三移栽臂水稻钵苗移栽机构设计与试验

吴国环,俞高红,项筱洁,王林伟

·农业装备工程与机械化·

三移栽臂水稻钵苗移栽机构设计与试验

吴国环1,2,俞高红2,3※,项筱洁1,王林伟2,3

(1. 温州职业技术学院机械工程系,温州 325035;2. 浙江理工大学机械与自动控制学院,杭州 310018;3. 浙江省种植装备技术重点实验室,杭州 310018)

为了实现水稻钵苗的高效、稳定的移栽,在分析现有水稻钵苗移栽机构的研究现状基础上,该文设计了一种应用于水稻钵苗自动移栽机的三移栽臂非圆齿轮行星系水稻钵苗移栽机构。构建了一种非圆齿轮节曲线方程,建立了非圆-不完全非圆齿轮机构的运动学理论模型。开发了该水稻钵苗移栽机构的计算机辅助分析与优化软件,通过人机交互的方式得到一组较优的满足水稻钵苗移栽机构工作要求的参数,然后进行虚拟仿真及物理样机试验,通过对比分析虚拟仿真得到的工作轨迹与物理样机试验得到的工作轨迹基本一致;理论计算得到的角度差为45.18°,实际测量得到的角度差为45.77°,误差为1.31%,在误差范围以内,验证了该移栽机构设计的正确性。该机构的提出解决了秧苗倒伏、低移栽成功率的问题,提高了移栽效率。

机械化;设计;优化;移栽机;水稻钵苗移栽;试验

吴国环,俞高红,项筱洁,王林伟. 三移栽臂水稻钵苗移栽机构设计与试验[J]. 农业工程学报,2017,33(15):15-22. doi:10.11975/j.issn.1002-6819.2017.15.002 http://www.tcsae.org

Wu Guohuan, Yu Gaohong, Xiang Xiaojie, Wang Linwei. Design and test of rice potted-seedling transplanting mechanism with three transplanting arms[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(15): 15-22. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.15.002 http://www.tcsae.org

0 引 言

大米作为中国最重要的主食之一,水稻生产在中国粮食生产中占有十分重要的地位。但中国水稻种植机械化水平还处于比较低的水平,而日本、韩国等发达国家机械化水平均达97%以上[1-4]。因此,提高水稻移栽机械化水平迫在眉睫。

移栽又分为毯状苗、半钵毯状苗和钵苗移栽3种,其中毯状苗移栽靠栽植臂旋转将秧苗从毯状苗上撕下插入水田,造成伤秧,移栽后需要一定的缓苗期对苗伤害大,影响缓苗,从而影响产量;水稻钵苗移栽具有不伤秧、扎根快、无缓苗期等特点,因此,水稻钵苗移栽在未来将有很好发展前景,但目前中国推广应用的水稻钵苗移栽机型较少[5-7]。目前国外水稻钵苗移栽机械化种植以日本为主,但日本水稻钵苗移栽机结构复杂、价格昂贵,不适合中国的国情[8-9];国内市场上常见的水稻钵苗移栽机构采用多杆式移栽机构,由于结构限制,存在振动大、效率低的问题[10-15];陈建能等[16-17]提出的旋转式水稻钵苗移栽机构移栽臂夹秧片尖点形成“企鹅形”特殊运动轨迹,依次完成取苗、持苗和栽植3个动作,相对于毯状苗移栽效率低,但相对现有的多杆式移栽机构具有较高移栽效率(旋转一周移栽2次)、立苗率高等优点。但是当移栽效率达到200次/分钟时,机器振动较大,取秧成功率受到影响。

为了提高移栽效率且不降低移栽成功率,本文提出一种三臂水稻钵苗移栽机构即非圆-不完全非圆齿轮行星轮系水稻钵苗移栽机构,该机构达到同样的移栽效率时,允许中心轴转速是原来的三分之二,减小震动且提高了移栽成功率。通过对机构运动学模型建立,开发计算机辅助优化软件,开展ADAMS三维虚拟样机仿真和台架试验等一系列工作,以确定较为理想的机构参数,确保机构能够实现水稻钵苗的移栽工作轨迹及农艺要求。

1 设计要求与工作原理

1.1 水稻钵苗移栽机构的设计要求

根据水稻钵苗移栽的农艺要求和移栽臂姿态要求,提出图1中轨迹2为移栽轨迹,该轨迹在文献[17]提出的椭圆—不完全非圆齿轮行星系水稻钵苗移栽机构中有良好应用。但文献[17]的机构在3套移栽臂的机构中无法满足秧苗直立度的要求,在模拟田间作业时,轨迹前倾明显,容易造成秧苗的倒伏、漂秧现象。在空转模拟时,移栽臂之间容易干涉。若要实现较好移栽效果,需要修改轨迹的形状,同时为了满足移栽农艺要求,仍需保留图1所示轨迹右上方的“环扣状”轨迹。因此本文重新提出了图1中的轨迹1,该轨迹在保留右上方的 “环扣状”的同时,轨迹明显后凸,在推完苗后,让移栽臂能往后移动更多距离,有利于田间模拟试验的动轨迹(提高直立度);同时轨迹变大,可以增大移栽臂之间的距离,有效减小移栽臂干涉的概率;而且相比较于图中的轨迹2,环扣略有增大,将会有利于取苗。

图1 水稻钵苗移栽轨迹Fig.1 Rice potted-seedling transplanting trajectory

1.2 机构的实现方案

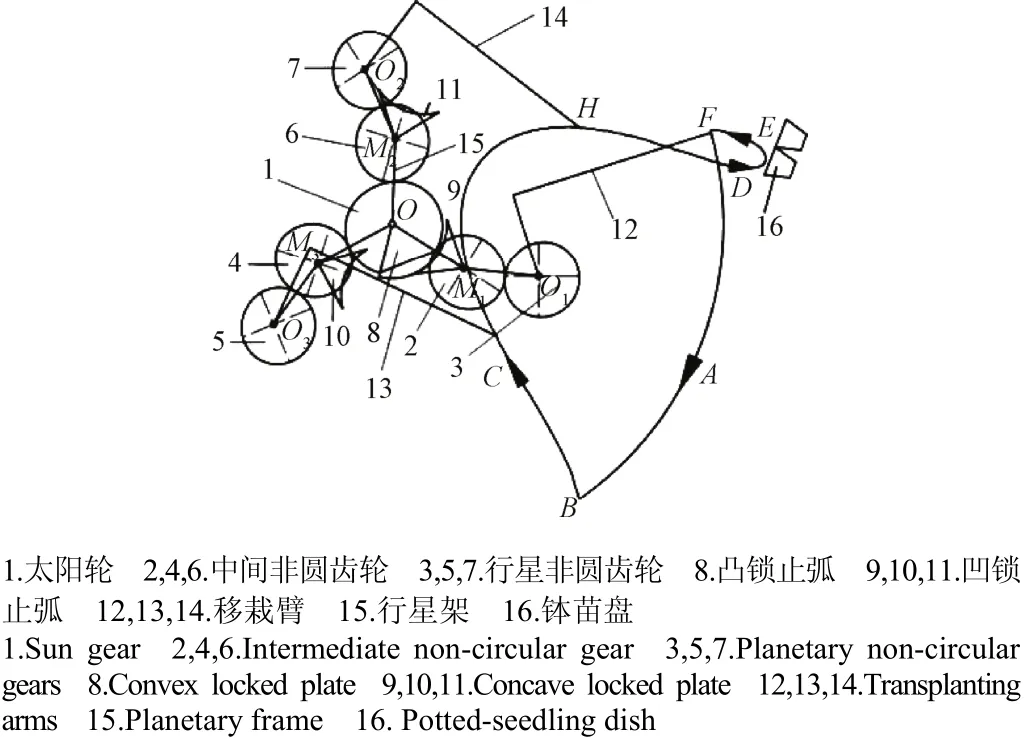

图2 非圆-不完全非圆齿轮行星轮系水稻钵苗移栽传动机构Fig.2 Transmission schematic of rice potted-seedlingtransplanting mechanism of planetary gear train with non-circular gears and incomplete non-circular

1.3 机构工作原理

如图2所示,移栽机构的传动部分包括三对共轭非圆齿轮(分别是中间非圆齿轮2和行星非圆齿轮3、中间非圆齿轮4和行星非圆齿轮5、中间非圆齿轮6和行星非圆齿轮7),3个凹锁止弧9、10、11,一个不完全非圆齿轮1和凸锁止弧8。其中不完全非圆齿轮1通过牙嵌式法兰固定在机架上,凸锁止弧8与不完全非圆齿轮1固接;凹锁止弧9、10、11分别与中间非圆齿轮2、4、6固接。3个移栽臂固接在行星轴上,与行星非圆齿轮实现同步转动,取苗爪尖点形成如图2所示轨迹。由于3个移栽臂工作轨迹、工作状态一致,因此本文以右下侧的结构为例,说明移栽机构的工作机理。当机构开始运行时,行星架15绕着旋转中心O顺时针转动,此时,凹锁止弧9和凸锁止弧8进入啮合状态,中间非圆齿轮2和行星非圆齿轮3相对于行星架静15止,整个机构形成一种间歇运动,移栽臂12的尖点H从F点开始向下滑动,在锁止弧啮合时段,形成FAB段持苗轨迹;当凹凸锁止弧开始分离,中间非圆齿轮2和不完全非圆齿轮1有齿部分开始啮合,行星非圆齿轮3开始转动,移栽臂在B点推苗;推苗完成后,行星架15继续转动,整个机构开始非匀速运动,移栽臂12的尖点H形成BCD段回程轨迹,即弹性取苗爪在释放秧苗后保持张开的状态,该机构在D点开始取秧,通过DE段轨迹完成取秧动作,持秧到F点完成DEF段取苗轨迹。

2 移栽机构的运动学模型

2.1 移栽机构的运动分析假设

在进行移栽机构的运动学建模时,假设各构件均为刚体,不考虑零件间的配合间隙,设定主动件行星架的工作转速为顺时针100 r/mim,行星架角速度为常数w1。(本文规定逆时针为正方向)。

2.2 不完全非圆齿轮与中间非圆齿轮的节曲线模型

中间非圆齿轮与不完全非圆齿轮啮合形成的非匀速间歇传动是形成本文所需的移栽轨迹的关键组成部分[18-26],图3为不完全非圆齿轮与中间非圆齿轮啮合关系图。不完全非圆齿轮有齿部分的圆心角为α,凸锁止弧的圆心角为(2π-α)。图3a为机构的起始位置,图3b为行星架顺时针转过角度(2π-α)后的位置,图3c为行星架顺时针转过大于角度(2π-α)后的位置。

图3 不完全非圆齿轮和中间非圆齿轮啮合Fig.3 Engagement of incomplete non-circular gear and intermediate non-circular gears

设不完全非圆齿轮的旋转中心O到啮合点J的距离为R1(φ1),啮合点J到中间非圆齿轮的旋转中心M1的距离为R2(φ2),由构造的非圆节曲线方程可得到如下的公式

式中a、b、c为非圆齿轮系数,mm;φ2为中间非圆齿轮相对于行星架转过的角位移,rad。

参考文献[17]中的公式推导,可得如下关系

式中φ1为行星架在一段时间内转过的角度,rad;L1为不完全非圆齿轮和中间非圆齿轮之间的中心距,mm。

由式(2)可知:当φ1=α时,φ2=2π。当行星架顺时针转过α角度,同时a,b,c参数确定时,通过数值积分,不完全非圆齿轮与中间非圆齿轮的中心距L1便可以确定。设

则有φ1=f(φ2)。中间非圆齿轮相对于行星架转过的角度φ2就可以得到

由于反函数f-1(φ2)不是常规函数,无法直接得到表达式,求解难度较大,但是利用数值计算的方法,就能快速建立φ1和φ2的关系,步骤如下:

1)已知行星架的转角φ1取值范围,φ1∈[0,2π]。由式(4)可知,当φ1∈[α,2π]时,φ2=2π,φ2保持不变;因此只要建立φ1∈[0,α]时,φ1和φ2的关系即可。设行星架转角每次递增角度为Δφ1。

2)当行星架的转角为φ1时,则根据不完全非圆齿轮与中间非圆齿轮啮合关系可知,中间非圆齿轮相对行星架转过的角度φ2大于行星架转角φ1。则有φ1<φ2<φ1+η,其中η为大于0的常数。

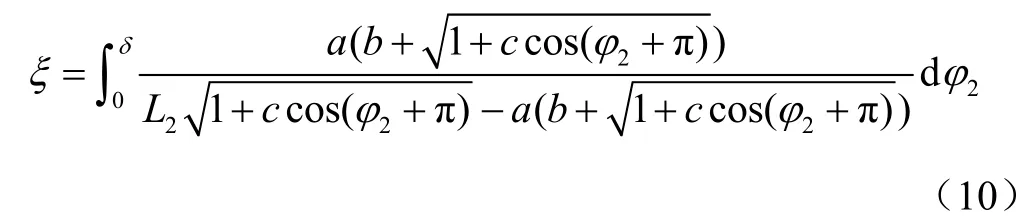

对φ2在(φ1,φ1+δ]区间内进行求解,每次递增步长为Δφ2。通过数值积分方法可求得该区间内每次迭代数值φ′1。此时φ2的迭代初始值为φ2=φ1+Δφ2。而φ′1为

3)设置计算精度ε,当|φ1′−φ1|≤ε时,此时输出φ2的值,建立了满足一定计算精度的φ1和φ2的关系。

4)以Δφ1为步长,重复上述计算过程,即可求出行星架转角φ1∈[0,α]时φ2的值。根据几何关系,可以求得凹锁止弧圆心角θ。

式中Rt为凸锁止弧半径,mm。

2.3 移栽机构的位移模型

以上述非圆—不完全非圆齿轮行星系水稻钵苗移栽机构一端为例进行位移模型的建立。如图4所示,以凹凸锁止弧开始啮合为起始位置,分析转过φ1角度后的位移方程。坐标原点为不完全非圆齿轮旋转中心O,建立坐标系XOY,此处为整个机构运动学分析,角位移设定顺时针为负,逆时针为正。图4a为起始位置,凹凸锁止弧刚进入啮合状态,行星架相对于X轴顺时针转过φ0,行星架在中间非圆齿轮中心M1点处逆时针旋转δ。中间非圆齿轮与行星非圆齿轮啮合的节曲线半径R′2的表达式

式中R3(φ2)为行星非圆齿轮节曲线半径,mm;φ3为行星非圆齿轮相对行星架转过的角位移,rad;L2为中间非圆齿轮和行星非圆齿轮之间的中心距,mm;δ为行星架M1O1与M1O的夹角,rad。

图4 非圆齿轮—不完全非圆齿轮行星系运动图Fig.4 Schematic of planetary gear train with non-circular gears and incomplete non-circular gear

由图4a可知,行星非圆齿轮和中间非圆齿轮之间行星架有一拐角δ,因此行星非圆齿轮在初始安装位置时已转过ξ,有非圆齿轮之间的特性可得

中间非圆齿轮2旋转中心M1的位移为

行星非圆齿轮3旋转中心O1位移为

取秧爪尖点H的位移

式中λ为取苗爪尖点与行星非圆齿轮旋转中心连线与行星非圆齿轮轴线之间的夹角,rad;S为行星非圆齿轮旋转中心O1到取苗爪尖点H的距离,mm。

2.4 移栽机构的速度模型

已知行星架以匀速转动,因此角速度11=φω˙为参数。通过分析不完全非圆齿轮和中间非圆齿轮间的传动比关系,可以求得中间非圆齿轮相对于行星架的角速度2φ˙

同理,通过中间非圆齿轮和行星非圆齿轮之间传动比关系,可以求得行星非圆齿轮相对行星架的角速度3φ˙

通过对式(11)进行时间t求导,可得中间非圆齿轮旋转中心M1的速度方程为

通过对(12)进行时间t求导,可得行星非圆齿轮旋转中心O1的速度方程为

通过对式(13)进行时间t求导,可得弹性取苗爪尖点H的速度方程为

3 移栽机构参数优化、虚拟仿真及样机试验

3.1 移栽机构的参数优化

基于Visual Basic可视化编程软件,开发了三移栽臂非圆-不完全非圆齿轮行星轮系水稻钵苗移栽机构的辅助分析与优化软件,借助人机交互的方式对移栽机构进行参数优化[27]。通过优化软件综合分析不同参数对移栽静轨迹的影响,得到一组满足移栽目标的较优的移栽机构参数。图5为各参数对移栽静轨迹的影响。

由图5可知,机构不同结构参数对移栽静轨迹形状、直立度、姿态等均有不同程度的影响,太阳轮以回转中心为坐标原点,X轴为移栽静轨迹X方向坐标,Y轴为移栽静轨迹Y方向坐标(单位:mm),随着参数的增大,具体影响结果如表1所示。

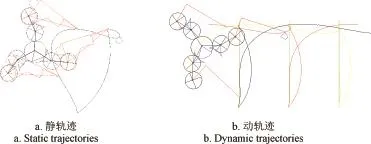

综合上述参数的影响,参数各自确定的范围内进行微调,直至获得满足姿态和尖点轨迹的一组较优参数:a=14.3,b=0.55,c=−0.6,α=288°,λ=46°,δ=26°,φ0=76°,S=152 mm;优化得到移栽轨迹如图6所示,其中该动轨迹为株距为180 mm情况下移栽臂取苗爪尖点运动得到的轨迹,通过动轨迹可以看出移栽机在田间作业的工作情况,竖直线假设为秧苗,动轨迹回程段基本与竖直线基本平齐,降低了秧苗回带的可能。

3.2 移栽机构的仿真分析

在完成了水稻钵苗移栽机构的三维实体建模、虚拟装配后,利用虚拟仿真软件ADAMS仿真,得到了三移栽臂非圆-不完全非圆齿轮行星轮系水稻钵苗移栽机构工作轨迹[28-30]。因此,可以与分析辅助软件可得到的理论工作轨迹比较分析,初步验证移栽机构的正确性。由于在机构结构设计时添加了缓冲装置,使得移栽轨迹下端的尖点变成了圆弧。图7为ADAMS仿真静轨迹。

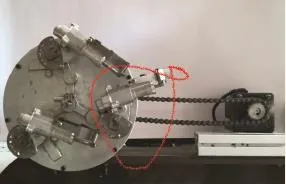

3.3 移栽机构样机试验

为了进一步验证移栽机构设计的正确性与实际工作的可行性,加工制造了移栽机构的物理样机,安装到试验台开展移栽机构物理样机的运动学试验。利用高速摄影设备对移栽机构工作进行高速摄像完成图像采集,利用Blaster’s MAS图像分析软件对采集得到的图片进行处理及分析,用红色线逐个连接(如图8所示)并与虚拟样机模拟仿真得到的移栽静轨迹进行对比,同时测得取秧角和推秧角与理论计算得到的取秧角和推秧角进行对比。通过水平测量仪分别测量移栽机构的取秧角和推秧角,如表2所示。

图5 各参数对移栽静轨迹的影响Fig.5 Influence of different parameters doing to transplanting static trajectory

表1 各参数影响结果Table 1 Effect of various parameters

图6 VB理论计算移栽轨迹Fig.6 Transplanting trajectory of theoretical calculation in VB

图7 ADAMS仿真静轨迹Fig.7 Static trajectory of ADAMS simulation

图8 物理样机试验轨迹Fig.8 Test trajectory of physical prototype

表2 理论计算和实际测量的比较Table 2 Comparison of theoretical calculation and actual measurement

将该轨迹与图7移栽机构的虚拟仿真得到移栽静轨迹对比,物理样机的工作轨迹与虚拟仿真得到的工作轨迹基本一致;理论计算得到的角度差为45.18°,实际测量得到的角度差为45.77°,误差为1.31%,在误差范围以内,因此,该水稻钵苗移栽机构的设计具有可行性和正确性。

4 结 论

1)基于Visual Basic6.0 可视化编程软件,开发了非圆-不完全非圆齿轮行星轮系水稻钵苗移栽机构的辅助分析与优化软件,根据不同结构参数对移栽静轨迹的影响优选出一组较优机构结构参数,完成机构结构设计。

2)基于Adams软件开展虚拟样机仿真,将其得到的移栽静轨迹与VB计算得到的运动轨迹对比,证明了VB模型的可行性。

3)研制物理样机并在试验台上进行高速摄像试验,处理得到机构移栽臂弹簧片尖点静轨迹,同时测得移栽机构取秧角、推秧角及其角度差误差为1.31%,验证姿态的合理性;比较VB计算、虚拟仿真及物理样机试验得到的移栽静轨迹验证轨迹的合理性,最终验证了三移栽臂非圆-不完全非圆齿轮行星轮系水稻钵苗移栽机构的正确性及应用于田间作业的可行性。

[1] 申承均,韩休海,于磊. 国内外水稻种植机械化技术的现状与发展趋势[J]. 农机化研究,2010,32(12):240-243.

Shen Chengjun, Han Xiuhai, Yu Lei. The situation and development trend of rice cultivation mechanization technology in domestic[J]. Agricultural Mechanization Research, 2010, 32(12): 240-243. (in Chinese with English abstract)

[2] 于晓旭,赵匀,陈宝成,等. 移栽机械发展现状与展望[J].农业机械学报,2014,45(8):44-53.

Yu Xiaoxu, Zhao Yun, Chen Baocheng, et al. Current situation and prospect of transsplanter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(8): 44-53. (in Chinese with English abstract)

[3] 高一铭,闫涛,刘文杰. 国内外水稻直播机械化研究进展[J].农业科技与装备,2013(1):28-29.

Gao Yiming, Yan Tao, Liu Wenjie, et al. Research and progress of direct rice seeding mechanization at home and abroad[J]. Agricultural Science & Technology and Equipment, 2013(1): 28-29. (in Chinese with English abstract)

[4] 邴延忠,陈宗凯. 水稻钵苗移栽机械化技术研发与应用[J].农机科技推广,2012(4):52.

Bing Yanzhong,Chen Zongkai. Development and application of mechanization technology for rice pot seedling transplanting[J]. Agriculture Machinery Technology Extension, 2012(4): 52. (in Chinese with English abstract)

[5] 庄乃生,李斌,宋建农. 水稻钵体苗机插秧推广前景广阔[J].农机科技推广,2010(12):38-39.

Zhuang Naisheng,Li Bin,Song Jiannong. Popularize prospect is vast for rice pot seedling transplanted by machine[J]. Agriculture Machinery Technology Extension, 2010(12): 38-39. (in Chinese with English abstract)

[6] 吕亚洲. 我国水稻栽插机械发展介绍[J]. 农业机械,2009(3):76-79.

[7] 李建桥,张国凤,陈建能,等. 钵苗有序移栽机构的研究进展及应用展望[J]. 农机化研究,2008(2):1-5.

Li Jianqaio, Zhang Guofeng, Chen Jianneng, et al. Developments and prospects of application of the ordered throwing mechanism for plotted rice-seedling[J]. Journal of Agricultural Mechanization Research, 2008(2): 1-5. (in Chinese with English abstract)

[8] 修德龙,范淼. 两种日本水稻钵育摆栽机在垦区的对比试验[J]. 现代化农业,2008(3):37-38.

Xiu Delong, Fan Miao. Two Japanese rice bowl planted machine set in agricultural areas of contrast test[J]. Journal of Agricultural Modernization, 2008(3): 37-38. (in Chinese with English abstract)

[9] 伊藤尚胜,清水修一,和田俊郎. 移植机的苗移植机构:199118740.7[P]. 2000-07-13.

[10] 赵匀,朱慧轩,辛亮,等. 拟合齿轮五杆水稻钵苗移栽机构的机理分析与试验[J]. 农业工程学报,2016,32(1):12-21.

Zhao Yun, Zhu Huixuan, Xin Liang, et al. Mechanism analysis and experiment of transplanting mechanism with fitting gear five-bar for rice pot seedling[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(1): 12-21. (in Chinese with English abstract)

[11] 张敏. 拟合齿轮五杆水稻钵苗移栽机构的研究[D]. 哈尔滨:东北农业大学,2014.

Zhang Min. Research on Fitting Gear Five Linkage Rice Seedling Transplanting Mechanism[D]. Harbin: Northeast Agricultural University, 2014. (in Chinese with English abstract)

[12] 赵匀,徐洪广,张允慧,等. 探出式钵苗移栽机分秧机构取苗臂:201110264626.X[P]. 2011-09-08.

[13] 徐洪广. 旋转“探出式”水稻钵苗分秧机构的机理分析与优化设计[D]. 杭州:浙江理工大学,2012.

Xu Hongguang. Principle Analysis and Optimal Design of Rotary Transplanting Mechanism with Extensile Claw Picking Seedlings[D]. Hangzhou: Zhejiang Sci-Tech University, 2012. (in Chinese with English abstract)

[14] 赵匀,辛亮,冯江,等. 双曲柄水稻钵苗移栽机夹钵式分插机构:201220206603. 3[P]. 2012-04-27.

[15] 宋建农,黄育仕,魏文军,等. 水稻钵苗对辊式拔秧机构[J].江苏大学学报,2006(4):92-94.

Song Jiannong, Huang Yushi,Wei Wenjun, et al. Evulsing rice potted-seedling mechanism equipped with double roller[J]. Journal of Jiangsu University, 2006(4): 92-94. (in Chinese with English abstract)

[16] 陈建能,黄前泽,王英,等. 钵苗移栽机非圆齿轮行星轮系栽植机构参数分析与反求[J]. 农业工程学报,2013,29(8):18-26.

Chen Jianneng, Huang Qianze, Wang Ying, et al. Parametric analysis and inversion of transplanting mechanism with planetary non-circular gears for potted- seedling transplanter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(8): 18-26. (in Chinese with English abstract)

[17] 俞高红,黄小艳,叶秉良,等. 旋转式水稻钵苗移栽机构的机理分析与参数优化[J]. 农业工程学报,2013,29(3):16-22.

Yu Gaohong, Huang Xiaoyan, Ye Bingliang, et al. Principle analysis and parameters optimization of rotary rice pot seedling transplanting mechanism[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(3): 16-22. (in Chinese with English abstract)

[18] 李丽. 水稻钵苗移栽机构的优化设计及试验研究[D]. 杭州:浙江理工大学,2015.

Li Li. Optimization Design and Tests of Rice Pot-Seedling Transplanting Mechanism of Planetary Gear Train with Incomplete Eccentric Circle Gear[D]. Hangzhou: Zhejiang Sci-Tech University, 2015. (in Chinese with English abstract)

[19] 俞亚新,骆春晓,俞高红,等. 椭圆-不完全非圆齿轮行星系取苗机构参数优化[J]. 农业机械学报,2013,44(6):62-68.

Yu Yaxin, Luo Chunxiao, Yu Gaohong, et al. Parameters optimization of pick-up mechanism of planetary gear train with ellipse gears and incomplete non-circular gear[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(6): 62-68. (in Chinese with English abstract)

[20] 左彦军,曹鹏,赵匀,等. B样条非圆齿轮行星轮系水稻钵苗移栽机构的设计与优化[J]. 农业工程学报,2014,30(15):10-17.

Zuo Yanjun, Cao Peng, Zhao Yun, et al. Design and optimization of transplanting mechanism with B-spline non-circular planet gear train for rice pot seedling[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(15): 10-17. (in Chinese with English abstract)

[21] 代丽,孙良,赵雄,等. 基于运动学目标函数的插秧机分插机构参数优化[J]. 农业工程学报,2014,30(3):35-42.

Dai Li, Sun Liang, Zhao Xiong, et al. Parameters optimization of separating-planting mechanism in transplanter based on kinematics objective function[J]. Transactions of the Chinese Society of Agricultural Engineering, 2014, 30(3): 35-42. (in Chinese with English abstract)

[22] 俞高红,俞腾飞,叶秉良,等. 一种新型行星轮系机构的研究[J]. 机械工程学报,2013,49(15):55-61.

Yu Gaohong, Yu Tengfei, Ye Bingliang, et al. Research on a new planetary gear train mechanism[J]. Journal of Mechanical Engineering, 2013, 49(15): 55-61. (in Chinese with English abstract)

[23] Jovan D,Ivan K,Marko D. One approach for modelling intermittent motion mechanism with non-circular gears[J]. Machine Design, 2011, 3(2): 121-126.

[24] 俞高红,陈志威,叶秉良,等. 一种新型非匀速间歇机构的研究[J]. 中国机械工程,2012,23(23):2778-2787.

Yu Gaohong, Chen Zhiwei, Ye Bingliang, et al. Study on a new non-uniform and intermittent mechanism[J]. China Mechanical Engineering, 2012, 23(23): 2778-2787. (in Chinese with English abstract)

[25] Mundo D. Geometric design of a planetary gear train with non-circular gears[J]. Mechanism and Machine Theory, 2006, 41(4): 456-472.

[26] Modler K H, Lovasz E C, Bär G F, et al. General method for the synthesis of geared linkages with non-circular gears[J]. Mechanism and Machine Theory, 2009, 44(4): 726-738.

[27] 武传宇,赵匀,陈建能. 水稻插秧机分插机构人机交互可视化优化设计[J]. 农业工程学报,2008,39(1):46-49.

Wu Chuanyu, Zhao Yun, Chen Jianneng. Optimization design of rice transplanter separating-planting mechanism with visualization human-computer interaction method[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2008, 39(1): 46-49. (in Chinese with English abstract)

[28] 高杨. 不完全偏心圆齿轮行星轮系水稻钵苗移栽机构的优化设计与试验[D]. 杭州:浙江理工大学,2016. Gao Yang. Optimization Design and Tests of Rice Pot-seedling Transplanting Mechanism of Planetary Gear Train with Incomplete Eccentric Circle Gear[D]. Hangzhou: Zhejiang Sci-Tech University, 2016. (in Chinese with English abstract)

[29] 叶秉良,吴国环,俞高红,等. 非圆齿轮行星轮系水稻钵苗移栽机构优化设计与试验[J]. 农业机械学报,2016,48(11):68-73.

Ye Bingliang,Wu Guohuan,Yu Gaohong, et al. Optimized design and tests on rice potted Seedling transplanting mechanism of planetary gear train with non-circular gears[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 48(11): 68-73. (in Chinese with English abstract)

[30] Ye Bingliang, Jin Xuejun, Yu Gaohong, et al. Parameter modification guiding optimization design and tests of a rotary transplanting mechanism for rice plug seedlings[J]. Applied Engineering in Agriculture, 2015, 31(6): 863-873.

Design and test of rice potted-seedling transplanting mechanism with three transplanting arms

Wu Guohuan1,2, Yu Gaohong2,3※, Xiang Xiaojie1, Wang Linwei2,3

(1. Department of Mechanical Engineering, Wenzhou Vocational & Technical College, Wenzhou 325035, China; 2. College of Machinery and Automation, Zhejiang Sci-Tech University, Hangzhou 310018, China; 3. Zhejiang Province Key Laboratory of Transplanting Equipment and Technology, Hangzhou 310018, China)

Rice potted-seedlings transplanting is one kind of rice planting way, and it can increase the production and improve rice quality because it has the advantages of not hurting root and not needing recovering period. The rice pot seedling transplanting will have a good prospect in the future, but at present the application of rice pot seedling transplanting machine is less in China because there are defects for domestic transplanter with tossing transplanting such as uncontrollable seedling perpendicularity, complex structure, low efficiency and heavy vibration. Foreign rice potted-seedling planting technology is not suitable in China for complicated structure and high cost, and the key to improve the mechanization of rice planting is to research the rice potted-seedling transplanting mechanism suitable to China. Aiming to the above problems, a three-transplanting-arm rice potted-seedling transplanting mechanism of planetary gear train with non-circular gears and incomplete non-circular gear, which is applied in automatic rice potted-seedling transplanter, was designed. The mechanism consists of an incomplete non-circular gear, 3 pairs of conjugate non-circular gears and 3 planting arms, which can transplant seedlings 3 times a week. It means that under the same transplanting efficiency, it can reduce the transplanting spindle rotation, so as to reduce the vibration and improve the success rate of transplanting. Firstly, the shortcomings of the rotary transplanting mechanism with 2 transplanters were analyzed, and the design requirements were put forward. According to the requirements, the implementation plan was advanced. Then, the operation principle of rice potted-seedling transplanting mechanism was introduced, the mathematical expression in parametric form for the trajectory and the equations of non-circular gears and incomplete non-circular gears were derived, and the kinematic model of transplanting mechanism was established. A computer-aided analysis and optimization software of this kind of rice potted-seedling transplanting mechanism was developed with the Visual Basic 6.0. With the method of human-computer interaction based on visualization, the optimization design of the transplanting mechanism was carried out. Using this software, by tuning the design parameters, the influence of every parameter on the optimization object could be found out. The curve of non-circular gears was optimized and the structural parameters were obtained, which can satisfy the requirements of trajectory and attitude in the transplanting process for rice potted-seedling. The 3D (three-dimensional) model of transplanting mechanism was built and assembled in UG’s entity modeling module. The virtual prototype was imported into Adams software after the interference checking of 3D model assembly was finished. According to the comparison between the virtual prototype simulation and the theoretical analysis of VB (Visual Basic), the trajectory of them was fundamentally consistent, so the correctness of the model of VB was verified, and the simulation results initially showed the design of mechanism was rational. In order to further verify the correctness of the design, the core components of transplanting mechanism were machined and assembled. Then, the physical prototype of the transplanting mechanism was developed to carry out the kinematics test in the test shelf. The results turned out that the static trajectory of the elastic tip of this transplanting arm and transplanting posture were basically consistent between the virtual prototype simulation and the physical prototype test, which proved the rationality and effectiveness of the parameters of transplanting mechanism. And the feasibility of this transplanting mechanism was verified. At the same time, the mechanism proposed solved the problem of seedling lodging and low transplanting success rate, and the efficiency of transplanting was improved. The research can provide a theoretical basis for developing transplanting mechanisms of rice potted-seedling.

mechanization; design; optimization; transplanters; rice potted-seedling transplanting; test

10.11975/j.issn.1002-6819.2017.15.002

S223.94

A

1002-6819(2017)-15-0015-08

2017-02-16

2017-06-01

浙江省教育厅一般项目(Y201636516)和国家自然科学基金项目(51575495)

吴国环,男,助教,博士生,主要从事农业机械设计和机构数值分析与综合研究。温州 温州职业技术学院机械工程系,325035。Email:422361992@qq.com.

※通信作者:俞高红,男,教授,博士,博士生导师,主要从事农业种植机械设计与机构学研究。杭州 浙江理工大学机械与自动控制学院,310018。

Email:yugh@zstu.edu.cn