利用冻胀能的农产品冷藏设备防结冰表面优化设计

丛 茜,陈廷坤,孙成彬,金敬福

利用冻胀能的农产品冷藏设备防结冰表面优化设计

丛 茜1,2,陈廷坤1,2,孙成彬1,2,金敬福1※

(1. 吉林大学生物与农业工程学院,长春 130022; 2. 吉林大学工程仿生教育部重点实验室,长春 130022)

农产品冷藏设备换热表面上的结冰堆积造成能源消耗,并影响了农产品的储藏品质。该文基于水结冰相变过程中的膨胀应力及不同冰点的溶液相变时差对结冰界面稳定性的影响现象,采用带有不同尺寸的凹坑且表面粘附双向拉伸聚丙烯薄膜(biaxially oriented polypropylene, BOPP)的6061铝合金为冻粘基体,探究凹坑直径、凹坑深度及凹坑内的不同质量分数的乙醇溶液对结冰附着强度的影响规律。对试验结果进行方差分析,建立了评价指标与各影响因素的数学回归模型,确定防结冰表面对结冰附着强度影响的主次顺序为凹坑深度、乙醇溶液质量分数、凹坑直径,结合响应面分析得到对结冰附着强降低率具有显著作用的工艺参数组合为:质量分数为8.05%的乙醇溶液和直径23.172 mm、深度4.349 mm的凹坑时,表面结冰附着强度的降低率达到了92.72%。利用水冻结成冰的过程中,释放的冻结膨胀能,破坏冰与材料之间接触界面的稳定性,降低了结冰附着强度,提高冷藏设备表面的主动除冰特性,为后期基于相变膨胀进行防除冰方法的开发提供新思路及试验依据。

制冷;冻结;回归分析;膨胀;附着强度

0 引 言

随着中国经济快速的发展和人们生活水平的提高,人们对肉类、海鲜、水果、蔬菜等农副产品保鲜质量的要求越来越高[1-3],推动了农副产品贮藏保鲜业的快速发展,增加了冷库、冷藏车等农产品冷藏保鲜设备的保有数量[4-6]。为大力支持和促进农副产品冷藏保鲜行业的发展,微型冷库等冷冻冷藏设备已经连续5 a被列入农业部补贴项目指南[7],并且国家发展和改革委员会和国务院于2010年、2014年分别印发了《农产品冷链物流发展规划》和《物流业发展中长期规划(2014-2020年)》[8-10]。

保鲜冷库作为农副产品保鲜链的核心部件,其运行的高效性、节能性一直是农副产品冷藏保鲜行业追求的目标,但冷风机、蒸发器等作为冷冻、冷藏库的关键零部件,在低温高湿条件下极易发生结冰、结霜现象[11-13],降低了冷风机的热交换能力和换热器的换热效率[14-16],增加了空气流动阻力和冷库运行的能耗,导致冷冻储藏设备的失效,造成蔬菜、水果等农副产品的冷藏失效[17-20],造成巨大的社会经济损失和资源浪费。

目前,国内外针对冷藏设备表面的结冰、结霜现象多采用超声振荡、热氨、电加热等常规融冰、除霜方式进行清除[21-23],但常规除霜/冰方法存在成本高[24]、能耗高[25]、污染环境等使用缺陷[26]。近年来,随着材料科学和制备技术的快速发展,诸多研究学者通过润湿性改良技术,制备了具有防结冰能力的疏水涂层,但已有文献表明,防结冰/霜涂层在使用过程中存在耐久性差[27-28]、成本高[28-29]、易受环境污染[28,30-31]等使用缺陷,不能满足工业领域中的使用要求。因此,如何提高农副产品冷藏保鲜设备表面的防结冰性能、降低材料表面的结冰附着强度一直是制冷行业中的核心问题之一。

该文通过回归方法设计试验,建立试验因素对结冰附着强度影响的数学模型,分析试验因素对材料表面结冰附着强度的影响效应,为开发利用相变膨胀的防结冰表面或防覆冰囊膜提供试验依据。

1 防覆冰模型作用原理

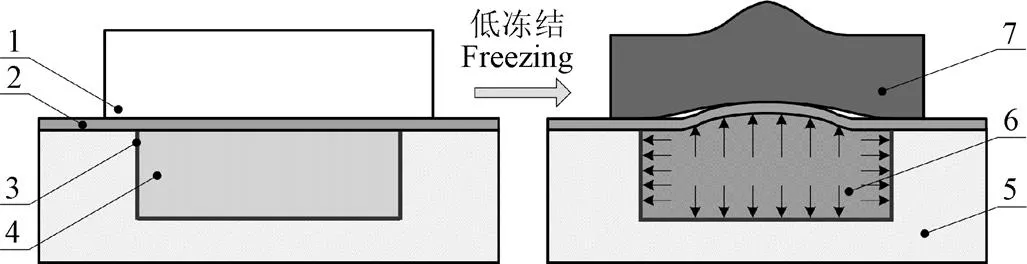

项目组根据冬季结冰膨胀对农业领域中输水沟渠、渡槽等水工建筑物岸壁造成严重破坏的现象[32-34],提出利用相变膨胀,使农产品冷藏设备表面具备主动防除冰的能力,设计了如图1所示的防除冰模型。在基体表面制备凹坑形态,并填充冰点不同于水的低冰点溶液,覆盖弹性薄膜,使同一种材料存在2种冰点不同的冻结介质。由于导热性等因素,基体表面附着的水首先冻结结冰,凹坑内后结冰的低冰点水溶液发生相变膨胀。但受到凹坑周围刚性边界的约束,膨胀应力只能作用于柔性边界,导致弹性接触界面产生膨胀凸起,破坏基体表面已形成的接触稳定性,降低表面结冰附着强度。

1.水 2.弹性边界 3.刚性边界 4.低冰点水溶液 5.基底 6.冰Ⅰ 7.冰Ⅱ

2 结冰附着强度测试试验

2.1 试验条件与材料

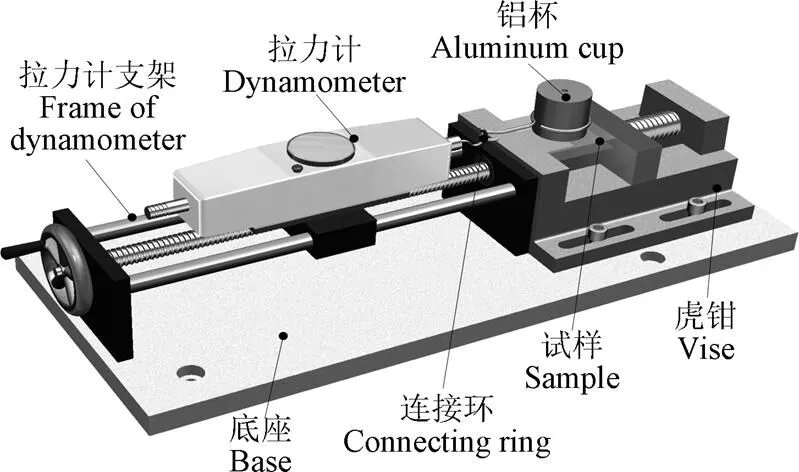

试验采用冷藏保鲜设备常用的6061铝合金材料作为冻粘试样(尺寸为60 mm×60 mm×6 mm),在表面制备凹坑,填充不同质量分数的乙醇溶液,并且表面覆盖双向拉伸聚丙烯薄膜(biaxially oriented polypropylene,BOPP)。利用项目组自制的结冰附着强度测试装置,如图2所示。在温度为−25 ℃的低温环境下,冻结1 h进行冰的制取。

图2 切向结冰附着强度测试装置

2.2 试验方法

通过结冰附着强度测试试验,以结冰附着强度的降低率作为衡量防覆冰模型的指标,以乙醇溶液的质量分数、凹坑直径及凹坑深度为影响因素,重复测试10次,进行二次回归正交组合试验。

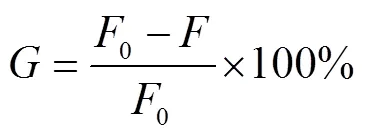

2.2.1 试验指标

结冰附着强度降低率越高,越有利于清除试样表面的覆冰,除冰难度和除冰成本越低。试样表面的结冰附着强度降低率为

2.2.2 试验因素

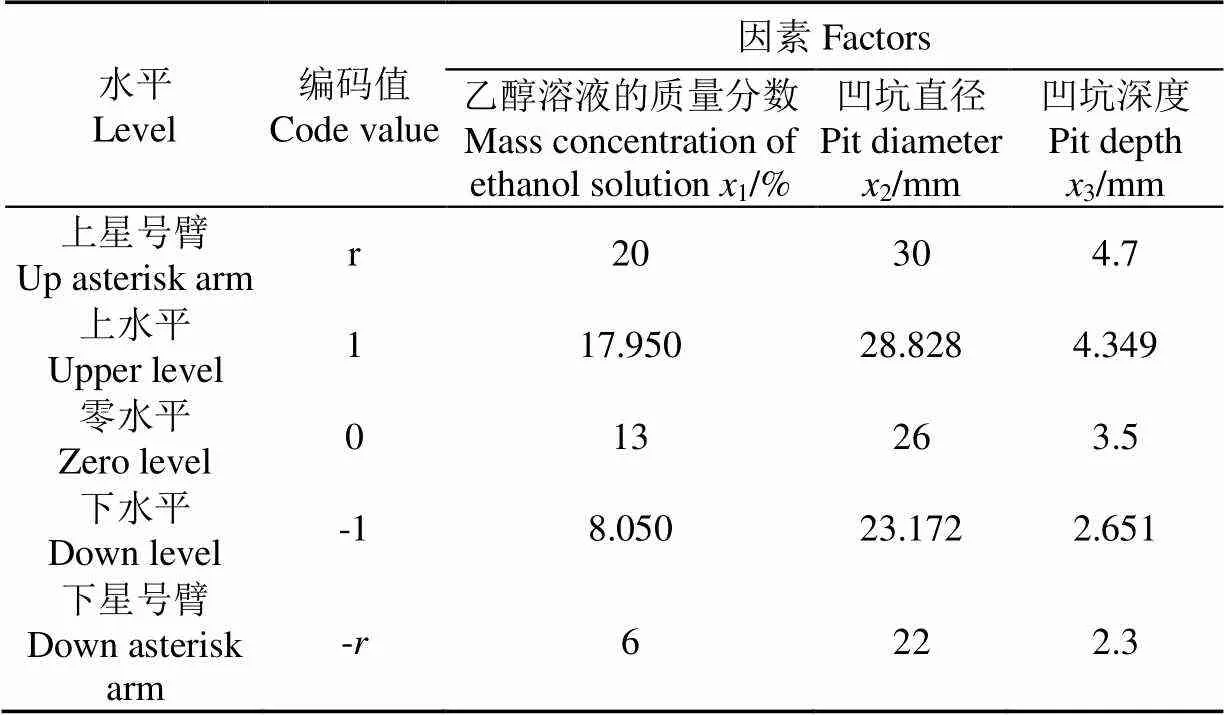

防覆冰模型采用凹坑内低冰点液体冻结释放的相变膨胀能,影响冰在材料表面的结冰附着强度。因此,乙醇溶液的质量分数、凹坑的尺寸决定凹坑内液体释放相变膨胀能的大小,达到影响材料表面结冰附着强度的目的。根据中国冬季的平均气温、试样的尺寸以及初期试验中凹坑尺寸对结冰附着强度的影响,该文中选取质量分数为6%~20%的乙醇溶液、22~30 mm的凹坑直径、2.3~4.7 mm的凹坑深度进行回归模拟试验。

2.2.3 试验设计

表1 因素水平编码表

注:代表编码空间中星号点与中心点之间的距离,=1.414。

Note:represents the distance between asterisk point and central point,=1.414.

根据文献[35]编制试验方案。试验测试方案中试样表面设计的凹坑尺寸达到了微米量级,而在实际工程应用中无须加工至此精度。但为确保试验的严谨性,试验时仍按照编制的试验方案,采用铣削加工的方式,分别在6061铝合金试样表面制备试验方案中规定尺寸的凹坑。

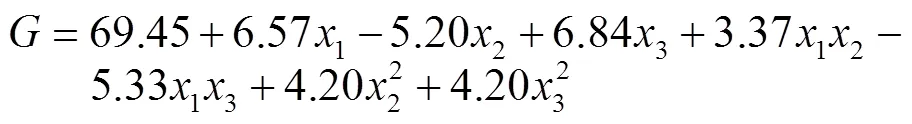

利用项目组自制的切向结冰附着强度测试装置,分别测试光滑铝合金试样及带凹坑试样的表面结冰附着强度,依据公式(1)计算每种试样的结冰附着强度降低率。试验中,每种试样表面的结冰附着强度进行10次重复测试试验,取结冰附着强度降低率的平均值作为防覆冰模型对试样表面结冰附着强度降低效果的评价指标。编制的试验方案及相应结果如表2所示。

2.3 回归模型建立与显著性分析

式中1为乙醇溶液的质量分数,%;2为凹坑直径,mm;3为凹坑深度,mm;取值范围为−1.414~1.414。

表2 试验方案及相应结果

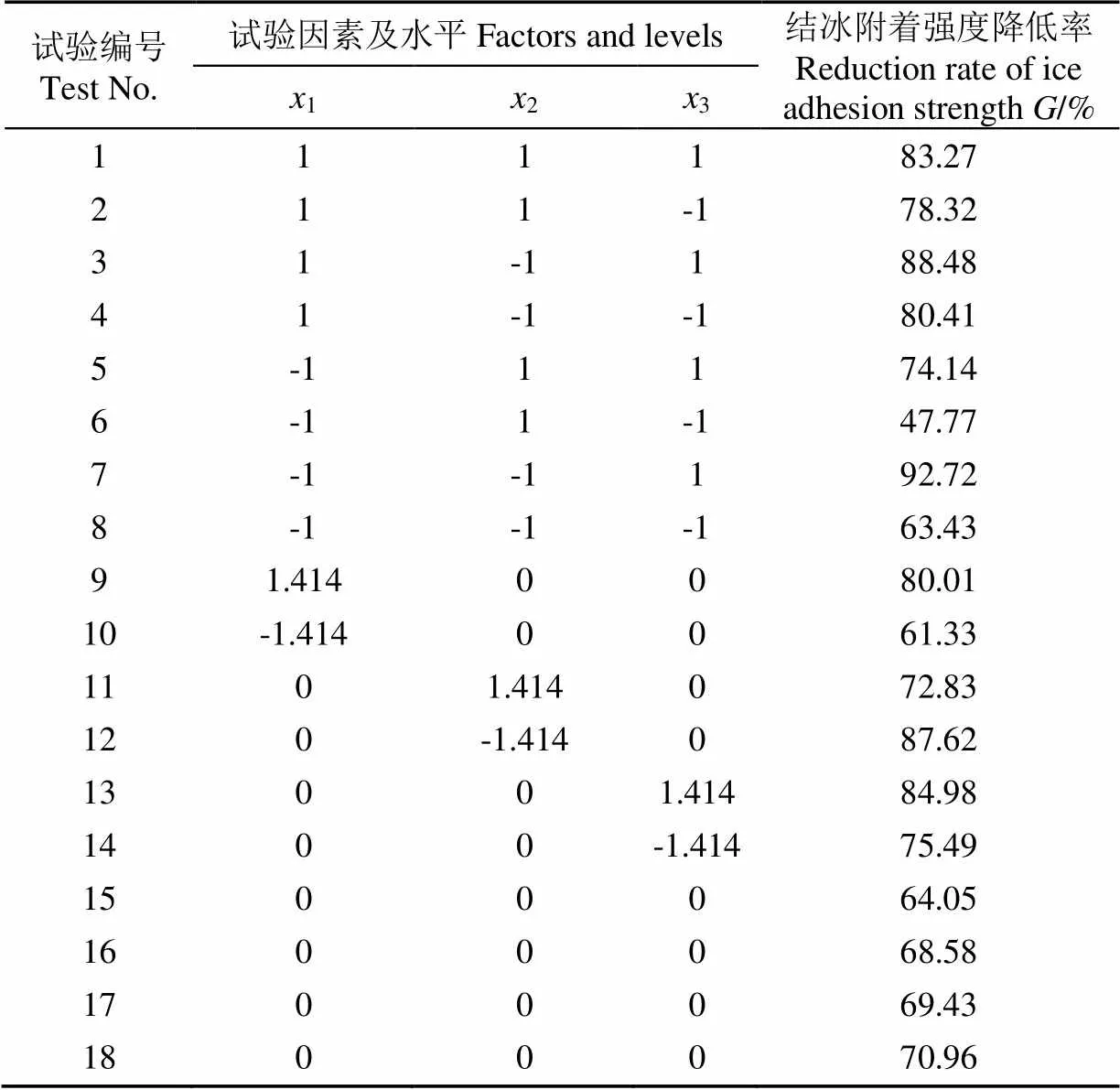

表3 结冰附着强度降低率G回归模型的方差分析

注:<0.05为显著,<0.01为极显著。

Note:<0.05 represents significance,<0.01 means extremely significance.

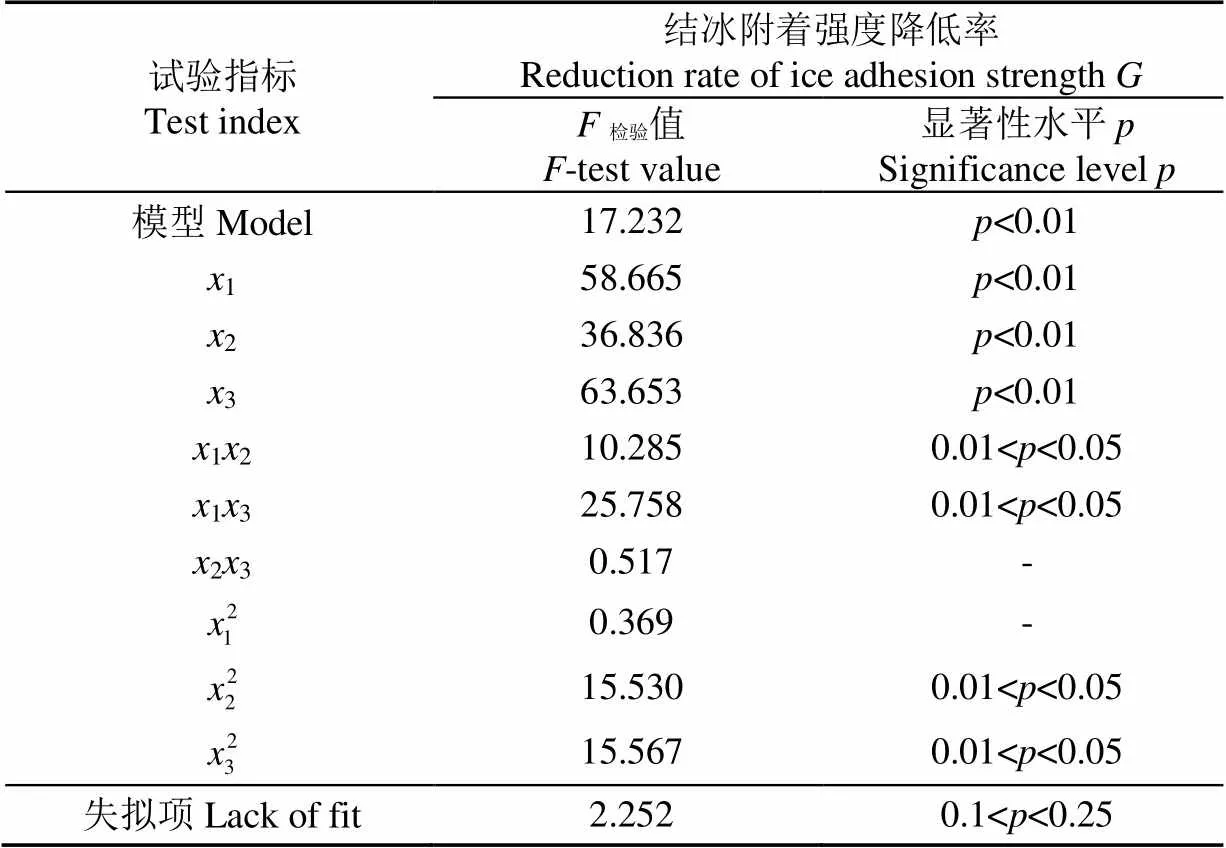

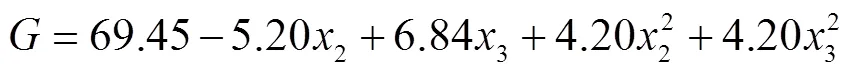

由表3的方差分析结果可知,结冰附着强度降低率的回归数学模型的值小于0.01,表明该回归数学模型具有极好的显著性,其中因子乙醇溶液的质量分数1、凹坑直径2、凹坑深度3对结冰附着强度降低率的影响极显著;该数学模型的失拟项的值大于0.1,拟合程度高,说明该回归模型可预测防覆冰模型中试样的结构参数与表面结冰附着强度降低率之间的关系。

2.4 响应面分析

运用响应曲面法分析各因素对结冰附着强度降低率的影响,固定3因素中的1个因素为零水平,考察其他2个因素对结冰附着强度降低率的影响。

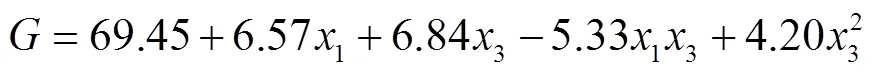

由公式(3)和图3可知,结冰附着强度降低率随凹坑直径2的增加,先降低并逐渐趋于平缓;随着凹坑深度3的增加,结冰附着强度降低率增大。响应曲面沿2方向的变化速率先降低后逐渐平缓,沿3方向的变化速率快,表明在该试验水平下,凹坑深度3对结冰附着强度降低率的影响比凹坑直径2的影响显著。

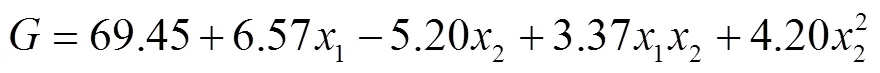

2)当凹坑直径保持26 mm不变时,得到乙醇溶液的质量分数1和凹坑深度3与结冰附着强度降低率的关系及其响应曲面图4分别为

由式(4)和图4可知,结冰附着强度降低率随乙醇溶液质量分数1的增加,结冰附着强度降低率逐渐增大;随凹坑深度3的增大而增大。响应面沿3方向的变化速率大于沿1方向的变化速率,说明在该试验水平下,凹坑深度3比乙醇溶液的质量分数1对结冰附着强度降低率的影响明显。

3)当固定凹坑深度保持3.5 mm时,得到乙醇溶液的质量分数1和凹坑直径2与结冰附着强度降低率的关系及其响应曲面图5分别为

由式(5)和图5可知,结冰附着强度降低率随乙醇溶液质量分数1的增加而增大;随凹坑直径2的增加,结冰附着强度降低率先降低而后逐渐增加。响应面沿1方向的变化速率大于沿2方向变化的速率,表明在该试验水平下,乙醇溶液的质量分数1比凹坑直径2对结冰附着强度降低率的影响显著。

综上可见,对结冰附着强度降低率的影响顺序依次为凹坑深度3、乙醇溶液的质量分数1和凹坑直径2。

2.5 讨 论

结合表2及响应面分析可见,试样表面的凹坑尺寸及凹坑内填充的乙醇溶溶液影响了试样表面的结冰附着强度,具有显著的降低作用,并且不同尺寸的凹坑、不同质量分数的乙醇溶液对结冰附着强度的降低作用不同。当凹坑直径为23.172 mm、凹坑深度为4.349 mm、填充8.05%质量分数的乙醇溶液,试样表面的结冰附着强度降低率可达到92.72%;质量分数为8.05%的乙醇溶液填充在直径为28.828 mm、深度为2.651 mm的凹坑,结冰附着强度降低率为47.77%。

低冰点溶液中水的质量分数升高时,低冰点溶液蓄含的相变膨胀能增加,降低了冰点,减小了防覆冰模型中凹坑内的低冰点溶液与界面上水之间的冻结时间差,导致表面覆冰重新附着于已变形的弹性界面,减小了基底表面的结冰附着强度降低率,如图4、图5所示,结冰附着强降低率沿乙醇溶液质量分数1增大的方向而逐渐降低。

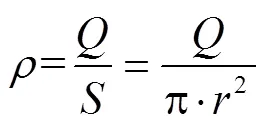

当防覆冰模型中的凹坑直径增大时,凹坑蓄含的相变膨胀能越多。如公式(6)所示,同等条件下,表面凹坑的接触面积成平方趋势增加,导致弹性界面单位面积承受的能量密度,对基底表面覆冰的接触稳定性影响减小,降低了材料表面的结冰附着强度降低率,如图3、图5所示,结冰附着强降低率沿凹坑直径2增大方向降低。当防覆冰模型中凹坑的深度增加时,凹坑体积增大,相同浓度下的低冰点溶液蓄含的相变膨胀能越高,作用于弹性界面的单位能量越高,致使弹性界面的变形越大,对冰与界面之间粘附稳定性的破坏程度越大,模型中材料表面的结冰附着强度越低,如图3、图4所示,结冰附着强降低率沿凹坑深度3增大方向升高。

式中为乙醇溶液的相变膨胀能,为试样表面的凹坑直径。

3 结 论

1)利用相变膨胀作为除冰动力的防覆冰模型可明显的降低材料表面的结冰附着强度,并且防覆冰模型对基底材料表面结冰附着强度的影响大小依赖于模型中凹坑的尺寸以及凹坑内填充的低冰点溶液。

2)采用二次回归正交组合设计方法,已确定乙醇溶液的质量分数、凹坑直径和凹坑深度对结冰附着强度降低率影响的数学模型,并且各因素对结冰附着强度降低率的影响显著性顺序依次为:凹坑深度、乙醇溶液的质量分数、凹坑直径,并且凹坑深度、凹坑直径分别与乙醇溶液质量分数对结冰附着强度降低率的影响具有交互作用。当防覆冰模型中采用质量分数为8.05%的乙醇溶液、凹坑直径为23.172 mm、凹坑深度为4.349 mm时,可使表面结冰附着强度降低率达到92.72%。

随着乙醇溶液质量分数的增加、凹坑直径的降低、凹坑深度的增大,扩大了乙醇溶液与水之间的冰点,增大了冻结时释放相变膨胀能,破坏冰与材料之间的接触稳定性,降低了冰在材料表面的结冰附着强度。利用冻结过程中产生的相变膨胀,提升冷藏设备表面的主动防除冰特性,降低冷藏保鲜行业对表面积冰的除冰成本,为后期通过冰的相变膨胀开发新式防、除冰方法提供试验数据的参考,如通过该原理制备胶囊状的防结冰覆膜。

[1] 张新林,成耀荣. 基于系统动力学的冷库发展调控模型与仿真[J]. 铁道科学与工程学报,2015,12(6):1464-1470.

Zhang Xinlin, Cheng Yaorong. Cold storage development control model and simulation based on system dynamics[J]. Journal of Railway Science and Engineering, 2015, 12(6): 1464-1470. (in Chinese with English abstract)

[2] 谢晶,邱伟强. 我国食品冷藏链的现状及展望[J]. 中国食品学报,2013,13(3):1-7.

Xie Jing, Qiu Weiqiang. Recent situation and development of food cod chain in china[J]. Journal of Chinese Institute of Food Science and Technology, 2013, 13(3): 1-7. (in Chinese with English abstract)

[3] 谭晶莹,王清,安伟科. 预冷库温湿度控制与热工响应试验[J]. 农业机械学报,2010,41(3):139-142,194.

Tan Jingying, Wang Qing, An Weike. Experiment on the control of temperature and humidity and thermal response for pre-cooling cold storage[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(3): 139-142, 194. (in Chinese with English abstract)

[4] 谢晶,缪晨,杜子峥,等. 冷库空气幕性能数值模拟与参数优化[J]. 农业机械学报,2014,45(7):189-195.

Xie Jing, Miao Chen, Du Zizheng, et al. Numerical simulation and parameter optimization on performance of air curtain in cold stores[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(7): 189-195. (in Chinese with English abstract)

[5] 钟晓辉,翟玉玲,勾昱君,等. 小型冷库内部融霜与预冷过程的数值模拟[J]. 工程热物理学报,2012,32(12):2103-2105.

Zhong Xiaohui, Zhai Yuling, Gou Yujun, et al. Numerical simulation of small cold storage under pre-cooling and defrosting conditions[J]. Journal of Engineering Thermophysics, 2012, 32(12): 2103-2105. (in Chinese with English abstract)

[6] 李锦,谢如鹤. 冷藏车开门状态升温影响因素分析[J]. 农业机械学报,2014,6(45):254-259.

Li Jin, Xie Ruhe. Influence factors analysis of air-temperature increasing within refrigerated trucks during the door-opening[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 6(45): 254-259. (in Chinese with English abstract)

[7] 赵松松,杨昭,陈爱强,等. 微型冷库复合加热循环除霜系统的研制与试验[J]. 农业工程学报,2015,31(2):306-311.

Zhao Songsong, Yang Zhao, Chen Aiqiang, et al. Development and experiment about recombination heating circulation defrosting system of mini cold storage house[J]. Transactions of the Chinese Society of Agricultural Engineering (Transaction of the CSAE), 2015, 31(2): 306-311. (in Chinese with English abstract)

[8] 刘晓辉,鲁墨森,王淑贞,等. 小型冷库多效冷凝制冷机组的能耗及节能分析[J]. 农业工程学报,2010,26(6):103-108.

Liu Xiaohui, Lu Mosen, Wang Shuzhen, et al. Analysis of energy consumption and energy conservation of multi-effect condensed refrigeration unit in small cold storage[J]. Transactions of the Chinese Society of Agricultural Engineering (Transaction of the CSAE), 2010, 26(6): 103-108. (in Chinese with English abstract)

[9] 中华人民共和国国家发展和改革委员会.《农产品冷链物流发展规划》[EB/OL]. 2010-06-18[2010-07-30]. http://bgt.ndrc.gov.cn/zcfb/201007/t20100730_498782.html.

[10] 国务院.《物流业发展中长期规划(2014-2020年)》[EB/OL].2014-09-12[2014-10-04]. http://www.gov.cn/zhengce/ content/2014-10/04/content_9120.htm.

[11] 吴松,陈雷,王艳华. 对某型船用冷库低温冷风机严重结霜问题的研究[J]. 制冷,2015,34(3):79-83.

Wu Song, Chen Lei, Wang Yanhua. Study on cold air cooler with severe frost problem of a certain type of ship[J]. Refrigeration, 2015, 34(4): 79-83. (in Chinese with English abstract)

[12] Huang J M, Hsieh W C, Ke X J, et al. The effects of frost thickness on the heat transfer of finned tube exchanger subject to the combined influence of fan types[J]. Applied Thermal Engineering, 2008(28): 728-737.

[13] 郭宪民,王善云,汪伟华,等.环境参数对空气源热泵蒸发器表面霜层影响研究[J].西安交通大学学报,2011,45(3):30-34.

Guo Xianmin, Wang Shanyun, Wang Weihua, et al. Effect of environmental condition on evaporator surface frost layer air force heat pump[J]. Journal of Xi’an Jiaotong University, 2011, 45(3): 30-34. (in Chinese with English abstract)

[14] 谭海辉,陶唐飞,徐光华,等. 翅片管式蒸发器超声波除霜理论与技术研究[J]. 西安交通大学学报,2015,49(9):105-113.

Tan Haihui, Tao Tangfei, Xu Guanghua, et al. Ultrasonic defrosting theory and technology for finned-tube evaporator[J]. Journal of Xi’an Jiaotong University, 2015, 49(9): 105-113. (in Chinese with English abstract)

[15] 董建锴,姜益强,姚杨,等. 空气源热泵相变蓄能除霜蓄能特性实验研究[J]. 土木建筑与环境工程,2011,33(2):74-79.

Dong Jiankai, Jiang Yiqiang, Yao Yang, et al. Experimental analysis on characteristics of energy storage for defrosting of air source heat pump with phase change energy storage[J]. Journal of Civil, Architectural & Environmental Engineering, 2011, 33(2): 74-79. (in Chinese with English abstract)

[16] 曹小林,曹双俊,段飞,等. 空气源热泵除霜问题研究现状与展望[J]. 流体机械,2011,39(4):75-79.

Cao Xiaolin, Cao Shuangjun, Duan Fei, et al. Current situation and development prospect of air source heat pump defrosting research[J]. Fluid Machinery, 2011, 39(4): 75-79. (in Chinese with English abstract)

[17] Knabben F T, Hermes C J L, Melo C. In-situ study of frosting and defrosting process in tube-fin evaporators of household refrigerating appliances[J]. International Journal of Refrigeration, 2011, 34(8): 2031-2041.

[18] 刘耀民,刘中良,黄玲艳,等.结霜对微型冷库性能影响的实验研究[J]. 工程热物理学报,2010,31(10):1755-1758.

Liu Yaomin, Liu Zhongliang, Huang Lingyan, et al. An experimental study of the influences of frost deposition on the performance of a cold store[J]. Journal of Engineering Thermophysics, 2010, 31(10): 1755-1758. (in Chinese with English abstract)

[19] Bansal P, Fothergill D, Fernandes R. Thermal analysis of the defrost cycle in a domestic freezer[J]. International Journal of Refrigeration, 2010, 33(3): 589-599.

[20] 赖艳华,吴涛,赵琳研,等. 低温吸湿复合吸附剂的制备及吸湿性能[J]. 化工学报,2015,66(S1):154-157.

Lai Yanhua, Wu Tao, Zhao Linyan, et al. Preparation and dehumidification performance of composite adsorbent for low-temperature desiccants[J]. CIESC Journal, 2015, 66(S1): 154-157. (in Chinese with English abstract)

[21] 李栋,陈振乾. 超声功率对冷壁面冻结液滴脱除效果的影响[J]. 东南大学学报:自然科学版,2014,44(4):751-755.

Li Dong, Chen Zhenqian. Effect of ultrasonic power on removal of frozen water droplets from cold surface[J]. Journal of Southeast University: Natural Science Edition, 2014, 44(4): 751-755. (in Chinese with English abstract)

[22] 秦海杰,李维仲,赵之海,等. 空气冷却器结霜特性的实验研究[J]. 太阳能学报,2014,6(34):1080-1085.

Qin Haijie, Li Weizhong, Zhao Zhihai, et al. Experimental study on frosting characteristics of fan cooler[J]. Acta Energiage Solaris Sinica, 2014, 6(34): 1080-1085. (in Chinese with English abstract)

[23] 王栋,陶乐仁,刘训海. 加湿量对低温冷库冷风机融霜的影响[J]. 化工学报,2014,65(S2):58-63.

Wang Dong, Tao Leren, Liu Xunhai. Effect of humidifying amount on defrosting of air cooler in low-temperature cold storage[J]. CIESC Journal, 2014, 65(S2): 58-63. (in Chinese with English abstract)

[24] Melo C, Knabben F T, Pereira P V. An experimental study on defrost heaters applied to frost-free household refrigerators[J]. Applied Thermal Engineering, 2013(51): 239-245.

[25] 王栋,陶乐仁. 有无隔断装置对冷风机热气融霜的影响[J].低温与超导,2014,42(2):56-58,61.

Wang Dong, Tao Leren. Influence of the partition board on the hot-gas defrosting of air-cooler[J]. Cryogenics & Superconductivity, 2014, 42(2): 56-58, 61. (in Chinese with English abstract)

[26] 李辉,赵蕴慧,袁晓燕. 抗结冰涂层院:从表面化学到功能化表面[J]. 化学进展,2012,24(11):2087-2096.

Li Hui, Zhao Yunhui, Yuan Xiaoyan. Anti-icing coatings: From surface chemistry to functional surfaces[J]. Progress in Chemistry, 2012, 24(11): 2087-2096. (in Chinese with English abstract)

[27] Tang Y Q, Zhang Q H, Zhan X L, et al. Superhydrophobic and anti-icing properties at overcooled temperature of a fluorinated hybrid surface prepared via a sol-gel process[J]. Soft Matter, 2015(11): 4540-4550.

[28] 郑海坤,常士楠,赵媛媛. 超疏水/超润滑表面的防疏冰机理及其应用[J]. 化学进展,2017,29(1):102-118.

Zheng Haikun, Chang Shinan, Zhao Yuanyuan. Anti-icing &icephobic mechanism and applications of superhydrophobic/ultra slippery surface[J]. Progress in Chemistry, 2007, 29(1): 102-118. (in Chinese with English abstract)

[29] 安光明,凌世全,王智伟,等. 基于微纳结构液体灌注的超滑表面的制备与应用[P]. 化学进展,2015,27(12):1705-1713.

An Guangming, Ling Shiquan, Wang Zhiwei, et al. Fabrication and application of ultra-slippery surfaces based on liquid infusion in micro/nano structure[J]. Progress in Chemistry, 2015, 27(12): 1705-1713. (in Chinese with English abstract)

[30] Boreyko J B, Collier C P. Delayed frost growth on jumping-drop surperhydrophobic surfaces[J]. Acs Nano, 2013, 7(2): 1618-1627.

[31] Hao Q Y, Pang Y C, Zhao Y, et al. Mechanism of delayed frost growth on superhydrophobic surfaces with jumping condensates: more than interdrop freezing[J]. Langmuir, 2014, 30(51): 15416-15422.

[32] 刘孟凯,王长德,冯晓波. 长距离控制渠系结冰期的水力响应分析[J]. 农业工程学报,2011,27(2):20-27.

Liu Mengkai, Wang Changde, Feng Xiaobo. Analysis on the hydraulic response of long distance canal control system during ice period[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(2): 20-27. (in Chinese with English abstract)

[33] 刘月,王正中,王羿,等. 考虑水分迁移及相变对温度场影响的渠道冻胀模型[J]. 农业工程学报,2016,32(17):83-88.

Liu Yue, Wang Zhengzhong, Wang Yi, et al. Frost heave model of canal considering influence of moisture migration and phase transformation on temperature field[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(17): 83-88. (in Chinese with English abstract)

[34] 陈武,刘德仁,董元宏,等. 寒区封闭引水渡槽中水温变化预测分析[J]. 农业工程学报,2012,28(4):69-75.

Chen Wu, Liu Deren, Dong Yuanhong, et al. Prediction analysis on water temperature in closed aqueduct in cold regions[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(4): 69-75. (in Chinese with English abstract)

[35] 任露泉. 回归设计及其优化[M]. 北京:科学出版社,2009:39-59.

Design of active de-icing surface for refrigeration equipment of agricultural by-products

Cong Qian1,2, Chen Tingkun1,2, Sun Chengbin1,2, Jin Jingfu1※

(1.130022,; 2.130022,)

The accreted ice on the exposed surface is well known to result in severe accidents to power transmission lines, aircraft, boats, and so on, and cause the significant economic losses. The refrigeration equipment of the agricultural by-products is no exception. With the rapid development of the refrigeration industry and the improvement of the food requirement, the number of the China’s refrigeration equipment to store the agricultural by-products increases gradually every year. The problem of the influence of the ice accumulation on the refrigeration equipment has become outstanding gradually. In order to reduce the harm and the economic losses of storage of agricultural by-products caused by the icing adhesion phenomenon, an active de-icing model was designed according to the volume expansion during the freezing process. The de-icing model adopted the swelling force as the active power to destroy the stability of the contact interface between the ice and the substrate surface. During the experiment, ternary quadratic regression orthogonal experiment method was adopted to design the experiment conditions, like the range of the solution mass concentration and the size of the pits, and the mathematic model was set up to analyze the relationship between the experimental factors and the ice adhesion strength. The test used the 6061 aluminum alloy whose size is 60 mm × 60 mm × 6 mm as the sample material and took the laser processing or milling to fabricate the different sizes of pits. And the pits were full of different mass concentrations of ethanol solution. The sample surface was covered by the biaxially oriented polypropylene (the abbreviation is BOPP). The experimental results showed that the de-icing model significantly reduced the ice adhesion strength, and the different pit sizes and mass concentrations of filled ethanol solution had different effects on reducing the ice adhesion strength. When the pit diameter was 23.172 mm, the depth was 4.349 mm, and the pit was filled with 8.05% ethanol solution, the reduction rate of ice adhesion strength by the model was 92.72%. The regression analysis method was used to solve the regression equation. And the order of the influence of different experiment factors on decreasing ice adhesion strength was determined, which was pit depth, mass concentration of ethanol solution and pit diameter from high to low. The mechanism of the de-icing model was analyzed through the adopted regression equation. The paper considered that the freezing of solution in the pits would release the expansion energy in a short time and directly act on the freezing interface due to both rigid sides of the pit. The ethanol solution would contain more and more phase transformation energy with the increasing of the pit depth. The higher the energy density acting on the BOPP film, the greater the damage to the stability of the contact interface, the greater the ice adhesion strength decreased. When the mass concentration of ethanol solution in the pits was reduced, it would generate more expansion energy. That meant that the elastic film would bear more expansion force under the same conditions and it would increase the reduction rate of the ice adhesion strength. However, the decrease rate of the ice adhesion strength would not increase as the radius of the pit increasing. As the radius increased, the area of the expansion load acting on the contact interface would increase in square. Therefore, it decreased the power density on the BOPP film and the reduction rate would be reduced. The study takes the phase expansion force to improve the surface active characteristics of the refrigeration equipment and provides the experimental basis for developing the active de-icing method and a new thought for de-icing methods.

refrigeration; freezing; regression analysis; expansion; adhesion strength

10.11975/j.issn.1002-6819.2017.24.037

TB131

A

1002-6819(2017)-24-0283-07

2017-06-05

2017-11-14

国家自然科学基金委员会与英国皇家学会合作交流项目(51711530236)资助

丛 茜,女,吉林长春人,教授,博士,博士生导师,主要从事工程仿生学、材料防冻粘的方向研究。Email:chentk16@mails.jlu.edu.cn

金敬福,男,吉林长春人,副教授,博士,主要从事机械界面效应及低温防冻粘方向的研究。Email:jinjingfu@jlu.edu.cn

丛 茜,陈廷坤,孙成彬,金敬福. 利用冻胀能的农产品冷藏设备防结冰表面优化设计[J]. 农业工程学报,2017,33(24):283-289. doi:10.11975/j.issn.1002-6819.2017.24.037 http://www.tcsae.org

Cong Qian, Chen Tingkun, Sun Chengbin, Jin Jingfu. Design of active de-icing surface for refrigeration equipment of agricultural by-products[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(24): 283-289. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.24.037 http://www.tcsae.org