基于激光感知的农业机器人定位系统

胡 炼,王志敏,汪 沛,何 杰,焦晋康,王晨阳,李明锦

·农业装备工程与机械化·

基于激光感知的农业机器人定位系统

胡 炼1,2,王志敏1,汪 沛1,2※,何 杰1,2,焦晋康1,王晨阳1,李明锦1

(1. 华南农业大学南方农业机械与装备关键技术教育部重点实验室,广州 510642; 2.岭南现代农业科学与技术广东省实验室茂名分中心,茂名 525000)

为解决基于全球导航卫星系统(global navigation satellite system,GNSS)的农业机器人和自动驾驶农机在机库、大棚等卫星信号弱或无环境下定位精度低甚至无法定位的问题,该研究提出了基于激光感知的农业机器人定位方法。采用二维激光雷达和激光接收器设计了基于激光感知的机器人定位系统,通过二维激光雷达发射扫描激光获取机器人上激光接收器的点云,同时激光接收器感应扫描激光,融合感应扫描激光时间差和激光接收器点云特征,得到移动激光接收器(即农业机器人)的定位。以全站仪测量为参照在大棚内开展验证试验,结果表明,在激光雷达扫描范围内,机器人行驶速度为0.8 m/s时,直线行驶时最大偏差绝对平均值为4.1 cm,最大均方根误差为1.5 cm;曲线行驶时最大偏差绝对平均值为6.2 cm,最大均方根误差为2.6 cm,满足农业机器人在农机库等环境中自动导航所需定位精度要求。

机器人;激光雷达;激光传感;定位;智能农机装备

0 引 言

农业机器人通常应用于结构化场景与随机的不确定场景,且作业任务日益复杂[1],定位和导航是农业机器人的关键技术[2]。当前农机自动驾驶技术和农机辅助导航技术快速发展[3-7],通过物联网、大数据和人工智能等先进信息技术的联合使用,农机自动驾驶和辅助导航技术已在无人化智慧农场开始实践应用[8]。

全球导航卫星系统(global navigation satellite system,GNSS)作为农业机械智能化技术中的一项关键技术,近年来已被广泛应用于农业生产各环节,其定位精度达到厘米级[9],基于GNSS的农业机械导航系统旱地作业直线路径跟踪精度优于±2.5 cm[4],水田作业直线路径跟踪横向偏差平均值为4.3 cm[10]。因此,智能农机依靠GNSS定位实现了大田高精度智能化无人作业[11],但在农机机库、农机转移行驶过程中经过树冠下和高架桥桥底以及温室大棚设施等场景时,存在GNSS卫星信号差或丢失的问题,难以实现导航定位,因此亟需其他定位方法融合补充。

Wi-fi、Zigbee、蓝牙和超宽带等无线通信技术[12]以及即时定位与地图构建(simultaneous localization and mapping,SLAM)技术是常用定位方法。无线通信技术中Wi-fi、超宽带信号定位易受环境因素干扰[12-13],Zigbee和蓝牙定位需要铺设大量设备[14]。SLAM指在没有环境先验信息下,通过使用各种传感器采集环境信息,在运动过程中构建环境地图,并估计机器人位置[15],目前,已经有许多解决SLAM问题的数学模型与理论基础[16]。SLAM技术包括视觉SLAM和激光SLAM,可以提供载体的相对位置信息,定位精度较高,已在物流、工业、医疗、安防、服务和农业等移动机器人以及无人驾驶领域广泛应用[17-21]。在农业机器人出库入库时,因库内外光照强度差异大,易导致视觉SLAM定位误差增大甚至无法定位,而且图像处理的运算量大、实时性较差[2,22]。此外,当环境中有较多移动物体时,视觉SLAM的环境地图构建偏差增大,定位精度降低[23]。相比之下,激光SLAM技术较成熟、定位误差更小[24],但激光SLAM构建的地图缺乏语义信息[25],对于大场景非固定地图仍需进一步研究[26],激光SLAM的地图构建可使用二维激光雷达和三维激光雷达,目前在物流和工业等领域主要使用成本较高的三维激光雷达[27]。

在无人化农场作业中,若每台无人驾驶农机均配备一套激光SLAM系统和高性能运算处理器实现小范围卫星信号被遮挡区域内的无人驾驶农机定位,不仅不能充分利用激光SLAM系统性能,而且增加了成本。因此,在保持现有农机无人驾驶系统定位解算算法等前提下,研究能够和GNSS系统融合补充的定位系统来解决无人驾驶农机出入库卫星信号弱或无的问题,对无人化农场的研究与建设具有重要意义。故本文设计了基于二维激光感知的农业机器人定位系统,并进行定位试验验证其定位精度。

1 基于激光感知的农业机器人定位方法

1.1 基于激光感知的农业机器人定位原理

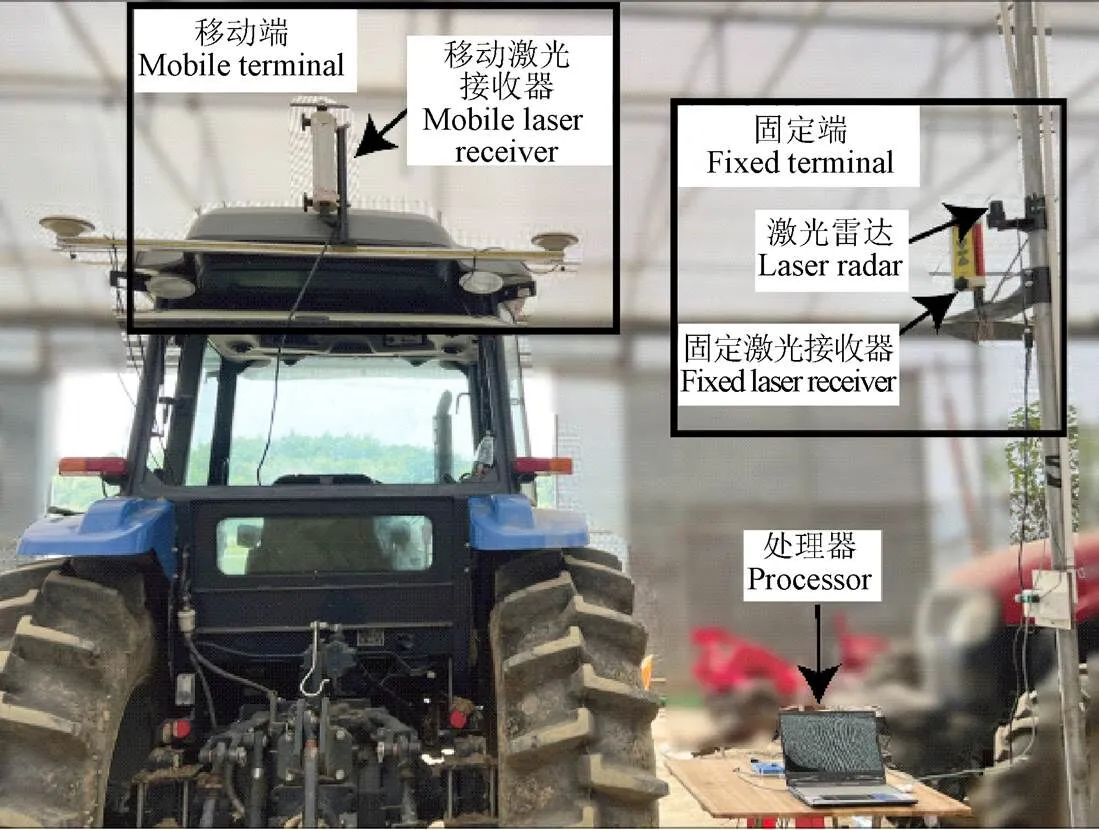

基于激光感知的农业机器人定位系统由移动激光接收器、处理器、固定激光接收器和二维激光雷达组成,如图1所示,移动激光接收器和处理器安装在机器人上,固定激光接收器和二维激光雷达固定在已知大地坐标位置,根据大地坐标点及激光雷达坐标系与大地坐标系的位置关系,基于激光感知的定位算法计算得到机器人的大地坐标,因此现有农机无人驾驶系统的定位解算和控制算法均无需修改即可实现无GNSS信号时实现定位和导航,例如,机器人出库时,在既有基于激光感知的机器人定位系统定位信号又有GNSS信号的区域切换GNSS定位系统进行导航,而入库时,在该区域切换采用基于激光感知的机器人定位系统进行导航。

图1 基于激光感知的农业机器人定位原理示意图

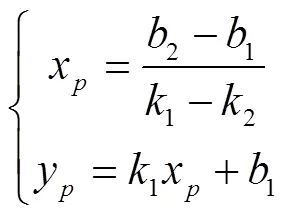

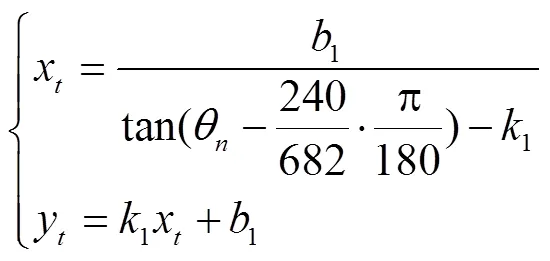

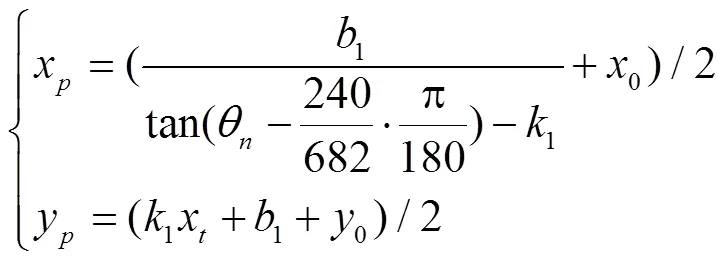

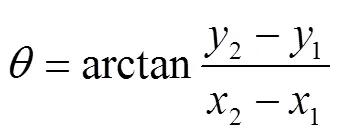

1.2 基于激光感知的农业机器人定位算法

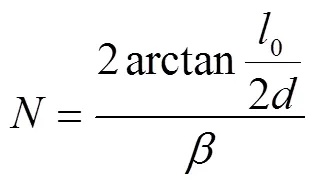

激光雷达以一定周期扫描获得数量已知且排序固定的点云数据,固定激光接收器感应激光雷达周期性照射产生固定激光信号,且固定激光接收器位置已知,机器人运动过程中移动激光接收器感应激光雷达周期性照射产生移动激光信号,在一个扫描周期中,根据固定激光信号与移动激光信号得到两者的触发时间差,由此获得照射到移动激光接收器的激光射线与照射到固定激光接收器的激光射线夹角Δ,以此快速准确找到移动激光接收器在激光雷达点云中的散点集,结合点云特征匹配算法获得移动激光接收器中心坐标,最后通过坐标转换得到移动激光接收器中心在大地坐标系中的位置,即农业机器人在大地坐标系中的位置。

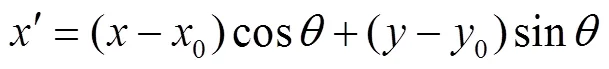

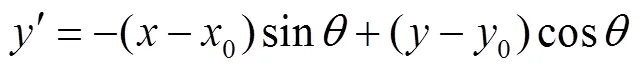

在激光雷达扫描平面建立以激光雷达为圆心的极坐标系和直角坐标系,极坐标系中任意点(,),其直角坐标系为(,),坐标转换关系如下:

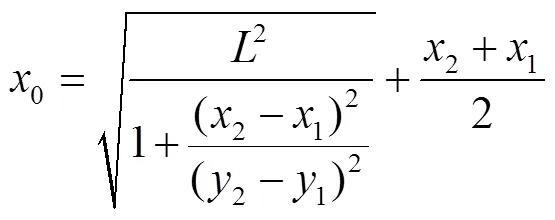

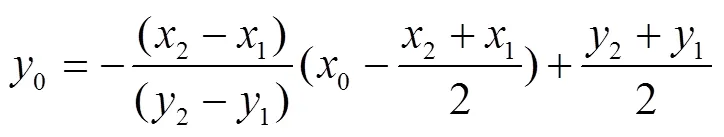

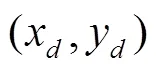

由激光接收器光电转换模块中心坐标推算出移动激光接收器中心坐标,再转换至大地坐标系下移动激光接收器中心坐标,即定位坐标。

注:为接收器外壳长边长度,cm;为接收器外壳短边长度,cm;0为接收器感光模块距外壳短边距离,cm;0为接收器感光模块距外壳长边距离,cm;为接收器感光模块与坐标原点连线;1为拟合出的接收器外壳长边所在直线;3为拟合出的接收器外壳短边所在直线,点为直线1和直线3的交点;2为接收器感光模块与点连线;、1、2和3分别为直线1、2和3的斜率;1、2和3分别为直线1、2和3的截距。l为离光电转换模块中心最近的激光雷达扫描射线,θ为激光雷达射线l扫描线对应极坐标的角度值。

Note:is the length of the long side of the mobile laser receiver housing, cm;is the length of the short side of the mobile laser receiver housing, cm;0is the distance from the photosensitive module of the mobile laser receiver to the short side of the housing, cm;0is the distance from the photosensitive module of the mobile laser receiver to the long side of the housing, cm; theis the connection line between the receiver photosensitive module and the coordinate origin, the1is the fitting line of the receiver housing on long side , pointis the intersection of line1and line3,2is the connection line between the photosensitive module of the mobile laser receiver and point, the3is the fitting line of the receiver housing on short side,,1,2and3is the slope of the straight line,1,2and3, respectively;1is the intercept of the straight line1,1is the intercept of the straight line2,3is the intercept of the straight line3, thelis the closest laser radar scanning ray to the center of the photoelectric conversion module,θis the angle value of the polar coordinate corresponding to the scanning line of the laser radar rayl.

图2 激光接收器光电转换模块中心坐标几何关系示意图

Fig.2 Schematic diagram of the central coordinate geometric relationship of the photoelectric conversion module of the laser receiver

2 基于激光感知的农业机器人定位系统试验

2.1 系统介绍

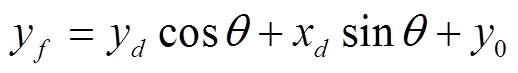

基于激光感知的农业机器人定位(ARPLS)系统如图3所示,以东风井关T954拖拉机为试验平台。ARPLS系统硬件部分主要由移动端和固定端组成,移动端包括移动激光接收器,固定端包括激光雷达和固定激光接收器。激光接收器通过滤光模块、光电转换模块、信号调制模块将激光雷达发射的光信号转换成电信号[28],数据处理与通信传输模块将激光感应信号通过CAN总线进行传输,激光接收器外壳长边11 cm,短边6.5 cm。移动激光接收器安装在拖拉机顶部机体(沿机头方向)中心线上,离地高度3 m,激光雷达和固定接收器固定在华南农业大学增城教学科研基地农机库支撑柱上,且移动激光接收器和固定激光接收器均能够接收到激光雷达发射的激光射线。移动激光接收器和固定激光接收器的CAN总线通过PCAN-USB传输到处理器,PCAN-USB用于监听CAN 网络消息,时间戳的分辨率为42 μs。激光雷达的测量距离为40~20 000 mm,扫描范围为270°,角度分辨率为0.117 2°,扫描频率为10 Hz,误差为测量距离的1%。

图3 安装在拖拉机上的基于激光感知的农业机器人定位系统

使用Visual studio 2022通过C#编程语言编写系统软件,采用多线程数据事件触发的方式进行数据处理与分析,得到准确的激光雷达、移动激光接收器和固定激光接收器的数据响应时间戳,固定端数据发送到移动端进行分析处理,从而实时获得定位数据。

试验以全站仪和RTK GNSS系统的测量轨迹作为参考对象,且均采用WGS-84坐标系。全站仪自动跟踪安装在移动激光接收器上的棱镜,进行动态跟踪测量,全站仪为Leica Ms60,测量频率10 Hz,100 m范围内测量误差1 mm;RTK GNSS系统直接测量获取拖拉机定位,RTK GNSS板卡为K728,测量频率10 Hz,平面定位精度1 cm。

试验时拖拉机在激光雷达扫描范围内以0.3、0.5和0.8 m/s分别进行往复的直线运动和曲线运动,行驶距离9~20 m,每组试验重复5次,ARPLS系统、全站仪和GNSS三套定位系统同时采集定位数据,采集时长3~5 min,其中激光感知定位系统每次试验获得定位点2 000个以上。

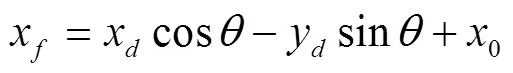

2.2 坐标系转换与机器人中心定位

3 结果与分析

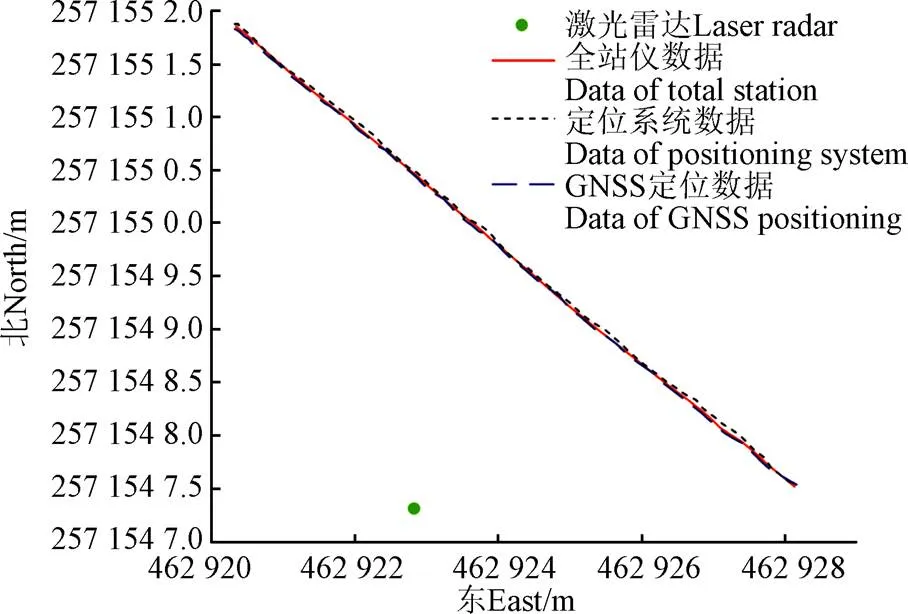

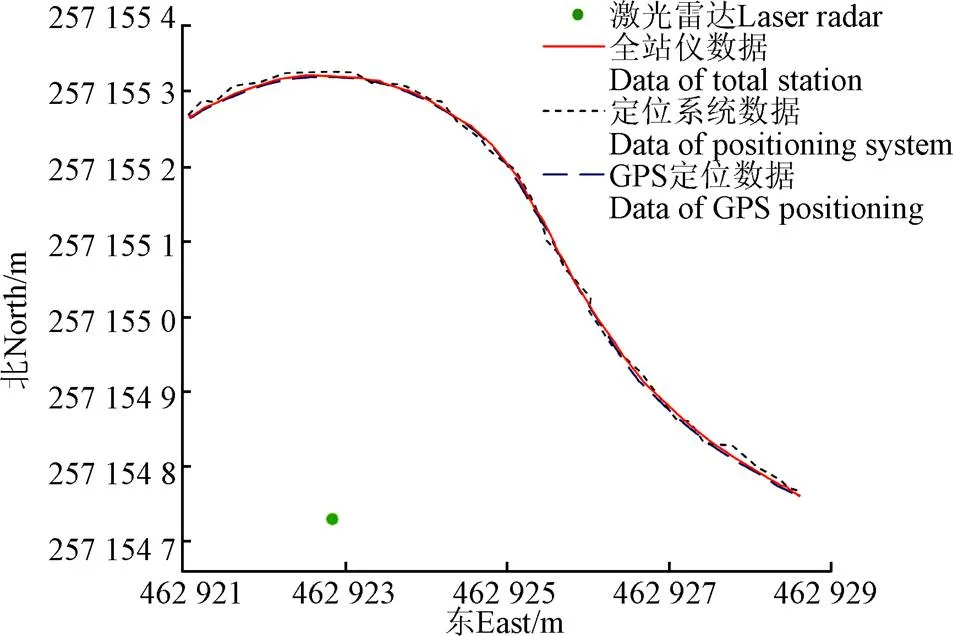

ARPLS系统、全站仪和GNSS测量的一组拖拉机以0.8 m/s速度直线行驶和曲线行驶的轨迹分别如图4和图5所示,其中直线行驶距离10 m、曲线行驶距离12 m。由图可知,ARPLS系统测量的拖拉机轨迹与全站仪和GNSS测量的轨迹基本重合,表明在试验行驶距离范围内,ARPLS系统提供了试验拖拉机在WGS-84坐标系下的定位。

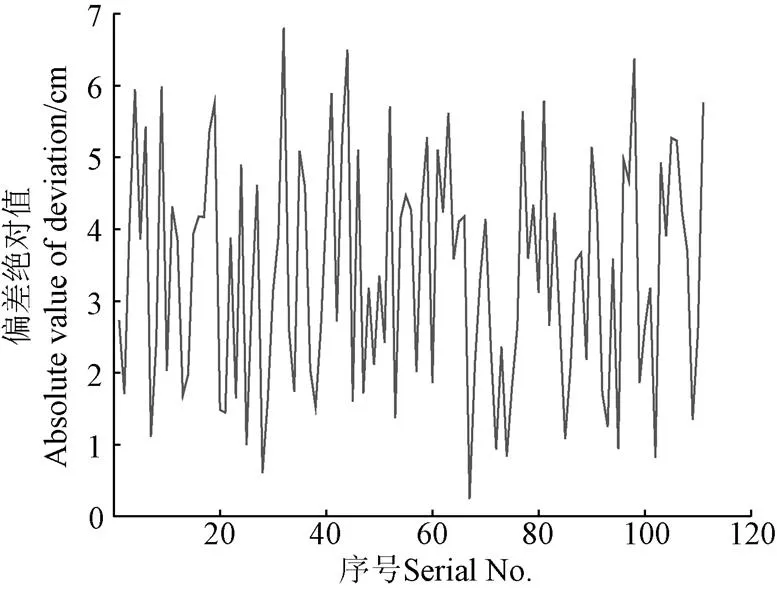

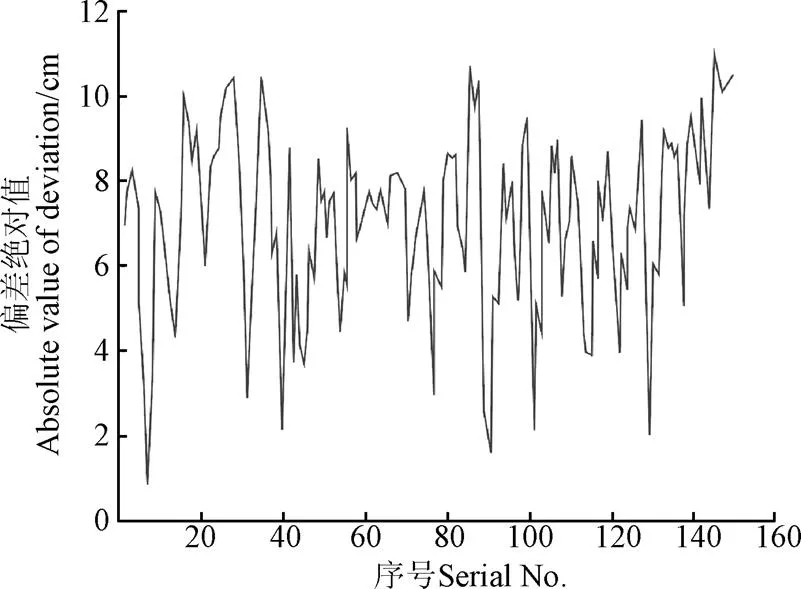

ARPLS系统动态测量拖拉机以0.8 m/s速度进行直线行驶和曲线行驶定位与全站仪测量定位的偏差绝对值曲线分别如图6和图7所示。在相同速度下,直线行驶定位的偏差绝对值明显小于曲线行驶定位的偏差绝对值,因此,ARPLS系统动态测量直线运动定位精度高于曲线运动定位精度,测量直线运动定位偏差不大于7 cm,测量曲线运动定位偏差小于12 cm。

图4 拖拉机直线行驶轨迹

图5 拖拉机曲线行驶轨迹

图6 直线行驶的定位偏差绝对值曲线

图7 曲线行驶的定位偏差绝对值曲线

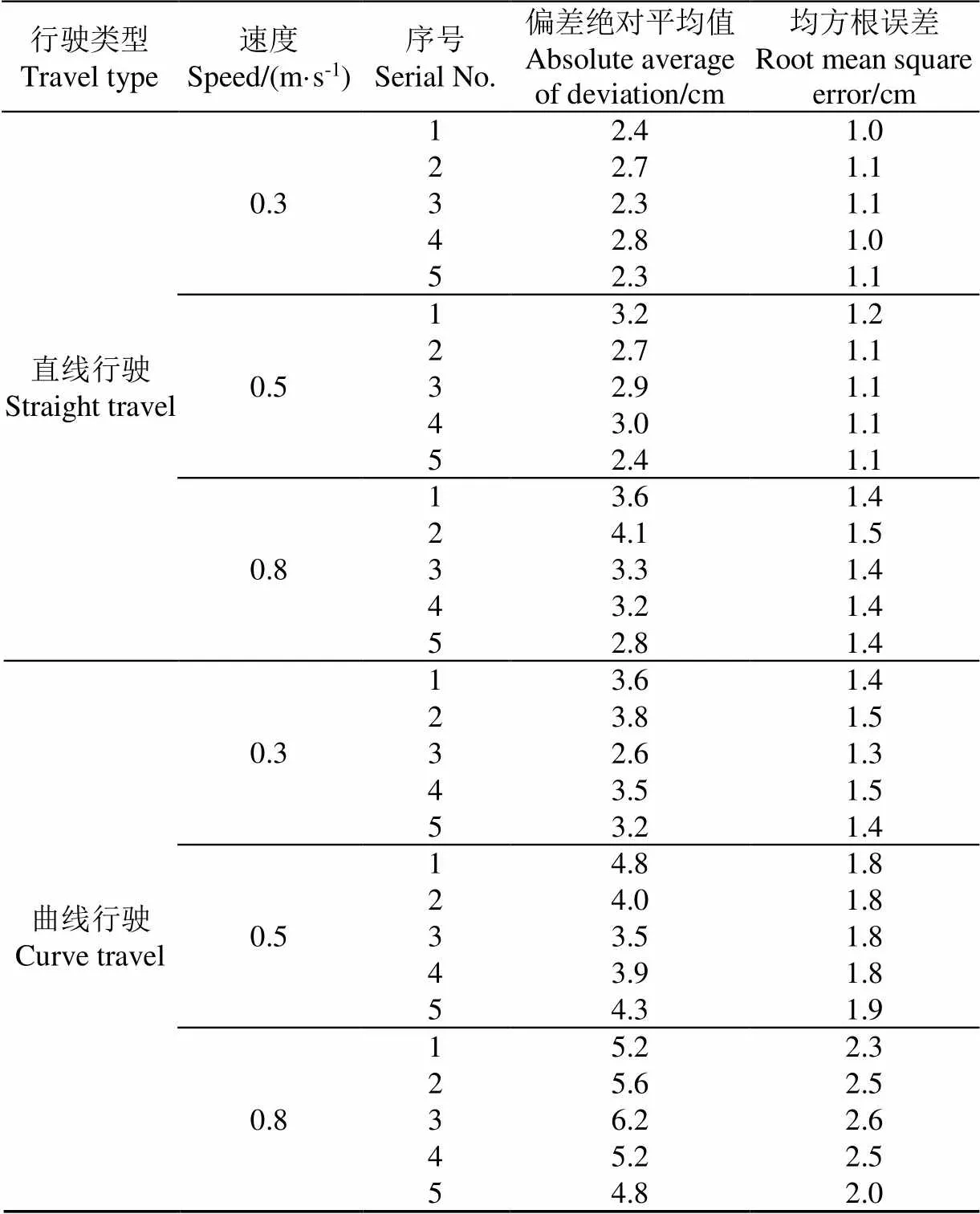

以全站仪测量定位为真值,各试验组次ARPLS系统相对全站仪测量定位的偏差绝对平均值和均方根误差如表1所示。表中试验数据表明,随着拖拉机速度越快,ARPLS系统定位相对全站仪定位的误差随之增大;行驶速度相同时,曲线行驶比直线行驶定位的误差大。0.8 m/s速度时,直线行驶时最大偏差绝对平均值为4.1 cm,最大均方根误差为1.5 cm;曲线行驶时最大偏差绝对平均值为6.2 cm,最大均方根误差为2.6 cm。

表1 激光感知定位相比全站仪定位误差

ARPLS系统的误差主要源于移动激光接收器和固定激光接收器感知激光的时间差误差以及点云拟合误差。随着拖拉机速度增加而定位误差增大是由于激光雷达需要完成一圈扫描才能输出点云数据,导致定位系统数据输出与测量时刻存在延时。曲线行驶定位误差比直线行驶定位误差大主要是因为曲线运动导致激光接收器长方形外壳的长边或短边点云数量少甚至没有,从而降低了算法推算精度。

4 结 论

1)本文提出了基于激光感知的农业机器人定位方法,利用激光感知和激光雷达点云特征得到移动激光接收器相对固定激光雷达的位置,通过坐标转换获得机器人的实时大地定位坐标。

2)基于激光感知的定位算法解决了难以从二维激光雷达点云中确定目标对象点云的问题,通过固定激光信号与移动激光信号触发时间差快速准确找到移动激光接收器在激光雷达点云中的散点集,结合点云特征匹配算法实现了快速准确地获得目标对象定位。

3)设计了基于激光感知的农业机器人定位系统,大棚内试验结果表明,在激光雷达扫描范围内,机器人行驶速度为0.8 m/s时,直线行驶时最大偏差绝对平均值为4.1 cm,最大均方根误差为1.5 cm;曲线行驶时最大偏差绝对平均值为6.2 cm,最大均方根误差为2.6 cm。

移动接收器外形以及激光雷达扫描外壳获得的点云数量直接影响基于激光感知的农业机器人定位系统的定位精度,因此后续将从大尺寸圆形外壳激光接收器设计、高频率点云激光雷达选用以及与惯性传感器融合算法等方面开展研究,进一步提高定位精度和环境适应能力。

[1] 宫金良,王伟,张彦斐,等. 基于农田环境的农业机器人群协同作业策略[J]. 农业工程学报,2021,37(2):11-19.

GONG Jinliang, WANG Wei, ZHANG Yanfei, et al. Cooperative working strategy for agricultural robot groups based on farmland environment[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(2): 11-19. (in Chinese with English abstract)

[2] 陈瑜,张铁民,孙道宗,等. 基于无线传感器网络的设施农业车辆定位系统设计与试验[J]. 农业工程学报,2015,31(10):190-197.

CHEN Yu, ZHANG Tiemin, SUN Daozong, et al. Design and experiment of locating system for facilities agricultural vehicle based on wireless sensor network[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(10): 190-197. (in Chinese with English abstract)

[3] 何杰,朱金光,张智刚,等. 水稻插秧机自动作业系统设计与试验[J]. 农业机械学报,2019,50(3):17-24.

HE Jie, ZHU Jinguang, ZHANG Zhigang, et al. Design and experiment of automatic operation systemfor rice transplanter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(3): 17-24. (in Chinese with English abstract)

[4] 何杰,高维炜,王辉,等. 基于MEMS陀螺仪的农机转向轮角测量方法[J]. 中国农机化学报,2020,41(4):123-129.

HE Jie, GAO Weiwei, WANG Hui, et al. Steering wheel angle measurement method of agricultural machinery based on dual MEMS gyroscope[J]. Journal of Chinese Agricultural Mechanization, 2020, 41(4): 123-129. (in Chinese with English abstract)

[5] 张雁,李彦明,刘翔鹏,等. 水田环境下水稻直播机自动驾驶控制方法[J]. 农业机械学报,2018,49(11):15-22.

ZHANG Yan, LI Yanming, LIU Xiangpeng, et al. An automatic drive control technique for rice drill seeder in uneven paddy fields[J]. Transactions of the Chinese Society for Agricultural Machinery, 49(11): 15-22. (in Chinese with English abstract)

[6] 钟银,薛梦琦,袁洪良. 智能农机GNSS/INS组合导航系统设计[J]. 农业工程学报,2021,37(9):40-46.

ZHONG Yin, XUE Mengqi, YUAN Hongliang. Design of the GNSS/INS integrated navigation system for intelligent agricultural machinery[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(9): 40-46. (in Chinese with English abstract)

[7] 潘新宇,赵英策,李建勋. GNSS/INS组合导航的随机时延卡尔曼滤波[J]. 指挥控制与仿真,2022,44(1):26-31.

PAN Xinyu, ZHAO Yingce, LI Jianxun. Random Delay Kalman Filtering of GNSS/INS integrated navigation[J]. Command Control & Simulation, 2022, 44(1): 26-31. (in Chinese with English abstract)

[8] 李道亮,李震. 无人农场系统分析与发展展望[J]. 农业机械学报,2020,51(7):1-12.

LI Daoliang, LI Zhen. System analysis and development prospect of unmanned farming[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(7): 1-12. (in Chinese with English abstract)

[9] 刘兆朋,张智刚,罗锡文,等. 雷沃ZP9500高地隙喷雾机的GNSS自动导航作业系统设计[J]. 农业工程学报,2018,34(1):15-21.

LIU Zhaopeng, ZHANG Zhigang, LUO Xiwen, et al. Design of automatic navigation operation system for Lovol ZP9500 high clearance boom sprayer based on GNSS[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(1): 15-21. (in Chinese with English abstract)

[10] 张宜宝,孙经纬,石绍军,等. 自动驾驶插秧机控制系统的设计与试验[J]. 农机化研究,2023,45(7):71-78.

ZHANG Yibao, SUN Jingwei, SHI Shaojun, et al. Design and experiment of control system for automatic driving transplanter[J]. Journal of Agricultural Mechanization Research, 2023, 45(7): 71-78. (in Chinese with English abstract)

[11] 罗锡文,廖娟,胡炼,等. 我国智能农机的研究进展与无人农场的实践[J]. 华南农业大学学报,2021,42(6):8-17.

LUO Xiwen, LIAO Juan, HU Lian, et al. Research progress of intelligent agricultural machinery and practice of unmanned farm in China[J]. Journal of South China Agricultural University, 2021, 42(6): 8-17. (in Chinese with English abstract)

[12] 陈沛宇,袁勤政,戴鹏飞,等. 多技术融合的室内无线定位方法发展综述[J]. 导航定位学报,2022,10(3):9-13.

CHEN Peiyu, YUAN Qinzheng, DAI Pengfei, et al. Overview of the development of indoor wireless positioning methods based onmulti-technology integration[J]. Journal of Navigation and Positioning, 2022, 10(3): 9-13. (in Chinese with English abstract)

[13] 闫大禹,宋伟,王旭丹,等. 国内室内定位技术发展现状综述[J]. 导航定位学报,2019,7(4):5-12.

YAN Dayu, SONG Wei, WANG Xudan, et al. Review of development status of indoor location technology in China[J]. Journal of Navigation and Positioning, 2019, 7(4): 5-12. (in Chinese with English abstract)

[14] 姚立健,Santosh K Pitla,杨自栋,等. 基于超宽带无线定位的农业设施内移动平台路径跟踪研究[J]. 农业工程学报,2019,35(2):17-24.

YAO Lijian, Santosh K Pitla, YANG Zidong, et al. Path tracking of mobile platform in agricultural facilities based on ultra wideband wireless positioning[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(2): 17-24. (in Chinese with English abstract)

[15] DONG F C, IENG S H, SAVATIER X, et al. Plenoptic cameras in real-time robotics[J]. International Journal of Robotics Research, 2013, 32(2): 206-217.

[16] GUALTIERI M, PLATT R. Robotic pick-and-place with uncertain object instance segmentation and shape completion[J]. IEEE Robotics and Automation Letters, 2021, 6(2): 1753-1760.

[17] KIM A, EUSTICE R M. Real-time visual SLAM for autonomous underwater hull inspection using visual saliency[J]. IEEE Transactions on Robotics, 2013, 29(3): 719-733.

[18] LU T T, YEH S C, CHEN C Y. A study of indoor positioning systems using iBeacons with different transmission power levels[J]. Journal of the Chinese Institute of Engineers, 2017, 40(6): 525-535.

[19] 王世峰,戴祥,徐宁,等. 无人驾驶汽车环境感知技术综述[J]. 长春理工大学学报(自然科学版),2017,40(1):1-6.

WANG Shifeng, DAI Xiang, XU Ning, et al. Overview on environment perception technology for unmanned ground vehicle[J]. Journal of Changchun University of Science and Technology (Natural Science Edition), 2017, 40(1): 1-6. (in Chinese with English abstract)

[20] 胡广锐,孔微雨,齐闯,等. 果园环境下移动采摘机器人导航路径优化[J]. 农业工程学报,2021,37(9):175-184.

HU Guangrui, KONG Weiyu, QI Chuang, et al. Optimization of the navigation path for a mobile harvesting robot in orchard environment[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(9): 175-184. (in Chinese with English abstract)

[21] 杨继之,乐毅,张加波,等. 移动机器人定位精度实时补偿策略研究[J]. 机械工程学报,2022,58(14):44-53.

YANG Jizhi, LE Yi, ZHANG Jiabo, et al. Real-time compensation strategy of mobile robot positioning accuracy[J]. Journal of Mechanical Engineering, 2022, 58(14): 44-53. (in Chinese with English abstract)

[22] 陈艳,张漫,马文强,等. 基于GPS和机器视觉的组合导航定位方法[J]. 农业工程学报,2011,27(3):126-130.

CHEN Yan, ZHANG Man, MA Wenqiang, et al. Positioning method of integrated navigation based on GPS and machine vision[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(3): 126-130. (in Chinese with English abstract)

[23] 王柯赛,姚锡凡,黄宇,等. 动态环境下的视觉SLAM研究评述[J]. 机器人,2021,43(6):715-732.

WANG Kesai, YAO Xifan, HUANG Yu, et al. Review of visual SLAM in dynamic environment[J]. Robot, 2021, 43(6): 715-732. (in Chinese with English abstract)

[24] 李晨阳,彭程,张振乾,等. 融合里程计信息的农业机器人定位与地图构建方法[J]. 农业工程学报,2021,37(21):16-23.

LI Chenyang, PENG Cheng, ZHANG Zhenqian, et al. Positioning and map construction for agricultural robots integrating odometer information[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(21): 16-23. (in Chinese with English abstract)

[25] 刘凌云,蔡成林,吴芊. 室外光照易变场景下的回环检测方法[J]. 传感器与微系统,2022,41(4):121-124.

LIU Lingyun, CAI Chenglin, WU Qian. Loop closure detection method in outdoor scene with variable illumination[J]. Transducer and Microsystem Technologies, 2022, 41(4): 121-124. (in Chinese with English abstract)

[26] 孙曼晖,杨绍武,易晓东,等. 基于GIS和SLAM的机器人大范围环境自主导航[J]. 仪器仪表学报,2017,38(3):586-592.

SUN Manhui, YANG Shaowu, YI Xiaodong, et al. Autonomous navigation of robot in large-scale environments based on GIS and SLAM[J]. Chinese Journal of Scientific Instrument, 2017, 38(3): 586-592. (in Chinese with English abstract)

[27] 单吉超,李秀智,张祥银,等. 室内场景下实时地三维语义地图构建[J]. 仪器仪表学报,2019,40(5):240-248.

SHAN Jichao, LI Xiuzhi, ZHANG Xiangyin, et al. Real-time 3D semantic map building in indoor scene[J]. Chinese Journal of Scientific Instrument, 2019, 40(5): 240-248. (in Chinese with English abstract)

[28] ZANG Y, MENG S, HU L, et al. Optimization design and experimental testing of a laser receiver for use in a laser levelling control system[J]. Electronics, 2020, 9(3): 536. (in Chinese with English abstract)

Agricultural robot positioning system based on laser sensing

HU Lian1,2, WANG Zhimin1, WANG Pei1,2※, HE Jie1,2, JIAO Jinkang1, WANG Chenyang1, LI Mingjin1

(1.,,,510642,; 2.,,525000,)

In order to solve the positioning problem of global navigation satellite system (GNSS) based robots and autonomous agricultural machinery, which is low accuracy or even unable to locate under the environment of weak or no satellite signals such as hangars and greenhouses. This research proposes an agricultural robot positioning system based on laser sensing. The system is designed by using two-dimensional laser scanner and laser receiver, which obtains the point cloud of the laser receiver on the robot through the scanning laser emitted by the two-dimensional laser scanner , and the laser receiver inductively scans by the laser scanner, the location of mobile laser receiver (i.e. agricultural robot) is obtained by fusing the time difference of laser scanning induction and the point cloud characteristics of mobile laser receiver. The agricultural robot positioning system based on laser sensing consists of mobile laser receiver, processor, fixed laser receiver and two-dimensional laser scanner. The mobile laser receiver and processor are installed on the robot, and the fixed laser receiver and two-dimensional laser radar are fixed at the known geodetic coordinate position. According to the position relationship between the laser scanner coordinate system and the known geodetic coordinate system. The laser scanner scanning at a certain period to obtain a known number of fixed-order point cloud data. The fixed laser receiver senses the periodic irradiation of the laser scanner to generate the base station laser signal, and the serial number of the fixed laser receiver shell in the point cloud is known. The mobile laser receiver senses the periodic irradiation of the laser radar to generate the mobile laser signal during the movement of the robot. According to the trigger time difference between the fixed laser signal and the mobile laser signal, the angle between the laser rays that are irradiated to the mobile laser receiver and the laser rays that are irradiated to the fixed laser receiver can be obtained in a scanning period of the laser scanner. And the scattered point set of the mobile laser receiver in the laser radar point cloud can be found, and the center coordinate of the mobile laser receiver can be obtained by combining the point cloud feature matching algorithm. The robot positioning can be calculated by combined with the geodetic coordinates of the laser scanner and the position relationship between the laser scanner coordinate system and the geodetic coordinate system, the central coordinates of the mobile laser receiver under the geodetic coordinate system. The geodetic coordinates of the robot are calculated by the positioning algorithm based on laser sensing, and the geodetic coordinates of the robot without GNSS signal are supplemented without changing the positioning solution and control algorithm of the existing robot unmanned system. For example, when the robot leaves the hangar, it switches to the GNSS positioning system for positioning and navigation in the area with both the positioning signals of the robot positioning system based on laser perception and the GNSS signal. When entering the hangar, switch to the robot positioning system based on laser sensing for positioning and navigation in the area cover with both the positioning signal of the robot positioning system based on laser perception and the GNSS signal. The verification test is carried out with the reference of total station which shows that within the scanning range of laser radar, when the robot is at a speed of 0.8 m/s, the absolute average value of the maximum deviation of the positioning error in a straight line is 4.1 cm, and the maximum root mean square error is 1.5 cm; when the robot driving on a curve, the absolute average value of the maximum deviation of positioning error is 6.2 cm , and the maximum root mean square error is 2.6 cm. The result shows that this method can achieve accurate robot positioning and meets the positioning accuracy requirements for automatic navigation of agricultural robots in agricultural machinery warehouses and other environments.

robot; laser radar; laser sensing; positioning; intelligent agricultural machinery equipment

10.11975/j.issn.1002-6819.202211144

S24; TP273

A

1002-6819(2023)-05-0001-07

胡炼,王志敏,汪沛,等. 基于激光感知的农业机器人定位系统[J]. 农业工程学报,2023,39(5):1-7.doi:10.11975/j.issn.1002-6819.202211144 http://www.tcsae.org

HU Lian, WANG Zhimin, WANG Pei, et al. Agricultural robot positioning system based on laser sensing[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(5): 1-7. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.202211144 http://www.tcsae.org

2022-11-14

2023-01-16

江苏大学农业装备学部项目(NZXB20210106);广东省科技计划项目(2021B1212040009);佛山市科技创新项目(2120001008424);国家现代农业技术体系(CARS-13)

胡炼,博士,研究员,研究方向为智能农机装备和无人农场。Email:lianhu@scau.edu.cn

汪沛,博士,讲师,研究方向为农业工程、精准农业研究。Email:wangpei@scau.edu.cn