radius of about 30 cm, and a spectral color illuminometer (SPIC- 200, Everfine, China). The temperature of the light spot was measured by using an infrared (IR) thermal imager (TIX580, Fluke, USA).

2 Results and discussion

2.1 Morphologies of YAG-based PiG films

The cross-section and top-view SEM images of YAG, YAG-TiO2, YAG-BN, YAG-Al2O3and YAG-SiO2PiG films are shown in Fig.1. All of the phosphor layers with different scattering media (TiO2, BN, Al2O3, SiO2) are uniform with a thickness of 35 μm, where the phosphor particles are well-distributed in the glass matrix. A amount of pores are detected in the YAG-TiO2, YAG-BN and YAG-SiO2PiG films, but the YAG-Al2O3PiG film is smooth and compact, which is probably due to the excellent wetting behavior of Al2O3particles. The SEM-EDS mappings show that TiO2is evenly distributed around the YAG phosphor particle, and no interfacial reactions occur during the firing process, evidenced by the smooth boundary between YAG particles and the glass matrix (Fig.1(k-o)). It is also true for other secondary phases. In addition, the photoluminescence spectra and lifetime of YAG-PiG films are not affected by adding the secondary phases (Fig. S2).

Fig. 1 (a-e) Cross-section and (f-j) top-view SEM images of (a, f) YAG, (b, g)YAG-TiO2, (c, h) YAG-BN, (d, i) YAG-Al2O3, (e, j) YAG-SiO2 PiG films; (k-o) SEM image of the selected area of the YAG-TiO2 PiG film and corresponding EDS mappings of Y, Al, Ca and Ti

Fig. 2 (a-e) Illumination images of laser-driven white light sources from YAG, YAG-TiO2, YAG-BN, YAG-Al2O3, and YAG-SiO2 PiG films under excitation of a laser power density of 1.72 W/mm2, and (f-j) speckle images of YAG, YAG-TiO2, YAG-BN, YAG-Al2O3, and YAG-SiO2 PiG films under 445 nm laser excitation

2.2 Uniformity of the laser-driven white light

The laser-driven white lighting sources were fabricated by pumping the YAG, YAG-TiO2, YAG-BN, YAG-Al2O3or YAG-SiO2PiG film with blue laser at a power density of 1.72 W/mm2, and their light uniformity is preliminarily evaluatedillumination images (Fig. 2(a-e)). An obvious “blue center” is observed from the YAG PiG film without the addition of secondary phases, and the brightness of the spot center is much higher than that at the edge. By contrast, the light becomes uniform when the YAG-TiO2, YAG-BN, YAG-Al2O3or YAG-SiO2PiG film is used. Further, the light uniformity was detected by the speckle analysis from a CCD detector, as shown in Fig. 2(f-j). It is clear to find that the speckle is serious for the YAG PiG film, and it can be eliminated to some extent with the introduction of TiO2, BN, Al2O3or SiO2. Among them, the YAG-TiO2PiG film has the best uniformity, followed by the YAG-Al2O3and YAG-BN PiG films.

In addition, the luminance uniformity of the light spot was further evaluated by using the imaging colorimeter (Fig. 3(a)). The luminance of 6×6 matrix points was measured for each light spot. The luminance standard deviationcan be calculated with the formula (1):

Fig. 3 (a) Luminance of light spots in YAG, YAG-TiO2, YAG-BN, YAG-Al2O3, and YAG-SiO2 PiG films under excitation with a laser power of 0.015 W, respectively, (b) luminance distribution curves along the light spot diameter, and (c) photograph of the light spot at a distance of 10 m when the YAG-BN PiG film pumped by a blue LD

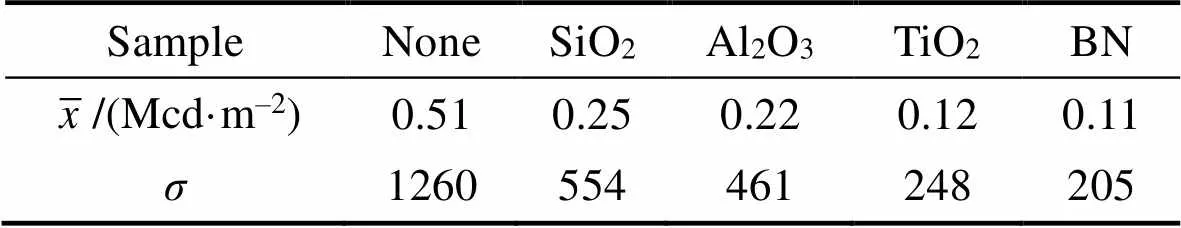

Table 1 Luminance uniformity of YAG-based PiG films with different scattering media

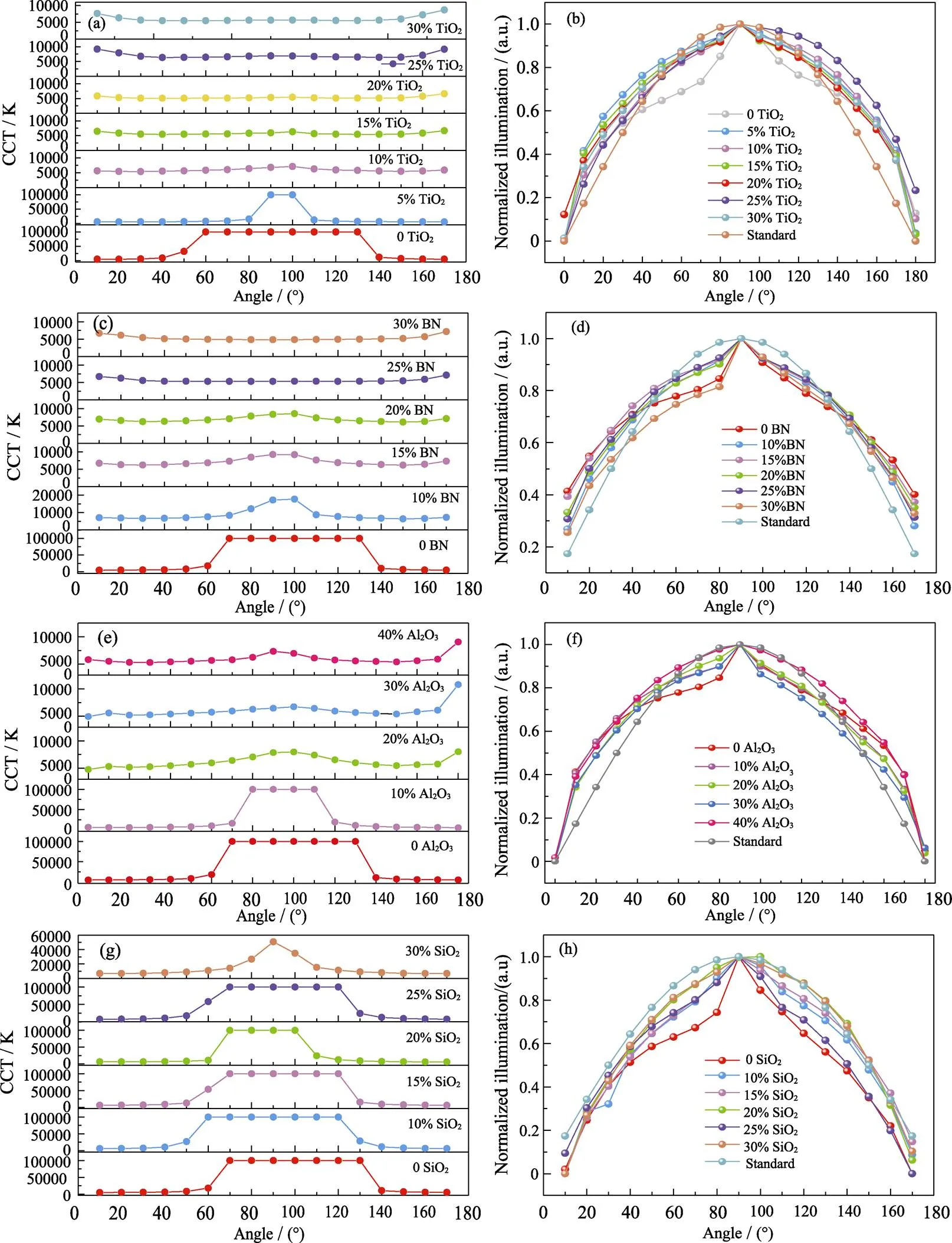

Further, the light uniformity was evaluated by the CCT and illuminance distribution curves of the white light source at different angles (10°~170°). The “blue center” of the YAGPiG film is reflected by higher CCT values at the center (Fig. 4(a)). The CCT uniformity (Uni) can be defined as the ratio of the minimum CCT (min) to the average CCT (ave), as given in formula (2):

As summarized in Table 2, the CCT uniformity increases from 10.4% (YAG) to 48.3% (YAG-SiO2), 89.3% (YAG-Al2O3), 94.1% (YAG-BN) and 94.8% (YAG-TiO2), respectively. It means that YAG-TiO2and YAG-BN PiG films can produce better uniformity in CCT. Moreover, the illuminance curve is much closer to the standard cosine curve when the secondary phase is introduced into the YAG PiG film (Fig. 4(b)).

The above results show that the introduction of a secondary phase can effectively improve the light uniformity of the YAG PiG film, but the effects are different from each other. To understand this difference, we calculate the relative reflective index () for each secondary phase by the Formula (3):

Fig. 4 (a) CCT and (b) illuminance distribution curves at different angles (10°–170°) of YAG,YAG-TiO2, YAG-BN, YAG-Al2O3, and YAG-SiO2 PiG films

Table 2 CCT uniformity of YAG,YAG-TiO2, YAG-BN, YAG-Al2O3, YAG-SiO2 PiG films under blue laser excitation

Table 3 Relative refractive indexes of secondary phases introduced into the YAG-PiG film

= (1−2)2/ (1+2)2(3)

Where1is the refractive index of the glass (., 1.5), and2is the refractive index of the secondary phase (Table 3). A largermeans stronger scattering ability, and more uniform light is thus produced. In addition, the pores generated in the PiG film also enhance the light scattering, which definitely contributes to the improvement of the light uniformity. As a result, the YAG- TiO2PiG film with a highestshows the best uniformity in light, luminance and CCT, followed by the YAG-BN and YAG-Al2O3PiG films. It indicates that the secondary phase with a higher relative reflective index enables to produce uniform white light, which provides a selection rule for scattering centers.

2.3 Optical performances

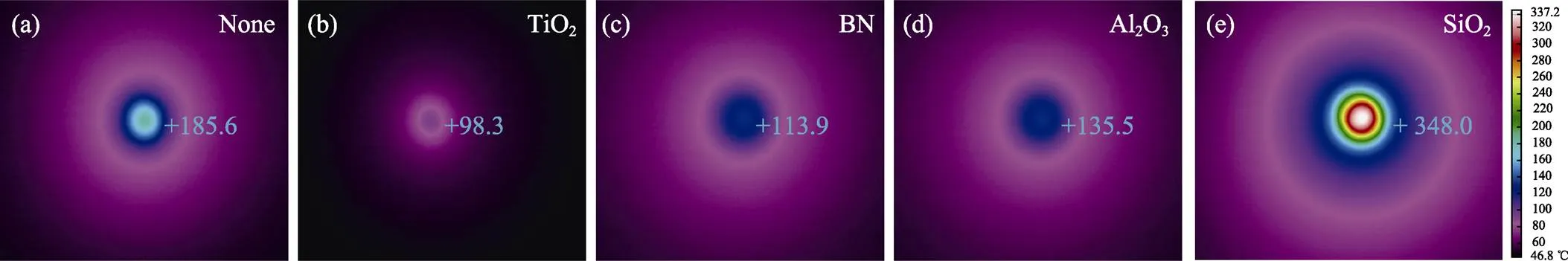

As shown in Fig. 5, the internal quantum efficiency (IQE) of the YAG-PiG film is slightly reduced by adding the secondary phase, which may be caused by some unexpected reactions between the phosphor particles and the secondary phases during the sintering process. There is a big drop in absorption efficiency (AE), due to the enhanced light scattering caused by the secondary phases in the PiG films. Therefore, the external quantum efficiency (EQE) largely declines with the addition of secondary phases, typically for BN, which results in the deceasing luminous efficacy of the white light in YAG-basedPiG films (Fig.5(c)).On one hand, less absorption means less heat generation under laser light excitation. On the other hand, the smaller IQE will create more heat, thus increasing the temperature of the PiG films. A balance between them finally determines the total heat production, and the temperature of the light spot decreases from 185.6 ℃(YAG PiG film) to 98.3, 113.9, 135.5℃for YAG-TiO2, YAG-BN and YAG-Al2O3PiG films, respectively. But for the YAG-SiO2PiG film, the temperature increases up to 348.0 ℃ (Fig. S3). As we know, thermal quenching of luminescence usually occurs rapidly at the temperature higher than 200 ℃[17], so the YAG-SiO2PiG film has the lowest luminous flux and luminance saturation threshold. The YAG-TiO2PiG film has the largest luminance saturation threshold of 20.12 W/mm2(11.73 W/mm2for the YAG-PiG film), and hence the highest luminous flux of 1056.6 lm (Fig. 5(b)).

3 Conclusions

In this work, the secondary phase of TiO2, BN, Al2O3or SiO2with varying refractive indexes was introduced into the YAG PiG film as scattering centers to obtain high light uniformity laser-driven white lighting sources. The addition of TiO2resulted in the best multidimensional uniformity in illumination image, speckle image, illuminance curve, CCT and luminance distribution, followed by BN and Al2O3, which is basically consistent with their relative reflective index. In addition, the luminous flux and saturation threshold of the YAG PiG film were improved by introducing the secondary phase except for SiO2, due to the less heat generation under blue laser excitation. The YAG-TiO2PiG film presents a maximal luminance saturation threshold of 20.12 W/mm2and a highest luminous flux of 1056.6 lm. This work provides a simple method for evaluating the light uniformity of the white light from multiple dimensions, and suggests a rule for selecting scattering media to realize uniform laser-driven white lighting sources with high luminance.

Fig. 5 (a) Quantum efficiency and absorption efficiency, (b) luminous flux, and (c) luminous efficacy of YAG,YAG-TiO2, YAG-BN, YAG-Al2O3, and YAG-SiO2 PiG films

Supporting materials

Supporting materials related to this article can be found at https://doi.org/10.15541/jim20220074.

[1] WIERER J J, TSAO J Y, SIZOV D S. Comparison between blue lasers and light-emitting diodes for future solid-state lighting., 2013, 7(6): 963–993.

[2] LI S, WANG L, HIROSAKI N,. Color conversion materials for high-brightness laser-driven solid-state lighting., 2018, 12(12): 1800173.

[3] LIANG Y, DING X, YAN C,. Phosphor-in-glass (PIG) converter sintered by a fast Joule heating process for high-power laser- driven white lighting., 2021, 29(10): 14218.

[4] ZHENG P, LI S, WANG L,. Unique color converter architecture enabling Phosphor-in-Glass (PiG) films suitable for high- power and high-luminance laser-driven white lighting., 2018, 10(17): 14930–14940.

[5] YOU S, LI S, ZHENG P,. A thermally robust La3Si6N11: Ce-in-glass film for high-brightness blue-laser-driven solid state lighting., 2019, 13(2): 1800216.

[6] YAO Q, HU P, SUN P,. YAG:Ce3+transparent ceramic phosphors brighten the next-generation laser-driven lighting., 2020, 32(19): 1907888.

[7] PENG Y, HUANG Y, LEI Z,. Rapid and efficient preparation of phosphor-in-glass converter by induction heating for high-power white LEDs/LDs.,2021, 29: 102839.

[8] AVANAKI A, ESPIG K, KIMPE T,. Perceptual uniformity of commonly used color spaces.Proceedings of SPIE-The International Society for Optical Engineering, 2014: 9041.

[9] LIU P, GUAN Z, ZHOU T,. Laser regulation for variable color temperature lighting with low energy consumption by microlens arrays.., 2021, 60(19): 5652–5661.

[10] MA Y, LUO X. Small-divergent-angle uniform illumination with enhanced luminance of transmissive phosphor-converted white laser diode by secondary optics design., 2019, 122: 14–22.

[11] CHEN K, HAN H, CHEN H,. White light emitting diodes with enhanced CCT uniformity and luminous flux using ZrO2nanoparticles., 2014, 6(10): 5378–5383.

[12] WU B, LUO X, ZHENG H,. Effect of gold wire bonding process on angular correlated color temperature uniformity of white light-emitting diode., 2011, 19(24): 24115–24121.

[13] LIU J, WANG W, LU X,. Controlling phosphor particle distribution for high-angular-color-uniformity and low-cost LEDs based on thermalcapillary flow., 2021, 68(2): 592-596.

[14] LAI M, QUOCANH N D, MA H,. Scattering effect of SiO2particles on correlated color temperature uniformity of multi-chip white light LEDs., 2016, 39(4): 468–472.

[15] HOU Y, CHEN C, YING S,. The effects of TiO2diffuser- loaded encapsulation on corrected color temperature uniformity of remote phosphor white leds., 2019, 9(4): 675.

[16] NGUYEN A Q D, NGUYEN T T, LEE H. Selection of scattering enhancement particles for improving color homogeneity and luminous flux of phosphor-converted LEDs., 2017, 40(4): 307–312.

[17] XU Y, LI S, ZHENG P,. A search for extra-high brightness laser-driven color converters by investigating thermally-induced luminance saturation., 2019, 7(37): 11449–11456.

Supporting materials:

Achieving High Light Uniformity Laser-driven White Lighting Source by Introducing Secondary Phases in Phosphor Converters

DENG Taoli1,2, CHEN Hexin1, HEI Lingli1, LI Shuxing1, XIE Rongjun1

(1. State Key Laboratory of Physical Chemistry of Solid Surfaces and Fujian Key Laboratory of Surface and Interface Engineering for High performance Materials, College of Materials, Xiamen University, Xiamen 361005, China; 2. College of Chemistry and Chemical Engineering, Anshun University, Anshun 561000, China)

Fig. S1 CCT (a) and illuminance (b) distribution curves at different angles (10°~170°) of YAG PiG films with different TiO2,BN, Al2O3, or SiO2contents

Table S1 CCT uniformity of YAGPiG films with different TiO2,BN, Al2O3, or SiO2contents under blue laser excitation

UniCCT/%010%15%20%25%30% TiO210.491.594.394.89191 BN10.473.686.988.494.190.9 Al2O310.418.1–84.2–89.3 SiO210.412.113.719.416.248.3

Fig. S2 Photoluminescence spectra and lifetime of YAG,YAG-TiO2, YAG-BN, YAG-Al2O3, YAG-SiO2PiG films

Fig. S3 Temperatures of light spots of YAG,YAG-TiO2, YAG-BN, YAG-Al2O3, YAG-SiO2PiG films

第二相引入荧光转换材料实现激光驱动高均匀性白光光源

邓陶丽1,2, 陈河莘1, 黑玲丽1, 李淑星1, 解荣军1

(1. 厦门大学 材料学院, 固体表面物理化学国家重点实验室, 福建省表界面工程与高性能材料重点实验室, 厦门 361005; 2. 安顺学院 化学化工学院, 安顺 561000)

激光驱动的白光光源在超高亮度、高准直性和远距离照明领域具有很大的应用潜力, 但由于蓝光激光和转换荧光在光源性质上的失配, 造成激光驱动白光光源的光均匀性差。本研究在Y3Al5O12: Ce3+(YAG)荧光玻璃薄膜(PiG)中引入不同种类的第二相, 如TiO2、BN、Al2O3或SiO2作为散射介质来调节光路, 并对第二相的掺杂浓度分别进行了优化。研究分析了掺入不同种类第二相的YAG PiG获得激光驱动白光光源的实物照明图像和散斑图像、亮度和色温的角分布情况及其光学性质。结果发现, 引入第二相大大改善了白光光源的亮度和色温均匀性, 其中具有最大相对反射率的YAG-TiO2PiG, 获得综合性能最佳的高均匀性白光光源, 在蓝光激光激发下, 其发光饱和阈值和光通量值达到最高, 分别为20.12 W/mm2和1056.6 lm。本研究为荧光转换材料中散射介质的选择提供了指导, 为实现高均匀性、高亮度的激光驱动白光光源奠定了基础。

光均匀性; 激光驱动白光光源; 光散射; 荧光玻璃薄膜; 光学性质

O482

A

1000-324X(2022)08-0891-06

10.15541/jim20220074

date:2022-02-15;

date: 2022-03-23;

2022-04-07

National Natural Science Foundation of China (51832005, U2005213); Fujian Provincial Science and Technology Project (2020I0002)

DENG Taoli (1989–), female, PhD candidate. E-mail: dengtaoli77@163.com

邓陶丽(1989–), 女, 博士研究生. E-mail: dengtaoli77@163.com

LI Shuxing, PhD. E-mail: lishuxing@xmu.edu.cn; XIE Rongjun, professor. E-mail: rjxie@xmu.edu.cn

李淑星, 博士. E-mail: lishuxing@xmu.edu.cn; 解荣军, 教授. E-mail: rjxie@xmu.edu.cn