Study on Fly Ash Based Porous Ceramsite as Biological Filter Media

Ruigang WANG Shuo WANG Weijie LI Hailong LIU

Abstract Using fly ash as a raw material, porous ceramic particles with an apparent density of 1.21 g/cm3, a visible porosity of 51.03%, and a specific surface area of 4.26 m2/g were prepared and used as biofilter materials for wastewater treatment. Through SEM, XRD analysis, and heavy metal leaching analysis, it was found that porous ceramsite were porous materials with rough surfaces. After calcination, the newly formed mineral was silicate calcium feldspar. The heavy metal concentration in the leaching solution of porous ceramsite met the national surface water quality requirements. The treatment of domestic sewage showed that the volumetric loads of CODCr, NH+4-N, and TN removed by the aerated biofilter were 5.23, 0.98, and 0.35 kg/(m3·d), respectively, with removal rates of 85.46%, 96.13%, and 32.31%.

Key words Porous ceramsite; Domestic sewage; Fly ash

DOI:10.19759/j.cnki.2164-4993.2024.01.017

Received: November 27, 2023

Accepted: January 28, 2024

Ruigang WANG (1978-), male, P. R. China, associate professor, devoted to research about waste treatment and recycling.

*Corresponding author.

Biological Aerated Filter (BAF) uses granular fillers and their attached biofilms as the main treatment medium, and utilizes biofilm adsorption, biodegradation, physical filtration and other functions to achieve the removal of pollutants. Due to its advantages such as small footprint, low infrastructure costs, and simple operation and management, BAF has been widely used in sewage treatment and pre-treatment of micro polluted source water. The properties of biological filter media affect the biological load and are key factors determining the performance of BAF, with surface roughness, apparent porosity, and density being the main performance indicators. Fly ash is mainly used as a concrete admixture, and there are few comprehensive utilization technologies for high value-added products. Therefore, in this study, fly ash from a certain power plant was used as a raw material to prepare porous ceramsite, which was used as biological filter media for sewage treatment in aerated biofilters, in order to investigate their effectiveness in treating domestic sewage.

Materials and Methods

Materials

Preparation of porous ceramsite

The fly ash, clay, and coal powder were ground separately and sieved through a 400 mesh sieve. The sieved portion was mixed evenly according to a certain ratio. It was granulated in a disc granulator, and then screened to obtain particles that met the particle size requirements. After drying the particles at 105 ℃ for 2 h, they were placed in a muffle furnace for calcination to obtain porous ceramsite with a particle size of 3-5 mm.

The apparent porosity and particle density of porous ceramsite was determined by a vacuum method. A TY-3 electronic pressure testing machine was employed to measure the compressive strength of ceramic balls. A Quanta200 electron backscatter diffractometer was used to observe the surface morphology of the sample. A XPert MPD Pro X-ray diffractometer (Cu target K α, 40 KV, 40 mA) was used to perform phase analysis on the sample.

Sewage treatment experiment

The formula for simulating domestic sewage[1]: A certain amount of glucose, starch, sodium acetate, ammonium sulfate and potassium dihydrogen phosphate were weighed and then added with a certain amount of tap water, and the pH value was adjusted to 7.5. The water quality indicators were as follows: CODCr200-250 mg/L, TN 30-35 mg/L, and NH+4-N 25-30 mg/L. The water temperature during the experiment was at room temperature.

The biological filter adopted a bottom inlet and top outlet operation mode. The bottom of the filter was aerated, and the sewage entered from the bottom of the filter through a peristaltic pump. After passing through the support layer, it entered the packing layer and finally flowed out from the top of the filter. In the initial stage of biofilm formation, actual domestic sewage was continuously introduced into the biological tank for biofilm cultivation. After 15 d, the biofilm grew and matured. After the completion of membrane hanging, the operating conditions of the aerated biofilter were as follows: hydraulic load of 0.5 m3/(m2·h), effluent DO concentration of 3-6 mg/L, and hydraulic retention time of 45 min.

Determination of water quality indicators before and after treatment: CODCrwas measured using potassium dichromate method; the determination of TN adopted alkaline potassium persulfate digestion spectrophotometry; NH+4-N was determined by Nesslers reagent spectrophotometry; the total biomass in the aerated biofilter was measured using the lipid phosphorus method; and microbial morphology was observed using an optical microscope[2-3].

Results and Analysis

Physical properties of porous ceramsite

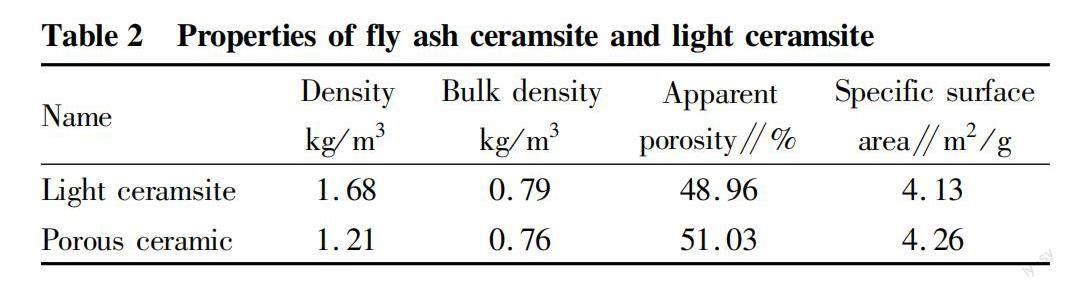

The performance comparison between the produced porous ceramsite and domestic lightweight porous ceramsite under the conditions of roasting temperature of 1 050 ℃ and pore forming agent addition of 20% is shown in Table 2[4]. From Table 2, it can be seen that the preparation of porous ceramsite using fly ash had a higher specific surface area and apparent porosity.

Surface morphology and phase composition of porous ceramic particles

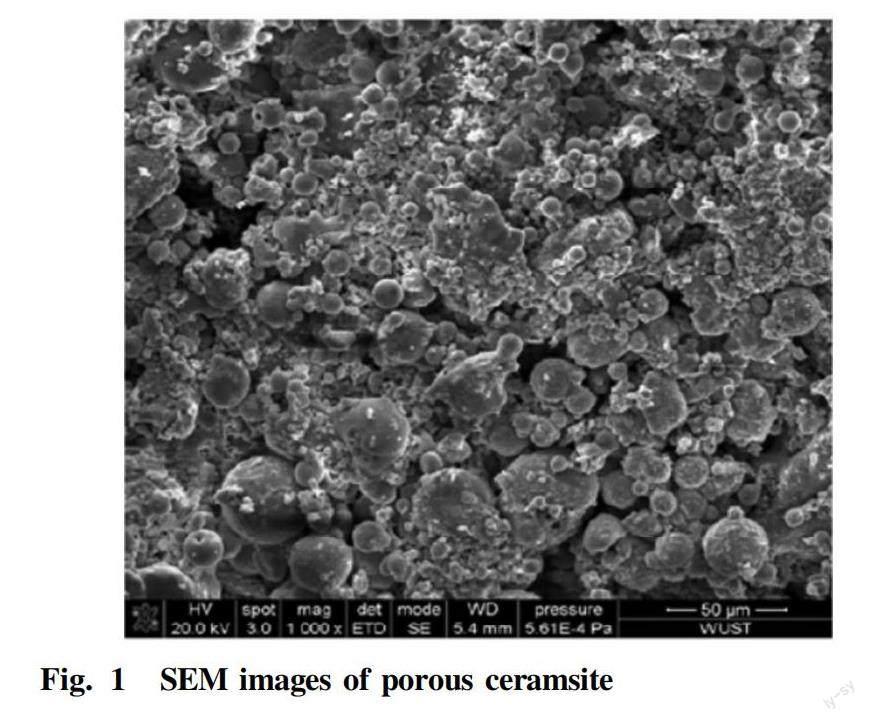

The SEM image of porous ceramsite is shown in Fig. 1. From Fig. 1, it can be seen that the surface of porous ceramsite was rough and the pores were well-developed, and these unique surface morphology were conducive to the loading of organisms.

The XRD patterns of fly ash and porous ceramsite are shown in Fig. 2. From Fig. 2, it can be seen that the main mineral phases of fly ash were SiO2, Fe2O3, Al2.3Si0.7O4.85, Na (AlSi3O8), etc; the main mineral phases of porous ceramsite after calcination were SiO2, Fe2O3, Al2Ca(SiO4)2, Al6Si2O13, etc. In the preparation process of porous ceramic particles, 5% clay was added, and the mineral components in the clay were generally minerals such as montmorillonite, illite, and kaolinite[5], without calcium feldspar. By comparing the changes in diffraction peaks of materials before and after calcination, it was found that the diffraction peaks of quartz were weakened, while the diffraction peaks of polyaluminite were enhanced. It was due to the transformation of quartz minerals into other bonding phases during the calcination process. When the calcination temperature is between 1 000-1 100 ℃, calcium feldspar begins to form[6]. Therefore, after high temperature calcination at 1 050 ℃, the mineral phase of polyaluminum andalusite increased and new mineral calcium feldspar was formed. These newly formed minerals had a stabilizing effect on heavy metals in the raw materials[7].

Toxic leaching of heavy metals from porous ceramsite

The toxic leaching results of heavy metals from porous ceramsite are shown in Table 3. From Table 3, it can be seen that after high-temperature calcination, the porous ceramsite stabilized heavy metals and had a low leaching rate, which met the surface water environmental quality standards[8]. Therefore, the porous ceramsite prepared from fly ash were environmentally friendly materials. When treating wastewater, they will not cause secondary pollution and will not pose any harm to the loaded organisms.

Heavy metalsCuPbZnCrCdNiConcentration∥kg/m30.0010.0280.0220.120.001 60.006 6

Porous ceramic particles for cleaning performance

The removal efficiency of CODCr, NH+4-N, and TN The removal effects of CODCr, NH+4-N, and TN by aerated biofilter are shown in Fig. 3, respectively. From Fig. 3, it can be seen that the aeration biofilter had a relatively stable pollutant removal effect. Taking the 5thday as an example, the volumetric loads for CODCr, NH+4-N, and TN removal were 5.23, 0.98, and 0.35 kg/(m3·d), respectively, with corresponding removal rates of 85.46%, 96.13%, and 32.31%. The concentrations of CODCrand NH+4-N in the effluent were lower than the limit values specified in the Class A standard for domestic sewage discharge in GB18918-2002.

Biofacies and biomass analysis After the operation of the aerated biofilter stabilized, it was found that bacteria, fungi, protozoa and micro metazoa were present in the biofilm attached to the filter material. Protozoa mainly include amoeba, bean shaped worms, small mouthed bell worms, etc., while micro metazoa mainly include rotifers, nematodes, etc. The microbial population in the aerated biofilter was abundant, forming a functionally stable ecosystem.

The surface and internal biomass of porous ceramic particles were 289.35 and 17.69 nmol P/g of filter material, respectively, with a total amount of 307.04 nmol P/g of filter material. The surface and internal biomass accounted for 94.24% and 5.76% of the total amount, respectively. It can be seen that the biological load of preparing porous ceramsite using fly ash as raw material is relatively large.

Conclusions

(1) Using fly ash to prepare porous ceramsite, its apparent density was 1.21 g/cm3, apparent porosity was 51.03%, and specific surface area was 4.26 m2/g. Porous ceramic particles had a rough surface and well-developed pores, making them environmentally friendly materials for wastewater treatment.

(2) The fly ash-based porous ceramsite aerated biofilter had a good operating effect in treating wastewater. The removal rates of CODCr, NH+4-N, and TN were 85.46%, 96.13%, and 32.31%, respectively. The removal volume loads were 5.23, 0.98, and 0.35 kg/(m3·d), respectively.

(3) The surface and internal biomass of porous ceramic filter media were 289.35 and 17.69 nmol P/g respectively, and the microbial population in the aerated biofilter was abundant.

Ruigang WANG et al. Study on Fly Ash Based Porous Ceramsite as Biological Filter Media References

[1] SUN HS, YANG CH, ZENG GM, et al. SBBR-CRI treatment of simulated domestic sewage based on ANN and its simulation research[J]. Chinese Environmental Science, 2019, 11(30): 1453-1457.

[2] State Environmental Protection Administration. Monitoring and analysis methods for water and wastewater[S]. Beijing: China Environmental Science Press, 2002.

[3] YU X, ZHANG XJ, WANG ZS. Determination of biomass in drinking water biological treatment by lipophosphate method[J]. Water Supply and Drainage, 2002, 28(5): 1-4.

[4] JIANG P, HU JC. Research on the use of domestically produced lightweight spherical ceramic particles in aerated biofilters[J]. Journal of Environmental Science, 2012, 22(4): 459-464.

[5] ZHANG RK, FAN G. Quantitative analysis method and experiment of X-ray diffraction phase of clay minerals[J]. Uranium Geology, 2018, 19(3): 180-185.

[6] LIU Q, PAN ZH, LI QB, et al. Preparation and formation process of calcium feldspar lightweight thermal insulation bricks[J]. Silicate Bulletin, 2019, 29(6): 1269-1274.

[7] DU F, LIU YS. Research on the firing of iron tailings into ceramic pellets and their properties[J]. Environmental Engineering, 2018, 28(S1): 369-372.

[8] State Environmental Protection Administration. Surface water environmental quality standards of the Peoples Republic of China[S]. Beijing: China Environmental Science Press, 2002.

[9] A OLAV SLIEKERS, N DERWORT, J L CAMPOS GOMEZ, et al. Completely autotrophic nitrogen removal over nitrite in one single reactor[J]. Water Research, 2002, 36(10): 2475-2482.

[10] K LINPING, W VERSTRAETE. Ammonium removal by the oxygen-limited autotrophic nitrification-denitrification system[J]. Applied and Environment Microbiology, 2008, 64(11): 4500-4506.

Editor: Yingzhi GUANG

Proofreader: Xinxiu ZHU

- 农业生物技术(英文版)的其它文章

- The Role of Jasmonates as Antibulbing Substances in the Bulb Formation of Onion

- Study on the Photosynthetic Characteristics of Six Varieties (Strains) in Chinese Chestnut

- Effects of Abscisic Acid on Cold Resistance in Digitaria sanguinalis (L.) Scop.

- Mapping of Purple Gene in Spears of Asparagus (Asparagus officinalis L.)

- Evaluation of Trace Elements in the Soil of Typical Peach Orchards in Zunyi City

- Research on Soil Conservation and Improvement Technology in Zhaoyang District