喷嘴结构对气流冲击式速冻机钢带表面换热特性的影响

谢 晶,柳雨嫣,王金锋

喷嘴结构对气流冲击式速冻机钢带表面换热特性的影响

谢 晶1,2,3,4※,柳雨嫣2,4,王金锋1,2,3,4

(1. 上海水产品加工及贮藏工程技术研究中心,上海 201306;2. 上海冷链装备性能与节能评价专业技术服务平台,上海 201306;3. 食品科学与工程国家级实验教学示范中心(上海海洋大学),上海 201306;4. 上海海洋大学食品学院,上海 201306)

喷嘴;数值模拟;传热;努塞尔数;射流冲击;速冻机

0 引 言

除了目标表面的外,传热均匀度也是衡量冲击射流传热特性的一个重要指标[10-11]。若食品在冻结过程中受冷不均匀,会直接影响冻结时间和冻品品质[12-13]。Wen等[14]进行了飞行器地面降温模拟试验,研究了喷嘴数量、喷嘴高度等因素对阵列空气射流传热均匀性的影响规律,通过正交试验获得了研究范围内传热均匀性最优的参数匹配方案,得出相应的表面对流传热系数的不均匀系数为0.20;通过添加挡板改变出口形式,不均匀系数减小了39.70%,试件局部表面传热均匀性得到了大幅提高。王金锋等[15]以速冻机中V型条缝喷嘴与平直条缝孔板为研究对象,发现V型条缝喷嘴在钢带表面的换热强度更强,换热均匀性更高。

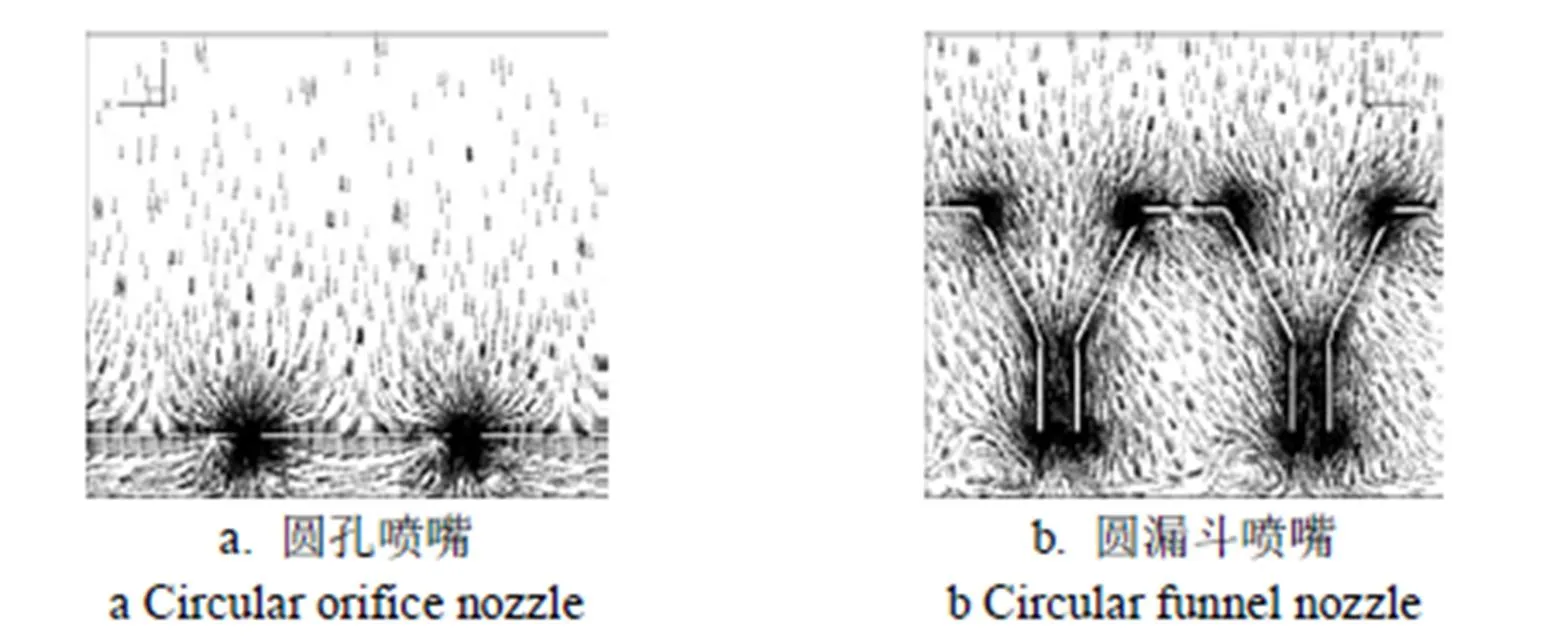

已有的文献主要研究了不同喷嘴结构的目标表面的变化,仅有少量文献涉及传热均匀性的研究。本文以冲击式速冻试验台为依托,提出了一种其他文献未涉及的新喷嘴结构即圆漏斗喷嘴,对比了圆孔和圆漏斗喷嘴结构的速冻设备内部流场的分布,从钢带表面和传热均匀度2个角度全面分析了2种喷嘴的优缺点,并对圆孔喷嘴出口处方向的速度分布进行了试验验证,以期为气流冲击式速冻机的优化设计提供理论依据。

1 数值模拟

1.1 物理模型建立

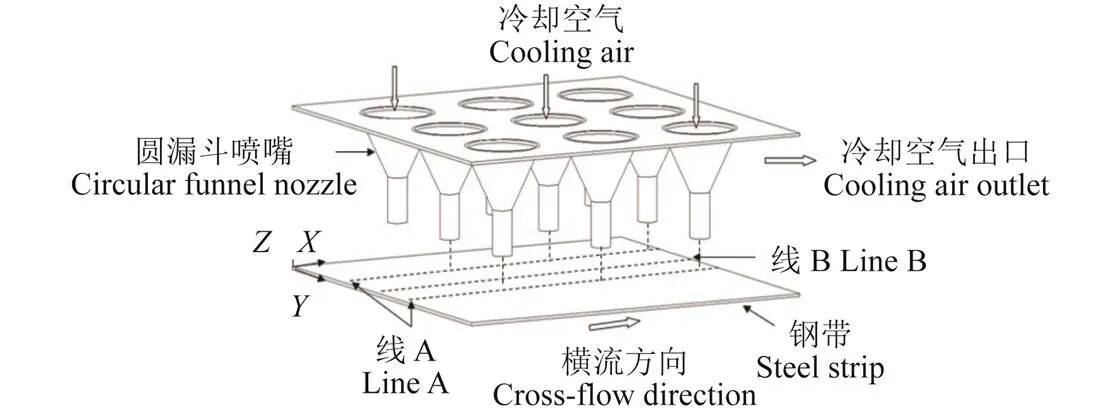

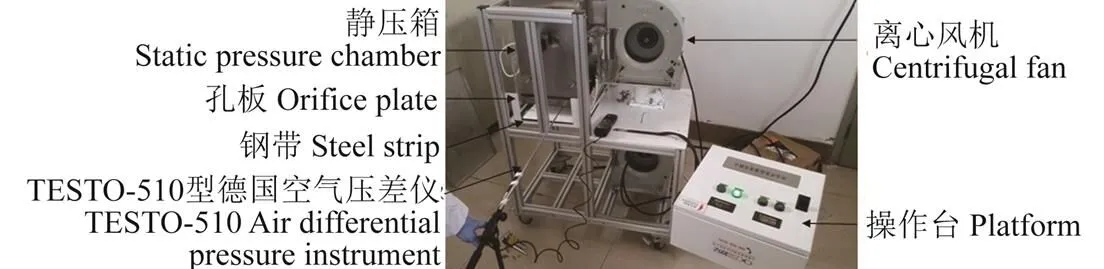

图1a为冲击式速冻试验台模型,由离心风机带动冷却空气进入冲击式速冻试验台静压箱内,通过孔板直接喷射至钢带表面,在限定的矩形通道内流动并由最末端的出口排出。

a. 冲击式速冻试验台模型

a. Model of impacting freezing test bench

b. 圆孔喷嘴模型

b Model of circular orifice nozzle

c. 圆漏斗喷嘴模型

c. Circular funnel nozzle model

d. 圆漏斗喷嘴结构

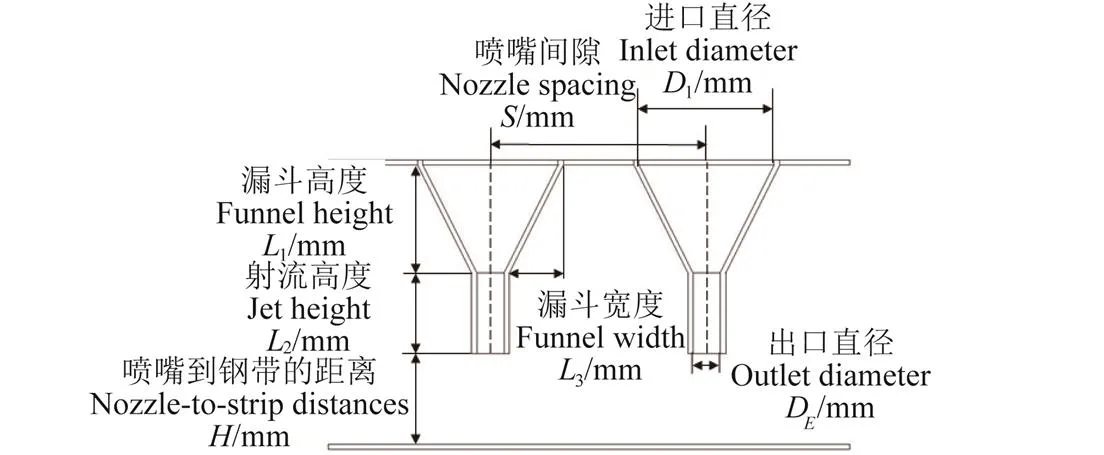

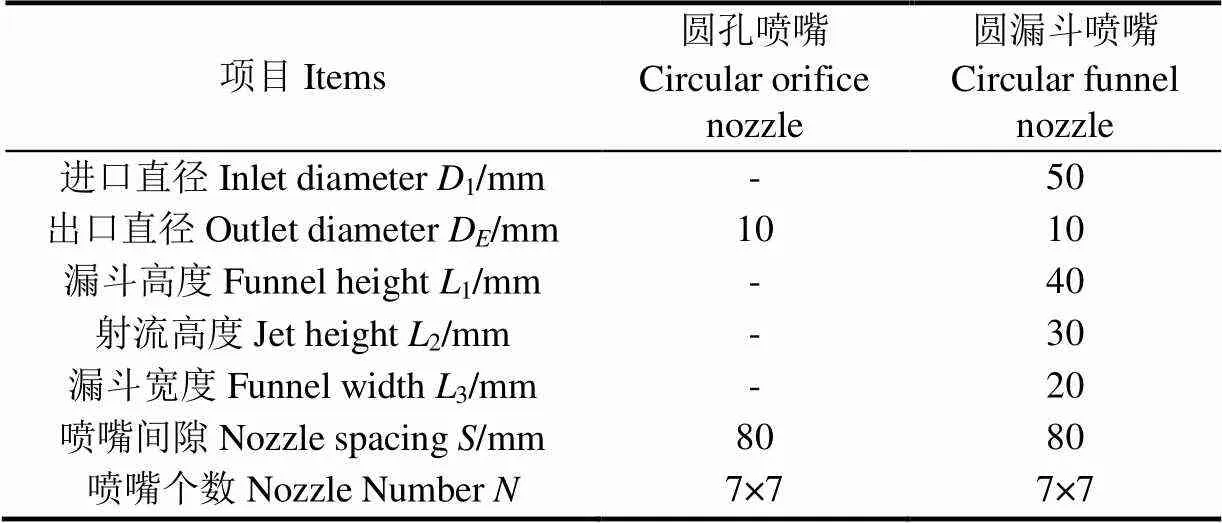

经与南通四方冷链装备股份有限公司的冲击式隧道速冻装置实测数据比对得出本模型静压箱尺寸为300 mm×300 mm×500 mm,孔板尺寸为300 mm×300 mm×2 mm,此结构尺寸下冲击式速冻试验台内部流场变化与气流冲击式速冻机内流场变化一致。为了合理分布喷嘴结构,清晰的观察到冲击式速冻试验台内部流场的变化趋势,本文在对冲击式速冻试验台进行数值模拟研究时,等比例增大了静压箱和孔板的尺寸[16],分别为600 mm×600 mm×500 mm和600 mm×600 mm×2 mm,此模型结构上下对称,故只采用1/2模型进行计算。在此模型尺寸下,圆孔和圆漏斗喷嘴的具体结构参数如表1所示。

表1 喷嘴结构参数

1.2 数值模拟

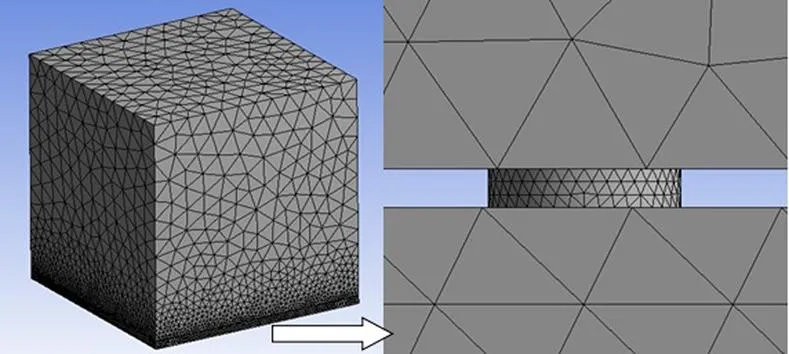

1.2.2 网格划分

将物理模型导入ANSYS15.0软件中,进行计算区域的离散化处理,将喷嘴周围的网格适当进行加密处理[17-18],对于圆孔喷嘴,喷嘴处加密网格最小尺寸为0.517 9 mm,整个计算域节点个数为634 363,网格单元数为2 224 215,如图2所示。

图2 网格划分

1.2.3 模拟参数设置

由于本文模拟的流体为空气,为了方便模拟计算,进行了下列假设:(1)空气为不可压缩流体[19-20];(2)模型在正常运行过程中,冲击式速冻试验台内部的流场视为稳态[21];(3)静压箱壁面视为绝热[22]。

本模型内部为有限空间的强制对流换热,流体的雷诺数Re>106,流体完全处于湍流状态,因此,本模型采用湍流模型,由于在冲击过程中有温度的变化,故使用能量方程[23-24]。参考王金锋等[15]的试验方法并稍作修改,冷却空气入口压力in=250 Pa,冷却空气出口压力out=0 Pa。冻结区域冷却空气入口温度设置为230 K,冷却空气出口温度为235 K。冷却空气入口处质量流量为0.064 4 kg/s。冲击表面为钢带,设置为壁面,其热导率为16.3W/(m·℃)[15]。

1.3 模型的试验验证

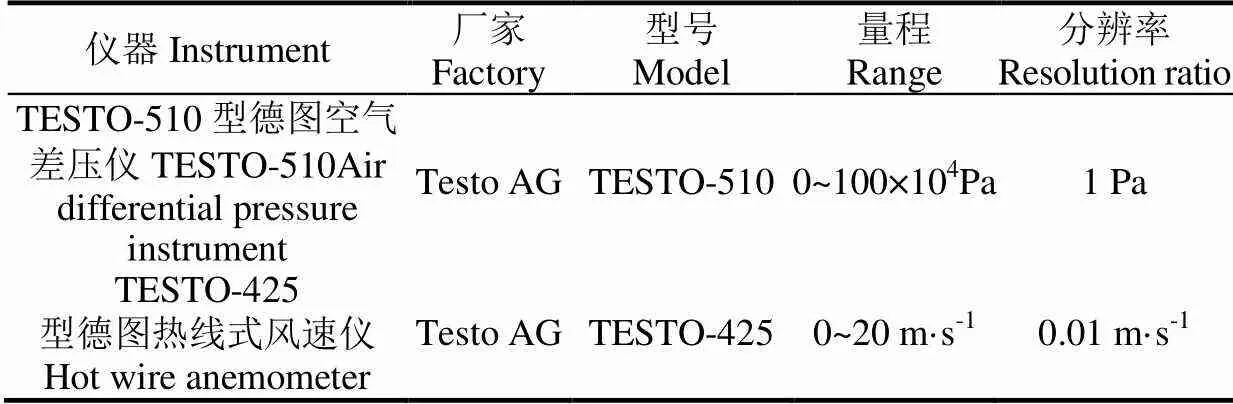

为了验证数值模拟的可靠性,本文进行了验证试验(图3)。试验测量的仪器设备包括TESTO-510型德图空气差压仪和TESTO-425型德图热线式风速仪(表2)。

图3 验证试验

表2 测试仪器的技术参数

1.3.1 试验方法

1.3.2 试验结果

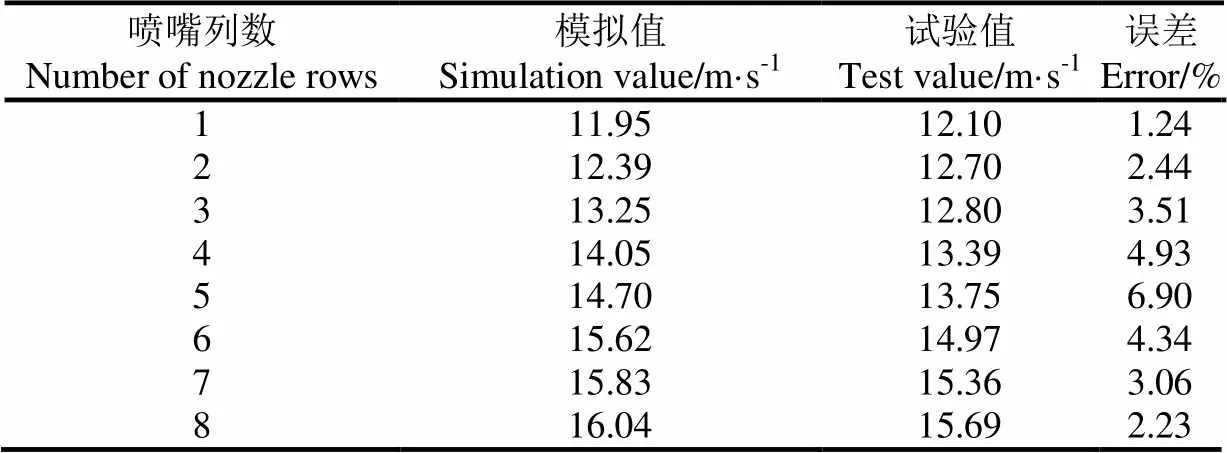

将试验测量结果与数值模拟结果进行比较,如表3所示。

表3 各列圆孔喷嘴出口处Z方向气流速度

由表3可见,数值模拟结果与试验测量结果的变化趋势是相同的,即沿孔板方向,随着圆孔喷嘴的列数增加,喷嘴出口处方向气流速度增加,数值模拟结果与试验测量结果的相对误差在1.24%~6.90%以内,因此可以确定对冲击式速冻试验台的数值模拟可靠[25]。因后续的数值模拟仅对模型尺寸等比例放大,其他模拟条件设置不变,因此后续可以采用相同的数值模拟条件对速冻机的喷嘴设计方案进行分析和优化[16]。

1.4 参数的定义

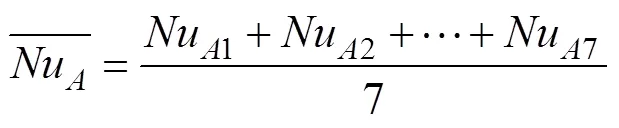

本研究在改变喷嘴到钢带的距离与出口直径的比值/D条件下,从钢带表面和传热均匀度2个方面出发,分析2种喷嘴结构的钢带表面的换热特性。参考Attalla等[26]的试验方法并稍作修改,在钢带表面上取线A和线B(见图1b)来具体分析钢带各个位置的换热特性,线A对应每排喷嘴中心正下方,喷嘴排数为7,因此分别为线A1,A2,···,A7,线B对应每2排喷嘴间隙的中心线正下方,喷嘴间隙数为6,因此分别为线B1,B2,···,B6[26]。线A和线B上的平均努塞尔数为

2 结果与分析

2.1 钢带表面的传热强度和传热均匀性

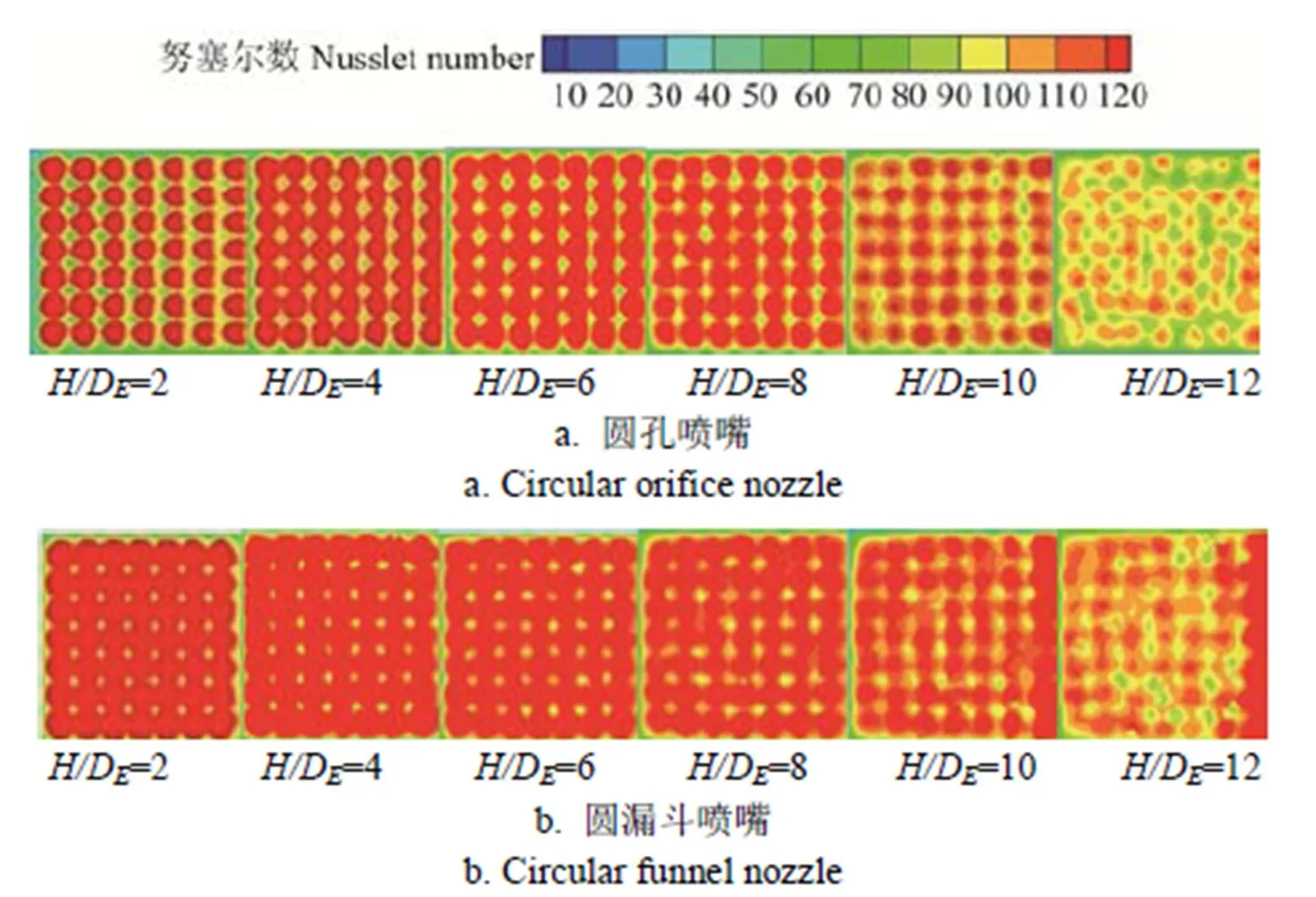

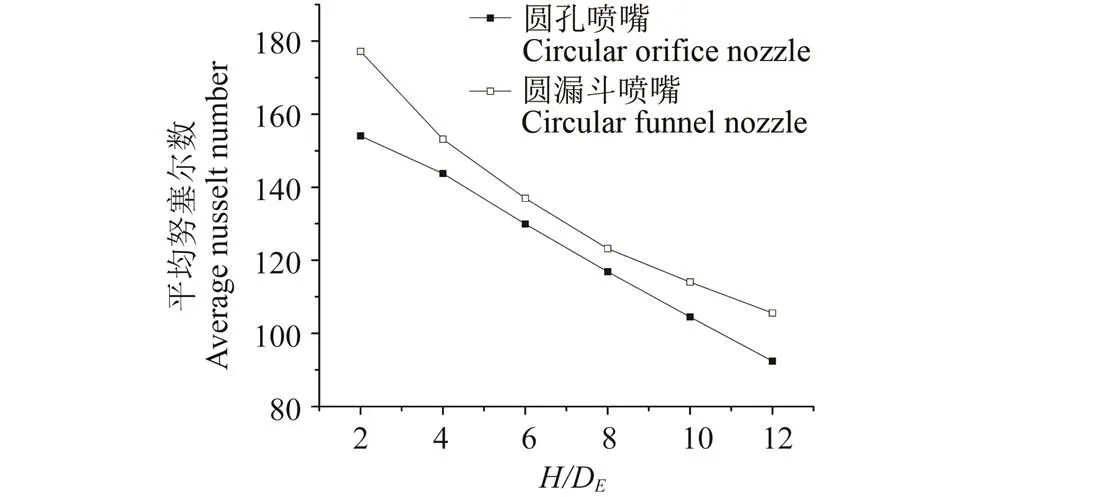

图4显示了冷却空气入口压力为in=250 Pa,冷却空气出口压力out=0 Pa,冻结区域冷却空气入口温度设置为230 K,出口温度为235 K,冷却空气入口处质量流量为0.064 4 kg/s时,不同的喷嘴到钢带距离与出口直径比值H/D的圆孔和圆漏斗2种喷嘴结构的钢带表面分布。由图4可知,当H/D值一定时,圆漏斗喷嘴结构的钢带表面值均比圆孔结构的钢带表面值高。随着H/D的增加,射流直接冲击到钢带表面的速度减小,因此钢带表面减小。

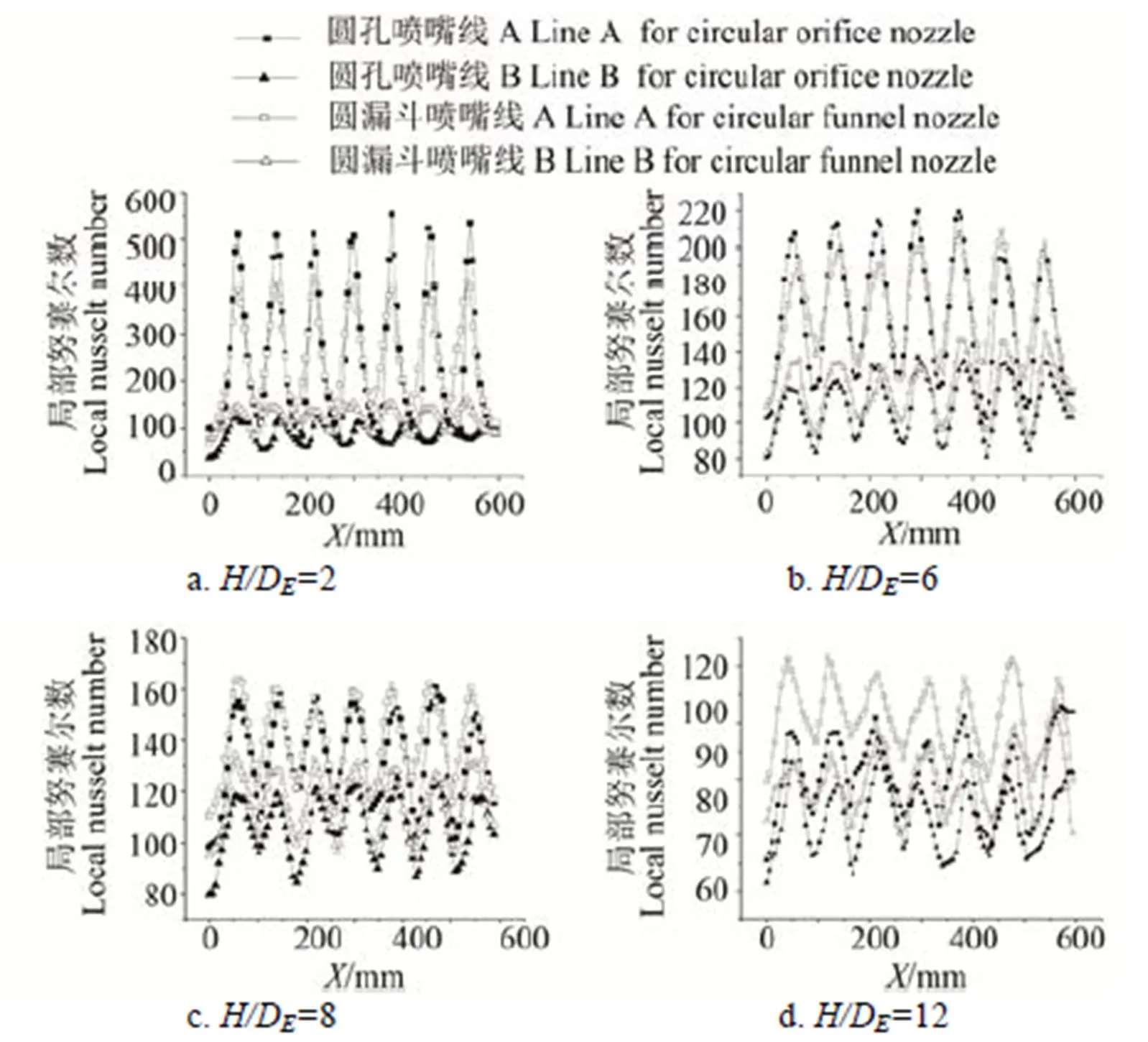

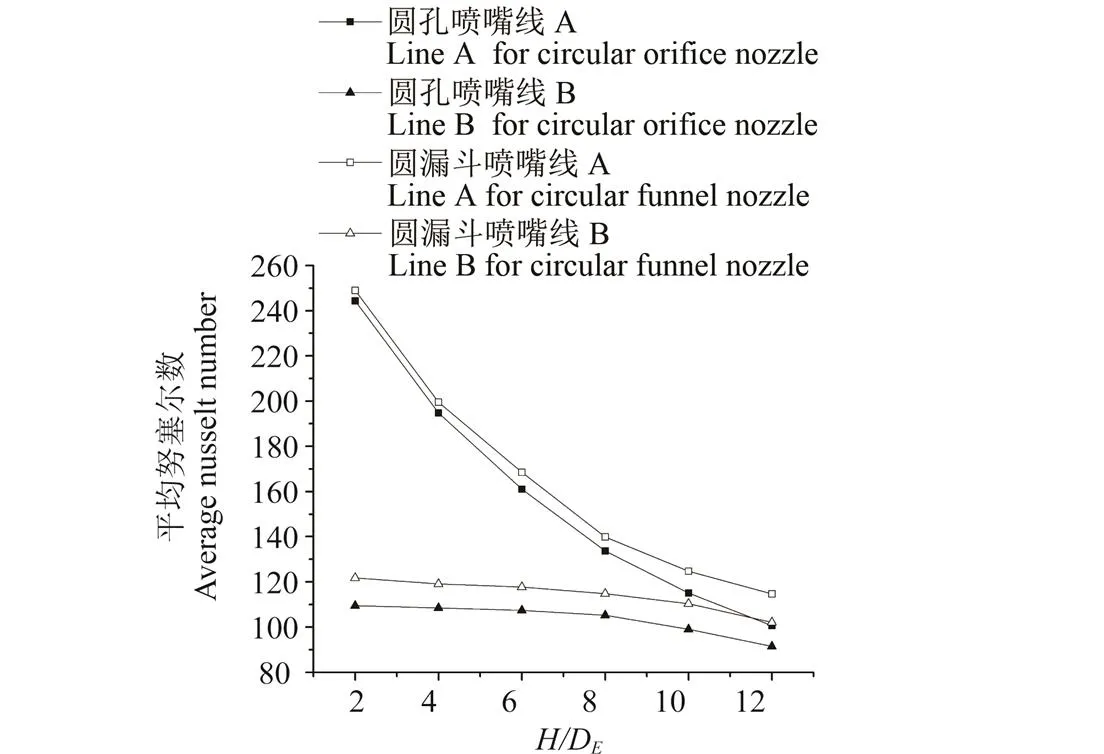

图5为2种喷嘴在不同H/D的线A和线B局部分布。由图5可知,对于线A,当H/D=2和6时,圆孔喷嘴的局部较高,但圆孔喷嘴的局部的最大值与最小值之差(即极差)分别为470.80和117.19,圆漏斗喷嘴的局部极差分别为343.67和99.69,圆漏斗喷嘴的局部极差比圆孔喷嘴的低27.01%,说明圆漏斗喷嘴结构的钢带表面局部分布更均匀;当H/D=8和12时,圆孔喷嘴的局部极差分别为53.04和25. 21,圆漏斗喷嘴的局部极差分别为50.19和20.43,2种喷嘴结构的钢带表面局部极差相差不大,说明2种喷嘴结构的钢带表面局部分布均匀程度相差不大,但圆漏斗喷嘴结构的钢带表面局部较高。对于线B,当H/D=2、6、8和12时,圆漏斗喷嘴结构的钢带表面局部都较高,说明圆漏斗喷嘴结构的线B上的换热强度较高。

注:冷却空气入口压力为Pin=250 Pa,冷却空气出口压力Pout=0 Pa,冻结区域冷却空气入口温度设置为230 K,出口温度为235 K,冷却空气入口处质量流量为0.064 4 kg/s。H为喷嘴到钢带的距离,mm;DE为喷嘴出口直径,mm。下同。

图5 不同H/DE值的线A和线B局部Nu分布

图6 不同H/DE的线A和线B的

图7 不同H/DE的钢带表面

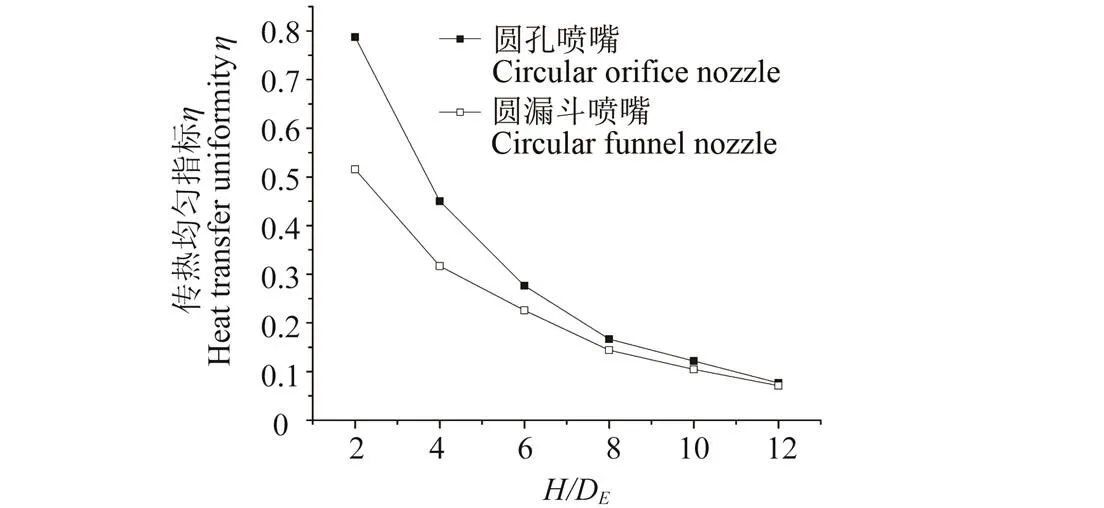

图8 钢带表面传热的均匀性指标η随H/DE值的变化

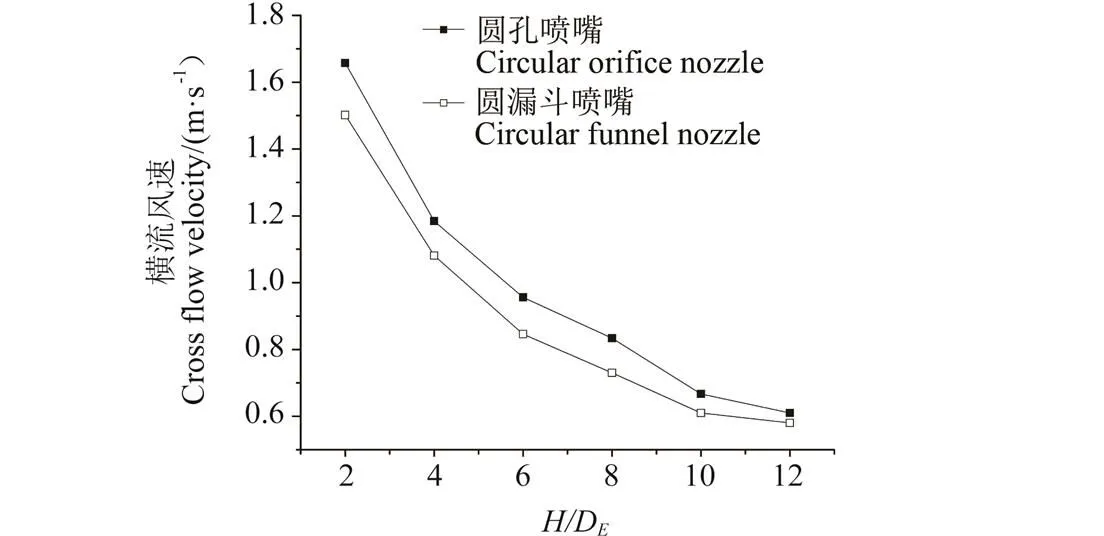

2.2 横流速度分析

从图9还可以看出,当H/D值在2~12范围内时,圆漏斗喷嘴结构的横流风速始终低于圆孔喷嘴的横流风速,低4.89%~12.46%。说明圆漏斗喷嘴结构的横流效应对冲击射流的影响较弱,因此钢带表面换热强度比圆孔喷嘴结构的换热强度高。

图9 钢带上方10 mm处横流风速分布

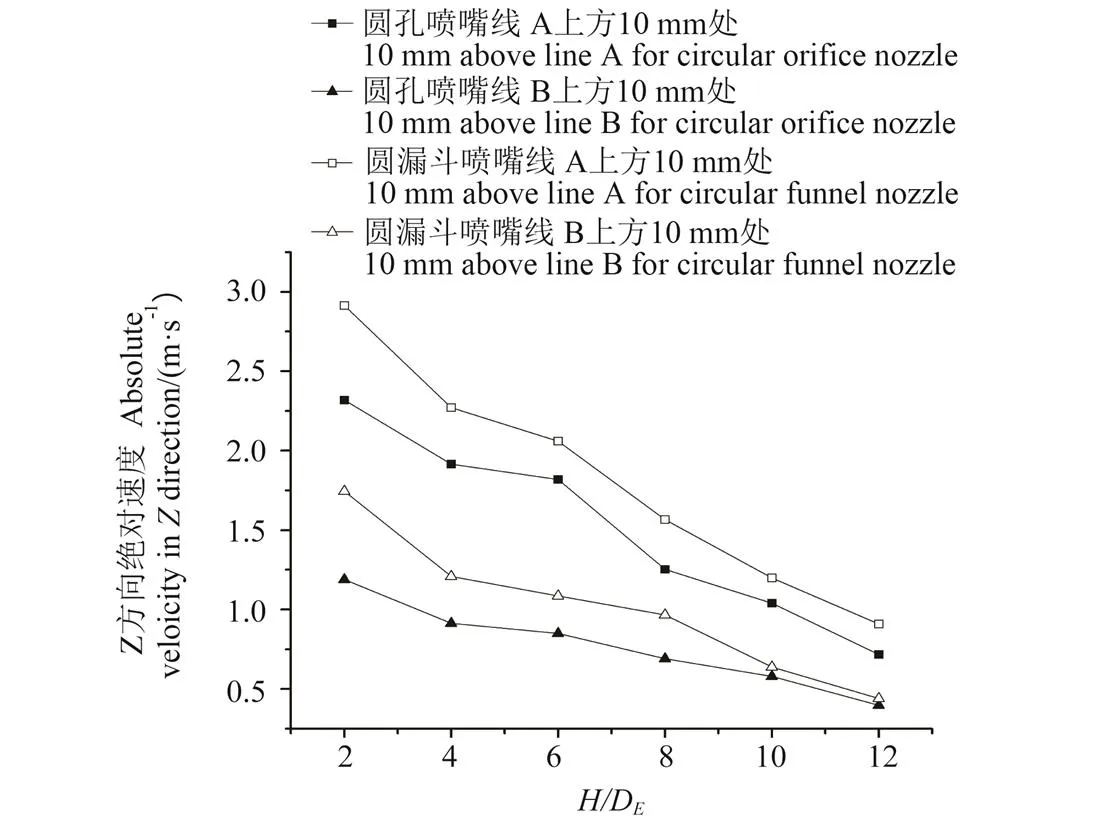

图10 不同H/DE的线A和线B上方10 mm处Z方向绝对速度

图11 喷嘴出口气流矢量图

3 结 论

本文以冲击式速冻试验台的喷嘴为研究对象,对比了圆孔和圆漏斗喷嘴在冷却空气入口处质量流量相同的情况下,改变喷嘴到钢带的距离对钢带表面换热特性的影响,得到以下结论:

2)当H/D值在2~12范围时,2种喷嘴结构的钢带表面的变化均受H/D值的影响较大,受横流影响较小。

3)当H/D值在2~12范围时,圆漏斗喷嘴结构的钢带表面传热均匀性指标值比圆孔喷嘴结构的值低7.06%~34.52%。随着H/D值的增加,2种喷嘴结构的差值逐渐缩小。圆漏斗喷嘴结构的值较低,即设备内部气流较为均匀,这有利于保证冻结的均匀性,提高食品的冻结品质。

[1] Huan Z, Ma Y, He S. Airflow blockage and guide technology on energy saving for spiral quick-freezer[J]. International Journal of Refrigeration, 2003, 26(6): 644-651.

[2] Shaikh N I, Prabhu V. Mathematical modeling and simulation of cryogenic tunnel freezers[J]. Journal of Food Engineering, 2007, 80(2): 701-710.

[3] Yang B, Chang S, Wu H, et al. Experimental and numerical investigation of heat transfer in an array of impingement jets on a concave surface[J]. Applied Thermal Engineering, 2017, 127(25): 473-483.

[4] Kumar K. Flow and heat transfer characteristics of confined noncircular turbulent impinging jets[J]. Drying Technology, 2004, 22(9): 2027-2049.

[5] Vinze R, Chandel S, M.D. Limaye, et al. Influence of jet temperature and nozzle shape on the heat transfer distribution between a smooth plate and impinging air jets[J]. International Journal of Thermal Sciences, 2016, 99: 136-151.

[6] Nuntadusit C, Wae-Hayee M, Tekasakul P, et al. Local heat transfer characteristics of array impinging jets from elongated orifices[J]. International Communications in Heat and Mass Transfer, 2012, 39(8): 1154-1164.

[7] Dano B P E, Liburdy J A, Kanokjaruvijit K. Flow characteristics and heat transfer performances of a semi-confined impinging array of jets: effect of nozzle geometry[J]. International Journal of Heat and Mass Transfer, 2005, 48(3): 691-701.

[8] Martin R H, Buchlin J M. Jet impingement heat transfer from lobed nozzles[J]. International Journal of Thermal Sciences, 2011, 50(7):1199-1206.

[9] Mangate L D, Chaudhari M B. Heat transfer and acoustic study of impinging synthetic jet using diamond and oval shape orifice[J]. International Journal of Thermal Sciences, 2015, 89: 100-109.

[10] Ianiro A, Cardone G. Heat transfer rate and uniformity in multichannel swirling impinging jets[J]. Applied Thermal Engineering, 2012, 49(1): 89-98.

[11] Yu P, Zhu K, Sun T, et al. Heat transfer rate and uniformity of mist flow jet impingement for glass tempering[J]. International Journal of Heat and Mass Transfer, 2017, 115: 368-378.

[12] Yulin L, Feng L, Juming T, et al. Radio frequency tempering uniformity investigation of frozen beef with various shapes and sizes[J].Innovative Food Science and Emerging Technologies, 2018, 48: 42-55.

[13] Li D, Zhu Z, Sun D W. Effects of freezing on cell structure of fresh cellular food materials: A review[J]. Trends in Food Science and Technology, 2018, 75:46-55.

[14] Wen Z X, He Y L, Ma Z. Effects of nozzle arrangement on uniformity of multiple impinging jets heat transfer in a fast cooling simulation device[J]. Computers and Fluids, 2018, 164(15): 83-93.

[15] 王金锋,李文俊,谢晶,等. 两种喷嘴结构对冲击式速冻机流场及换热特征的影响[J]. 食品与机械,2017,33(12):80-85+90. Wang Jinfeng, Li Wwenjun, Xie Jing, et al. Influence of two ddifferent nnozzle fforms on the flow field and heat transferring characteristics[J]. Food and Machinery, 2017, 33(12): 80-85+90.

[16] 闻建龙. 工程流体力学[M]. 北京:机械工业出版社,2011.55-65.

[17] Xu L, Jin L, Ma Y, et al. Numerical study on heat transfer by swirling impinging jets issuing from a screw-thread nozzle[J]. International Journal of Heat and Mass Transfer, 2017, 115: 232-237.

[18] Guan T, Zhang J Z, Shan Y. Convective heat transfer by a row of tab-excited impinging jets on a wedge-shaped concave surface[J]. International Journal of Thermal Sciences, 2016, 100: 37-53.

[19] Zhu X W, Zhu L, Zhao J Q. An in-depth analysis of conjugate heat transfer process of impingement jet[J]. International Journal of Heat and Mass Transfer, 2017, 104: 1259-1267.

[20] Singh D, Premachandran B, Kohli S. Effect of nozzle shape on jet impingement heat transfer from a circular cylinder[J]. International Journal of Thermal Sciences, 2015, 96: 45-69.

[21] Li Y, Li B, Qi F, et al. Flow and heat transfer of parallel multiple jets obliquely impinging on a flat surface[J]. Applied Thermal Engineering, 2018, 133(25): 588-603.

[22] Lingling C, Robin B, Bernhard W, et al. Experimental and numerical heat transfer investigation of an impingement jet array with V-ribs on the target plate and on the impingement plate[J]. International Journal of Heat and Fluid Flow, 2017, 68: 126-138.

[23] Hosain M L, Fdhila R B, Daneryd A. Heat transfer by liquid jets impinging on a hot flat surface[J]. Applied Energy, 2016, 164(15): 934-943.

[24] Hou Y, Tao Y, Huai X, et al. Numerical simulation of multi-nozzle spray cooling heat transfer[J]. International Journal of Thermal Sciences, 2018, 125: 81-88.

[25] 陈黎卿,张栋,陈无畏. 基于流固耦合的分动器齿轮两相流动数值模拟与试验[J]. 农业工程学报,2014,30(4):54-61. Chen Liqing, Zhang Dong, Chen Wuwei. Numerical simulation and test on two-phase flow inside shell of transfer case based on fluid-structure interaction[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(4): 54-61.

[26] Attalla M, Maghrabie H M, Qayyum A, et al. Influence of the nozzle shape on heat transfer uniformity for in-line array of impinging air jets[J]. Applied Thermal Engineering, 2017, 120(25): 160-169.

[27] 马朝,严超,曹学伟,等. 阵列空气射流传热均匀性问题的数值研究[J]. 工程热物理学报,2016,37(11):2378-2384. Ma Cao, Yan Cao, Cao Xuewei, et al. Numerical Study on Array Air jet heat transfer uniformity[J]. Journal of Engineering Thermophysics, 2016, 37(11): 2378-2384.

[28] 葛茂生,吴普特,朱德兰,等. 卷盘式喷灌机移动喷洒均匀度计算模型构建与应用[J]. 农业工程学报,2016,32(11):13-137.Ge Maosheng, Wu Pute, Zhu Ddlan, et al. Construction and application of mobile spraying uniformity model of hard hose traveler[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(11): 130-137.

[29] 张珍,谢晶. 带有上下均风孔板的速冻装置中流场及温度场的数值模拟[J]. 制冷学报,2009,30(05):36-40.

Zhang Zhen, Xie Jing. Numerical simulation on flow and temperature fields in quick freezer with perforated plates[J]. Journal of Refrigeration, 2009, 30(05):36-40.

[30] Meena H C, Reodikar S A, Vinze R, et al. Influence of the shape of the orifice on the local heat transfer distribution between smooth flat surface and impinging incompressible air jet[J]. Experimental Thermal & Fluid Science, 2016, 70: 292-306.

[31] Vinze R, Chandel S, M.D. Limaye, et al. Effect of compressibility and nozzle configuration on heat transfer by impinging air jet over a smooth plate[J]. Applied Thermal Engineering, 2016, 101: 293-307.

[32] Katti V, Prabhu S V. Influence of streamwise pitch on local heat transfer distribution for in-line arrays of circular jets with spent air flow in two opposite directions[J]. Experimental Heat Transfer, 2009, 22(4): 228-256.

Effects of nozzle structures of air impinging freezer on heat transfer characteristics of steel strip surface

Xie Jing1,2,3,4※, Liu Yuyan2,4, Wang Jinfeng1,2,3,4

(1.201306,; 2.,201306;3.,201306,; 4,,201306,)

In view of the low efficiency and high energy consumption of air impinging freezer, 2 kinds of nozzle structures were compared in this paper in order to find out the best structure and improve the Nusselt number and heat transfer uniformity. Based on the impinging freezing test bench, the performance of 2 kinds of nozzle was analyzed and compared by using computational fluid dynamics (CFD) Numerical simulation technology. Theturbulence model was used. Since there was a temperature change during the jet impinging, the energy equation was selected. The cooling air inlet and outlet pressure were 250 Pa(P) and 0 Pa(P) respectively. For the frozen area, the cooling air inlet temperature was set to 230 K and outlet temperature was 235 K. The mass flow rate at the cooling air inlet is 0.064 4kg/s. The thermal conductivity of steel strip was 16.3 W/(m.°C). In order to verify the reliability of numerical simulation, experimental verification was carried out.Taking the circular orifice nozzle as an example, the outlet diameter of circular orifice nozzle wasD=10 mm, nozzle spacing was=34 mm, nozzle number was 64(8 rows×8 ranks), and the ratio between nozzle-to-strip distances and outlet diameters wasH/D=2.The absolute velocity of steel strip surface in vertical direction at the outlet nozzle (direction) was measured.The error between simulation value and test value was 1.24%6.90%, thus it could be concluded that the numerical simulation of the impinging freezing test bench was reliable. Based on the Nusselt number distribution and heat transfer uniformity on steel strip, the heat transfer characteristics on steel strip surface under the circular orifice nozzles and circular funnel nozzles at the different ratio between nozzle-to-strip distances and outlet diameters were analyzed. The results showed that when theH/Dwas in the range of 2-12, the average Nusselt number on steel strip surface under the circular funnel nozzle was about 5.41%-15.10% higher than that under the circular orifice nozzle. The change of the Nusselt number on steel strip surface under both 2 kinds of nozzle structures were greatly influenced by theH/Dand was less affected by the cross flow. The heat transfer uniformityon steel strip surface under the circular funnel nozzle was about 7.06%-34.52% lower than that of the circular orifice nozzle. As theH/Dincreasing, thedifference between the 2 kinds of nozzle structures was gradually decreased. This was because that for the circular funnel nozzle, the “convex” region which was formed between 2 kinds of nozzle structures could form a cross flow buffer zone. On the one hand, the flow direction of the cross flow was changed, so the cross flow velocity in the channel was decreased, and the adverse effect of cross flow was reduced. The average Nusselt number on steel strip surface under the circular funnel nozzle was higher, so that the heat transfer characteristics on steel strip surface was higher. On the other hand, the large vortex formed on the left side of the circular funnel nozzle enhanced the line B above the steel strip surface. The velocity indirection increased the Nusselt number on the line B, so thevalue of the steel strip surface was decreased, so that the airflow in the air impinging freezer was relatively uniformity. By comparing the structures of the 2 nozzles, it is recommended to use a circular funnel nozzle in the case of the same air supply volume to reduce the freezing time, increase the output of the air impinging freezer, and improve the quality of the frozen food.

nozzles; numerical simulation; heat transfer; nusselt number; jet impingement; freezer

10.11975/j.issn.1002-6819.2018.18.036

TP391.4; S431.9

A

1002-6819(2018)-18-0292-07

2018-05-03

2018-08-17

国家“十三五”重点研发项目课题(2016YFD0400303);上海市科委平台能力建设项目(16DZ2280300);上海市科委公共服务平台建设项目(17DZ2293400);上海高校青年教师培养资助计划(ZZSHOU16013);上海海洋大学科技发展专项基金(A2-0203-17-100207);上海海洋大学博士科研启动基金(A2-0203-17-100317)

谢 晶,女(汉族),教授,博士,博士生导师,主要从事制冷工程研究。Email:jxie@shou.edu.cn

谢 晶,柳雨嫣,王金锋. 喷嘴结构对气流冲击式速冻机钢带表面换热特性的影响[J]. 农业工程学报,2018,34(18):292-298. doi:10.11975/j.issn.1002-6819.2018.18.036 http://www.tcsae.org

Xie Jing, Liu Yuyan, Wang Jinfeng. Effects of nozzle structures of air impinging freezer on heat transfer characteristics of steel strip surface[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(18): 292-298. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.18.036 http://www.tcsae.org