Effect of Extrusion Treatment on Rheological Properties and in Vitro Digestibility of Pea Starch

QI Mingming, REN Zhishang, ZHANG Guangyao, HE Zhuangzhuang, WANG Chenjie,2, ZHANG Dongliang,2, MA Chengye,2,*

(1. School of Agricultural Engineering and Food Science, Shandong University of Technology, Zibo 255000, China;2. Key Laboratory of Agricultural Products Functionalization Technology of Shandong Province, Zibo 255000, China)

Abstract: This study investigated the influence of different extrusion conditions including pea starch moisture content (25%, 35%, 40%, 45% and 55%), barrel temperature (50, 60, 70, 80 and 90 ℃) and screw speed (100, 120, 140, 160 and 180 r/min) on the in vitro starch digestibility and rheological properties of pea starch. Hydrolysis degree (HD) was measured using an in vitro digestion model, and rheological properties were determined through steady shear test, frequency sweep test and temperature sweep test. The results showed that after extrusion treatment, HD and the relative content of slowly digestible starch (SDS) increased whereas the relative content of resistant starch (RS) decreased. The maximum relative content of SDS of 34.41% was obtained under the following extrusion conditions: moisture content 25%, barrel temperature 70 ℃ and screw speed 140 r/min. When screw speed increased to 180 r/min with moisture content 40%, barrel temperature 70 ℃, the relative content of RS reached the minimum value of 10.49%. Particle size was positively correlated with SDS relative content and consistency coefficient (K value) (r = 0.60 and r = 0.61, P < 0.05). The extruded pea starch suspension was pseudoplastic. In frequency and temperature sweep tests, storage and loss moduli increased with the degree of starch damage increasing caused by extrusion. The results showed that the extruded pea starch exhibited enhanced structure and elastic gel properties. Therefore, extrusion can affect the in vitro starch digestibility and rheological properties of pea starch, thereby improving food functionality and quality.

Keywords: extrusion; pea starch; starch digestibility; rheological properties

Peas, which are leguminous plants containing approximately 53% starch and 24% protein, are widely cultivated worldwide and contribute considerably to the total production of legumes[1]. The world’s top four legume crops are soybean, peanuts, dry beans and peas[2]. Pea is a semi-hardy crop with short production cycle, low production cost and good market. In 2018, 1.49 million tonnes of dried peas have been consumed in China.

In daily diets, starch is the main source of carbohydrates and is an important source of energy for humans. Englyst et al[3]classified starch into three categories, namely, rapidly digestible (RDS), slowly digestible (SDS) and resistant (RS) starches. RDS and SDS are digested in the small intestine in 20 and 20–120 min, respectively, whereas RS is not digestible in the small intestine ( > 120 min). However, it can be fermented by microorganisms in the large intestine to produce short-chain fatty acids. Extrusion, which has been used in the food and polymer industries since the 1940s, is a complex reaction process that can provide high pressure and temperature in a short time[4]. The use of a twin-screw extruders in food processing has steadily increased because its ability to change or mix with other materials to achieve the desired quality. Starch granules change from a compact structure to a loose polyhedral after extrusion, and from fewer pits to a numbers of cavities[5]. The relative crystallinity of extruded corn starch decreases and the crystal structure changes from the A-type pattern to V-type pattern, indicating that the structure becomes more thermally stable[6]. The SDS content decreases with increasing barrel temperature[7], and a moderate screw speed of 300 r/min and low moisture content results in high SDS and RS contents, respectively[8]. This technology has been widely used in the food and animal feed industries worldwide[9]. The extruded starch affects the characteristics and quality of a product. For instance, pea starch noodles prepared by using a twin-screw extruder has increased firmness, increased surface stickiness and reduced cooking loss[10]. Extruded wheat flour/pregelatinized cassava starch has reduced proofing and baking time and improves the quality of French bread made from frozen dough[11]. Extruded black gram flour improves the dough properties and enhances the sensory properties of the end product[12].

A number of studies have reported the characteristics of pea starch, such as high gel strength, high gelatinisation temperature, good transparency, easy retrogradation[1-2],in vitrodigestibility and rheological characteristics[13-14]. However, these studies have not reported the effects of extrusion processes on the rheological and digestive properties of pea starch. Therefore, the aim of this work is to investigate the effect of extrusion on thein vitrodigestibility, particle size and rheological properties of pea starch to improve the quality of pea starch-based products.

1 Materials and Methods

1.1 Materials and reagents

Native pea starch (NPS) Shandong Jianyuan Biological Engineering Co. Ltd.; Alpha-amylase from porcine pancreas (Cat. no. A3176, 19.6 U/mg) Sigma-Aldrich Co. Ltd. (Shanghai); Amyloglucosidase (EC3.2.1.3, 100000 Units/mL) Shanghai Yuanye Bio-Technology Co. Ltd.;D-Glucose (GOPOD format) assay kit Ireland Megazyme Co. Ltd.; All other chemical reagents were analytical grade.

1.2 Instrument and equipment

UVTE36-24 Twin-screw extruder Hunan Chuangxiang Biotechnology Co. Ltd.; Matersize 2000 laser diffraction particle size analyzer, Kinexus lab + rotational rheometer UK Malvern Instrument Co. Ltd..

1.3 Methods

1.3.1 Measurement of pea starch chemical composition

The moisture, crude protein, starch, crude fat and ash contents of NPS was analysed in accordance with the methods described by Hu Lei et al[15]. Apparent amylose content was determined using the iodine reagent method[16].

1.3.2 Extrusion of pea starch

The extrusion process was carried out on a twin-screw extruder with the length to diameter ratio of 26. The parameters of the extrusion process were set as follows: feeding rate was constant at 15 kg/h; the temperatures in the first zone (feed zone), second zone (mix zone), fourth zone (screw conveying zone) and fifth zone (die) zones were 60, 90, 50 and 50 ℃, respectively, and the temperature in the third zone (shearing compression) was varied (50, 60, 70, 80 and 90 ℃), while maintained the screw speed at 140 r/min and the moisture content of samples was 40%; the moisture contents of pea starch were adjusted to 25%, 35%, 40%, 45% and 55% respectively by using an automatically controlled water influent device, while maintained the screw speed at 140 r/min and the temperature of the third zone at 70 ℃; the screw speed variations were 100, 120, 140, 160 and 180 r/min at a moisture content of 40% and the third zone temperature of 70 ℃. The extrudates were air-dried at room temperature, ground and passed through a 100-mesh sieve. All samples were dried to constant weight. The extrudates were denoted as 25M, 35M, 40M, 45M and 55M on the basis of the moisture content during extrusion; 50T, 60T, 70T, 80T and 90T on the basis of the extrusion temperature and 100R, 120R, 140R, 160R and 180R on the basis of the screw speed.

1.3.3In vitrodigestibility analysis

The RDS, SDS and RS contents and starch digestibility was measured using the Englyst’s method[3]with some modifications. The enzyme solution was prepared by placing 1.3 g porcine pancreatin into a 50 mL centrifuge tube suspended in 20 mL distilled water. The mixture was stirred for 10 min by using a magnetic stirrer and centrifuged for 10 min at 5000 r/min. The supernatant (17 mL) was collected and mixed with 2.55 µL amyloglucosidase.

Each sample (200 mg) was placed into a 50 mL tube, added with 20 mL sodium acetate buffer (0.1 mol/L, pH 5.2), sealed and mixed using a vortex mixer. The tube was placed into a water bath maintained at 100 ℃ for 30 min to completely gelatinise the starch. The tube was cooled to 37 ℃ and added with five glass balls (0.4 cm diameter) and 5 mL enzyme solution. The tube was sealed and placed into a shaking water bath (37 ℃, 200 times/min). Every 20 min, 0.1 mL of digestion solution was collected, then mixed with 1 mL 95% ethanol and centrifuged for 10 min at 5000 r/min. The hydrolysed glucose content was measured using theD-glucose assay kit. Starch hydrolysis degree was calculated using the equation (1).

Where Gh is the content of glucose produced/(mg/g); Si is the initial content of starch/(mg/g).

1.3.4 Measurement of particle size

Water was used as dispersing medium for all samples. Mechanical stirring (2000 r/min) was applied to ensure uniform dispersion and particle distribution. The volume-weighted mean diameterD[4,3] was calculated using Mastersize 2000 laser diffraction particle size analyzer version 5.22 software.

1.3.5 Measurement of rheological properties

The rheological properties of extrudates were determined using the rotational rheometer equipped with a pair of coaxial cylinders. The inner and outer diameters were 25 and 27.5 mm, respectively. Rheological measurements were made at (25.00 ± 0.01) ℃. Solution of 10 g/100 mL was prepared for the tests.

1.3.5.1 Measurement of steady flow properties

The viscosity flow curves were obtained using a measuring cup and vanned rotor geometry with shear rate ranging from 0.1 to 100 s-1. The Ostwald-de Waele model (equation (2)) was used to calculate the viscosity of all the samples.

Whereηappis the apparent viscosity/(Pa·s);γis the shear rate/s-1;Kis the consistency coefficient/(Pa·sn);nis the flow behaviour index (dimensionless) reflecting near-Newtonian flow. Linear regression analysis was applied to extrudates to calculateKandn.

1.3.5.2 Measurement of dynamic viscoelasticity

The dynamic viscoelastic properties were measured over a frequency range of 0.1–10 Hz, and a constant strain of 1% at 25 ℃ was used. The linear viscoelastic region was determined using strain sweeps at a frequency of 1 Hz at 25 ℃. The temperature sweep was recorded from 40–90 ℃ at a heating rate of 5 ℃/min, frequency of 1 Hz and controlled shear stress of 1 Pa. The storage (Gʹ/Pa) and loss (G”/Pa) modulus responses were recorded. After heating, the samples were cooled immediately to 25 ℃. All tests were performed at least in triplicate.

1.4 Statistical analysis

Values were expressed as mean ± standard deviation of three replicates. Statistical differences were determined employing the Duncan’s multiple range test (P< 0.05), and correlation analysis was performed employing the Pearson correlation coefficients by using the SPSS 17.0 software.

2 Results and Analysis

2.1 Chemical composition of NPS

NPS was composed of (15.46 ± 0.04)% moisture (wet basis), (83.75 ± 0.71)% starch (dry basis), (0.32 ± 0.04)% crude protein (dry basis), (3.41 ± 0.05)% crude fat (dry basis) and (0.06 ± 0.00) % ash (dry basis). The apparent amylose content was (34.56 ± 1.21)% (dry basis).

2.2 In vitro digestibility of NPS and the extrudates

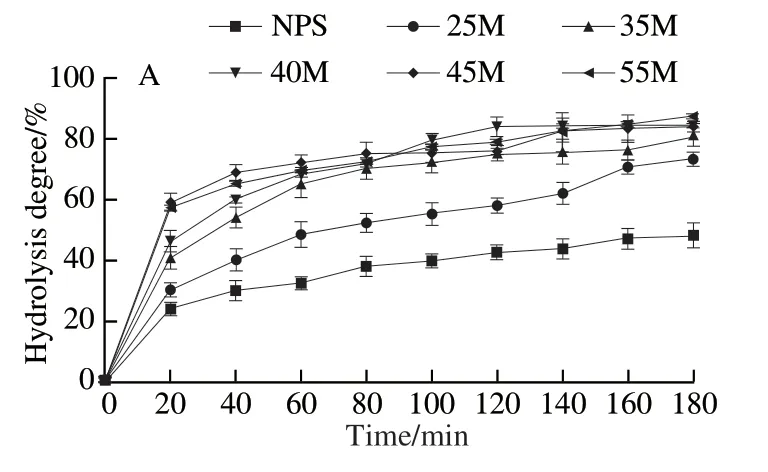

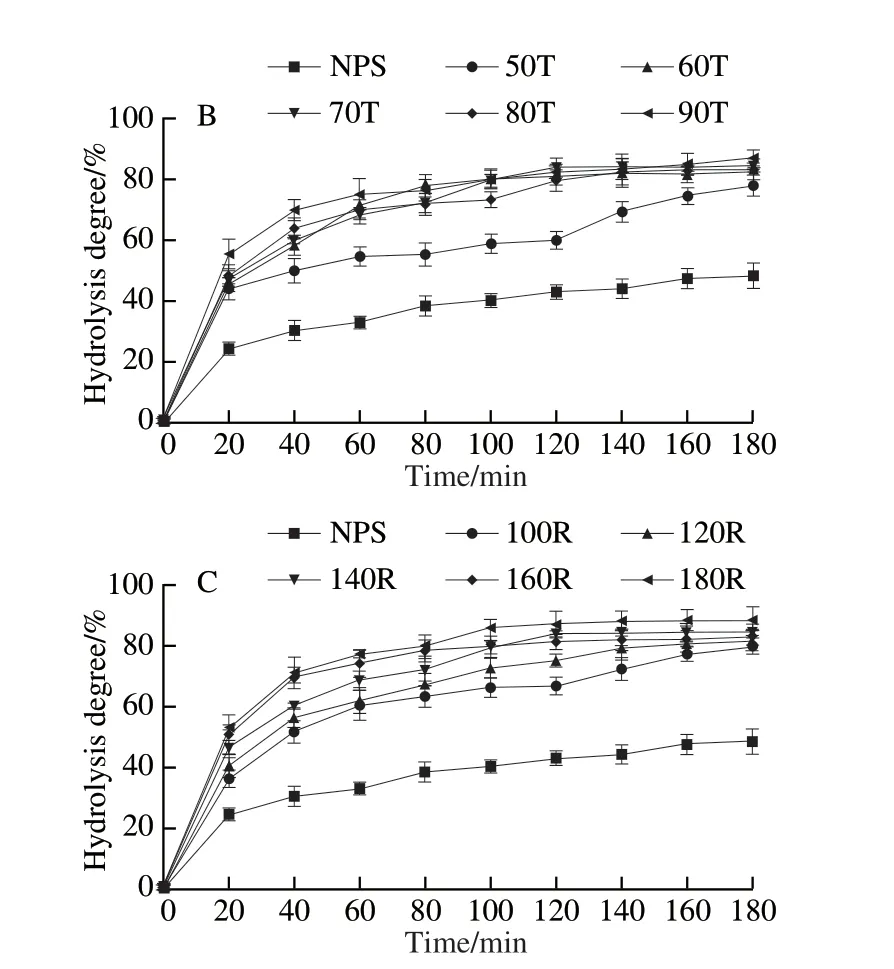

The RDS, SDS and RS contents of the NPS and the extrudates were shown in Table 1. The enzymatic hydrolysis curves of the NPS and the extrudates are presented in Fig. 1. The starch hydrolysis rate of the NPS was much lower than that of the extrudates. The hydrolysis degree of NPS after 180 min was 48.42%. Results supported previous findings, which reported that legume starch, in its native form, was slowly digestible[17].

Table 1 Relative contents of RDS, SDS and RS and D[4,3] of native and extruded starch samples

Fig. 1 Influence of moisture content (A), barrel temperature (B) and screw speed (C) on digestibility of extruded pea starch

The hydrolysis degrees for extrudates were higher than those of 25M and 35M extrudates (Fig. 1A). Furthermore, the hydrolysis degree after 180 min was highest for the 55M extrudate, indicating the higher digestibility of extrudates at higher moisture content. The 25M extrudate had the lowest RDS and the highest SDS contents (Table 1). Moisture increases the heat capacity, which reduces the physicochemical transformation in the extrudates[18]. Low moisture content created a severe condition in the extruder due to lack of water lubrication, resulting in the increase of the starch fragmentation. Therefore, short starch polymers were generated after cooling for increased molecular mobility, thereby increasing the SDS content[8].

With all the variables kept constant (moisture content of 40% and screw speed of 140 r/min), NPS was extruded at 50–90 ℃. The relationship between the barrel temperature and the starch hydrolysis degree of pea starch is shown in Fig. 1B. At 180 min, the hydrolysis degree increased from 78.03% to 87.26% as the barrel temperature increased from 50 ℃ to 90 ℃. During extrusion at limited moisture content (40%), more heat is required for starch gelatinisation[19], which means that higher temperature results in higher gelation of starch, making it more susceptibility to enzymatic digestion. Furthermore, the hydrogen bonds between the starches have been disrupted, and extreme starch chain mobility contributes to high hydrolysis degree[12]. Some reports have evaluated the effect of extrusion temperature on starch digestibility and revealed similar results[10,20].

Starch was extruded at screw speeds of 100–180 r/min at 40% moisture content and 70 ℃. The behaviour of the hydrolysis of extrudates with respect to screw speeds is shown in Fig. 1C. The hydrolysis degree increased with the increase of screw speed. This observation was explained on the basis of the high shear force in the extruder led to increasing the degree of molecular degradation.

The relative contents of RDS, SDS and RS of NPS and extrudates were shown in Table 1. NPS showed higher RS relative content (47.73%) than extrudates (10.49%–27.68%), which suggested that the chain activity was limited in NPS, and the breakdown of starch during extrusion changed the structure organisation of the starch molecules, thereby changing their susceptibility to enzymatic hydrolysis[21]. Increased sensitivity to enzymatic hydrolysis following extrusion has been observed in whole grain oats and lentil split[8,22]. SDS is generally the most desirable form of dietary starch[17]. The optimum moisture content, barrel temperature and screw speed for the highest SDS content were 25%, 70 ℃ and 160 r/min, respectively.

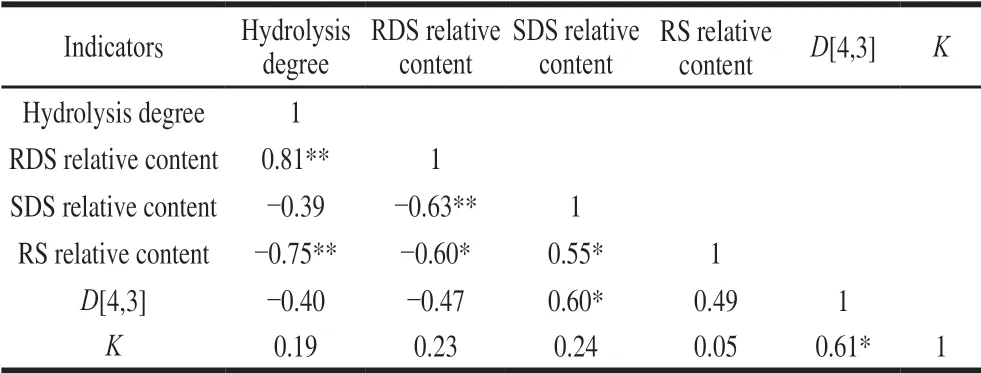

In summary, extrusion treatment increasedin vitrostarch digestibility, RDS relative content, and decreased the RS relative content. The Pearson correlation coefficients of the digested properties of extrudates are shown in Table 2. SDS relative content was negatively associated with RDS relative content (r= −0.63,P< 0.01).

Table 2 Pearson correlation coefficients among in vitro digestibility, particle size and consistency coefficient of extrudates

2.3 Particle size of NPS and the extrudates

The particle sizes of all samples are shown in Table 1. The Pearson correlation (Table 2) demonstrated moderately relevant relationship betweenD[4,3] and hydrolysis degree (r= −0.40,P> 0.05), RDS relative content(r= −0.47,P> 0.05) and RS relative content (r= 0.49,P> 0.05). These findings suggested that theD[4,3] was not the main factor influencing the digestibility properties under the conditions of the present study. However,D[4,3] had positive association and with the SDS relative content (r= 0.60,P< 0.05) andK(r= 0.61,P< 0.05) of the extrudates. This result agreed with the results of Svihus et al[23], which showed the relationship between water affinity and specific surface area.

2.4 Rheological properties of NPS and the extrudates

2.4.1 Steady shear test

The flow curves of the samples are presented in Fig. 2. Theηappcan be described using the Ostwald-de Waele model (R2> 0.93) in the range ofγfrom 0.1 to 100 s-1, which showed the strong dependence ofηapponγ. This result indicates a significant increase inηappfor the extrudates, which can be primarily attributed to the arrangement of the particles in the samples and breakdown of their interactions under the influence of theγ[24].

Fig. 2 Rheological curves of native and extruded pea starch suspensions

TheKandnvalues of the different samples are shown in Table 3.Kdecreased as the moisture content increased but increased as the barrel temperature and screw speed increased. In addition, allnvalues were less than 1, which indicated that the flow curves presented the shear thinning or pseudoplastic behaviour (ηappdecreased with the increased ofγ).

The pea starch was partially gelatinised after extrusion, which led to high viscosity. The difference amongst the consistency coefficients for all extrudates may be attributed to the differences in particle size[25]. Positive relationships were observed between particle size andK(r= 0.61,P< 0.05) (Table 2). These results suggested that the disruption and resistance of swollen large starch granules were responsible for the shear thinning behaviour at lowγ. At highγ, amylose entangles shrinks, lixiviates from the swollen granules and forms the stabilised network structure.

Table 3 Parameters of the Ostwald-de Waele model describing the shear thinning behaviour of samples

2.4.2 Dynamic viscoelasticity tests

2.4.2.1 Frequency sweep test

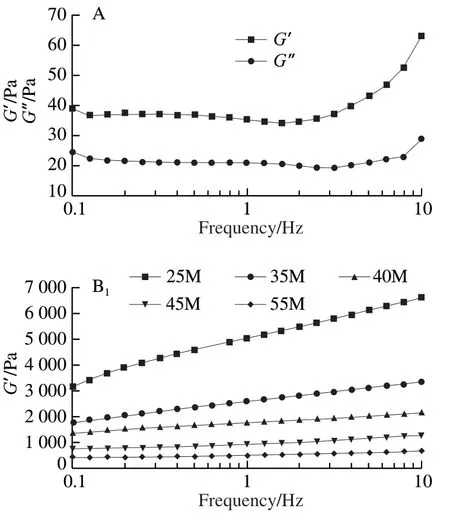

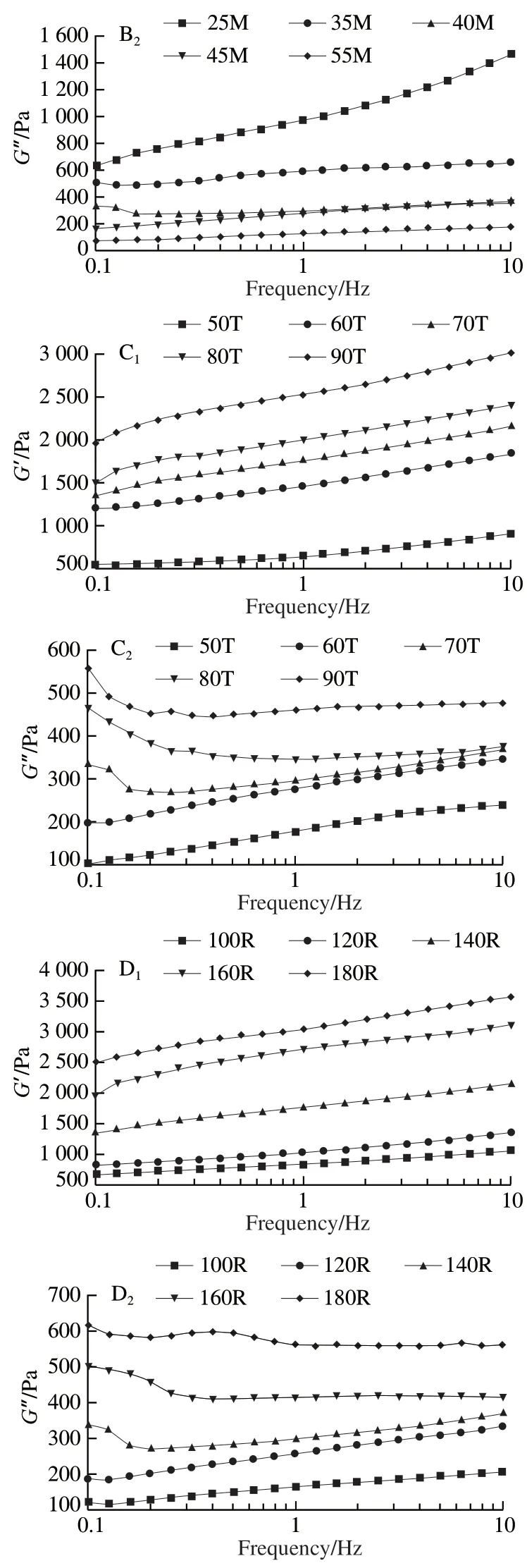

The mechanical spectra obtained at 25 ℃ forG’ andG” of the different rheological parameters from the NPS and the extrudates are presented in Fig. 3. The plateau relaxation zone was observed in all samples at low frequencies. The area ofG’was higher than that ofG”, and both moduli depend on frequency but follow different patterns[24]. Fig. 3 showed strong frequency dependence, which indicated that the material structure had molecular entanglement[26].

Fig. 3 Elastic (G’) and loss (G”) moduli dependence on frequency as obtained from frequency sweep test at 1% strain

The dynamic moduli increased with the severity of the pea starch extrusion process, i.e., with increasing extrusion temperature and barrel speed and with decreasing moisture content. TheG’ of the NPS and the extrudates increased with an increase in frequency from 0.1 to 10 Hz.G’was higher thanG”,indicating that the elastic behaviour was superior than the viscous behaviour. Wani et al[27]has reported comparable results on the flow behaviour for Bengal gram starch, which may be due to the extension and intertwining of molecular chains in the extrudates, leading to their structural reorganisation due to the continuous increase in frequency. However,G”showed various trends under different extrusion conditions. At relatively high barrel temperatures (70, 80 and 90 ℃) and screw speeds (140, 160 and 180 r/min), theG” slightly decreased with increasing frequency and stabilized gradually. In addition to these conditions,G” increased with increasing frequency. The probability of such behaviour may be linked to the gelatinised starch molecules that were dispersed under the external force to reduce itsG” at the beginning and aggregated and stabilised. The starch granules were partially destroyed due to the relatively low screw speed and barrel temperature. Therefore, the increase inG” caused by molecular rupture was offset by the decreased external force. According to the flow curves, these results demonstrated that the extruded starch can enhance the structure and increaseG’ andG”because of extrudates’ high-water absorption capacity.

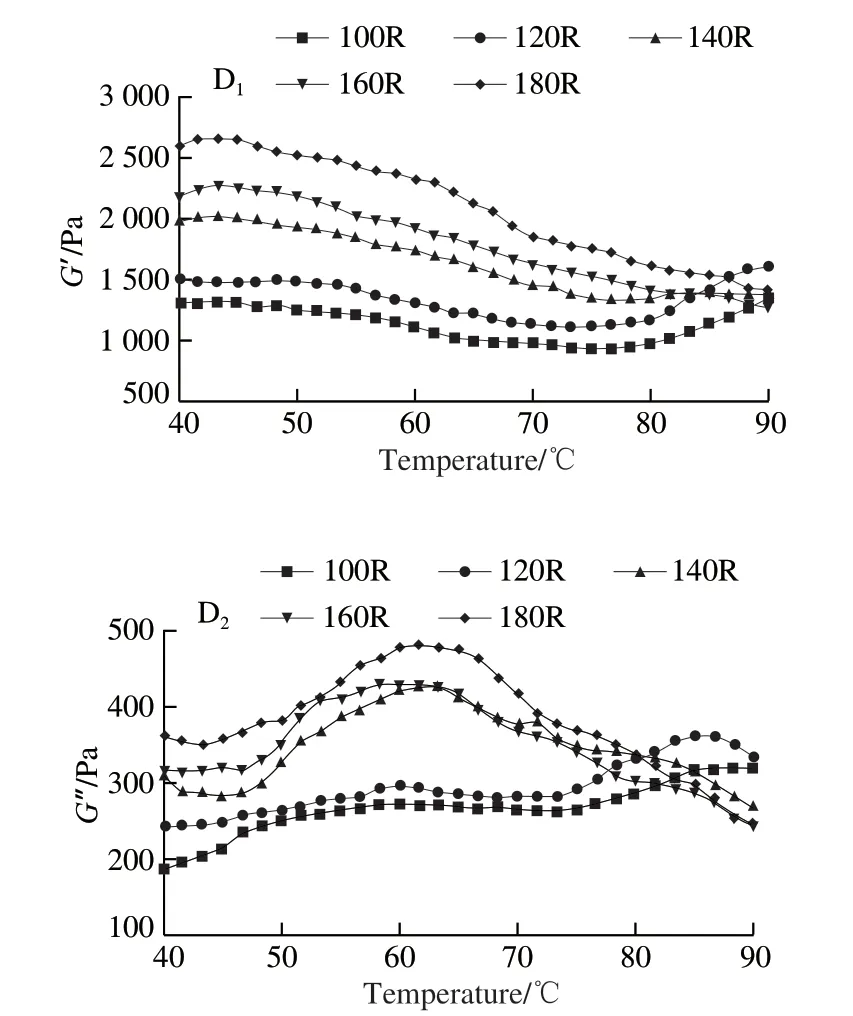

2.4.2.2 Temperature sweep test

G’ andG” curves versus temperature for NPS and extrudates at selected temperature (40–90 ℃) were reported in Fig. 4. For the NPS, theG’ andG” initially increased to a maximum value and then decrease with temperature increasing. Viscoelastic properties were greatly influenced by swollen starch granules in the heated starch system[28], and the heating process promotes the close association of the gelatinized and swollen starch granules, increasing the mobility and collision of these swollen granules[29]. The decrease inG’ may be attributed to the breakdown of starch granules and destruction of the intermolecular interactions, which finally resulted in decreased degree of chain entanglements[29]. Ji Zhili et al[30]studied the rheological properties of corn starch and reported similar results. Compared with NPS, theG’of the extrudates decreased from 60 ℃. The degree of decline was proportional to the severity of the starch. This observation indicated that extrusion ruptured the starch granules, resulting in the quick water absorption of partially gelatinised starch, which led to the lowerG’ of the extrudates than that of the NPS except 25% and 35% moisture content. At higher extrusion temperature conditions, less damaged starch granules were less susceptible to water loss, causing an increase inG’. However, theG” curves were observed to initially increase and decline, which was also observed in extrudes with high screw speeds (140, 160 and 180 r/min) or with high barrel temperature (70, 80 and 90 ℃), which indicated that the pea starch had better viscosity capacity under relative extreme extrusion conditions. It had been considered that starch suspensions withG’> 500 Pa and tanθ(G”/G’)< 0.2 during temperature sweep could be regarded as an elastic gel[31], which indicates that the pea starch suspensions converted to an elastic gel after extrusion process.

Fig. 4 Elastic (G’) and loss (G”) moduli of native and extruded pea starch

3 Conclusion

Thein vitrodigestibility, rheological properties and particle size of the NPS and the extrudates were determined. The hydrolysis degree of the extrudates differed in different moisture contents, barrel temperatures and screw speeds. Pea starch was gelatinised and disrupted in the extruder, increasing the accessibility of the digestive enzymes to the starch granules. The minimum RS relative content was obtained at 180 r/min (180R), whereas the maximum SDS relative content was obtained at 25% moisture content (25M). Based on the Ostwald-de Waele model, the rheological analysis showed that the NPS and the extrudates were affected by particle size. For frequency sweep from 0.1 to 10 Hz, theG’ andG” were dramatically increased in the extrudates compared with that of NPS because the former obtained higher water absorption capacity and enhanced structure than the latter.G’ was higher thanG”, indicating that the elastic behaviour was better than the viscous behaviour for extrudates. For the temperature sweep,G’ andG” were negatively associated with moisture content and positively associated with barrel temperature and screw speed. Although further investigations are required to fully understand the mechanisms of the changes in pea starch in the extruder, the trends obtained are important for the development of new pea starch-based foods and the optimisation of extrusion processes.