Test and Analysis for Spraying Ammonia in Diesel Engine

ZHOU Hua-xiang(周华祥),LIU Jing-ping(刘敬平),HE Li-ke(贺力克),CHEN Fang(陈方),SHEN Qi-zhi(申奇志),LUO Rui(骆锐),ZHOU Zheng(周正)

(1.Key Laboratory of Internal Combustion Engine,Hunan University,Changsha 410082,Hunan,China;2.Automotive Engineering Institute,Hunan Industry Polytechnic,Changsha 410007,Hunan,China;3.Changsha Zoomlion Heavy Industry Science and Technology Development Co.,Ltd.Changsha 410013,Hunan,China)

Introduction

To reduce NOxin emissions to meet EuropeanⅤstandard and not to decrease the thermal efficiency of diesel engines is an important and difficult problem in current emission researches[2-4].Directly spraying the ammonia reducer into the engine cylinder,in the absence of catalyst conditions,may be a feasible method to solve this problem.When the combustion temperature in the engine decreases into the range in which the ammonia reducer can react effectively,the ammonia reducer may be injected into the combustion gas.It can effectively reduce the levels of NO in emission,generate harmless N2and H2O,and does not decrease the engine’s thermal efficiency.The test in engine 4102BZLQ verifies the technical feasibility.

1 Test Mode of Spraying Ammonia in Diesel Engine

A typical diesel engine 4102BZLQ is used in the test.Behind the compression TDC(360°CA),the engine ignites and works,and when the gas temperature drops to 1 573 K,the ammonia reducer can be injected directly into the cylinder,as shown in Fig.1.

Fig.1 Injection mode for fuel and ammonia reducer

2 Test Scheme

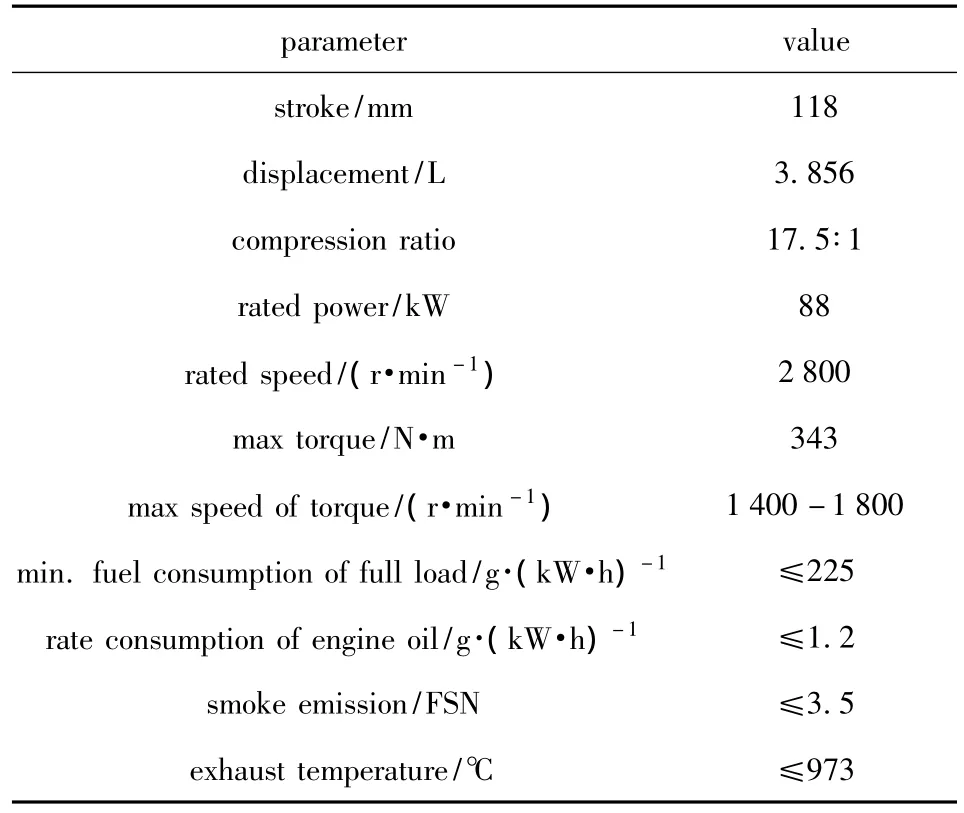

The engine’s main technical parameters are shown in Tab.1.

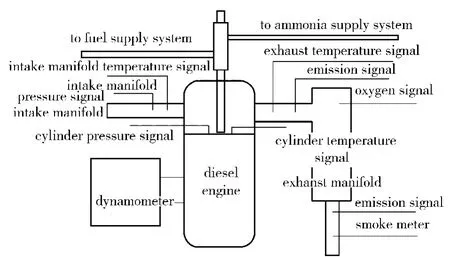

In the test,the original parameters of the engine keep no change.The ammonia injection and electronic control systems are installed on the cylinder head.Injection point is set to 20°CA -90°CA after compression top dead and controllable.The injection volume of am-monia can be determined according to the molar ratio NOx/NH3of 1∶3.3,and controlled according to the typical and excessive conditions.The pressure of industrial bottled ammonia is 10-22 MPa.The sketch of test and detection scheme is shown in Fig.2.

Tab.1 Main parameters of engine typed 4102BZLQ

Fig.2 Sketch of test scheme

3 Test Apparatus

1)Hydraulic power dynamometer typed by Y120-S with the max power of 120 kW and the max speed of 7 500 r/min;

2)Discharging analyzer typed by AVL DiGas4000 with measurement range of 0-5 000 ppm and accuracy of 1 ppm;

3)Transient fuel consumption meter typed by FCM07 with bandwidth of 0.5 Hz,data update rate of 1 Hz and accuracy of 2%FS in the transient fuel consumption rate and 0.5%in the average fuel consumption rate;

4)Data acquisition board typed by AT-MIO-16E-2 with software LabView;

5)Fiber temperature sensor typed by H-G-3-A with measurement range of 623-3 273 K,accuracy of±0.5%,repeatability of±0.1%and response time of 10 ms;

6)Pressure sensor typed by PT702 with measurement range of 0-20 MPa and accuracy of 0.5%FS;

7)Homemade multi-function electric injector;

8)Oxygen sensor typed by O2S-FR-T2-18X.

4 Test Method

4.1 Determination of Ammonia Injection Timing[5 -6]

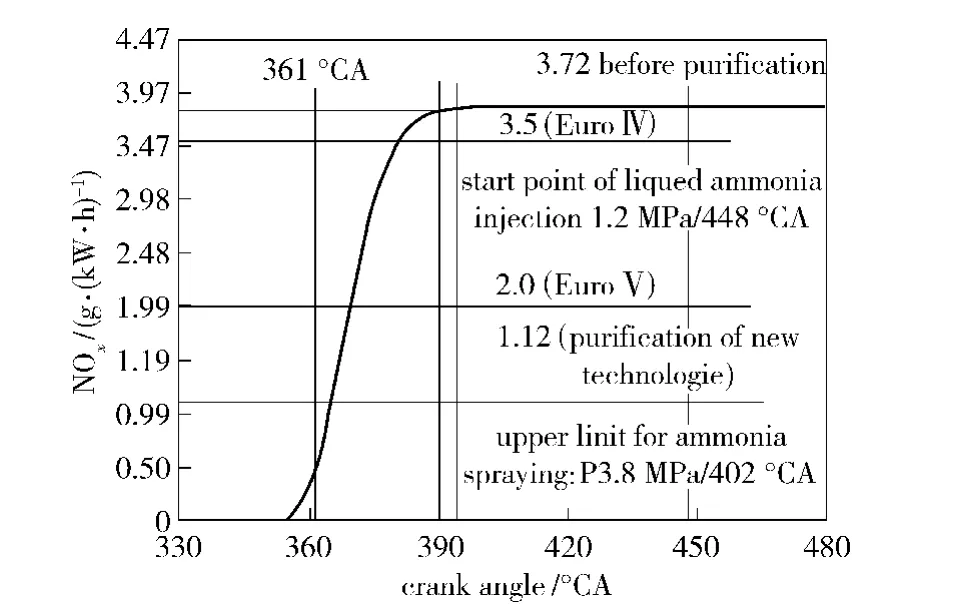

The volume of NOxgenerated in 4102BZLQ engine’s cylinder is measured in different crank angles,as shown in Fig.3.The point,at which NOxproduces rapidly,corresponds to the crank angle of 361°CA.In Fig.4 indicating the measured average temperature,it corresponds to the temperature of 1 700 K.

Fig.3 NOx in different crank angles

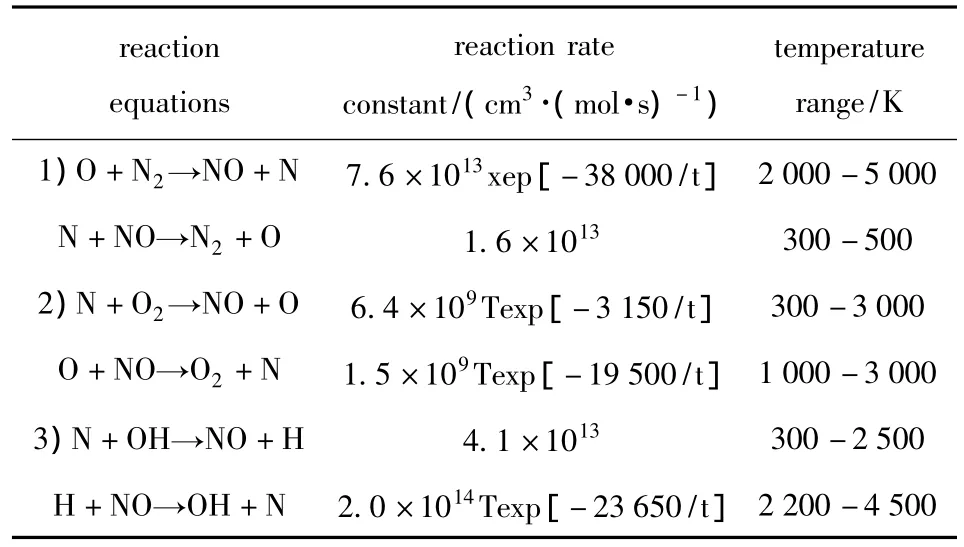

Based on the detailed PRF fuel mechanism given by Lawrance Livermore National Laboratory and Zeldovich theory,the main chemical reaction equations on the thermal NOxformation can be written as

whereK1,K-1,K2andK-2denote the reaction rate constants in the forward and reverse reactions.Tab.2 shows these measured reaction rate constants.

Tab.2 Measured reaction rate constants

The measured effective reaction temperature of ammonia ranges from 1 573 K to 1 073 K,thus,when the combustion chamber temperature reduces into this range,the ammonia can be injected into the chamber to react with NOxeffectively.In the test,the spraying start point and volume are determined according to the conditions and emission control standards.For 4102BZLQ engine,the best spraying start point corresponds to the temperature of 1 273 K,and it can obtain better thermal efficiency and purification effect.That is,when the combustion temperature reduces to 1 273 K,the reducer ammonia can be injected into the chamber.The crank angle,that is,448°CA,corresponding to 1 273 K can be found in the average temperature curve shown in Fig.4.

Fig.4 Average temperature curve

4.2 Determinations of Injection Pressure and Volume

The measured average pressure curve of 4102BZLQ engine can be used to determine the injection pressure and volume,as shown in Fig.5.The cylinder pressure corresponding to 1 273 K and 448°CA is 1.2 MPa.Thus,the ammonia injection pressure can be taken as 12 MPa.The ammonia injection volume can be determined according to the molar ratio of 1∶3.3 for NOxand NH3.These data can all be written in the control program.

Fig.5 Average pressure

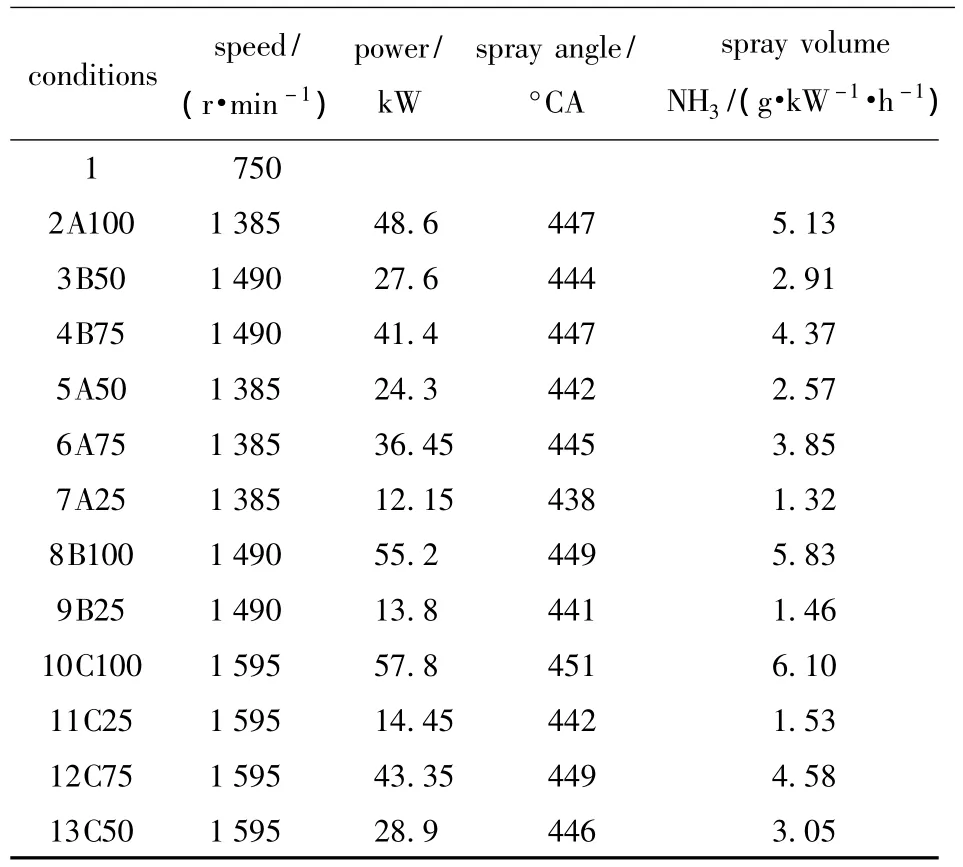

Tab.3 Basic ammonia spraying angle and volume of 4102BZLQ engine

4.3 Experiment Results and Analyses[7-8]

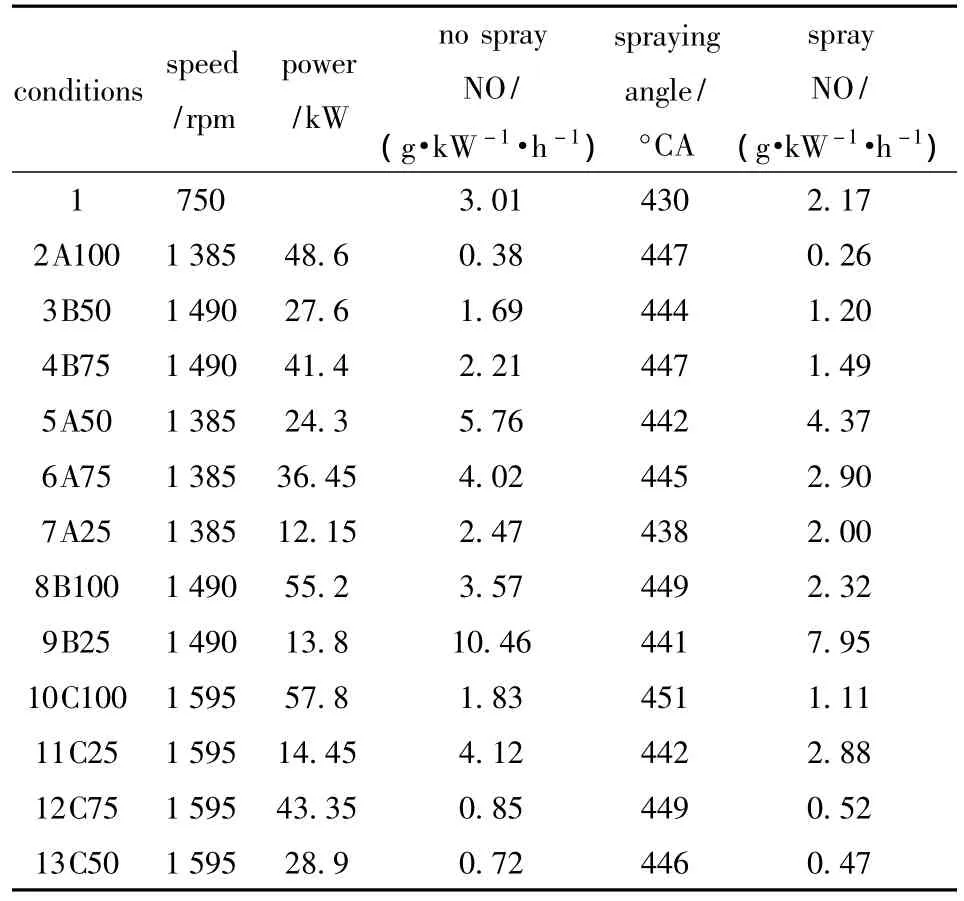

The experiment results show that the spraying of reducer ammonia in appropriate time can effectively reduce NOxin the exhaust composition.NOxvolume generated in the diesel engine without ammonia spraying is of 3.7 g/(kW·h),equivalent to EuroⅢ standards.Spraying ammonia in 451°CA and 1 237 K,NO volume can be reduced to 1.11 g/(kW·h),less than EuroⅤstandard,2.0 g/(kW·h).Meanwhile,NOx,in about 20°CA generates rapidly,and its concentration keeps no change after reaching a certain value.In the diesel combustion process,in 347°CA,the cylinder tempera-ture is 1 030 K;in 351°CA,the diesel begins to fire,and the temperature rises sharply;in 365.4°CA,the cylinder pressure reaches to the maximum,12.74 MPa;in 376°CA,the temperature inside the cylinder is up the maximum,1 763 K;in 451°CA,the temperature reduces to 1 237 K.

The emission test results in thirteen ESC conditions are listed in Tab.4.

Tab.4 Emission test results

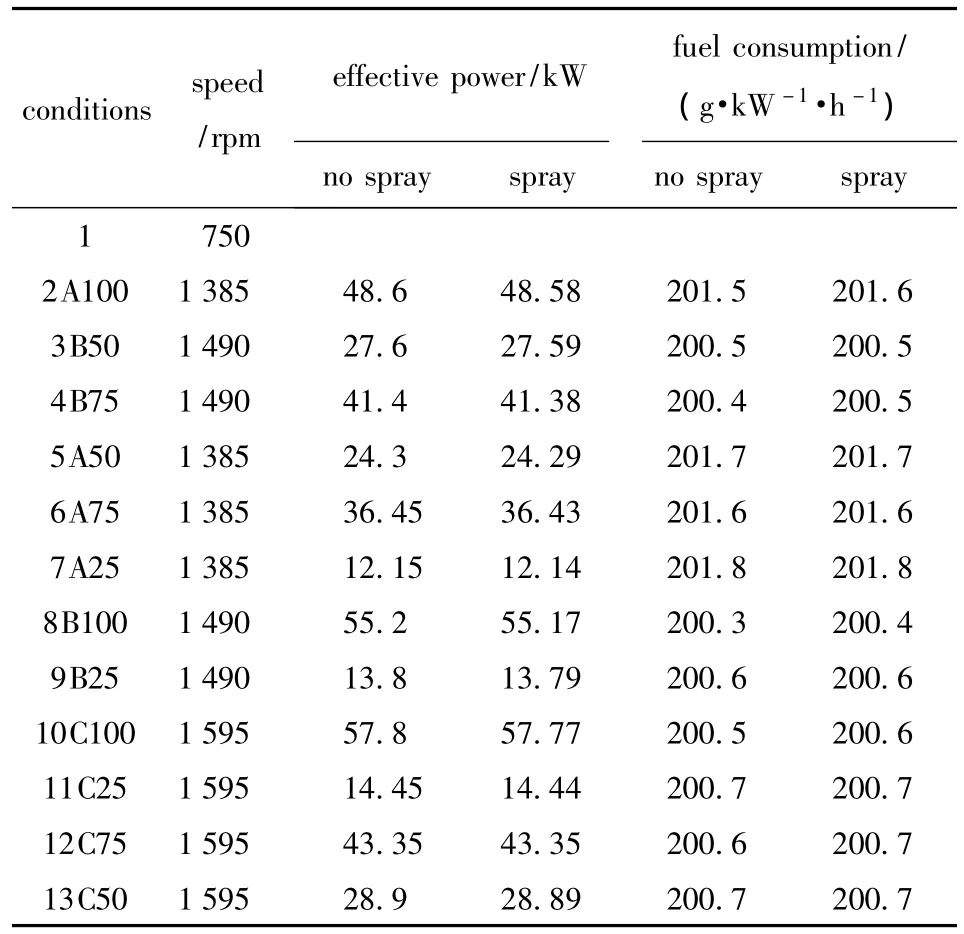

The effective power and fuel consumption with and without ammonia spraying are shown in Tab.5.

Tab.5 Effective power and fuel consumption in different conditions

5 Conclusions

1)In the appropriate time,the ammonia injection to the diesel engine can effectively reduce NOxin the combustion gas,and the EuroⅤ standard could be reached.

2)Spraying ammonia in diesel engine can avoid to use the catalyst,eliminate the catalyst sinter,alkali metal and arsenic poisoning,and gas erosion,and increase the purification effect.It greatly simplifies the engine’s purification system also.And,it does not limit the diesel’s combustion temperature and influence the engine’s thermal efficiency.

[1]XU Yun,LIU Zhong-chang,HAN Yong-qiang.Comparison of test cycle of 13 conditions and European steadystate test cycle to evaluate heavy-duty diesel engine emissions[J].Automotive Engineering,2003,(1):46 -48.(in Chinese)

[2]LENG Xian-yin,LONG Wu-qiang.Modern purification technology for NOxemissions of marine diesel engine[J].Diesel,2009,31(2):19 -25.(in Chinese)

[3]MAO Xiao-jian,LOU Cheng-wei,XIAO Wen-yong.Key technologies satisfying future emission regulations for car’s diesel engine[J].Vehicle Engine,2006,(2):6 -14.(in Chinese)

[4]XU Yang.Technical scheme of exhaust post-processing for diesel based on regulations of EURO Ⅲ above[J].Journal of Wuhan University of Technology,2006,(8):34-37.(in Chinese)

[5]DU Jian-bo,WANG Zhen,FANG Mao-dong.Post-processing for diesel car to meet new emission regulations[J].Shanghai Automobile,2006,(4):40 - 43.(in Chinese)

[6]LIAO Shi-yong,JIANG De-ming.Research progress and problems on post-processing technology for diesel exhaust[J].Internal Combustion Engine,2002,(3):3 - 6.(in Chinese)

[7]MAO Xiao-jian,XIAO Wen-yong,ZHOU Xing-li.Exploration on technical measures for diesel cars[J].Automotive Engineering,2006,(7):611 -617.(in Chinese)

[8]LIANG Hong,LIN Wei-ming.Research on emission control technology for diesel engines[J].Guangdong Chemical Industry,2004,(6):28-30.(in Chinese)

- Defence Technology的其它文章

- Research on the Application of Explosive Network in the Shaped Charge Warhead

- Improvement of Intercept Probability Algorithm for Anti-ship Missile Based on Search Theory

- Research on the Fracture Mechanism of Scored Liner Under Explosive Loading

- Research on Complex Refraction Indices of Expanded Graphite

- Variable-mass Thermodynamics Calculation Model for Gas-operated Automatic Weapon

- Modeling and Simulation of Aerial Dispersion on Piston Dispersal Mechanism