Heat recovery ventilation system combined with boiler room preheating to improve the indoor environment of rabbit house in severe cold areas

Liu Peng, Guo Yao, Jiqin Ni, Wang Meizhi, An Lei, Tian Jianhui, Wu Zhonghong

Heat recovery ventilation system combined with boiler room preheating to improve the indoor environment of rabbit house in severe cold areas

Liu Peng1, Guo Yao1, Jiqin Ni2, Wang Meizhi1, An Lei1, Tian Jianhui1, Wu Zhonghong1※

(1.,,,, 100193; 2.,,47907)

Heat recovery ventilation (HRV) is type of energy saving ventilation. It has been widely used in animal house to alleviate contradiction between thermal comfort and ventilation in recent years. However, air heat exchanger freeze of HRV caused by severe cold weather limited HRV application in northeast China. It is necessary to find an economic way to ensure HRV being operated without freezing. Establish a more reasonable integration of heating and ventilation system in severely cold area. An experiment was conducted in rabbit house during winter in Arun Banner, northeast China. The rabbit house was heated by a coal boiler in the next room. Hot water produced by boiler was supplied to heating radiator inside the rabbit house. The boiler room was warm because of some extra heat release by boiler. To prevent freezing, the boiler room was used to preheat cold fresh air before it entered the heat exchanger. The HRV was installed on the ground of the rabbit house. It was an integration of HRV and boiler heating system. Temperature, relative humidity and concentration of noxious was measured with automatic recording sensor instrument. Data was collected to evaluate the decrease in air pollutants and air temperature of the rabbit house. Preheating effect of the boiler room and the HRV were tested when the system was in operation. The performance of the HRV and prevention of freezing in heat exchanger was evaluated in typical cold weather in northeast China. The economic benefit of the system was analyzed. The results showed that when the HRV and boiler system began to operate, concentrations of ammonia (NH3) and carbon dioxide (CO2) in rabbit house dropped by 46% and 64%, respectively. Moreover, indoor air temperature only dropped by an average of 1.8 ℃ when the outdoor air temperature varied from -15.8 to -11.8 ℃. It means that the system can significantly improve indoor air quality with barely a slight decline of indoor air temperature. Respiratory and skin disease decreased by 16% and 4%, respectively. It is great potential for better health and production of rabbits. The boiler room heated fresh air by 8.1 ℃, and the HRV heated fresh air by 6.4 ℃ on average. No frozen of the heat exchanger was observed. Heated load of the boiler room and the heat recovery load of the HRV were 6.8 and 5.6 kW, respectively. Sensible heat recovery efficiency of the HRV was 75.6%. Coefficient of performance of the HRV was 6.2. The system was operated efficiently. The method of freezing prevention ensure HRV in good condition among the whole cold season in northeast China. It is an economic option because the system can operated without extra energy consumption. The return of investment is 3 years in this work condition. The integration of HRV and boiler allowed HRV and boiler heating to operate with high efficiency and solve the contradiction between heating and ventilation in severely cold weather in the rabbit house. This finding can provide a sound reference for the design of animal house heating and ventilation system in severely cold climate northeast China.

heat recovery; ventilation; energy conservation; cold climate; rabbit house; boiler preheating

0 Introduction

Natural ventilation and conventional mechanical ventilation in rabbit houses can cause large amounts of energy loss in cold weather. Thermal comfort in these houses can only be poorly maintained even at minimum ventilation rate, especially in extremely cold weather during long winter. Therefore, a large amount of heat is required to maintain acceptable indoor air temperature. Many animal farmers prefer to decrease ventilation rates to maintain acceptable indoor air temperature and cut heating costs. However, insufficient ventilation can result in an accumulation of moisture and harmful gasses such as ammonia (NH3) and carbon dioxide (CO2), leading to higher rates of respiratory, digestive and skin diseases[1].

Heat recovery ventilation (HRV) uses warm exhaust air to preheat cold incoming air through an air-to-air heat exchanger. A higher ventilation rate can be supplied at low ambient temperatures when HRV was applied. The HRV is a valuable method for reducing energy loss from ventilation[2]. The HRV usually decreases heat loss in ventilation by about 60%-90%, cutting about 20% heating costs[3].

There is a great potential for the application of HRV in rabbit houses. However, HRV cannot work efficiently in cold weather for the reason that condensed water in the warm side of the heat exchanger can freeze at low temperature and partially block the air passage, causing airflow rate to fall quickly due to the increasing pressure drop. It has been proved that energy efficiency could decrease by about 30%-40% when freezing happened in heat exchanger[4]. A lot of work has been done to improve the performance of HRV in cold work condition. A new type of counter flow heat exchanger can run normally in an inlet at temperature of -6 ℃[5]. When the HRV technique was applied to swine houses, the acceptable temperature of incoming air was from -9 to -5 ℃, and the theoretical freezing temperature for the heat exchanger was -8 ℃[6]. A modified heat recovery ventilation system for rabbit house application can endure inlet air temperature not below -15 ℃[7].

Boiler heating can maximize energy use efficiency. Additionally, boiler heating does not consume rabbit house air or add combustion exhaust air into the house, such as a forced air furnace does[8]. A boiler heating system integrated with HRV can allow for independent and precise control of heating loads and ventilation rates while keeping the optimal indoor air quality in rabbit houses.

The contradiction between air exchange and thermal insulation can be more serious in severely cold weather. Although HRV is supposed to be more efficient in cold weather, freezing of the heat exchanger in HRV can limit its potential.

In this study, a HRV system was integrated with boiler heating to solve the problem of insufficient ventilation in rabbit house in severely cold weather. The wasted heat radiated by boiler was used to preheat the cold supply air to prevent frozen in the heat exchanger. The improvement of the indoor air quality and the HRV operation performance was studied.

1 Materials and methods

1.1 Experimental rabbit house

The experiment was carried out in winter, from 4th December 2015 to 27 th January 2016. The average outdoor temperature during the day and night were -15.6 and -21.3 ℃ in these two months. The lowest outdoor air temperature at night was recorded at below -30 ℃.

The experimental rabbit house was a breeding rabbit house located in Arun Banner in northern China at 47.56 N latitude and 122° longitude. The south-facing rabbit house was measured 25 m (Length) × 8 m (Wide) × 3 m (Height) and well-insulated (Figure 1). It was built with an external wall (Thermal resistance = 2.317 m2·℃/W) of 37 cm brick and 8 cm exterior polystyrene insulation board. It had double-pane windows, a 10cm insulation color plate roof (= 2.288 m2·℃/W), and cellulose insulation material in the ceiling. Eight windows (2.4 m × 1.8 m) and one door (1.2 m × 2.0 m) on the south sidewall (1.5 m × 1.2 m) and four windows on the north sidewall. A boiler room was located at the east end of the rabbit house (5 m Length × 8 m Wide × 3 m Height). A coal-fired boiler (9.3 kW) produced hot water and controlled heat supply based on weather. Five heating units were installed in the north side wall of the rabbit room that was located at the west end of the house.

The rabbit room had four rows of 3-tier rabbit cages with 252 reproductive rabbits and 160 growing rabbits of 70 days age at the beginning of the study. The average body weight of the reproductive rabbits and the growing rabbits were 4 and 2 kg, respectively. The rabbits had water available at all times with nipple drinker. They were fed at 05:00 and 17:00 and the rabbit manure was manually removed from the rabbit room at 8:00 each day. The rabbits produced a total heat load of 21 kW[9]. According to the stocking density, the minimum ventilation rate was controlled at 2 000 m3/h (standard ventilation rate of 1.5 m3/h kg body weight).

1.2 The HRV system design and operation schedule

The HRV system consisted of a supply fan, an exhaust fan, an air-to-air heat exchanger, galvanized sheet ducts and an air filter. The size of the plate type cross-flow heat exchanger was 600 mm × 600 mm × 600 mm with a total heat exchange area of 43.2 m2. The supply fan and the exhaust fan were both centrifugal fans, each with an air flow rate of 2 000 m3/h. The pressure drop of the heat exchanger was 120 Pa when the system operated according to design parameters. The heat exchanger was made of aluminum foil only for sensible heat exchange because there was high moisture load in the rabbit house and latent heat recovery was not suitable in this experiment[10].

Because the outdoor cold incoming air to the exchanger could easily freeze condensate in the warm side of the exchanger and prevent the HRV from working properly and efficiently, it was decided to preheat the incoming air before it entered the heat exchanger as supply air. Thus, the waste heat from the boiler inside the boiler room was used as the source of energy to preheat the cold incoming air.

The air supply inlet of the HRV was located inside the boiler room and the supply air outlet was located in the southwest inside the rabbit room. The exhaust air inlet was located in the northeast inside the rabbit room and the exhaust air outlet was located in the south sidewall outside the rabbit house. A spiral duct (300 mm) was used as the ventilation duct. The installation height of the HRV device was 2 m from the room floor (Figure 1). The HRV operated at daytime from 10:00 to 15:00 to offer ventilation for the rabbit room, but not at night because of the very low temperature (below -30 ℃). The boiler and the HRV maintained rabbit room temperatures during day and night at 6.6 and 6.1 ℃, respectively.

1.3 Measurement of temperature, gas concentration, and airflow speed

1.3.1 Temperature measurement

The heat exchanger of the HRV served to decrease heat loss to alleviate indoor air temperature decline induced by ventilation. In order to learn the effect of the heat exchanger on indoor air temperature, the rabbit house temperature difference between the heat recovery ventilation and unventilated cases was studied. Thirty-four 2-channel temperature and humidity digital recorders (Model 179-TH, Apresys Inc., Duluth, GA, USA) were used to monitor indoor and outdoor air temperature and relative humidity (Figure 1). These recorders logged data independently and automatically every 10 min. They had a temperature measurement range from -40 to 85 ℃ with ±0.5 ℃ accuracy and a relative humidity measurement range from 0 to 100% with ±3% accuracy. Temperatures and humidity were monitored at 0.5 and 1.5 m heights to indicate the vertical temperature gradient between the first- and third-tier of the rabbit cages, and every 7 m, along the length of the cages (Figure 1). Outdoor ambient temperatures were measured 3 m north of the building. The results at different locations were averaged.

1.3.2 Gas concentration measurement

A portable ammonia (NH3) sensor (Model MIC-800-NH3, Environmental Sensors, FL, USA) with measurement range of 0-38 mg/m3and accuracy of ±1% was used to measure NH3concentrations. A photoelectric carbon dioxide (CO2) sensor (Telaire Inc., CA, USA) with measurement range of 0-9 800 mg/m3and accuracy of ±3% was used to monitor CO2concentrations. Concentrations of NH3and CO2were measured in the cage room at 1 m height of 16 locations (Fig 1). The sensors were hand-held during measurement for every hour at each location. Measurements were conducted 13 times a day from 7:00 to 19:00 for 22 days (from January 1st, 2015 to January 21 th, 2016). The measurement covered the time with and without the HRV operation. Measured concentrations at the same hours on different days were averaged to compare the effects of the HRV on indoor air quality.

1.3.3 Airflow measurement

A hot-wire anemometer (Model 6004, Kanomax, Japan) with a measurement range of 0-20 m/s and an accuracy of ±1% was used to monitor airflow velocity inside the HRV device to calculate ventilation rate. The anemometer was inserted into the HRV to measure air velocity. The measure points were located in the inlets of fresh air duct and exhaust air duct.

1.4 Heat exchanger performance calculation

Equation (1) was used to calculate the sensible heat efficiency () of the HRV based on the ratio of recovered energy and energy difference between the fresh supply air and the exhaust air when the air flow rate of the supply air equal to the exhaust air[11].

In the formula,is sensible heat efficiency;is air temperature, K; subscriptsis supply,is exhaust,is inlet, andis outlet.

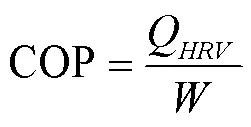

Coefficient of performance (COP), defined by the ratio of recovered heating power (Q) and electrical consumption by the fans ()[12], was calculated using Eqns. (2) and (3).

In the formula,Cis specific heat of air, kJ/ kg ℃;is capacity rate of air supply, kg/s;Tis inlet air temperature, ℃; andTis exhaust inlet air temperature, ℃.

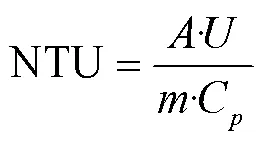

A total number of transfer units (NTU) was used to reflect the sensible heat transfer in the exchanger. For the heat exchanger that had an equal area on both sides of the airstreams, the total number of transfer units for the sensible heat was calculated using Eqns. (4) and (5)[13].

In the formula,is total exchange area, m2;is total heat transfer coefficient, kW/(m2·℃); andis mass flow rate, kg/s.

In the formula,his convective heat transfer coefficient of the supply air, kW/(m2·℃);is thickness of aluminum sheet;is thermal resistance, m2·℃/kW; andhis convective heat transfer coefficient of the exhaust air, kW/(m2·℃).

The sensible effectiveness is a function of two dimensionless parameters. For unmixed cross flows, it was expressed using Eqn. (6)[14].

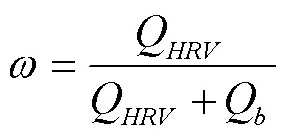

A variable,, was specified as the ratio of heat recovery to total preheat load, including HRV and boiler room [Eqn. (7)][15].

In the formula,Qis preheat load of the HRV, and Qis preheat load of the boiler room.

All the environmental data was collected during the experiment process. Data was showed in the form of average value ±standard deviation.

2 Results and discussion

2.1 Rabbit house air temperature without ventilation

Data was collected when no ventilation was provided in the rabbit house. Figure 2 shows that the experiment was carry out in typical server cold weather in northeast China. The outdoor average air temperature was -13.6 ℃ (varied from -27 to 5 ℃), while the indoor air temperature was 6.3 ℃ (varied from 0.2 to 10 ℃). Rabbit houses were recommended to maintain a temperature of not below 10 ℃ for growing and production rabbits. The result showed that the rabbit house was too cold for adult rabbit even no ventilation was provided.

2.2 Improvement of indoor air quality during HRV operation

A 9-day (from Jan 6th to Jan 21th) measurement result (Figure 3) demonstrated that the use of HRV improved indoor air quality. Before operation of the HRV, the rabbit room was unventilated and harmful gases had accumulated for a whole night. The RH and concentrations of NH3and CO2reached 81.5%, 9.5 mg/m3and 0.22%, respectively. After operating the HRV from 10:00 for 1 h, the RH and the concentrations of NH3and CO2were reduced to 65%, 5.1 mg/m3and 0.08%, decreased by 20%, 46% and 64%, respectively. During the HRV operation time, these parameters consistently remained at low levels. After the HRV stopped operating for 3 h, the RH and concentrations of CO2and NH3gradually returned to the initial high levels (Figure 3).

Indoor air quality is crucial for the health and performance of livestock. Ammoniacan affect the respiratory tract by impairing mucus flow and tracheal ciliary action. Ammonia can also damage tracheal mucus membranes and increase lung atrial wall thickness[16-18]. High levels of NH3concentration can greatly weaken the rabbit upper respiratory tract and open the door to bacteria, such as Pasteurella and Bordetella[1]. Moisture in the air is a good heat conductor, and can cause the cold to become more penetrating, resulting in convection and conduction heat loss in animals. When the surrounding air is cold, excess humidity can modify the secretion and viscosity of the mucus protecting the upper respiratory apparatus, which often causes respiratory disorders. Although CO2does not pose a direct threat to the animal health, it could lower immunity, cause pulmonary hypertension syndrome, and increase mortality of boilers[19]. Therefore, the HRV system demonstrated to improve air quality and, as such, could potentially benefit the rabbit health and performance.

2.3 Effect of the heat exchanger on air temperatures in the rabbit room

The linear regression relationship between the ambient temperature and indoor temperature during the unventilated period is shown in Figure 4 (a, b and c). The regression results in the absence of ventilation (descripted as “calculated temperature without ventilation” in Figure 4d) demonstrated that the rabbit room temperature difference between the non-ventilation case and the HRV ventilation case was equal to the temperature increase induced by the HRV.

The results also showed that, with the HRV operation, the air temperatures decreased by 2.0 ℃ at the first-tier cage height, 1.7 ℃ at the third-tier cage height, and 1.8 ℃ on average in the room (Figure 4d). The indoor air temperature dropped slightly.

It may not increase potential cold stress and adverse impact on the rabbit performance and health. According to the data from 2015 to 2017 in cold season, there was no significant increase in diarrhea rate which mainly caused by low air temperature, and respiratory and skin disease decreased by 16% and 4% respectively after HRV was used to improve air quality.

Considering that the temperature of cold fresh air was below -15 ℃, introducing the cold fresh air directly into the rabbit room would have caused the indoor air temperature soon drop to below 0 ℃. Moreover, a large energy supply would have been needed to heat the rabbit room to an acceptable indoor temperature and to prevent rabbit litters from freezing to death as well as drinking waterlines from becoming frozen.

2.4 Indoor air temperature distribution during operation process of the HRV

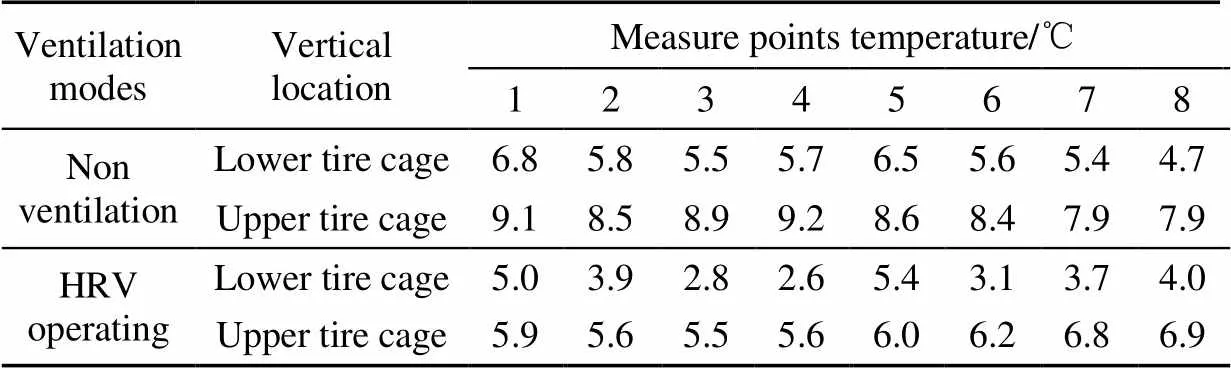

With no ventilation, the average upper-tier cage air temperature was 2.8 ℃ higher than the lower tier. On the other hand, when the HRV was in operation, the average upper tier air temperature was 2.2 ℃ higher than the lower tier. This indicated that ventilation decreased the stratification between the upper- and lower-tier cages. In the non-ventilation case, there was no significant air temperature difference between east end and west end on the upper tier (the lowest temperature was 8.4 ℃ and the highest temperature was 8.9 ℃), demonstrating a decreasing trend in the lower tier (the lowest temperature was 5.8 ℃, and the highest temperature was 6.7 ℃). Upon operation of the HRV, the upper tier air temperature in the north side was higher in the east and lower in the west (the lowest temperature was 6.0 ℃ and the highest temperature was 6.9 ℃). The lower tier air temperature showed a decreasing trend from west to east (the lowest temperature was 3.8 ℃ and the highest temperature was 5.2 ℃. Table 1). Generally, the ventilation of the HRV created a more uniform thermal comfort environment in the vertical direction, and a slightly increased temperature gradient in the horizontal direction.

The uniformity of air temperature distribution can influence the cold stress in animals at different locations in a room. The design of a ventilation system can greatly affect the uniformity of air temperature distribution in animal rooms. In this experiment, the fresh air supply outlet and the exhaust air inlet were located in the opposite end of the rabbit room, resulting in horizontal air temperature stratification from the west end to the east end. To achieve a better air distribution, a uniform ventilation design using a perforated duct along the rabbit room could be adapted to distribute the supply air more evenly.

Table 1 The distribution of indoor air temperature in the HRV operating period and non-ventilation period

Note: The north and south arrays indicate the two sides of the middle passage to avoid the difference of daft and solar radiation between the two sides

The air temperature gradient could affect heat loss from the ground of an animal house[20]. For this reason, the vertical temperature gradient induced by the ventilation design of the HRV had good effects on thermal comfort. The airflow arrangement of the HRV decreased the indoor air temperature stratification, which was beneficial to reducing heat loss and maintaining uniform thermal comfort on different tier cages.

2.5 Performance of the heat exchanger

Figure 5 a shows that the supply air temperature rose for 8.1 ℃ through the boiler room and 6.4 ℃ through the HRV when the outdoor air temperature was -9.2 ℃ (varied from -16.2 to 2.5 ℃). The cold supply air was still below 0 ℃ after it was preheated in the boiler room. However, the supply air temperature rose to approximate 5 ℃ when the air got through the heat exchanger and was much favorable to rabbits.

The HRV operated normally during the experiment and demonstrated an average sensible heat recovery efficiency of 75.6% (ranging from 55% to 91%. Figure 5 b), when the outdoor ambient air temperature ranged from -21 ℃ to 0 ℃. Above all, due to the preheating process in the boiler room, no freezing was observed in the heat exchanger even when the ambient temperature dropped below -20 ℃. The heat recovery load of the HRV was 5.0 kW and the COP was 6.2 on average.

The heat recovery efficiency of HRV systems in residential buildings is generally from 60% to 95%[3]. The HRV in this experiment was designed with a high approach air velocity to meet the high ventilation rate requirement in the rabbit room. However, this approach could prevent the heat exchange process and reduce the heat recovery efficiency. A previous study showed that when an approach velocity increased from 1 to 3 m/s, the sensible HRV efficiency could decrease from 66% to 48%[21]. Considering the designed high approach velocity of 4 m/s, 75.6% could be a good performance on sensible heat efficiency of the HRV. The efficiency of the heat exchanger calculated with themethod [Eqn. (4)] was 75.3% (NTU = 5.2), which was in good agreement with the results calculate with Eqn. (1).

A typical HRV COP [Eqn. (2)] is required to be no less than 2.5[10]. The COP is influenced by the amount of recovered energy and fan energy consumption. High approach velocities can greatly impact the magnitude of the increase in ventilation fan energy consumption[22]. Considering meeting the COP value requirement, the air temperature in the rabbit room should be at least 2.8 ℃ higher than that in the boiler room. When the HRV was off, the air temperature in the boiler room was 8.2 ℃ higher than the rabbit room. It was not necessary for heat recovery in this period. When the HRV began to operate, it took about 0.5 h for the boiler room temperature to decline to the required level.

The results showed that the operation schedule of the HRV influenced its performance. It was not economical to operate the HRV when the boiler room temperature was too high. In this instance, only the HRV supply fan would be needed to run for fresh air supply from the boiler room to the rabbit room. As the temperature of the boiler room declined to an acceptable level, the supply fan and exhaust fan could run at the same time to recover heat from the exhaust air stream.

According to our former experiment, a 576 m2rabbit house saved 9.4 t coal during the whole heating season in Jilin province when HRV was used. Coal price was ¥ 800/t. The investment of HRV equipment was ¥19 000. Power of fan in HRV was 2.8 kW in all. The service life of the HRV is 8 years. So the calculated ROI (return on investment) of the HRV in rabbit house was 3 years. Besides, rabbit can benefit from better air quality. It also make a contribution to more profit.

2.5.1 Preheating effect of the boiler room

The system was designed that the fresh air was preheated by boiler room firstly, and then preheated by the heat recovery ventilator. It was not necessary to recovery heat from exhaust air when the air temperature in the boiler room was too high. The heat exchanger could be frozen if the preheat of the boiler room was insufficient. As we learned from a previous study, the HRV in the rabbit house was not able to operate when fresh air temperature dropped to below -15 ℃ because of heat exchanger freezing[7]. So it is necessary to operate both boiler and HRV when the outdoor temperature was below -15 ℃.As the HRV was running, the boiler room air temperature was maintained at -7.6-4 ℃ when the ambient temperature ranged from -21 to 0 ℃. The boiler room temperature was mainly affected by the heat supply of the boiler and the ambient temperature. Figure 8 shows the boiler room air temperature corresponding to the different hot water supply temperatures. The boiler room temperature was from -5.7 to -1.7 ℃ when the supply water temperature of the boiler ranged from 25 to 70 ℃.

The heat recovery load of the heat exchanger was 5.6 kW, and the preheat load of the boiler room was 6.8 kW on average. The value of obtained using Eqn. (7), was 45%. When the temperature of the supply hot water was 70, 60, 40 and 25 ℃, value ofwas 36%, 43%, 46% and 55%, respectively (Figure 6). This meant thatvalue of the preheat load of the boiler room covered more than half of the total fresh air preheat load. This largely increased the energy efficiency of the system from 36% to 55% as the hot water temperature declined the value of obtained from 70 to 25 ℃.

When there was a large discrepancy between outside and inside temperatures, the boiler temperature should be set higher. Under these circumstances, the boiler would transmit more waste heat, which would more effectively preheat the incoming fresh air in the boiler room. When the preheat load of boiler room increased, the temperature difference between the air supply and exhaust air of the HRV would decrease. This was less economical for the HRV operation in this condition.

When the boiler provided less heat to the rabbit room, the air temperature in the boiler room would decline, so the incoming fresh air would be preheated less as well. However, there would be a greater temperature difference between the air supply and the exhaust air of the HRV. An increased temperature difference meant more energy could be recovered from the exhaust air stream.

In this integrated HRV boiler system, the ventilation rate and heat supply needed to be adjusted to maintain the boiler room and rabbit room air temperature at an appropriate level and to meet both thermal comfort and HRV energy conservation standards. In the experiment, offering hot water supply temperature between 40 to 50 ℃ was most efficient for both the boiler and HRV system when the ventilation rate set point was 2 000 m3/h.

High CO2concentration in the boiler room may have adverse effects on the air quality of the rabbit room. In this study, the CO2concentration in the boiler house declined from 2 950 to 980 mg/m3in 15 min when the heat recovery ventilation was operating. The level of CO2inside the boiler room remained similar to outdoor, and therefore did not affect air quality inside the rabbit room.

2.5.2 Degree of filter blocking on ventilation process

Rabbit hair and dust floating around the rabbit house were observed to soon accumulate on the filter and increased the resistance of the air flow and therefore reduced ventilation performance of the HRV. When the filter was not regularly cleaned, the air flow rate of the HRV was greatly influenced. The results of a test on the degrees of filter blocking using filter mesh sizes of 160 and 80, and no filter showed that the airflow rates of the HRV were 800, 1 200 and 2 000 m3/h, respectively. Ammonia concentration was reduced by 26%, 44% and 53%, respectively, and CO2concentration was reduced by 32%, 34% and 68%, respectively, at these three conditions (Figure 7). We deemed a mesh size of 80 as the most suitable exhaust air filter, which had the least impact on ventilation performance. A completely blocked filter resulted in an airflow rate reduction of 30% to 40%.

According to our observations, we recommended cleaning the filter every 42 h of HRV operation. However, during the delivery period when there was an increase in hair volume caused by the nesting behavior of male rabbits, the filter had to be cleaned more frequently.

2.6 Balance of air quality and thermal comfort

In this experiment, the CO2and NH3concentrations were at acceptable levels even during the periods without ventilation. However, the indoor air temperatures were still too low for rabbit production. Therefore, the ventilation rates could be reduce on this condition to improve the rabbit room thermal comfort while still maintaining acceptable air quality.

Contribution of the HRV to the indoor environment is affected by air exchange rates in rabbit houses. A rabbit house of high density needs high air exchange rate to supply sufficient volume of fresh air; and a HRV can have the potential to maintain comfort indoor air temperature in such a house. On the contrary, less fresh air is needed for a rabbit house of low density. The air exchange rate is suggest to lower down for the rabbit house; and the HRV is suggested to contribute less to indoor air temperature in this working condition.

3 Conclusions

In cold weather, heat recovery ventilation can be very useful in reducing heat loss and improving ventilation in the rabbit house. However, in severely cold weather, the application of heat recovery ventilator for rabbit house must be carefully considered for the reasons of heat exchanger frozen and indoor air temperature decline. The analysis of the present study showed the following conclusive observations:

1) It was demonstrated that a system that integrated heat recovery ventilator with boiler heating could be used in severely cold climates to improve air quality and maintain acceptable air temperatures in the rabbit room. This system considerably improved indoor air quality with minimum indoor temperature drop when the ambient air temperature was -15 ℃ on average.

2) The fresh air could be preheated to above the freezing temperature in the boiler room before it entered the heat exchanger of the HRV to prevent freezing of the heat exchanger without extra energy consumption. The sensible heat efficiency and COP achieved a good energy conservation performance. The operation schedule had a close relationship with the performance of heat exchanger.

[1] Lebas F, Coudert P, Rouvier R, et al. The rabbit: Husbandry, Health and Production[M]. Rome: Food and Agriculture Organization of the United Nations, 1997, 63-80.

[2] Vassilakis S, Lindley J. Cold weather performance of two, counter-flow parallel plate, air-to-air heat exchangers in swine housing[J]. Applied Engineering in Agriculture. 1998, 14(1): 73-77.

[3] Mardiana-Idayu A, Riffat S. Review on heat recovery technologies for building applications[J]. Renewable and Sustainable Energy Reviews. 2012, 16(2): 1241-1255.

[4] Kragh J, Rose J, Svendsen S, et al. Mechanical ventilation with heat recovery in cold climates[C]. // Proceedings of the 7th Symposium on Building Physics in the Nordic Countries. The Icelandic Building Research Institute and KTH, Royal Institue of Technology, 2005. 8.

[5] Kragh J, Rose J, Nielsen T R, et al. New counter flow heat exchanger designed for ventilation systems in cold climates[J]. Energy and Buildings. 2007, 39(11): 1151-1158.

[6] Zagorska V, Ilsters A. Possibilities of heat exchanger use in pigsty ventilation systems[C]. //International Scientific Conference: Biosystems Engineering, Tartu, Estonia, 2010, 272-279.

[7] Liu P, Wang M, An L, et al. Amodified heat recovery ventilation system for rabbit houses in cold climates in northeast China[J]. Transactions of the ASABE. 2016, 59(6): 1823-1830.

[8] MacDonald R. Saving money by maximizing energy use efficiency in swine production[J]. Advances in Pork Production. 2002, 13: 99-105.

[9] Pedersen S, Sällvik K. Climatization of animal houses - heat and moisture production at animal and house level. 4th report of CIGR working group[R]. Research Centre Bygholm, Danish Insitute of Agricultural Sciences, Horsens, Demark. 2002.

[10] Kang Y, Wang Y, Zhong K, et al. Temperature ranges of the application of air-to-air heat recovery ventilator in supermarkets in winter, China[J]. Energy and Buildings. 2010, 42(12): 2289-2295.

[11] “Method of Testing Air-to-Air Heat/Energy Exchangers”. ASHRAE 84-2020. 2020.

[12] Roulet C-A, Heidt F, Foradini F, et al. Real heat recovery with air handling units[J]. Energy and Buildings. 2001, 33(5): 495-502.

[13] Kays W M, Crawford M E, Weigand B. Convective Heat and Mass Transfer[C]. //New Delhi: Tata McGraw Hill, 2012.

[14] Zhang L, Niu J. Energy requirements for conditioning fresh air and the long-term savings with a membrane-based energy recovery ventilator in Hong Kong[J]. Energy. 2001, 26(2): 119-135.

[15] Zhou Y, Wu J, Wang R. Performance of energy recovery ventilator with various weathers and temperature set-points[J]. Energy and Buildings. 2007, 39(12): 1202-1210.

[16] Al-mashhadani eh, Beck mm. Effect of atmospheric ammonia on the surface ultrastructure of the lung and trachea of broiler chicks[J]. Poultry Science. 1985, 64(11): 2056-2061.

[17] Beker A, Vanhooser S, Swartzlander J, Teeter R. Atmospheric ammonia concentration effects on broiler growth and performance[J]. The Journal of Applied Poultry Research. 2004, 13(1): 5-9.

[18] Miles D, Branton S, Lott B. Atmospheric ammonia is detrimental to the performance of modern commercial broilers[J]. Poultry Science. 2004, 83(10): 1650-1654.

[19] Eltzschig H K, Carmeliet P. Hypoxia and inflammation. New England Journal of Medicine. 2011, 364(7): 656-665.

[20] Cordeau S, Barrington S. Heat balance for two commercial broiler barns with solar preheated ventilation air. Biosystems Engineering[J]. 2010, 107(3): 232-241.

[21] Mardiana-Idayu A, Riffat SB. An experimental study on the performance of enthalpy recovery system for building applications[J]. Energy and Buildings. 2011, 43(9): 2533-2538.

[22] Besant RW, Simonson CJ. Air-to-air energy recovery[J]. ASHRAE Journal. 2000, 42(5): 31-42.

热回收通风系统结合锅炉房预热改善严寒地区兔舍室内环境

刘 鹏1,郭 瑶1,Jiqin Ni2,王美芝1,安 磊1,田见晖1,吴中红1※

(1. 中国农业大学动物科技学院,动物营养学国家重点实验室,北京 100193;2. 美国普渡大学农业和生物工程系 西拉法叶 47907 美国)

热回收通风在寒冷地区畜舍中应用越来越广泛,但严寒地区热回收通风的热交换器的结冰问题限制其应用。为找到经济的办法解决热回收通风在严寒地区冬季运行的问题,探索严寒地区冬季兔舍通风与供暖合理搭配的模式,缓解通风与保温之间的矛盾,本研究在中国东北阿荣旗冬季兔舍开展了热回收通风结合锅炉供暖的试验。试验中利用锅炉散发的余热对寒冷空气预热后,再进入热交换器中进行排风热回收,防止热交换器结冰导致其无法运行。结果显示,当该系统运行时,兔舍内氨气和二氧化碳浓度分别降低了46% 和64%。室外温度为-15.8~-11.8 ℃时,通风带来的兔舍温度下降仅为1.8 ℃;家兔呼吸道和皮肤病冬季的发病率相比上一年分别降低了16%和4%。室外冷空气通过锅炉房预热,温度提高了8.1℃,再通过空气热交换器时,温度从提高了6.4 ℃,运行过程中未观察到热交换器结冰的现象。锅炉房预热和热回收通风对冷风的加热能量负荷分别为6.8和5.6 kW。热回收通风系统的显热回收效率为75.6%,能效比为6.2,设备投资回收期为3年。将热回收通风系统结合锅炉房预热可以在不额外增加耗能的情况下,大幅改善冬季兔舍的环境,为改进严寒地区兔舍冬季通风与供暖模式提供了参考。

热回收;通风;节能;严寒气候;兔舍;锅炉预热

10.11975/j.issn.1002-6819.2021.18.028

S81 Documents code: A Article ID: 1002-6819(2021)-18-0244-08

Liu Peng, Guo Yao, Jiqin Ni. et al. Heat recovery ventilation system combined with boiler room preheating to improve the indoor environment of rabbit house in severe cold areas[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(18): 244-251. (in English with Chinese abstract)doi:10.11975/j.issn.1002-6819.2021.18.028 http://www.tcsae.org

刘鹏,郭瑶,Jiqin Ni,等. 热回收通风系统结合锅炉房预热改善严寒地区兔舍室内环境[J]. 农业工程学报,2021,37(18):244-251. doi:10.11975/j.issn.1002-6819.2021.18.028 http://www.tcsae.org

date: 2020-11-01

date: 2021-09-01

s: This study was supported by China Agriculture Research System of MOF and MARA (CARS-43-D-2)

Liu Peng, Ph.D, Engineer, Research interest: Animal husbandry engineering and environment. Email: liupeng010125@163.com

※Corresponding author: Wu Zhonghong, Ph.D, Professor, Research interest: Livestock envronmental engineering, animal environmental physiology. Email: wuzhh@cau.edu.cn