Surface Roughness and Roundness of Bearing Raceway Machined by Floating Abrasive Polishing and Their Effects on Bearing’s Running Noise

PANG Guibing , QI Xuezhi MA Qinyi ZHAO Xiujun WEN Chunsheng, XU Wenji,

and PENG Yanping1

1 School of Mechanical Engineering and Automation, Dalian Polytechnic University, Dalian 116034, China

2 Dalian Wazhou Precision Motor & Automobile Bearing Co., Ltd, Dalian 116102, China

3 School of Mechanical Engineering, Dalian University of Technology, Dalian 116024, China

1 Introduction

Bearings are important basic parts in modern industry.With the development of machinery of high-speed,precision and low noise etc, performance of bearing are demanded increasingly higher and higher[1–3]. Running noise is an important index of bearings’ performance, and is usually strictly controlled in the field of precision motor,precision machine tools, and precision instruments and so on. Raceway is the physical contacting position between the rolling body and the ring when bearing runs. So, its geometrical characteristics directly affect the bearing noise.As two most important indexes of the bearing raceway,surface roughness and roundness have significant influence on the bearing noise[4]. Some researchers have carried out studies in this field[5–6], however, the reason and extent of the influence of raceway surface geometric characteristics on the bearing running noise are not perfectly clear up to now.

Super finishing is widely used as the final process of bearing raceway at present[7–9]. In the process of super finishing, oilstone moves along the raceway surface fast,which will refine the surface roughness and improve the roundness of raceway[10–12]. However, the rigid consolidation abrasive is usually used in super finishing,which easily leads to the micro scratches on the parts’surface. So, super finishing has limitation for improving the surface roughness. To produce high precision bearing raceway, other precision finishing methods are necessary after super finishing. Lapping, which uses hard abrasive tools and adds the floating abrasives in between the tool and the machined surface, can effectively improve the surface roughness of parts and avoid the scratching phenomenon caused by oilstones. The lapping tool’s precision has influence on the accuracy of the workpiece.However, due to the tool is made of hard material, there is possibility that the raceway accuracy degrades. Especially for deep groove ball bearing raceway, whose cross section is semicircle shape, it is difficult to manufacture the high precision lapping tool. In order to improve the surface roughness and roundness of bearing raceway after super finishing, we apply Floating Abrasive Polishing Adopting Soft Abrasive Pad (FAPASAP) to machine the bearing raceway. The soft abrasive pad has an “adaptive”characteristic, and its shape can be changed with the cross section of the raceway when they are contacting. Therefore,the tool shape precision has less influence on the raceway’s precision[13–14]. At present, researches of FAPASAP are mainly focused on the final polishing for the optical elements such as the silicon wafer, etc[15–16]. It is not found that this method has been used to machine bearing raceway in public reports.

In this paper, FAPASAP is used to machine the bearing raceway. The surface roughness and roundness characteristics of bearing raceway before and after FAPASAP are studied. Furthermore, their effects on bearing’s running noise are analyzed.

2 Experimental Procedures and Conditions

2.1 Experimental procedures

Machining the raceway by super finishing—cleaning the ring by ultrasonic method—measuring the roughness and roundness of raceway—cleaning the ring by ultrasonic method—machining the raceway by FAPASAP—measuring the roughness and roundness—measuring the raceway size—selecting and grouping the rings according to the raceways’ clearance—assembling the bearing— cleaning the bearing by ultrasonic method—testing the running noise.

2.2 Experimental conditions

2.2.1 Polishing conditions

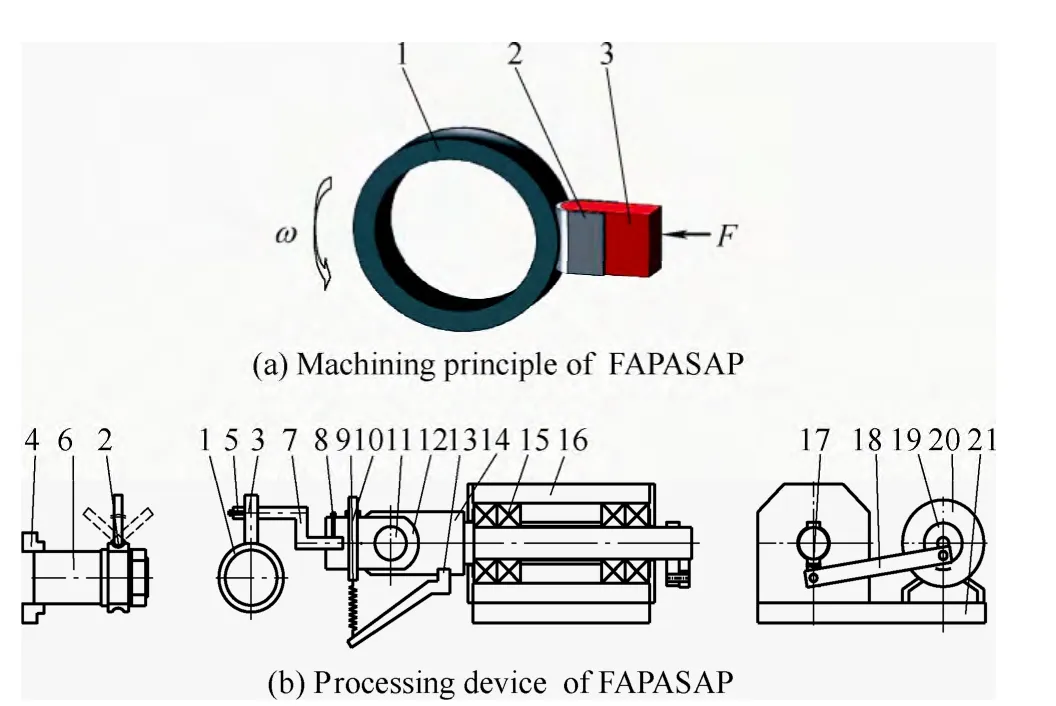

The basic machining principle of FAPASAP is shown in Fig. 1. The polishing pad is fixed on the polishing tool and pressed on the surafce of the workpiece. The abrasive is placed in between the polishing pad and the special fixture.When the workpiece rotates, the surface of the workpiece will be polished by the polishing pad and the abrasive.

The experiment was carried out by modifying a lathe.The workpiece was fixed on a special fixture, which was driven by the lathe spindle chuck. The polishing pad was pressed on the raceway by the polishing tool. The polishing tool was hold by lever 1 which is fixed on lever 3. Lever 3 could rotate around the revolving shaft and dragged by spring 9 elastically. The pulling force of spring 9 could be adjusted by lever 2. Lever 4 was used to fix the spring. The pendulum shaft was driven by a crank rocker mechanism.The center of the pendulum shaft coincided with the center of the semi-circle of the raceway’s cross section. The bracket was fixed on the lathe carriage.

The experimental objects were inner and outer rings of 6309 type bearing and twenty groups of rings were taken as the samples. Material of the ring is GCr15 bearing steel,whose composition is shown in Table 1. The original process of raceway was super finishing, in which the oilstone with the abrasive size of 3.5um was used. Before experiment, the experimental conditions were optimized and FAPASAP is carried out under the optimized machining conditions. The main experimental conditions are shown as follows: the main ingredient of the floating abrasive is diamond with the particle size of 1um; the relative velocity between the workpiece and the tool is 5 m/s; polishing pressure on the workpiece surface is 2–6 MPa; the machining time was 5–10 min.

Fig. 1. Principle and device of machining bearing raceway with FAPASAP

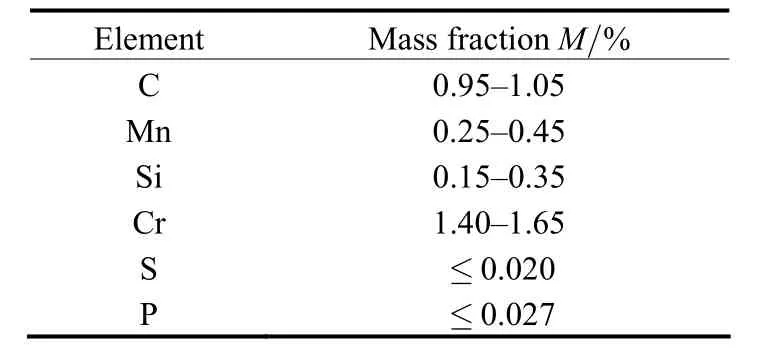

Table 1. Composition of GCr15 material

2.2.2 Testing conditions

The roundness was measured along the raceway circumferential point-by-point with the CL-1A type roundness and waviness instrument produced by Shanghai Taile Precision Instrument Manufacturing Co., Ltd.. The roughness was measured along the raceway section point-by-point with the YD-201B type roughness profile instrument made by Shanghai Taile Precision Instrument Manufacturing Co., Ltd.. The noise was measured with the S0910-3 type bearing vibration instrument produced by Dalian Kehui bearing instrument Co., Ltd., on condition that the running speed was 1500 r/min.

3 Experimental Results and Discussions

3.1 Polishing experimental results and discussions

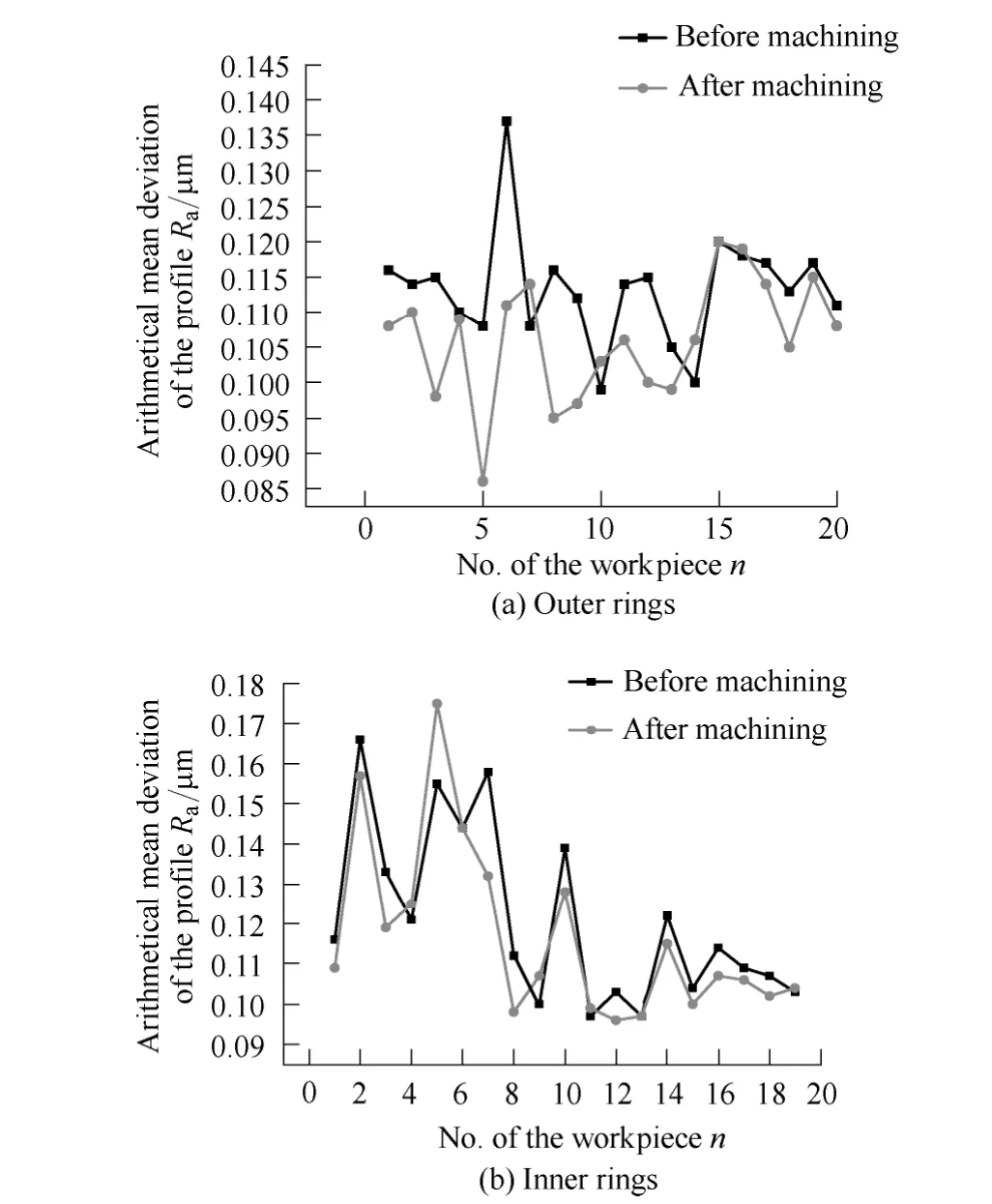

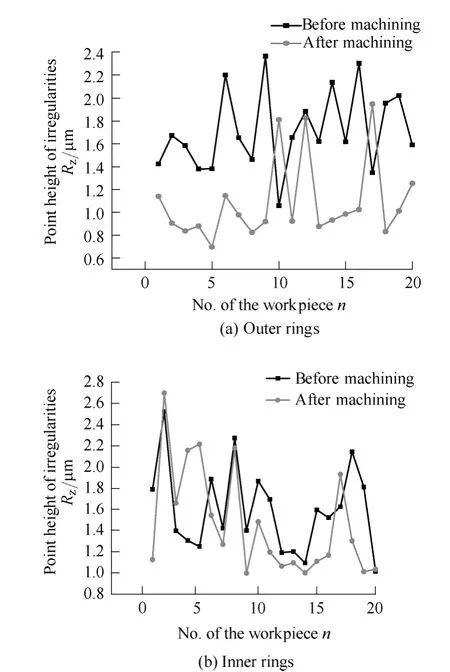

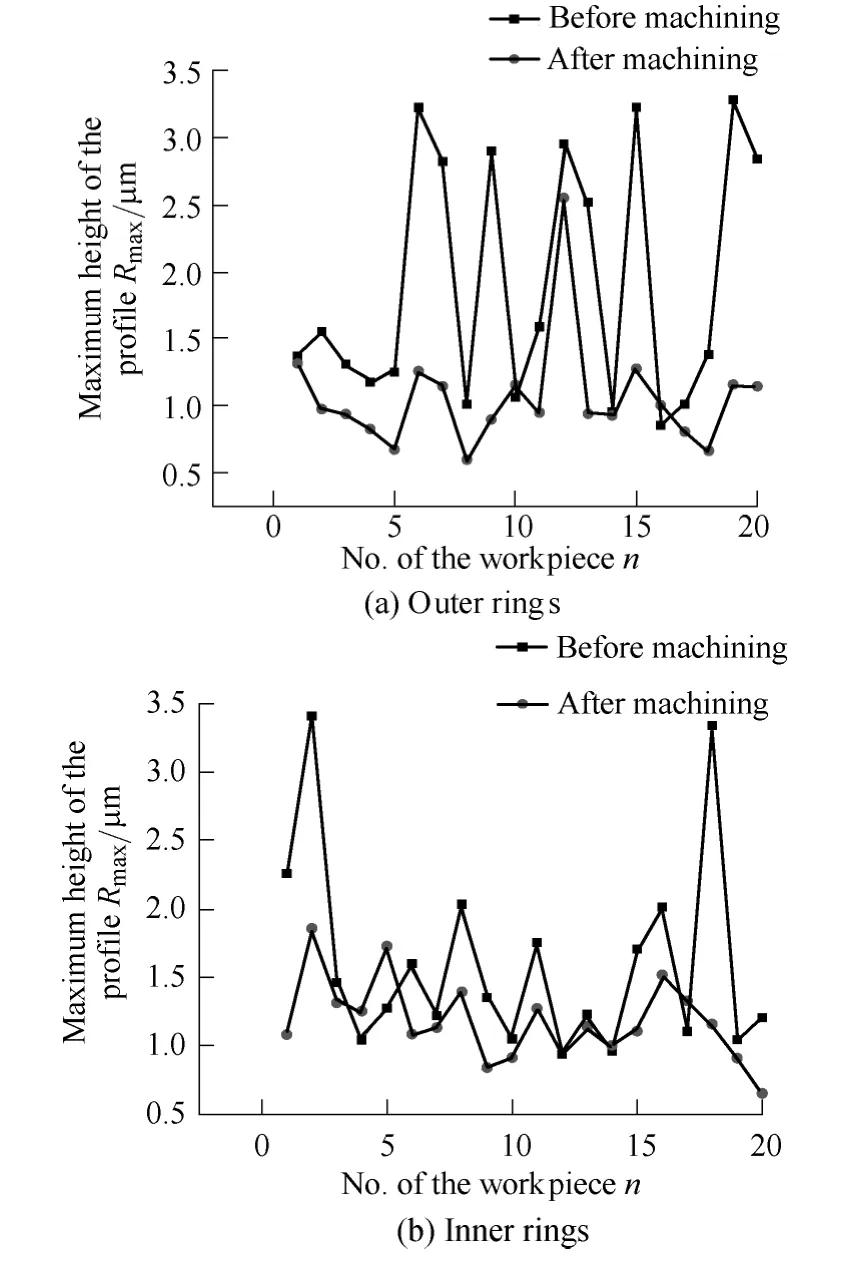

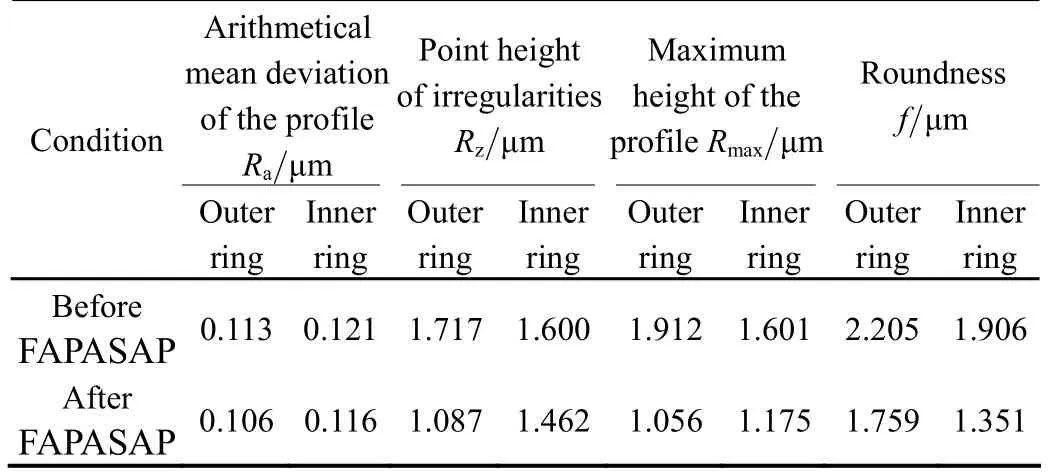

Fig. 2 shows the arithmetical mean deviation of the profile Ravalues before and after FAPASAP (Datum of No.3 inner ring is deleted, because it exceeds the normal range largely). Fig. 3 shows the point height of irregularities Rzvalues before and after FAPASAP. Fig. 4 shows the maximum height of the profile Rmaxvalues before and after FAPASAP. Fig. 5 shows the roughness f before and after FAPASAP. Table 2 shows the mean values of the raceway surface roughness values and roundness values before and after FAPASAP. Table 3 shows the variation amplitude of raceway surface roughness and roundness parameters.

Fig. 2. Values of Ra before and after FAPASAP

Fig. 3. Values of Rz before and after FAPASAP

Fig. 4. Values of Rmax before and after FAPASAP

Fig. 5. Values of f before and after FAPASAP

According to the experimental results shown in Figs. 2–5,Table 2 and Table 3, surface roughness and roundness values of the inner and outer ring raceway are all decreased after FAPASAP. However, the reducing amplitudes are different: Ravalue decreases less, whose average range of reduction is 5%; the reducing amplitude of Rzvalue is greater than that of Ra, averagely 22%; the reducing amplitude of Rmaxvalue is greater than that of Rz, averagely 35.5%;the roundness errors are greatly reduced, averagely 25%.

Table 2. Mean values of Ra, Rz, Rmax, f before and after FAPASAP

Table 3. Variation amplitudes of raceway roughness and roundness values %

FAPASAP is different from the lapping process, which mainly lies in their tools. The lapping process uses rigid tool,whose precision can be passed to the machined surface, so it can improve both the surface roughness and the accuracy.FAPASAP uses soft and elastic polishing pad, which is pressed on the parts elastically. It can improve the surface quality, and will not have much impact on the accuracy in theory. However, the experimental results show that the roundness error has got obvious improvement after polishing.

According to the definition, Rais arithmetic mean of the absolute ordinate values of the profile within the sampling length, reflecting the comprehensive deviation of the assessed profile. Rzis the sum of the average of five highest peaks’ height and the five deepest valleys’ depth within the sampling length, reflecting the mean deviation of the assessed profile. Rmaxis the altitude difference between the highest point and the deepest point within the sampling length, reflecting the local limit deviation of the assessed profile. Roundness is the radius’ difference of the two concentric circles containing the raceway’s real profile. In this paper, the roughness and roundness were measured with contacting method by scanning the raceway point by point, so the micro change on any region of the measured surface may affect the relative position of the concentric circles. Therefore, when Rmaxand Rzare changing, it will inevitably affect the roundness error. Especially, when their order is close to that of the roundness error value, this effect is more obvious. For Ra, although it may also affect the roundness, its influence is obviously less than Rmaxand Rzbecause it reflects the arithmetic mean of the assessed profile.

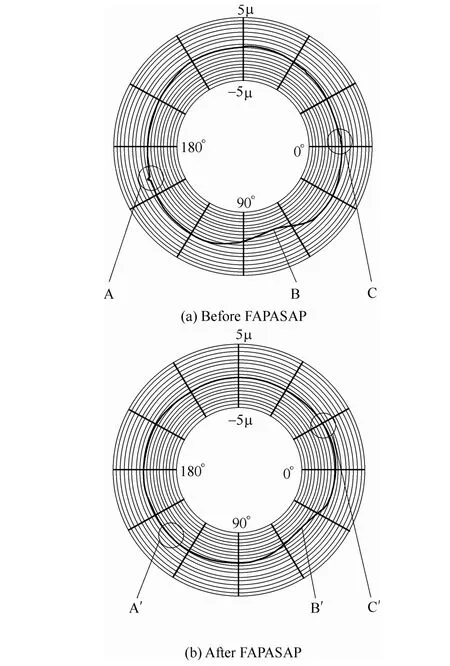

According to above analysis, there is certain relevance between surface roughness and roundness. Improvement of some parameters of surface roughness is beneficial to improving the raceway roundness to some extent.Especially for the workpiece with high precision, this improvement is more obvious. Fig. 6 and Fig. 7 show the roundness curve and roughness curve of No. 2’s outer ring before and after FAPASAP. It can be found in Fig. 7(a) and Fig. 7(b), that after machining, the macro error does not change obviously, but the local error gets correction. Before machining, surface profile has obvious deviation both in macroscopic and microscopic, such as the error in A(A¢)and C(C¢) positions is micro error, and the error in B(B¢)positions is macro error. Contrasting Fig. 7(a) with Fig.7(b), although the profile has not be changed macroscopically after machining, the local peaks have been effectively removed. This can be verified from the comparison of the roughness curves before and after FAPASAP shown in Fig. 6(a) and Fig. 6(b). Therefore, for those parts with high precision, the accuracy is affected obviously by the local errors of the surface profile. To distinguish the scale of the geometric factors affecting the parts’ accuracy, this paper divides the geometric factors affecting roundness into two kinds according to the scale:one is the roundness error caused by the macro error,named the first type of roundness error; another is the roundness error caused by the local error, named the second type of roundness error. For the bearing raceway,FAPASAP can level the local error of the raceway effectively, and reduce the surface roughness Rmax, Rzand the second type of roundness error. But it can not correct the first type of roundness error basicly. Ravalue of the raceway is mainly decided by the size of the abrasive particle used in the FAPASAP process. In this paper, the size is close to the one in super finishing, so the reduction of Ravalue is not obvious.

Fig. 6. Measuring results of the roughness of the No. 2 outer ring before and after FAPASAP

Fig. 7. Measuring results of the roundness of the No. 2 outer ring before and after FAPASAP

3.2 Noise experimental results and discussions

According to the data provided by the cooperation factory, the running noise of 6309 type bearing after super finishing is between 42 dB to 45 dB. After FAPASAP,average running noise is 37.6 dB (removing the abnormal sound data), reducing by 10.5% to 16.4%.

In order to discuss the relationship between the raceway’s evaluating parameters and the noise value further,the experiment data of Ra, Rz, Rmax, roundness and noise value were processed as follows:

(1) The average of the experimental data of Ra, Rz, Rmax,roundness and noise value were calculated for the inner and outer rings respectively;

(2) The average value and the experimental data were compared;

(3) The datum was identified with (+) when the experimental value was greater than the average, whereas with (-);

(4) For every experiment, the consistency between (+/-)corresponding the noise and (+/-) corresponding the geometric evaluating parameters was evaluated;

(5) The amount of (+) and (-) for which the geometric evaluating parameters has consistency with the noise was summed. For every parameter, the percentage of the summed amount to the total experiment number was calculated. By this percentage, the relevance between the evaluating parameter and the noise can be obtained;

(6) The average of the percentage of the inner and outer rings obtained above were calculated.

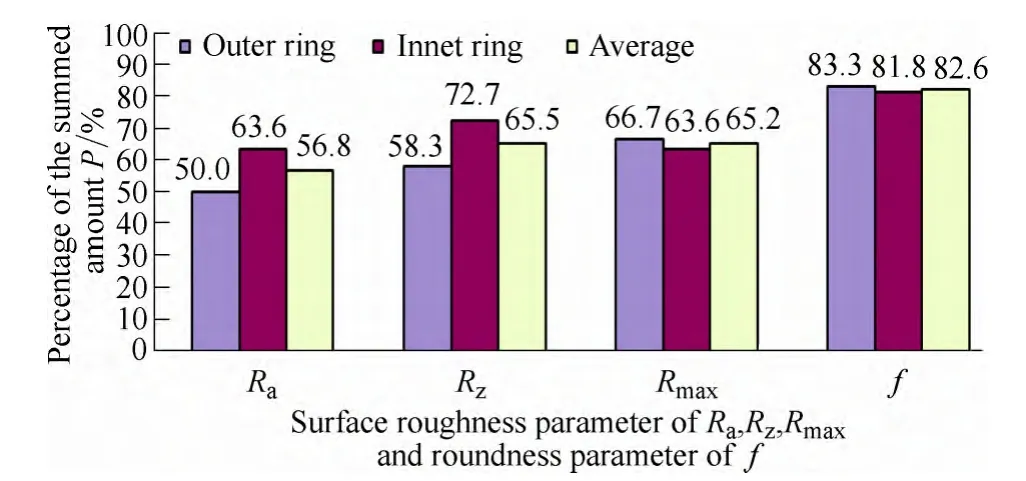

The results obtained from step (1) to step (5) are shown in Table 4 and Table 5 , and the result obtained by step (6)is shown in Fig. 8.

Table 4. Relationship between geometry parameters of the outer ring raceway and the bearing noise

Table 5. Relationship between geometry parameters of the inner ring raceway and the bearing noise

Fig. 8. Synthesis of the inner and outer ring raceway data

According to the testing results shown in Table 4 and Table 5, surface roughness and roundness of the raceway affects the bearing noise in different degrees. Roundness error’s influence is the highest, Rmaxand Rz’s influence takes second place, and Ra’s influence is the weakest.Therefore, from the viewpoint of reducing noise, values of roundness error, Rmaxand Rzof bearing raceway should be strictly controlled in the manufacturing process.

The nature behind the noise is vibration. Vibration is generated when the relative movement between the parts touched each other suddenly changes. According to the experimental results, different raceway surface geometric errors have different effects on the bearing noise.According to the definition of the evaluating index, Rameans the average of profile geometric parameter within the scope of the evaluating length, and Rmaxand Rzmean the distance between the limit position or average value of local profile within the scope of the evaluating length.Therefore, the change of Rmaxand Rzvalues means the change of the local raceway surface peaks and valleys. As shown in Fig. 9, in the circumstance that the raceway’s precision is high, the magnitude of the surface roughness error is close to that of the roundness. When the rolling body contacts with different postions of raceway, both the first and second type of roundness errors will make the rolling body’s movement produce a sudden change and cause the running noise. The difference maybe lie in that the movement change in a round of the bearing rotation caused by the first type of roundness error is more overall than that by the second type of roundness error, which will result in the change of their noise frequency, but it needs further investigation.

Fig. 9. Influence of the raceway geometry error on the rolling body movement trajectory

According to the research results in section 3.1, FAPASAP can smoothen the raceway surface effectively. Rmaxand Rzvalues can be greatly reduced, meanwhile the second type of roundness error can be effectively corrected, which is beneficial to the reduction of the bearing running noise.

4 Conclusions

(1) After the super finished bearing raceway is machined by FAPASAP under this paper’s experimental conditions,Ravalue is reduced slightly, however Rz, Rmaxand f values are reduced significantly. On average, Rzvalue of the inner and outer ring is reduced by 22%, Rmaxvalue is reduced by 35.5%, and roundness error value is reduced by 25%.FAPASAP can effectively reduce Rz, Rmaxand f values by smoothening the local error of the raceway.

(2) Change of profile at any place of the raceway will affect the relative position of the inner circle and the outer circle used for evaluating the roundness, so both the macro error and the local error of the raceway will affect the roundness error. This paper names the macro error as the first type of roundness error and the local error as the second type of roundness error. For FAPASAP, there is almost no correcting function on the first type of roundness error, and its effect on the roundness error is mainly dependent on the correction of the second type of roundness error.

(3) Ravalue of raceway surface has little, while Rmaxand Rzvalues have obvious influence on the noise. Ravalue means the average of profile and Rmaxand Rzvalue means the limit value or the average of some points of the profile within the scope of the evaluating length. When the raceway’s precision is high, magnitude of the surface roughness error is close to the roundness. When the rolling body contacts with the different postion of surface profile,it can make the rolling body’s movement produce a sudden change and cause noise.

(4) In the manufacturing process of bearing ring, the raceway’s roundness error should be strictly controlled, and for the surface roughness parameters, Rmaxand Rzshould be mainly controlled. After FAPASAP, Rmaxand Rzvalue can be effectively reduced, and the roundness can also be improved. After super finishing, the bearing running noise is between 42dB to 45dB Machined by FAPASAP, average noise is 37.6dB, reducing by 10.5% to 16.4%. So, it is an effective method to obtain the low noise bearing by machining the raceway with FAPASAP after super finishing.

Acknowledgements

The authors are grateful to Professor SHAO Tianmin’s advices and Dr. HAN Jiwan’s help of English grammar for this paper!

[1] HUANG H H, WANG H P. An integrated monitoring and diagnostic system for roller bearings[J]. The International Journal of Advanced Manufacturing Technology, 1996, 12(1): 37–46.

[2] UEDA T, MITAMURA N. Mechanism of dent initiated flaking and bearing life enhancement technology under contaminated lubrication condition. Part II: Effect of rolling element surface roughness on flaking resulting from dents, and life enhancement technology of rolling bearings under contaminated lubrication condition[J]. Tribology International Special Issue: 35th Leeds-Lyon Symposium, 2009, 42(11–12): 1832–1837.

[3] TAHA Z, WIDIYATI K. Artificial neural network for bearing defect detection based on acoustic emission[J]. The International Journal of Advanced Manufacturing Technology, 2010, 50(1): 289.

[4] LIN J R. Surface roughness effect on the dynamic stiffness and damping characteristics of compensated hydrostatic thrust bearings[J]. International Journal of Machine Tools and Manufacture, 2000, 40: 1671–1689.

[5] TURAGA R, SEKHAR A S, MAJUMDAR B C. The effect of roughness parameter on the performance of hydrodynamic journal bearings with rough effects[J]. Tribology International, 1999, 32:231–236.

[6] JAW RenLin, TZU ChenHung, TSU LiangChou, et al. Effects of surface roughness and non-Newtonian micropolar fluids on dynamic characteristics of wideplane slider bearings[J]. Tribology International, 2013(66): 150–156.

[7] NEAGU-VENTZEL S, CIOC S, MARINESCU I. A wear model and simulation of superfinishing process: analysis for the superfinishing of bearing rings[J]. Wear, 2006, 260(9–10):1061–1069.

[8] ABDEL-LATIF L A, MOKHTAR M O A. Misalignment effects on hydrodynamicaly lubricated journal bearings with rough surfaces[J].Wear, 1988, 128(3): 225–237.

[9] BUSH A W. Predicting the behaviour of lubricated bearings from surface measurements[J]. Wear, 1985, 109(1–4): 315–327.

[10] EL-KADEEM M A, SALEM E A, EL-SAYED H R. Surface finish effects on the performance of externally pressurized rectangular thrust bearings[J]. International Journal of Machine Tool Design and Research, 1972, 12(2): 85–104.

[11] GRZESIK W, RECH J, WANAT T. Surface finish on hardened bearing steel parts produced by superhard and abrasive tools[J].International Journal of Machine Tools and Manufacture, 2007,47(2): 255–262.

[12] TZENG S T, SAIBEL E. Surface roughness effect on slider bearing lubrication[J]. Wear, 1968, 11(5): 385.

[13] HARNOY A. Bearing design in machinery: engineering tribology and lubrication[M]. 3rd ed. New York: Henry Dream press, 2003.

[14] NADUVINAMANI N B, HIREMATH P S, GURUBASAVARAJ G.Effect of surface roughness on the static characteristics of rotor bearings with couple stress fluids[J]. Computers & Structures, 2002,80(14–15): 1243–1253.

[15] MANOHARAN C, ARUNACHALAM V. Dynamic analysis of hydrodynamic bearing performance in IC engines by using Taguchi technique and Response Surface Methodology (RSM)[J]. The International Journal of Advanced Manufacturing Technology, 2008,36(11): 1061.

[16] BUJURKE N M, KUDENATTI R B, AWATI V B. Effect of surface roughness on squeeze film poroelastic bearings with special reference to synovial joints[J]. Mathematical Biosciences, 2007,209(1): 76–89.

Chinese Journal of Mechanical Engineering2014年3期

Chinese Journal of Mechanical Engineering2014年3期

- Chinese Journal of Mechanical Engineering的其它文章

- Theoretical Analysis and Experimental Verification on Valve-less Piezoelectric Pump with Hemisphere-segment Bluff-body

- Carbody Structural Lightweighting Based on Implicit Parameterized Model

- Prediction-based Manufacturing Center Self-adaptive Demand Side Energy Optimization in Cyber Physical Systems

- Effectiveness of a Passive-active Vibration Isolation System with Actuator Constraints

- Numerical Simulation and Analysis of Power Consumption and Metzner-Otto Constant for Impeller of 6PBT

- Proceeding of Human Exoskeleton Technology and Discussions on Future Research