氧化石墨烯对水泥基复合材料微观结构和力学性能的影响

王 琴, 王 健, 吕春祥, 刘伯伟, 张 昆, 李崇智

氧化石墨烯对水泥基复合材料微观结构和力学性能的影响

王 琴1, 王 健1, 吕春祥2, 刘伯伟1, 张 昆1, 李崇智1

(1.北京建筑大学土木与交通工程学院工程结构与新材料北京市高校工程研究中心绿色建筑与节能技术北京市重点实验室,北京100044; 2.中国科学院山西煤炭化学研究所碳纤维制备技术国家工程实验室,山西太原030001)

研究了不同掺量下氧化石墨烯(GO)对水泥石以及胶砂微观结构和力学性能的影响。含16.5%水的水泥浆、0.05%GO及3倍于水泥的沙子共混物作为添加剂制备成砂浆。通过SEM、液氮吸附仪和一系列标准实验分别对水泥石的微观形态、孔隙结构、抗压抗折强度以及水泥净浆的流动度、黏度、凝结时间进行表征;考察不同GO掺量下水泥水化放热的变化情况。结果表明:GO对水泥浆有显著增稠和促凝作用;GO的掺入可以有效降低水泥的水化放热量;GO对水泥石有显著的增强增韧效果,28天龄期时,GO质量分数为0.05%的水泥石,3、7和28 d抗压强度和抗折强度同比对照组分别增加52.4%、46.5%、40.4%和86.1%、68.5%、90.5%,胶砂的抗压强度和抗折强度同比对照组分别增加43.2%、33%、24.4%和69.4%、106.4%、70.5%;GO在水泥硬化过程中对水泥石中晶体产物的产生有促进作用并能规整晶体的排布而形成针状晶体簇,改善水泥石中的孔结构,降低水泥石中微孔的体积,增加水泥石的密实度,对水泥石有显著地增强增韧效果。

氧化石墨烯;水泥基复合材料;增强增韧;微观结构;水泥水化热

1 Introduction

With the development of the infrastructure,high performance concrete is urgently needed in the key projects such as high-rise buildings,cross-sea bridges,subsea tunnel and hydraulic or marine works, which are usually under the environment attacked easily by salts and alkalis[1].Compared with the conventional concrete,high performance concrete requires the concrete with considerably improved performances such as high strength,high durability,high chloride ion migration resistivity,high freeze resistance,high sulphate resistance,low shrinkage,low abrasion and low carbon footprint et al.[2,3].

The cementcomposites have a noticeable feature of relatively high compressive strength and low tensile and flexural strength,which belong to brittle materials.New carbon materials such as carbon fibers,carbon nanotubes and carbon black were used to enhance the strength of cement composites or provide the cement composites with improved electric or thermal performance[4-8].Nevertheless,the reinforcing materials such as carbon fibers and carbon nanotubes only play a physical role in the cement composites,which does not participate in the hydration and microstructure modification of the cement,especially the pore structure and crystalline structure of cement paste. And the dispersion of carbon fibers and carbon nanotubes in the cementmatrix is also challenging because of the hydrophobic surface of these reinforcing materials[9-11].Therefore,it is urgent to find a new material which can notonly disperse uniformly in the aqueous system of hydrated cement,but also improve the toughness of hardened cement paste by microstructure modifications.Graphene oxide(GO)is an intermediate product in grapheme preparation,which has many advantages as a reinforcing material such as ambiphilicity,excellent mechanical,electrical and thermal properties[12-14].It is easy to disperse uniformly in cements,which is beneficial to the reinforcing effect. The application of GO in the cement was seldom reported in the literature,and further attention should be paid on this field.

In this paper,the influence of GO addition on the fluidity,viscosity,setting time of cement paste, and the pore structure,surface morphology,compressive strength and flexuralstrength of hardened cement paste is investigated.And the mechanism of the reinforcing and toughening effect is discussed.

2 Experimental

2.1Materials and reagents

The cement paste and mortar investigated in this study were prepared using an ordinary Portland cement type 42.5 and GO dispersion having a solid content of 4 mg/mL[15]was provided by Institute of Coal Chemistry,Chinese Academy of Sciences.The chemical and physical properties of the cement and the GO are presented in Table 1 and Table 2 and Fig.1.Polycarboxylate superplasticiser with a solid contentof 50%was used.Standard sand used in this study was produced by Xiamen.

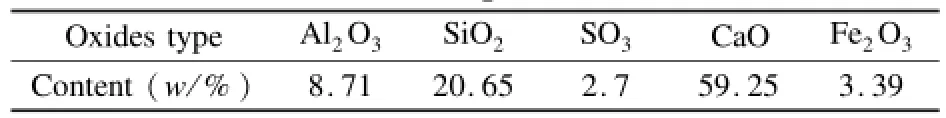

Table 1 Chemical components of the cement.

Table 2 Main physical index of cement.

2.2Preparation

2.2.1 Preparation of the cement paste

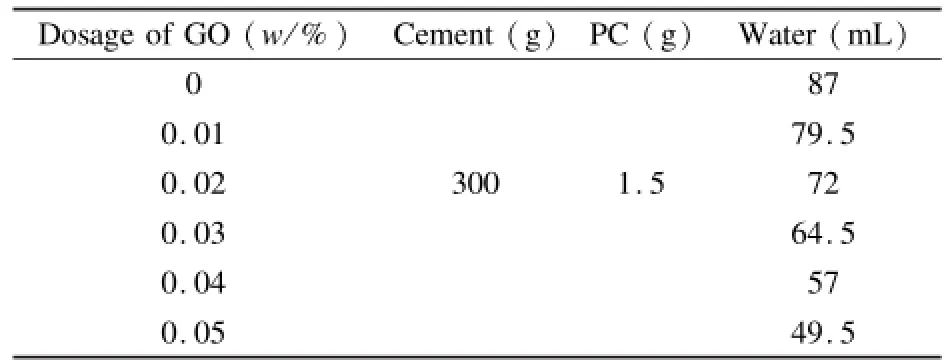

The mixing proportion of cement paste was designed according to GB/T8077-2000“Test methods of concrete admixtures homogeneity”.The GO dosage was varied from 0.01%to 0.05%in cement paste to investigate the influence in the fluidity,viscosity,setting time and strength.The dosage of water-reducing agent is 0.5%of cement.After testing the fluidity,viscosity and setting time of the cement paste,the cementpaste was putinto a mould(40 mm ×40 mm×160 mm)and maintained at standard conditions.The compressive strength and flexural strength were tested at different ages.The mixing proportion is shown in Table 3.

2.2.2 Preparation of the cement mortar

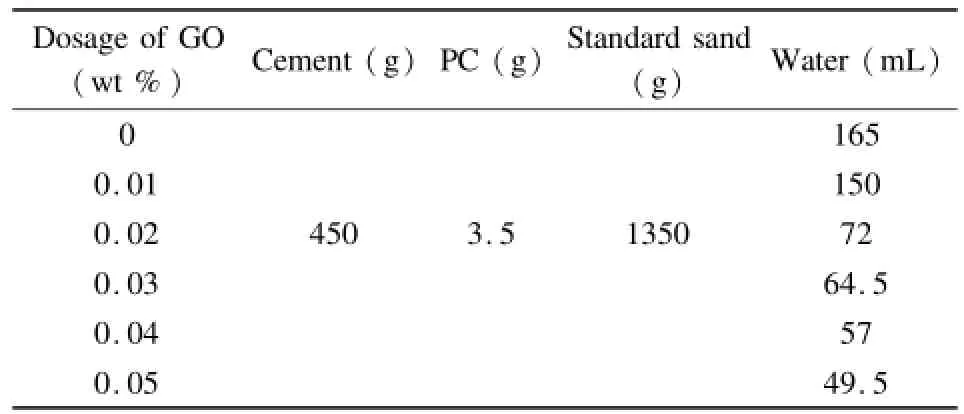

The mixing proportion of cement mortar was designed according to GB/T2419-2005“Test methods of fluidity of cement mortar”,with some parameters modified according the test.The ratio of water to cement(W/C)is 0.37,the dosage of water-reducing agent is 3.5 g,the dosage of antifoaming agentsis 2 g.After testing the fluidity of the cementmortar, the cement mortar was put into a mould(40 mm× 40 mm×160 mm)for curing under a standard condition.Detail mixing proportion is shown in Table 4.

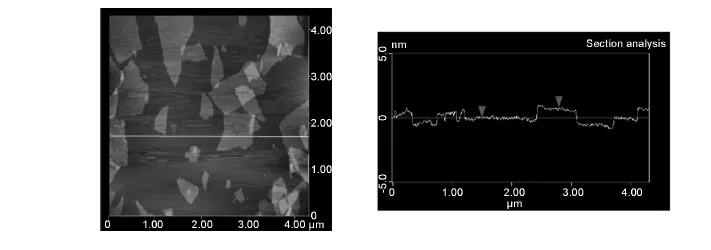

Fig.1 AFM image of graphene oxide nanosheets.

2.3Characterization

2.3.1 Characterization of GO

The size and thickness of GO was characterized by an atom force microscope(AFM)of SPI3800N/ SPA400.GO dispersion was diluted to the required concentration and then placed on a mica sheet.

Table 3 Mixing proportions of cement paste with different dosages of GO.

Table 4 Mixing proportions design of mortar with different dosages of GO.

2.3.2 Composition of cement

The oxides in the cement were characterized by a X-ray fluorescence spectrometer of supermini wavelength dispersion type.

2.3.3 Setting time of the cement paste

The setting time of the cement paste was tested according to GB/T1346-2001“Testmethods of water requirement of normal consistency,setting time,stability of cement paste”.

2.3.4 Fluidity of the cement paste

The fluidity of the cement paste was measured according to GB/T8077-2000“Test methods of concrete admixtures homogeneity”.

2.3.5 Viscosity of the cement paste

The viscosity of the cement paste was tested by a NDJ-5S digitalrotary viscosity meter.Due to the limit of non-Newtonian fluidity of the cement paste,the results of viscosity are used only by comparison.

2.3.6 Fluidity of the cement mortar

The fluidity of the cement mortar was measured according to GB/T2419-2005“Testmethods of fluidity of cement mortar”

2.3.7 Mechanicalstrength of hardened cementpaste and mortar

The strength of the cement paste and mortar is tested according to GB/T17617-2007“Test methods of strength of cement mortar”.

2.3.8 Heat of hydration of the cement

The heat of hydration of cement was characterized by a Toni CAL cement heat of hydration meter. The hydration time was chosen to be 72 h at 25℃with a cement weight of 10 g and a W/C ratio of 0.5.

2.3.9 Surface morphology

The morphology of the hardened cement paste was characterized by a S-4800 Scanning Electronic Microscope.

2.3.10 Pore structure

The pore structure of the samples was characterized by a ASAP2460 nitrogen adsorption equipment.

3 Results and discussion

3.1Characterization of GO

AFM image of GO is shown in Fig.1.From Fig.1,it can be seen that the size and thickness of GO sheetis 100-1000 and 0.7 nm,respectively,indi-cating that GO is one or two atom thick layers.

3.2Influence of GO addition on the workability of the cement paste and mortar

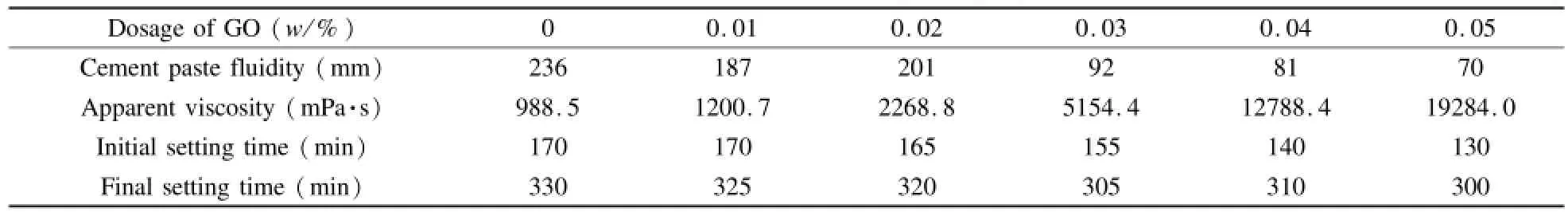

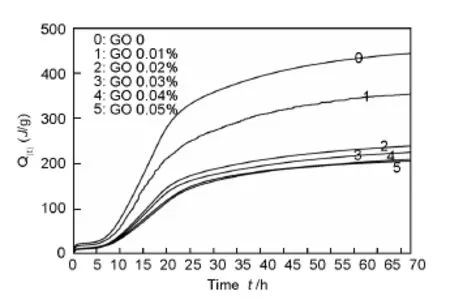

The influence of GO addition on the fluidity, viscosity and setting time of the cement paste are shown in Table 5.From Table 5,with the increase of GO dosage,the fluidity of cement paste decreases, the viscosity of cement paste increases and the setting time of cement paste is shortened.Especially,when the GO addition is up to 0.03%,there is an evident change in the fluidity,viscosity and setting time.This illustrates that the GO addition may make the cement paste thicker and may accelerate the hydration of the cement.The decrease of fluidity and increase of viscosity may be attributed to the nanometer size effect and surface chemistry of GO.The super large specific area together with oxygen-containing functional groups of GO may increase its interaction with hydrated cement,leading to the aggregation of cement granular.The large number of functional groups on the surface and edges of GO may also produce chemical reaction in the alkaline environment of cement,accelerating the hydration of cement and shortening the setting time.Though the GO addition may result in the reduction of setting time,the reduction of setting time is no more than 0.5 h,which is within the range of the national standard and has no bad effect on the usage of cements.

The influence of GO addition on the fluidity of the cement mortar is shown in Table 6.From Table 6,it can be seen that GO also reduces the fluidity of the cement mortar,which is similar to the result obtained for the cement paste.

Table 5 Effect of GO on cement paste properties.

Table 6 Effect of GO on mortar fluidity.

3.3Influence of GO addition on the hydration heat of cement

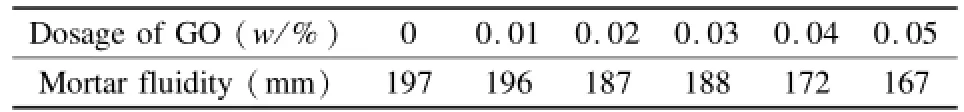

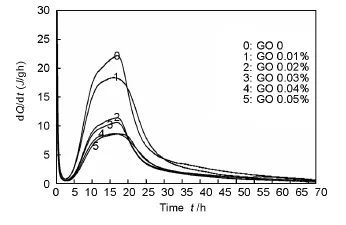

The influence of GO addition on the hydration heat of cement and rate of heat release are shown in Fig.2 and Fig.3.

Fig.2 Effect of GO on cement hydration exothermic rate.

From Fig.2 and Fig.3,it can be observed that the hydration heat of cement during 3 d decreases first and levels off thereafter.At a dosage of 0.02%,the rate of heat release and the total amount of heat release have a sharp decrease over 50%.Although with the increase of the,dosage of GO,the rate of heatrelease and the total amount of heat release gradually decrease and level off with the dosage of GO.

Fig.3 Effect of GO on cement hydration heat.

Silicon fume and fly ash is generally added to the concrete to reduce the hydration heatof cement.Their mechanism of reduction of hydration heat is considered to be a combination of replacement of cement, retarding the time of the peak of heat release and the secondary hydration reaction[16-18].From Fig.2,itis found that the heat release curves of hydration at the different GO dosages,the occurrence time and the duration time of hydration reaction at all stages and the shape of curves are all similar to each other with no other peak of heat release observed,indicating that the GO addition doses not retard the occurrence of the peak of heat evolution and,the mechanism of hydration heat reduction of cement is different from that ofsilicon fume and fly ash.This may be correlated to the physico-chemical interaction of GO with cement during the hydration.The high specific surface energy and oxygen functionalgroups of GO may promote the hydration procedure through adsorption of the ion in the hydration system and accelerate nucleation, growth and phase separation of the hydrated crystalline compounds at early hydration stages.This may result in the reduction of the total amount of heat released.The detailed mechanism of GO action during the cement hydration needs investigating further.

3.4Influence of GO addition on the mechanical strength of the hardened cement paste and mortar

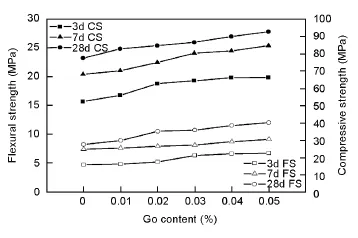

The influence of GO addition on the compressive strength and flexural strength of the ement paste and mortar at different ages are shown in Fig.4 and Fig. 5,respectively.From Fig.4,it can be seen that with the increase of dosage of GO,the compressive and flexural strength of the hardened cement paste all increase.When the dosage of GO is 0.05%,the flexural strength increase by 86.1%,68.5%and 90.5% and the compressive strength by 52.4%,46.5%and 40.4%at 3,7 and 28 d,respectively compared with the sample with no GO.

Fig.4 The flexural and compressive strength of hardened cement pastes with different dosages of GO.

From Fig.5,it can be seen that with the increase of dosage of GO,the compressive and flexural strength of the hardened cement mortar all increase. When the dosage of GO is 0.05%,the flexural strength increase by 69.4%,106.4%and 70.5% and the compressive strength by 43.2%,33%and 24.4%at 3,7 and 28 d,respectively,compared with the control groups.GO has a more obvious effect on flexural strength than compressive strength for both the cement paste and mortar.

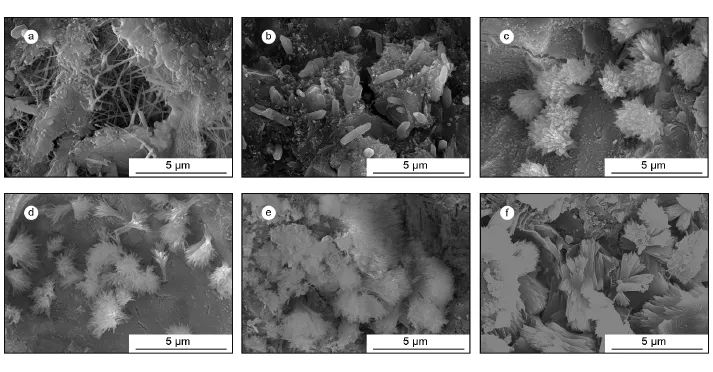

3.5Surface morphology and texture structure of the hardened cement paste

Fig.6 shows the SEM graph of the hardened cement paste with different GO contents at28 d.Fig.6 (a)shows the morphology of the hardened cement paste with no GO.Inter-growing ettringite crystals and a large amount of pores can be observed. Fig.6(b)-6(f)showed the morphology of hardened cement paste with the GO content from 0.01%to 0.05%,respectively.Flower-like crystals can be observed in Fig.6(c)-(e).With the increase of GO content,the amount of flower-like crystals increase, the numbers of harmful pores decrease,and the texture structure become more compact.This phenomenon illustrates that GO can accelerate the hydration of cement and produce more regular crystal which may improve the crystalline defect and contribute to the increase of flexural strength and compressive strength.

Fig.5 The flexural and compressive strength of mortar with different dosages of GO.

It is worth noting that,in comparison with Fig. 6(d)and(e),although more amount of flower-like crystals were observed in Fig.6(f),more crystal imperfection and disorderly arrangement were also observed.This phenomenon may help to explain the aforementioned results that the flexural strength of cement paste and mortar at 0.05%has no noticeable increase as compared with 0.04%.

3.6Influence of GO addition on the pore structure of the hardened cement paste

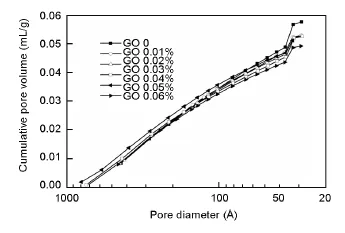

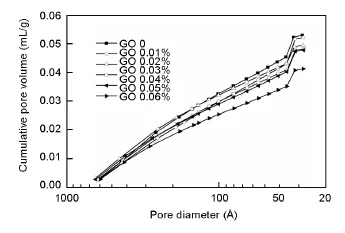

The hardened cement paste is comprised by the solid state of hydrated cement and pores.These pores may be formed by the excess water and air in the cement paste during the hardening process,which have a noticeable effect on their strength,durability and shrinkage.In this paper,nitrogen adsorption was used to investigate the pore sizes and their distribution.

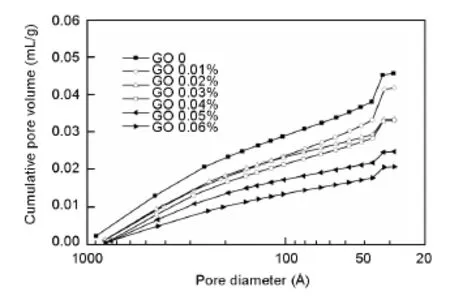

According to the pore size,the pores in the hardened cement paste are divided into four types:large pores(>1 000 nm),capillary pores(100-1 000 nm),transitional pores(10-100 nm)and gel pores(<10 nm).On the basis of this theory,the pores in sample are mainly transitional pores and gel pores.Moreover,the pores lager than 50 nm is regar-ded as macroscopic pores,which contribute to the strength and permeability,and the pores smaller than 50 nm is viewed as microscopic pores,which may have an important influence on the dry shrinkage and creep[19-21].

Fig.6 Effect of GO dosage on SEM images of the hardened cement paste at28 d.

The influence of GO addition on the cumulative pore volume distribution of the hardened cementpaste at 3,7 and 28 d are illustrated in Fig.7,Fig.8 and Fig.9,respectively.From Fig.7-9,it can be seen thatwith the increase of the age,the cumulative pore volume decrease.With the GO addition,there is an evident change of pore volume of the hardened cement paste,that is the cumulative pore volume (<100 nm)decrease with the increase of GO dosage. In addition,with the increase of hardening time,GO play a more important role.

Fig.7 Effect of GO dosage on the cumulative pore volume distribution of the hardened cement paste at3 d.

From Fig.7,the cumulative pore volume curves with different contents of GO have no evident changes,except for the pores of around 3 nm,which is considered to be the pores between the calcium silicate hydrate gel(C-S-H)layers[22].This results indicate thatin the initial stage of hardening,GO has an important effect on the gel pores and the total pore volume of gel pores decrease straightly with the increase of GO dosage.From Fig.8 and Fig.9,the pore volume curves with different contents of GO have more evident changes,indicating that the addition of GO not only influence the pore volume with small pore size,but also influence the pore volume with large pore size with increasing age.

Fig.8 Effect of GO dosage on the cumulative pore volume distribution of the hardened cement paste at7 d.

The above-mentioned results show that the GO addition can effectively modify the pore structure,reduce the pore volume,and make the hardened cement paste compacted,which is in accordance with the results obtained from SEM.The GO addition into thecement paste accelerates the crystalline hydrated products and make the crystal aligned regularly,which modifies pore structure and improves tightness of hardened cement paste.And this may elaborate the mechanism of reinforcing and toughening action of GO.In addition,due to the fact that the micro-pores is correlated to the performance of freezing resistance, permeability resistance and dry shrinkage of the hardened cement paste,the GO addition may improve the durability and anti-shrinkage performance of concretes.This will be further investigated in the subsequent work.

Fig.9 Effect of GO dosage on the cumulative pore volume distribution of the hardened cement paste at28 d.

4 Conclusions

The influence of GO dosage on the fluidity,viscosity and setting time of fresh cement paste and on the morphology,pore structure and mechanical strength of hardened cement paste and mortar were investigated in this paper.The main results are as follows.

The GO addition can increase the viscosity and shorten the setting time of the cement paste.When the dosage of GO is 0.05%,the viscosity increases sharply and the setting time is reduced by 30 min. The fluidity of the cement mortar has the same tendency with the cement paste.The GO addition can reduce of hydration heat of cement,which may be ascribed to the heat absorption in oxidation-reduction reaction between GO and cement.When the dosage of GO is 0.05%,the hydration heat of cement can be reduced by 54%.GO have a reinforcing and toughening effect on the cement-based composites.The GO addition can remarkably increase the compressive and flexural strength of the hardened cement paste and mortar,especially strength in the early stage.When the dosage of GO is 0.05%,the flexural strength of hardened cement paste increase by 86.1%,68.5% and 90.5%and the compressive strength by 52.4%, 46.5%and 40.4%at 3,7 and 28 d,respectively. The flexural strength of hardened cement mortar increase by 69.4%,106.4%and 70.5%and the compressive strength by 43.2%,33%and 24.4%at3,7 and 28 d,respectively.The GO may take part in the hydration reaction of cement,accelerate the nucleation,growth and phase separation of hydrated products,promote the hydration procedure,make the crystal aligned regularly,which result in modification of pore structure and improvement of tightness of the hardened cementpaste.

[1] Tang J H,Cai J W,Zhou M K.The status of researching and developing in high performance concrete[J].Science and Technology of Overseas Building Materials,2006,27(3):11-15.

[2] Boulekbache B,Hamrat M,Chemrouk M,et al.Influence of yield stress and compressive strength on direct shear behaviour of steel fibre-reinforced concrete[J].Construction and Building Materials,2012,27(1):6-14.

[3] Sun M,Liu Q,Li Z,etal.A study of piezoelectric properties of carbon fiber reinforced concrete and plain cement paste during dynamic loading[J].Cement and Concrete Research,2000,30 (10):1593-1595.

[4] Chung D D L.Carbon materials for structural self-sensing,electromagnetic shielding and thermal interfacing[J].Carbon, 2012,50(9):3342-3353.

[5] Luo J L,Duan Z D,Zhao T J,etal.Hybrid effect of carbon fiber on piezoresistivity of carbon nanotube cementbased composite [J].Advanced Mater Res,2011,143-144(1):639-643.

[6] Bahar D,Salih Y.Thermoelectric behavior of carbon fiber reinforced light weight concrete with mineral admixtures[J].New Carbon Materials,2008,23(1):21-24. (Bahar D,Salih Y.炭纤维增强轻质矿粉泥混土的热电行为[J].新型炭材料,2008,23(1):21-24)

[7] Li H,Xiao H G,Ou J P.Effect of compressive strain on electrical resistivityof carbon black-filled cement-based composites[J]. Cement and Concrete Composites,2006,28(9):824-828.

[8] Chung D D L.Electrically conductive cement-based materials [J].Advances in Cement Research,2004,16(4):167-176.

[9] Li K Z,Wang C,Li H J,et al.Development and study of carbon fiber reinforced cement composites[J].Materials Review, 2006,20(5):85-88.

[10] Li G Y,Wang P M.Microstructure and mechanical properties of carbon nanotubes cement matrix composites[J].Journal of The Chinese Ceramic Society,2005,33(1):105-108.

[11] Lao Y S,Zhang L,Wang X P,et al Research progress in effect of nanoparticles on the performance of cement-based materials[J].Materials Review,2014,28(3):93-96.

[12] YANG Quan-hong.Dreams may come:from fullerene,carbon nanotube to graphene[J].New Carbon Material,2011,26 (1):1-4.

(杨全红."梦想照进现实"——从富勒烯、碳纳米管到石墨烯[J].新型炭材料,2011,26(1):1-4.)

[13] Du H J,Pang S D.Transport of water and chloride ion in cement composites modified with graphene nanoplatelet[J].Key Engineering Materials,2015,629-630(1):162-167.

[14] Yang Y G,Chen Ch M,Wen Y F,et al.Oxidized graphene and graphene based polymer composites[J].New Carbon Materials,2008,23(3):193-200.

(杨永岗,陈成猛,温月芳,等.氧化石墨烯及其与聚合物的复合[J].新型炭材料,2008,23(3):193-200.)

[15] Chen C M,Yang Q H,Yang Y G,et al.Self-assembled freestanding graphite oxide membrane[J].Adv Mater,2009,21 (29):3007-3011.

[16] Nawa M N A T.Effectof fly ash on the kinetics of portland cement hydration atdifferentcuring temperatures[J].Cementand Concrete Research,2011,41(6):579-589.

[17] Snelson D G,Wild S,O'Farrell M.Heat of hydration of Portland Cement-Metakaolin-Fly ash(PC-MK-PFA)blends[J]. Cement and Concrete Research,2008,38(6):832-840.

[18] Langan B W,Weng K,Ward M A.Effect of silica fume and fly ash on heat of hydration of Portland cement[J].Cementand Concrete Research,2002,32(7):1045-1051.

[19] ZENG Q,LI K,FEN-chong T,et al.Pore structure characterization of cement pastes blended with high-volume fly-ash[J]. Cement and Concrete Research,2012,42(1):194-204.

[20] Provis J L,Myers R J,White C E,et al.X-ray microtomography shows pore structure and tortuosity in alkali-activated binders[J].Cement and Concrete Research,2012,42(6):855-864.

[21] Neithalath N,Sumanasooriya M S,Deo O.Characterizing pore volume,sizes,and connectivity in pervious concretes for permeability prediction[J].Materials Characterization,2010,61 (8):802-813.

[22] Constantinides G,Ulm F.The effect of two types of C-S-H on the elasticity of cement-based materials:Results from nanoindentation and micromechanicalmodeling[J].Cementand Concrete Research,2004,34(1):67-80 .

Influence of graphene oxide additions on the microstructure and mechanical strength of cement

WANG Qin1, WANG Jian1, LU Chun-xiang2, LIU Bo-wei1, ZHANG Kun1, LI Chong-zhi1

(1.BeijingKeyLaboratoryofGreenBuildingandEnergyEfficiencyTechnology,BeijingCollegeEngineeringResearchCentreofEngineeringStructure andNewMaterial,BeijingUniversityofCivilEngineeringandArchitecture,Beijing100044,China;2.NationalEngineeringLaboratoryofPreparationTechnologyofCarbonFiber,InstituteofCoalChemistry, ChineseAcademyofSciences,Taiyuan030001,China)

The effect of adding graphene oxide(GO)to cement on its microstructure and mechanicalstrength was investigated.A paste of cement(16.5%of water)and GO(0.05%)was prepared together with an identical mixture to which sand(3x the weight of the cement)had been added to form a mortar.The fluidity,viscosity and setting time of the mortar and the morphology,pore structure and compressive and flexural strengths of both the hardened cement paste and mortar,were investigated using SEM,nitrogen adsorption,and fluidity,viscosity,mechanical and hydration tests.The influence of the GO addition on the hydration heat of the cement was also tested.Results show that the addition of GO increases the viscosity,decreases the fluidity and shortens the setting time of the mortar.It also reduces the heat of hydration of the cement.The compressive and flexural strengths of the hardened cement paste at different times are increased by the addition of GO.The flexural strength was greater by 86.1%,68.5%and 90.5%after 3,7 and 28 days,respectively,and the corresponding compressive strength increases were 52.4%,46.5%and 40.4%For the hardened mortar,the corresponding increases are 69.4%,106.4%and 70.5%for flexural strength and 43.2%, 33%and 24.4%for compressive strength.The addition of GO promotes hydration,decreases pore volume,accelerates crystallite formation and causes the crystallites to align,which increases the tightness of both the hardened cement paste and mortar.

Graphene oxide;Cement composites;Reinforcing and toughening;Microstructure;Hydration heatEnglish edition available online ScienceDirect(http://www.sciencedirect.com/science/journal/18725805).

:WANG Qin,Lecturer.E-mail:wangqin@bucea.edu.cn

10.1016/S1872-5805(15)60194-9

TB332

A

2015-04-20;

:2015-08-01

北京市教委基金(KM201510016003);北京高校创新团队建设与教师职业发展计划项目(IDHT2013);国家自然科学基金(51408622);北京市自然科学基金(8144043).

王 琴,讲师.E-mail:wangqin@bucea.edu.cn

1007-8827(2015)04-0349-08

Foundation item:Beijing Municipal Commission of Education(KM201510016003);Beijing College Innovation Team-building and Teacher Career Development Project(IDHT2013);State Natural Sciences Foundation(51408622);Beijing Natural Sciences Foundation(8144043).