Coupled Faults Analysis and Evaluation Methods Based on Cellular Automata

XIAO Jing (肖 静), REN Yi (任 羿), WANG Zi-li (王自力), YANG De-zhen (杨德真)

School of Reliability and Systems Engineering, Beihang University, Beijing 100191, China

Coupled Faults Analysis and Evaluation Methods Based on Cellular Automata

XIAO Jing (肖 静)*, REN Yi (任 羿), WANG Zi-li (王自力), YANG De-zhen (杨德真)

SchoolofReliabilityandSystemsEngineering,BeihangUniversity,Beijing100191,China

The reliability analysis of coupled faults may be difficult due to its properties of multiple and intermittent. The challenge is to find the rule and depict of the cross-linking relationship by mathematical model. The method in this study was developed around the Cellular Automata (CA) with a novel neighborhood definition and the structure of network model to build the failure cellular automata. And the simulation of the coupled faults influence combined with the importance evaluation method of network node to find the most critical faults which were beneficial to improve the design, without consuming massive computational overhead.

reliability;CellularAutomata(CA);coupledfaultinfluence;evaluation

Introduction

Coupled faults analysis in safety-critical systems, such as power plants, aircraft, automobiles, commercial facilities requiring ultra-high availability of service, and precision manufacturing systems, is a complex and challenging task when there are multiple and intermittent faults in the system. Because the faults and/or their propagation are coupled, and the failure modes can either be active or passive[1], it becomes even more difficult. Reference [2] showed that a passive failure didn’t affect any other healthy component (e.g., open circuit faults). In contrast, the active faults may cause further damage (e.g., short circuit faults), and are also the frequent causes of malfunctioning in other coupled/inter-related systems, such as those in integrated aircraft and automotive systems. Therefore, designers must be clear about their active faults and their cross-linking relationship in the development stage of complex products. Otherwise, the coupled faults can result in catastrophic system behavior and large economic costs.

The research on coupled faults focused primarily on dynamic characteristic analysis of mechanical failures, such as rotor-ball-bearing system with pedestal looseness and crack[3], with pedestal looseness and rubbing[4]. Most of these methods are specific for particular failures of mechanical products. However, for complex products, electronic products and photoelectric products are also contained. And the functional relationship between the cross-linking is very complex. These methods are not applicable.

Cellular Automata (CA) are mathematical idealizations of physical systems in which space and time are discrete, and physical quantities take on a finite set of discrete values[5]. CA has been widely used in a variety of complex systems, such as soil erosion[6], the fire spread[7], and infectious diseases[8]. The fault propagation of these systems and products have a certain commonality, which are due to internal and external problems for one component failed, while causes delivery problems to the next component. We can apply the principles of CA to simulating the transfer process by this method: the failure mode is compared with the cell; at the same time the occurrence of failure is compared with the cell state; the physical entity or the functional unit with an interface for the transfer of energy, material and signal is compared with neighbors; the interface and the failure criterion are compared with the transfer rules; the methodology of cellular automata will be applied to simulating the transfer process of one or more failures soon after their occurrence. This method is not limited to product type and product levels, which can effectively compensate for the lack of the current method.

1 Preliminaries

In this paper, we consider synchronous CA only. The cells are hence the squares of an infinited-dimensional checker board, addressed byZd, which is called ad-dimensional CA. In order to facilitate the simulation model, we first give the mathematical definition of CA.

The states of the automaton come from a finite state setS. At any given time, the configuration of the automaton is a mappingc:Zd→Sthat specifies the states of all cells. The set SZdof all configurations is denoted byC(d,S), or brieflyCwhendandSare known from the context.

The local rule is a functionf:Sn→S, wherenis the size of the neighborhood. Statef(a1,a2, …,an) is the state of a cell whosenneighbors were at statesa1,a2, …,an. This update rule then determines the global dynamics of the CA: configurationcturns into the configurationg, for allli∈Zd,

(1)

2 Failure Cell Sphere and Its Performance

There are multiple failure modes for a component of the product. Each failure mode could be treated as a cell which could be represented as a fixed size cellular sphere. The cellular only has two states: occurrence and not occurrence, with black and gray respectively, as shown in Fig.1.

Fig.1 Failure mode cell sphere

Each failure mode cellular has a certain properties, including neighbors and the probability of occurrence and output.

2.1 A novel neighborhood

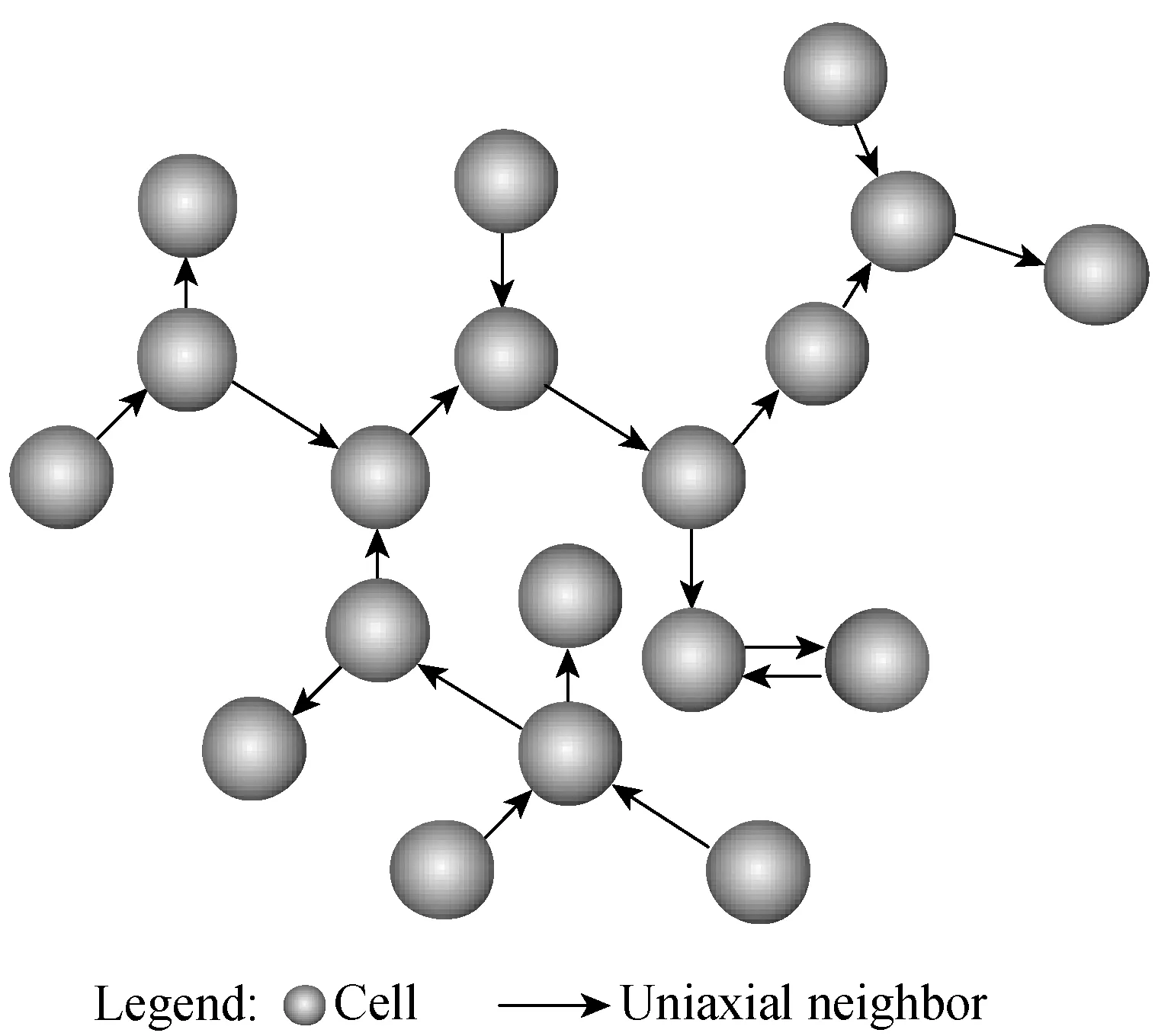

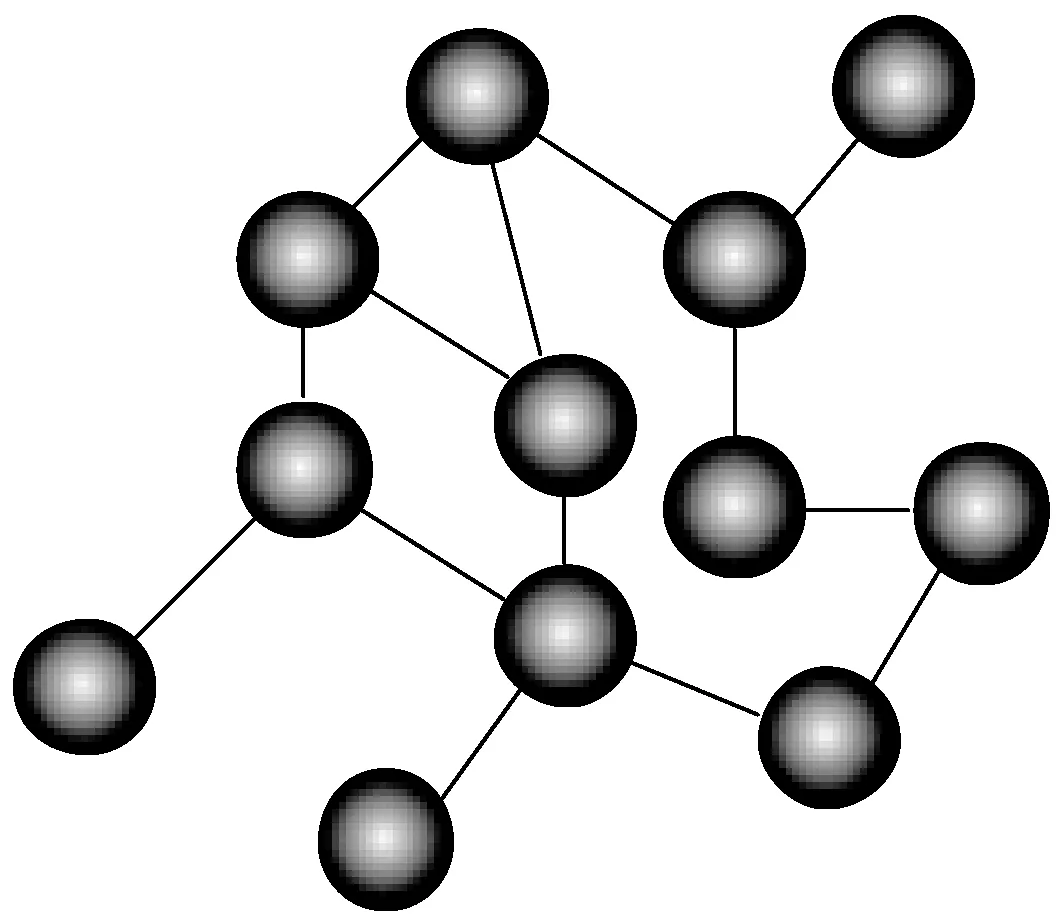

Combined with interface features, the paper defines the link of neighborhood as a unidirectional connection. Moreover, the product is three-dimensional, whose neighbors are around 360 ℃, and some may not be in the same area. To this end, we draw on the experience of network model[9]concept to rebuild CA model. If the output from cellularais the input of cellularb, we can establish a one-way line to connect the two cells,e.g.,a→b, as shown in Fig.2.

Fig.2 Cellular automata based on new neighborhood definition

If the output of cellularlεiis the input of cellularlεj, then the matrix elementlεijis equal to 1, otherwiselεijis equal to 0. Combined with the above, we give the mathematical expression of neighbor of cellcεiin productεcells:

Nεi=

(2)

wherenεrepresents the number of cellular neighbors in productε.

2.2 The cellular probability of occurrence

As mentioned above, we consider only two cell states: occurrence and not occurrence. The probability of occurrence of cellular is needed to be further considered in providing input for the subsequent evaluation of coupling faults.

A cellular is representative of a failure mode. The cellular occurrence probabilityλεiis the failure mode occurrence probability. Its expression is as follows:

λεi=αεiλε,

(3)

whereαεidenotes the frequency ratio of failure modelεiin productε, andλεdenotes the failure rate of productε, which can be obtained through reliability prediction.

2.3 Output of cellular and failure criterion

When settling the problem of simulation analysis by using CA model, a criterion of the occurrence of failure is essential for each cellular. Therefore, we mainly check the output of the corresponding product whether meets the requirements to define the failure criterion. Since the output is determined by the input, we need to determine the input conditions of the product first.

2.3.1 The input of disturbance

The cellular of the product may be classified into two categories according to the relationship between the input and output of the disturbance.

1) The input of disturbance which has a definite function relationship with the output, such as temperature and noise, can be represented by setIDεi. This kind of input directly affects the output of such products.

2) The input of disturbance which does not have a definite function relationship with the output can be represented by setDεi. Such factor is difficult to be expressed by a generic model, for it only concentrates on specific products and working environment. This article does not consider such disturbances.

2.3.2 The input with function relationship

For the input of products which is functional-dependent is surely the output of the front-end product, it can be represented by setsIFεi.

Whether it is hardware failure or malfunction, the product ultimately shows that its performance indicators cannot be bounded by some given threshold. So we should define that the output of the cellular is the subset of the product input. Generally assume,

1)the cellularlεiin productεhas performance indicatorspεi=(pεi1,pεi2, …,pεiv, …,pεiV), where the output of the performance indicatorvcan be presented bypεiv(IFεi,IDεi);

2)the threshold range of performance indicator for cellularlεiin productεisΩεiv.

The purpose of this paper is to analyze the influence generated by failure modes. It is not focused on the cause of the malfunction. When settling the problem of simulation analysis by using CA model, the initial failure of products ε may be simulated by the random function. That is, within a random task time, the performance outputvof cellularlεiis made beyond the constraintsΩεiv:

Above all, the cellularlεifor the productεcan be represented by:

Further, the failure cellularlεifor the productεcan be expressed as

(5)

Based on the model referred above, the coupled faults can be taken into simulation. Through the simulation, we obtained a range of set of coupled faults:

(6)

wherendenotes the total number of cellular in the cellular automata, andncfdenotes the number of coupled faults set.

Coupling faults can be further evaluated based on the results obtained by simulation, and then find the weak links in the product design to improve the reliability of products.

3 Evaluation of Coupled Faults’ Effects

3.1 The influence of coupled faults

Seen from failures CA model, we know that multiple failures may occur at the same time. The cellular which results in more malfunctions is the most critical beginning cellular. Based on these findings, we can combine with CA model to evaluate the influence of coupled faults. Prior to this, firstly, a few concepts are defined below.

The occurrence probability of the source netλNsis determined by the probability of occurrence of the source. Its expression is as follows:

(7)

Further, we can obtain the influence modelIsof the sourceS, which can be expressed by:

(8)

WhenINSis greater, the influence of cellularNsis greater. It should be solved earlier in the design.

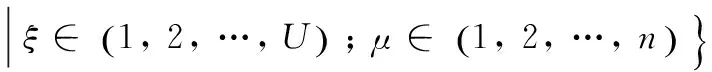

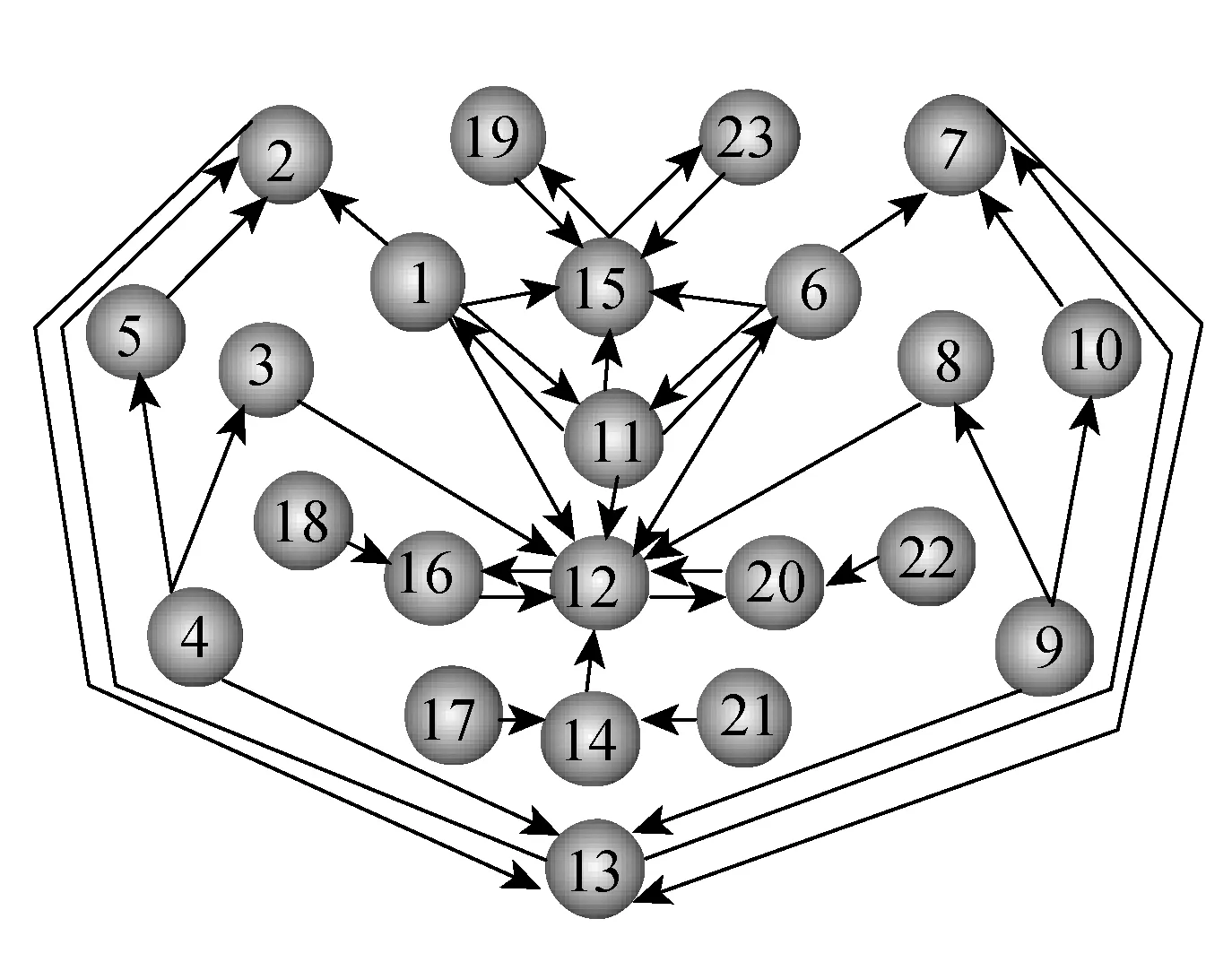

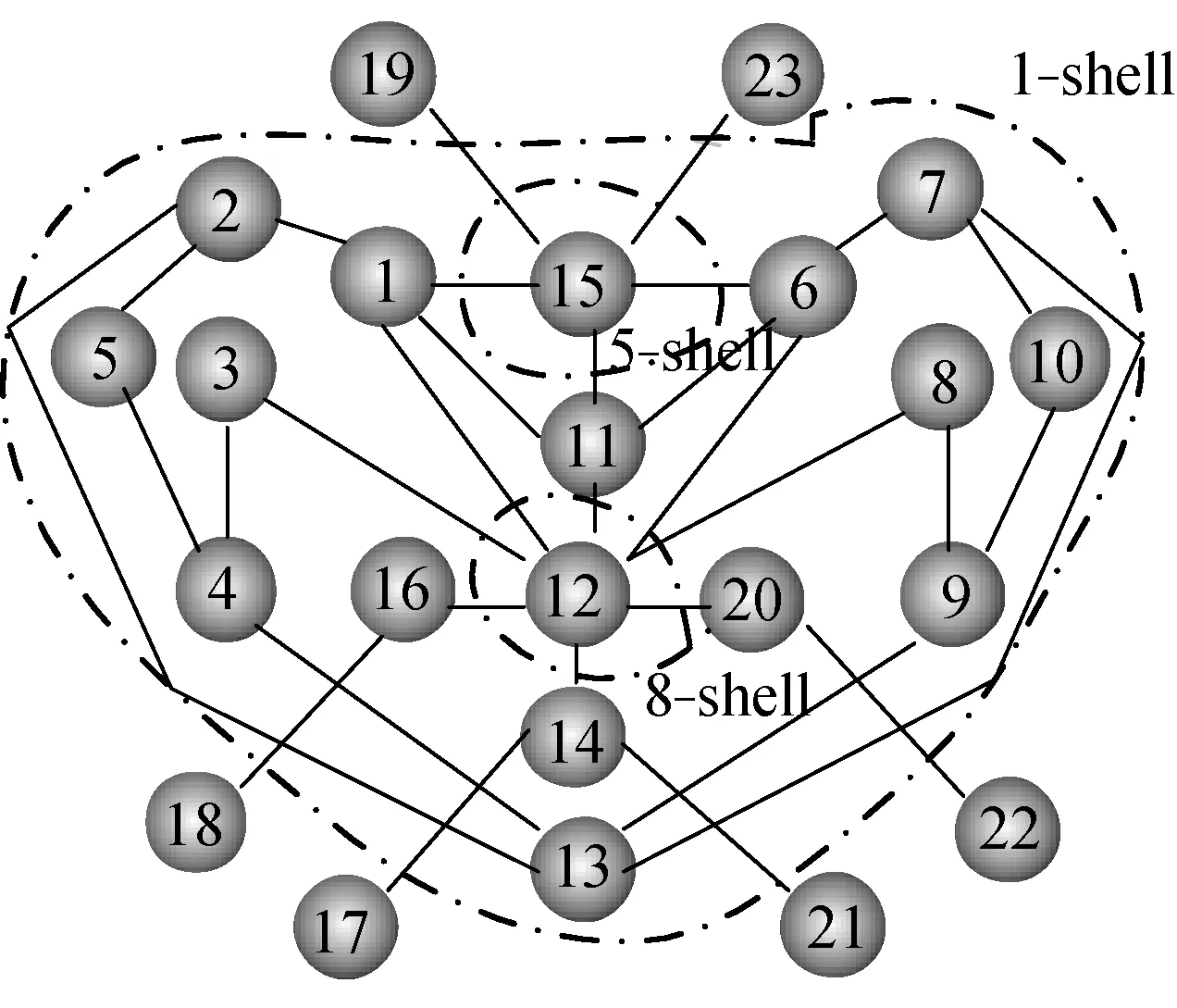

3.2k-shell andk-core

The importance evaluation method of network node is necessary to assist finding the common part of the coupled fault sets, that is, the common part is the greater degree node. Thek-shell andk-core are the important indicators to measure the significant degree of network nodes without direction. The proposed model based on CA is directed model. In the analysis of key nodes, we should consider the nodes which are malfunction due to the coupled faults. Thus, before making decomposition of thek-shell, we should delete the unaffected node, as shown in Fig.3.

Fig.3 Cellular automata without direction

In the model, node 1 is the worst note in design improvement. All of the nodes which are 1 and connected line constitute 1-shell. If 1-shells are deleted, the node of the new model is at least 2. Similarly, the cell whose node is 2 and its connected line constitutes the 2-shell. We can further obtain a higher shell, referred to ask-shell (k= 1, 2, …,K), as shown in Fig.4.

Fig.4 Example of 1-shell and 2-shell

Whenk-shells are decomposed, we get the union set ofk-shell that allks≥kin the model, that is,k-core. When the numberkis greater, it indicates that the node ink-core is more critical, which is the key to improve the product design important.

4 A Case Study

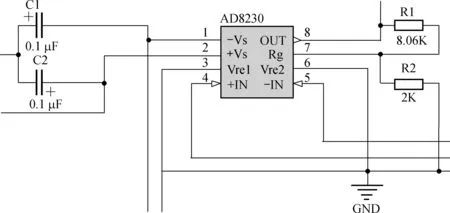

We take an amplifier circuit of a strain tester (shown in Fig.5) as an example to illustrate how the failure CA is modeled and evaluated using the proposed approaches.

Fig.5 The amplifier circuit

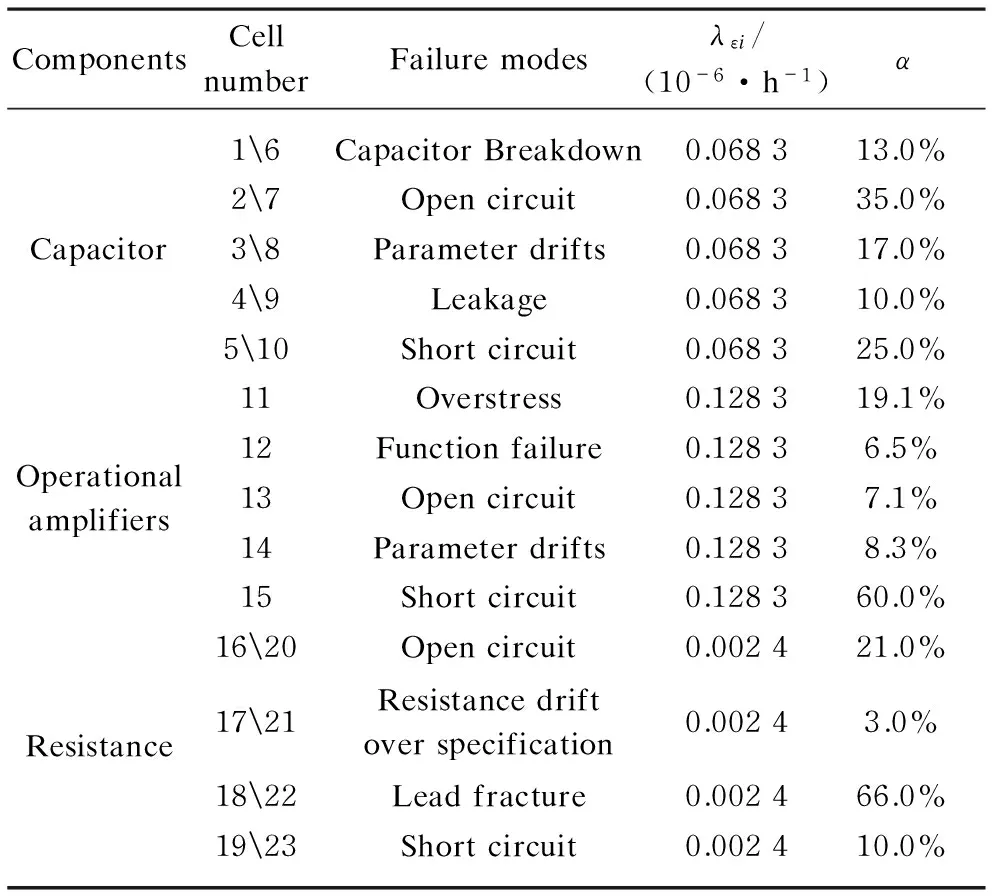

There are two capacitors C1 and C2, two resistances R1 and R2, and an operational amplifier AD8230. The failure modes of these components and its performance are shown in Table 1.

Table 1 The data sheet of the amplifier circuit

Note: the cell numbers 1 to 5 represent the failure modes of capacitor C1; the cell numbers 6 to 10 represent the failure modes of capacitor C2; the cell numbers 11 to 15 represent the failure modes of operational amplifiers; the cell numbers 16 to 19 represent the failure modes of resistance R1; and the cell numbers 20 to 23 represent the failure modes of resistance R2

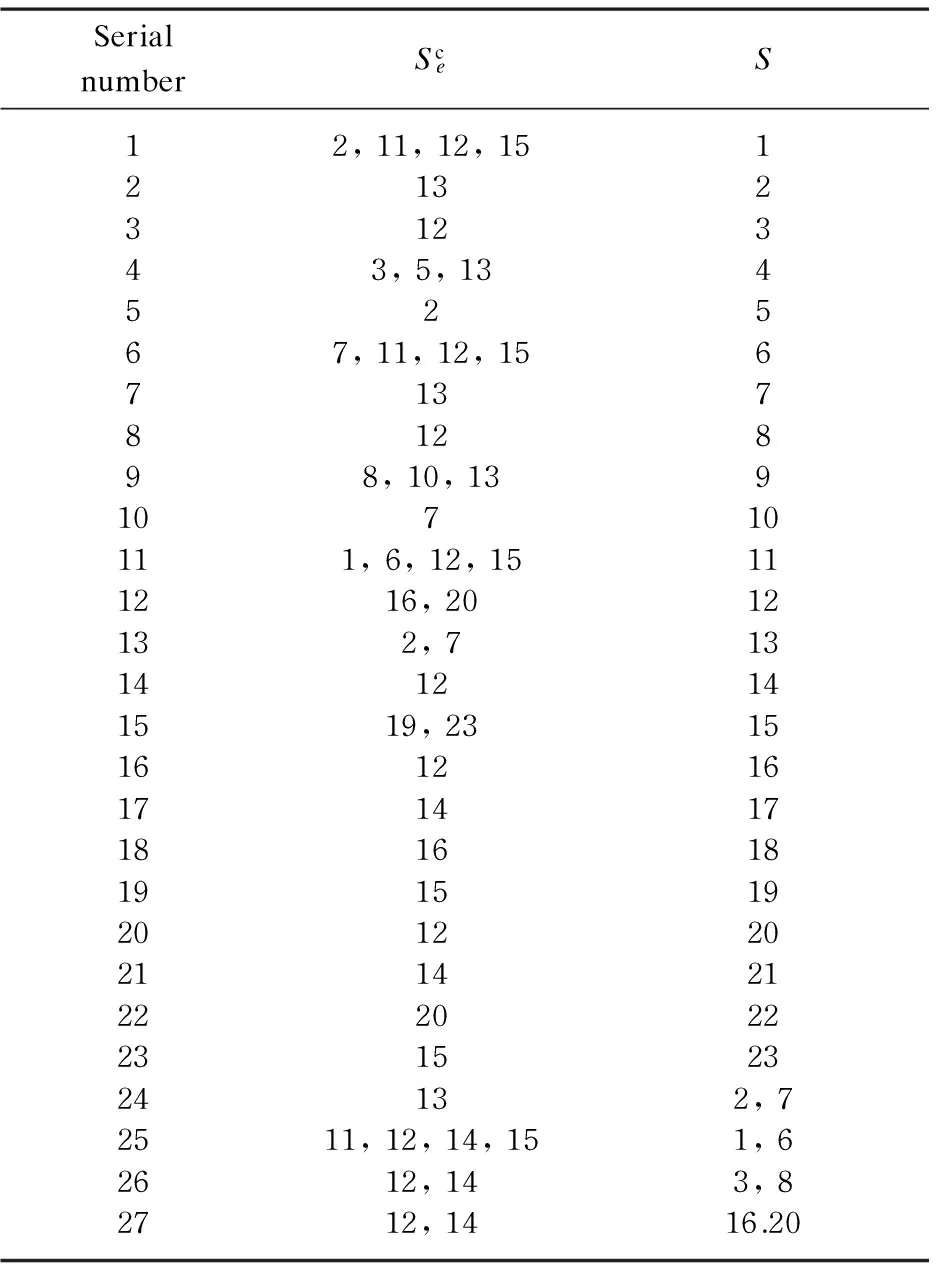

According to the definitions and rules in Section 3 we depicted the failure CA model of the amplifier circuit in the below Fig.6. Therefore, we obtained the failure CA model without direction by using importance evaluation methods of network node. Apparent from Fig.7, we find 8-shell and 5-shell whose numberskare greater. According to the rules shown in Section 3, the serial numbers 15 and 16 are the key in design improvement.

Fig.6 The failure CA of the amplifier circuit

Fig.7 8-shell decomposition

We obtain the coupled faults set and its source through simulation, as shown in Table 2.

Table 2 The coupled faults set and its source

According to the result, we further evaluate the coupled faults and its source, as shown in Table 3.

Table 3 Coupled faults evaluation result

From the result, it is obvious that the influenceIsof the serial number 15 is the largest of allIsby comparison. Therefore, we can conclude that the influence of the serial number 15 is the greatest and it should be solved earlier in design improvement.

5 Conclusions

An efficient scheme is proposed to evaluate the coupled faults to facilitate finding the most critical malfunction in a complex product. The solution is developed around the structure of CA and a novel rule of neighbors. A special rule of coupled faults influence model is chosen for the reported scheme. The characterization of failure CA has been reported to realize the proposed coupled faults analysis and evaluation methodology.

[1] Li W Y. Risk Assessment of Power Systems: Models, Methods, and Applications [M]. NJ: IEEE Press, 2005.

[2] Kodali A, Pattipati K, Satnam S. A Coupled Factorial Hidden Markov Model (CFHMM) for Diagnosing Coupled Faults[C]. IEEE Aerospace Conference, Big Sky, MT, USA, 2010: 1-11.

[3] Zhang Y P , Huang S H, Hou J H,etal. Continuous Wavelet Grey Moment Approach for Vibration Analysis of Rotating Machinery[J].MechanicalSystemsandSignalProcessing, 2012, 20(5): 1202-1220.

[4] Li M, Wang Y, Li F C,etal. Modelica-Based Object-Orient Modeling of Rotor System with Multi-faults[J].ChineseJournalofMechanicalEngineering, 2013, 26(6):1169-1181.(in Chinese)

[5] Wolfram S. Statistical Mechanical of Cellular Automata[J].ReviewsofModernPhysics, 1983, 55(3): 601-644.

[6] Vanwalleghem T, Jimenez-Hornero F J, Giraldez J. V,etal. Simulation of Long-Term Soil Redistribution by Tillage Using a Cellular Automata Model[J].EarthSurfaceprocessesandLandforms, 2010, 35(7): 761-770.

[7] Zheng Y, Jia B, Li X G,etal. Evacuation Dynamics with Fire Spread Based on Cellular Automaton[J].PhysicaA:StatisticalMechanicsandItsApplication, 2011, 390(18/19): 3147-3156.

[8] de Paula Ferreira E I, de Andrade Moral R, Ferreira C P,etal. Modelling Fungus Dispersal Scenarios Using Cellular Automata[J].EcologicalInformatics, 2013, 14(SI): 53-58.

[9] Omta S W F, Trienekens J H, Beers G. Chain and Network Science: a Research Framework[J].JournalonChainandNetworkScience, 2001, 1(1): 1-6.

1672-5220(2014)06-0875-04

Received date: 2014-08-08

*Correspondence should be addressed to XIAO Jing, E-mail: xjingbuaa@gmail.com

CLC number: TB114.3 Document code: A

Journal of Donghua University(English Edition)2014年6期

Journal of Donghua University(English Edition)2014年6期

- Journal of Donghua University(English Edition)的其它文章

- Optimization of Quality Consistency Problem of Electromechanical Component due to Manufacturing Uncertainties with a Novel Tolerance Design Method

- Effect of Starch Dodecenylsuccinylation on the Adhesion and Film Properties of Dodecenylsuccinylated Starch for Polyester Warp Sizing

- Interval Fault Tree Analysis of Excavator Variable-Frequency Speed Control System

- Combinatorial Optimization Based Analog Circuit Fault Diagnosis with Back Propagation Neural Network

- Reliability Allocation of Large Mining Excavator Electrical System Based on the Entropy Method with Failure and Maintenance Data

- Deployment Reliability Test and Assessment for Landing Gear of Chang’E-3 Probe