Electrospun Small Diameter Tubes to Mimic Mechanical Properties of Native Blood Vessels Using Poly(L-lactide-co-ε-caprolactone)and Silk Fibroin:a Preliminary Study

ZHAO Hui-jing (赵荟菁) ,WU Qian-yao (吴倩瑶),WANG Lu (王 璐),LIN Jing (林 婧)

1 National Engineering Laboratory for Modern Silk,College of Textile and Clothing Engineering,Soochow University,Suzhou 215123,China

2 Key Laboratory of Textile Science and Technology,Ministry of Education,Donghua University,Shanghai 201620,China

3 College of Textiles,Donghua University,Shanghai 201620,China

Introduction

Cardiovascular diseases remain one of the leading causes of death all over the world.Large diameter vascular prostheses are satisfying in clinical applications.However,small diameter(φ≤6 mm) vascular grafts come across barriers like anastomotic intimal hyperplasia and thrombi[1].It was found that one of the main reasons of the barriers were mismatch in mechanical properties between the natural blood vessels and the artificial ones[2].Therefore,to fabricate a small diameter artificial blood vessel with reliable mechanical properties as native blood vessels is not only necessary,but also very important.

Besides matchable mechanical properties, good biocompatibility is also one of the key factors for a tissue engineering scaffold.Silk fibroin (SF)consists of heavy and light chain polypeptides of 350 and 25 kDa respectively,which are connected by a disulfide link[3].SF is a kind of natural proteins which is biocompatible and biodegradable.Literature showed that SF materials could be applied in blood vessel engineering,peripheral nerve regeneration materials,artificial ligament,and etc[3].Besides,SF is so easy to process that it can be fabricated by various techniques to form a variety of biomaterials,such as gels,sponges,and films,for medical applications.Among those processing techniques,electrospinning is a versatile technique that can produce nanofiber-based biomaterial scaffolds which have promising applications in tissue engineering since they mimic the in vivo nanoscale natural extracellular matrix (ECM),which acts as structural elements to hold and bring cells together,as well as control the tissue structure and regulate cell phenotypes.Electrospun SF materials have showed excellent biocompatibility studied in vitro and in vivo[4-5].However,the mechanical properties of the pure electrospun SF materials were not satisfying to be used as artificial blood vessels.

In order to improve the mechanical properties of SF electrospun materials,blending another biodegradable polymer with SF were normally used[6].In particular,poly(L-lactideco-ε-caprolactone) (PLCL) copolymer, ring opening polymerized by the monomers of poly(L-lactide)(PLLA)and poly(ε-caprolactone)(PCL),exhibits a rubber-like elasticity because of the physically cross-linked structure[7].Together with its satisfying biocompatibility,PLCL has been used at vascular application very recently, and its elasticity and flexibility needed for blood vessel reparation also have been approved[8].Thus,blending PLCL with SF to improve the mechanical properties of pure SF used for small diameter artificial blood vessels becomes the main purpose of this study.

1 Materials and Methods

1.1 Preparation of aqueous SF solution

Bombyx mori fibroin solution was prepared according to the previously published procedures[9].Briefly,cocoons were boiled for 20 min in an aqueous solution of 0.02 mol/L Na2CO3and then rinsed thoroughly with distilled water to extract the sericin proteins.After drying the extracted SF was dissolved in 9.3 mol/L LiBr solution at 60 ℃ for 4 h and then dialyzed against distilled water for 72 h to remove salt.The obtained solution was diluted by deionized water, and the final concentration of the solution was 3% by mass.

1.2 Preparation of polymer solutions

Solid SF film was obtained by drying the aqueous SF solution in room temperature.Solid SF film and PLCL (MW=154 000 g/mol,Dai-gang Biomaterial Co.,Ltd.,China)were mixed together at weight proportions of 70/30,50/50,30/70 respectively,and then they were dissolved in 1,1,1,3,3,3-hexafluoro-2-propanol (HFIP,molecular weight is 168.04)(Fluorochem Ltd.Unit 14,UK)at room temperature for more than 12 h.The concentration of final polymer solutions was 6%by mass.

1.3 Electrospinning

The electrospinning experiments were performed on an electrospinning machine (Future Materials Co.,Ltd.,China)at room temperature.Polymer solution was put in a syringe with a pinhead with 0.7 mm outer diameter.A positive voltage of 20 kV was applied on the pinhead that was shifted at a speed of 20 mm/s.Delivery speed of the solution was 1 mL/h.The electrospun fibers were collected as a tube by a rotating mandrel with the diameter of 4 mm.The rotating speed of the mandrel was 200 r/min.A negative voltage of -2 kV was applied on the mandrel to guarantee effective collection.A schematic view was shown in Fig.1.In order to take off the tube easily,a longitudinal elastic braided tube was covered on the mandrel before collecting.The collecting distance was 15 cm.

Fig.1 Electrospun tubes from SF and PLCL solutions

1.4 Post treatment of the electrospun tubes

The tubes were treated by ethanol to make them water insoluble and improve their strength.Tubes were soaked in ethanol with concentration of 75% by volume for 30 min and then rinsed by deionized water for 3-5 times,and air dried.

1.5 Scanning electron microscopy (SEM)

The tubes were viewed under an S-4800 SEM (Hitachi Co.,Ltd.,Japan)using an accelerating voltage of 3 kV.Specimens were mounted on small size copper plates and then coated with gold.

1.6 Mechanical testing

1.6.1 Radial tensile testing

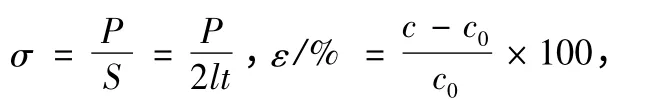

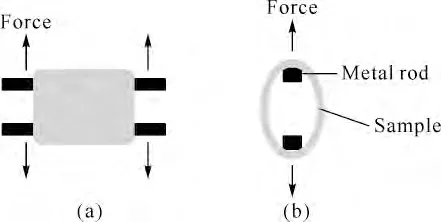

The tubes were cut into 1 cm in length and tested on YG(B)026G-500 electronic tensile tester in dry condition,which was shown in Fig.2.Drawing speed of the tester was 50 mm/min.Thickness of the samples were tested by a thickness meter.Tensile strength σ and elongation at break ε are calculated by the following equations respectively.

where P is peak load,S is cross sectional area,l is length,c is the circumference,c0is the original circumference.

Fig.2 The radial testing for (a)front view and (b)side view

1.6.2 Compliance testing

The tubes were cut into 6 cm in length and tested on TM1 Test Bench System (Bose Electro Force,USA) in wet condition.A thin rubber tube with diameter of 4 mm was inserted into the sample before testing in order to prevent leakage.The flow rate of the fluid was 100 mL/min,and testing frequency was 1 Hz.Compliances under three pressure ranges (6.67 - 12.00,10.66 - 16.00,and 14.66 - 20.00 kPa,which equals 50 -90,80 -120,and 110 -150 mmHg)were obtained.

2 Results and Discussion

2.1 Morphological properties

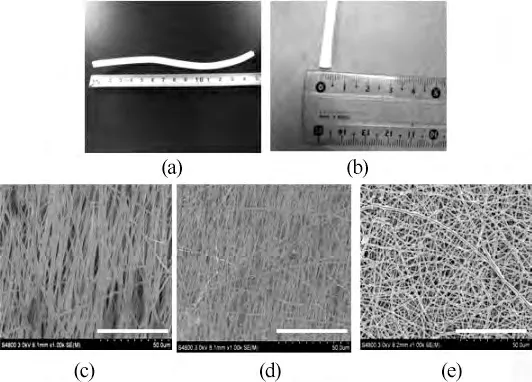

The tube length was about 15 cm (Fig.3 (a)),and tube diameter was about 5 mm (Fig.3 (b)).In Figs.3(c)and(d)the electrospun fibers were oriented when SF content was more than 50%.The orientation of the fibers was influenced not only by the rotating speed of the collecting mandrel,but also by the state of the polymer solution.The viscosity of the solution was increased greatly through blending PLCL.The higher the viscosity of polymer solution was,the more difficult for the electrospinning fibers to be oriented.

Fig.3 Morphologies of (a)(b)the tubes;(c)SF/PLCL =70/30;(d)SF/PLCL = 50/50;(e)SF/PLCL =30/70;scale bar is 50 μm

2.2 Mechanical properties

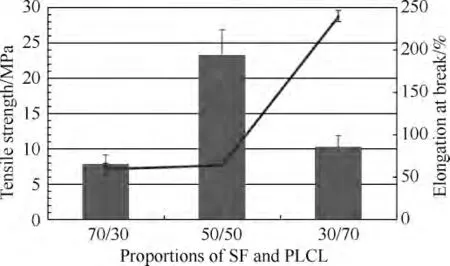

Tensile strength of the blended tubes were all higher than 7 MPa (Fig.4),even reached to 23 MPa when the blending mass ratio was 50/50,which was much higher than most of the native blood vessels[10].Elongation at break of the blended tubes was mainly determined by the content of PLCL.With the increase of PLCL contents,elongation at break reached to about 59%,64%,and 239% respectively,which were significantly higher than that of the pure electrospun SF materials[11].

Fig.4 Tensile properties of the blended electrospun tubes

SF is mostly composed of hydrophobic amino acid residues,such as glycine and alanine.Similarly,PLCL has considerable amounts of hydrophobic chemical groups,such as non-polar methylene.The similarity in the chemical compositions of PLCL and SF lead to miscibility and interactions between the two phases.Consequently, the mechanical properties of the blended material will be different with those of both pure SF and pure PLCL.Elongation at break of the blended tubes increased gradually with the increase of PLCL.However,tensile strength didn't follow a certain trend.With the increase of PLCL,tensile strength first increased and then decreased gradually.When the content of PLCL was 50%,tensile strength of the tubes reached the highest point.

Table 1 showed that compliances of the blended tubes were higher than 1% /13.33 kPa (1% /100 mmHg)under the three pressure ranges,which illustrated that compliances of the samples were relatively good.Comparing the data of the three blending ratios of SF and PLCL comprehensively,compliance of the samples with blending mass ratio of 50/50 was the most optimal.According to the reference[12],compliance of human femoral arteries was 6.5% /13.33 kPa (6.5% /100 mmHg)when they were tested under the pressure of 8.00 kPa (60 mmHg).That is to say,compliance of the samples with blending ratio of 50/50 in this study was similar to the compliance of human native femoral arteries.

Table 1 Compliance of the electrospun blended tubes under three pressure ranges(% /13.33 kPa,which equals% /100 mmHg)

3 Conclusions

The prototype small diameter tubes made of electrospun PLCL/SF materials with various blending ratios were fabricated successfully in this study.Morphological and mechanical properties were studied.Results showed that electrospun fibers could be oriented under the rotating speed of 200 r/min.However,the orientation of the fibers was also influenced by viscosity of the polymer solution.It was found that the higher the viscosity of polymer solution was,the more difficult for the electrospinning fibers to be oriented.Results of mechanical testing showed that with the increase of PLCL content,tensile strength first increased and then decreased gradually.When the content of PLCL was 50%,tensile strength of the tukes reached the highest point.Meanwhile,elongation at break of the tubes was also improved significantly.Combining the data of radial compliance,it could be deduced that the mechanical properties of the tubes with a blending mass ratio of 50/50 had a potential to be used for vascular applications.

[1]McClure M J,Sell S A,Simpson D G,et al.A Three-Layered Electrospun Matrix to Mimic Native Arterial Architecture Using Polycaprolactone,Elastin,and Collagen:a Preliminary Study[J].Acta Biomaterialia,2010,6(7):2422-2433.

[2]Wise S G,Byrom M J,Waterhouse A,et al.A Multilayered Synthetic Human Elastin/Polycaprolactone Hybrid Vascular Graft with Tailored Mechanical Properties [J].Acta Biomaterialia,2011,7(1):295-303.

[3]Vepari C,Kaplan D L.Silk as a Biomaterial[J].Progress in Polymer Science,2007,32(8/9):991-1007.

[4]Lovett M,Cannizzaro C,Daheron L,et al.Silk Fibroin Microtubes for Blood Vessel Engineering [J].Biomaterials,2007,28(35):5271-5279.

[5]Zhang X,Baughman C B,Kaplan D L.In vitro Evaluation of Electrospun Silk Fibroin Scaffolds for Vascular Cell Growth[J].Biomaterials,2008,29(14):2217-2227.

[6]Zhang X, Reagan M R, Kaplan D L.Electrospun Silk Biomaterial Scaffolds For Regenerative Medicine[J].Advanced Drug Delivery Reviews,2009,61(12):988-1006.

[7]Jung Y,Park M S,Lee J W,et al.Cartilage Regeneration with Highly-Elastic Three-Dimensional Scaffolds Prepared from Biodegradable Poly (L-lactide-co-ε-caprolactone) [J].Biomaterials,2008,29(35):4630-4636.

[8]Inoguchi H,Kwon ⅡK,Inoue E,et al.Mechanical Responses of a Compliant Electrospun Poly (L-lactide-co-ε-caprolactone)Small-Diameter Vascular Graft[J].Biomaterials,2006,27(8):1470-1478.

[9]Zhang X L, Fan Z H, Lu Q, et al.Hierarchical Biomineralization of Calcium Carbonate Regulated by Silk Microspheres[J].Acta Biomaterialia,2013,9(6):6974-6980.

[10]He W,Ma Z,Teo W E,et al.Tubular Nanofiber Scaffolds for Tissue Engineered Small Diameter Vascular Grafts[J].Journal of Biomedical Materials Research Part A,2009,90(1):205-216.

[11]Zhou J,Cao C B,Ma X L.A Novel Three-Dimensional Tubular Scaffold Prepared from Silk Fibroin by Electrospinning [J].International Journal of Biological Macromolecules,2009,45(5):504-510.

[12]Zou F,Wang L.Research on Compliance of Synthetic Vascular Prosthesis[J].Journal of Medical Biomechanics,2004,19(3):188-192.(in Chinese)

Journal of Donghua University(English Edition)2013年5期

Journal of Donghua University(English Edition)2013年5期

- Journal of Donghua University(English Edition)的其它文章

- Properties of Scaffold Reinforcement for Tendon Tissue Engineering in vitro Degradation

- Mineralized Composite Nanofibrous Mats for Bone Tissue Engineering

- Promoted Cytocompatibility of Silk Fibroin Fiber Vascular Graft through Chemical Grafting with Bioactive Molecules

- Fatigue Performance of Fabrics of Stent-Grafts Supported with Z-Stents vs.Ringed Stents

- Effect of Media on the in vitro Degradation of Biodegradable Ureteral Stent

- Radial Force Analysis of Polydioxanone Coronary Stent by Finite Element Method