Fabrications and applications of fiber gratings based on microstructured optical fibers

Wang Yiping,Liao Changrui,Zhou Jiangtao,Liu Yingjie,Li Zhengyong,and Zhong Xiaoyong

Key Laboratory of Optoelectronic Devices and Systems of Ministry of Education,Key Laboratory of Optoelectronic Devices and Systems of Guangdong,Shenzhen University,Shenzhen 518060,P.R.China

Optical fiber gratings already play a vital role in the field of optical communications and sensors.There are two types of in-fiber gratings:fiber Bragg gratings(FBGs)with periodicities of the order of the optical wavelength[1]and long period fiber gratings(LPFGs)with periodicities of several hundred wavelengths[2-3].Various fabrication methods,such as UV laser exposure[2],CO2laser irradiation[3-7],electric arc discharge[8],femtosecond laser exposure[9],mechanical microbends[10], and etched corrugations[11],have been demonstrated to write LPFGs in different types of optical fibers.Compared with the UV laser exposure technique,the CO2laser irradiation technique is much more flexible and low cost because no photosensitivity and any other pretreated process are required to write a grating in the glass fibers[3-6].Moreover,the CO2laser irradiation process can be controlled to generate complicated grating profiles via the well-known point-to-point technique without any expensive masks.This technique could be,hence,used to write LPFGs in almost all types of fibers including pure-silica photonic crystal fibers(PCFs).We reviewed recent development on the CO2-laser-induced LPFGs.

Over the past decade,microstructured optical fibers have attracted a great deal of interest due to their unique microstructures and optical properties[12]. Microstructured optical fibers are usually divided into two different types of fibers:solid-core photonic crystal fibers(PCFs)and air-core photonic bandgaps fibers(PBGs).This paper presents the fabrication methods and applications of optical fiber gratings written in both solid-core PCFs and air-core PBGs.

1 Fabrication methods of gratings

1.1 To write LPFGs in solid-core PCFs

Since Eggleton et al[13]reported the first grating in a photosensitive PCF with a Ge-doped core in 1999,a large number of gratings have been written in different types of PCFs with or without photosensitivity by the use of various fabrication techniques such as UV laser exposure[14],CO2laser irradiation[15-16],electric-arc discharge[17],femtosecond laser exposure[18],and twophoton absorption[19].UV laser exposure is a common technique for writing a FBG/LPFG in a Ge-doped PCF with a photosensitivity[13,20-22].In contrast,CO2laser irradiation is a highly efficient,low cost technique for writing a LPFG in a pure-silica PCF without photosensitivity.

We demonstrated,for the first time,a novel grating fabrication system based on 2-dimentional scanning of the CO2laser beam[5-6],as shown in Fig.1.One end of the employed fiber is fixed and the other end is attached to a small weight to provide a constant prestrain in the fiber,thus enhancing the efficiency of the grating fabrication.The focused high-frequency CO2laser pulses scanned periodically across the employed fiber along‘X’direction and then shifted a grating pitch along‘Y’direction,i.e.the fiber axis,to create next grating period by means of 2-dimensional optical scanners under computer control.Compared with typical point-to-point fabrication systems[4], no exactly simultaneous controlling is required in such a system because the employed fiber is not periodically moved along the fiber axis.Such a system can write high-quality LPFGs with a nearly zero insertion loss in different types of optical fibers,including solidcore PCFs and air-core PBFs.

Fig.1 Schematic diagram of LPFG fabrication system based on 2-dimentional scanning of focused high-frequency CO2laser pulses[5].图1 CO2激光二维扫描技术制作长周期光纤光栅示意图[5]

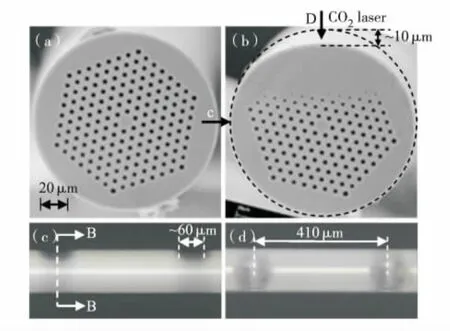

As shown in Fig.2,an asymmetrical LPFG with periodic grooves was written in a pure-silica large-mode-area PCF by the use of a focused CO2laser beam[15-16].The repeated scanning of the focused CO2laser beam creates a local high temperature in the fiber,which leads to the collapse of air holes and the gasification of SiO2on the fiber surface.Consequently,periodic grooves with a depth of about 15 μm and a width of about 50 μm are created on the fiber,as shown in Fig.2(b).Such grooves,especially collapse of air holes,induce periodic refractive index modulations along the fiber axis due to the well-known photoelastic effect,thus creating a LPFG in the PCF.This asymmetrical LPFG has unique optical properties,e.g.high strain sensitivity,low temperature sensitivity and high polarization dependence[15-16].

Fig.2 Asymmetrical LPFG with periodic grooves in a pure-silica PCF[15]图2 纯硅光子晶体光纤中写入带有周期性刻槽的非对称长周期光纤光栅[15]

A highly compact LPFG with only 8 periods and a short total length of 2.8 mm was written in a pure-silica large-mode-area PCF by the common point-by-point technique employing a CO2laser[23],in which clear physical deformation was also observed.In contrast,another LPFG without geometrical deformation and fiber elongation was written in an endlessly single-mode PCF by periodic stress relaxation resulting from CO2laser irradiation[24].Moreover,a LPFG pair has been successfully created in a puresilica PCF with a CO2laser to develop a stain sensor.A novel coupled local-mode theory could be used to model and analyze this type of PCF-based LPFGs with periodic collapses of air holes[25].Such a theory is based on calculating the variations of local-mode profiles and propagation constants over the perturbed regions and on solving the coupled local-mode equations to obtain a quantitative description of the intermodal energy exchange.

1.2 To write LPFGs in air-core PBFs

As discussed above,a large number of gratings have been demonstrated in different types of PCFs by the use of various fabrication techniques.All of these gratings,however,were written in index-guiding PCFs,instead of bandgap-guiding fibers.Recently,PBF-based gratings were also written in a new kind of bandgap-guiding fibers such as fluid-filled PBFs[26-30]and allsolid PBFs[31].However,PBF-based gratings have not been reported in air-core PBFs until recent success in writing a highquality LPFG in an air-core PBF[32].

Since almost 100%of the light propagates in the air holes of an air-core PBF and not in the glass,PBF-based gratings offer a number of unique features including:high dispersion,low nonlinearity,reduced environmental sensitivity,unusual mode coupling,and new possibilities for long-distance light-matter interactions(by incorporating additional materials into the airholes).Bandgap-based grating in air-core PBFs,therefore,represent an important platform technology with manifest applications in areas such as communications,fiber lasers and sensing.Periodic index modulations are usually required to realize mode coupling in in-fiber gratings.Although this presents no difficulties in conventional glass fibers[4-5],solid-core PCFs[13,15],and solid-core PBFs[27],it is very difficult,even impossible,to directly induce index modulations in an air-core PBF due to the air core structure,thereby seriously obstructing the development of PBF-based gratings over the past decade.

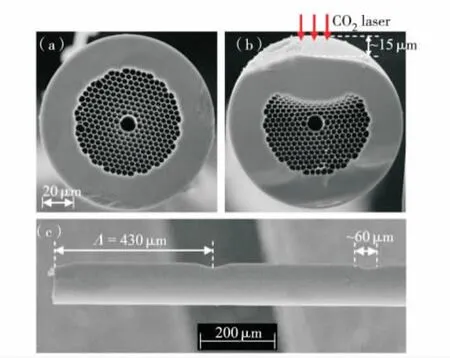

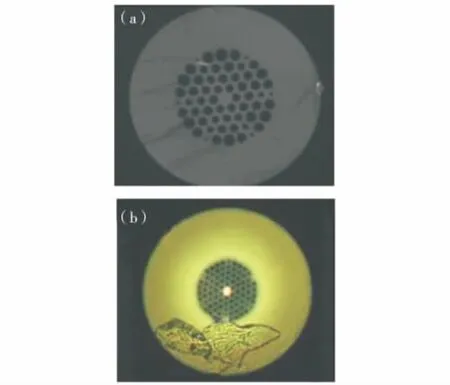

We report what is believed to be the first example of gratings written in an air-core PBF by the use of a focused CO2laser beam to periodically deform/perturb air holes along the fiber axis in 2008[32-33],as shown in Fig.3.This reveals that it is experimentally possible to write a grating in an air-core PBF.Both the excellent stability of CO2laser power and the good repeatability of optical scanning are very critical to writing a high-quality grating in an air-core PBF.An experimental setup being similar to that in Fig.1 was used to write a LPFG in an air-core PBF(Crystal-Fiber's HC-1500-02).Compared with the fabrication parameters for writing a grating in a solid-core PCF[15-16],a lower average laser power of about 0.2 W and shorter total time of laser irradiation were used to write a LPFG in an air-core PBF[32].The focused CO2beam scans periodically the PBF with a line speed of scanning of 2.9 mm/s,causing the ablation of glass on the fiber surface and the partial or complete collapse of air holes in the cladding due to the CO2-laser-induced local high temperature,as shown in Fig.7.The outer rings of air holes in the cladding,facing to the CO2laser irradiation,were largely deformed;however,little or no deformation were observed in the innermost ring of air-holes and in the air core.As a result,periodic index modulations are achieved along the fiber axis due to the photoelastic effect,thus creating a novel LPFG in the air-core PBF.For the LPFG written in air-core PBF,periodic perturbations of the waveguide(geometric)structure could be the dominant factor that causes resonant mode coupling,although the stress-relaxation-induced index variation may also contribute a little.

Fig.3 Cross-section image of an air-core PBF(a)before and(b)after CO2laser irradiating,(c)side image of a LPFG written in the air-core PBF,where about two periods of the LPFG are illustrated[32].图3 CO2激光 (a)曝光前和 (b)曝光后的空气芯光子带隙光纤的横截面图;(c)空气芯光子带隙光纤中写入的长周期光纤光栅的侧面图[32]

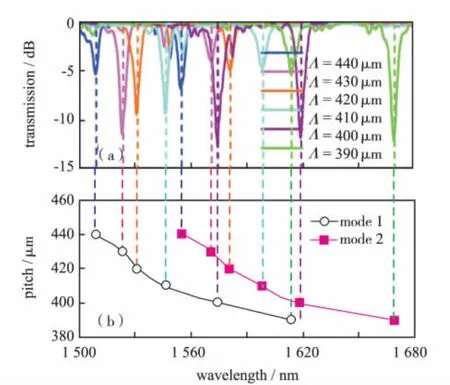

Normal LPFGs written in the index-guiding fibers have a positive relationship between resonant wavelength and grating pitch.In contrast,the LPFGs written in the bandgap-guiding aircore PBF have distinct phase matching condition as function of wavelength.As shown in Fig.4,the resonant wavelengths of the LPFGs written in an air-core PBF decrease with the increase of grating pitch,which is opposite to the LPFGs written in the indexguiding fibers[33].Moreover,this PBF-based LPFG has unique optical properties such as very large PDL,large strain sensitivity,and very small sensitivity or insensitivity to temperature,bend and external refractive index,as shown in Fig.4 in ref[32].Further investigations are being done to well understand resonant mode coupling and unique optical properties in the gratings written in air-core PBFs.

Fig.4 (a)Transmission spectra of six LPFGs,with different grating pitches,written in an air-core PBF,(b)the relationship between the pitch of each LPFG and the corresponding research wavelength,where two attenuation dips for each LPFG are observed from 1 500 to 1 680 nm,indicating that the fundamental mode is coupled to two different higher order modes[32]图4 (a)空气光子带隙光纤中写入的带有不同光栅周期的6个长周期光纤光栅的传输谱图;(b)光栅周期和谐振波长的关系曲线[32]

1.3 To write FBGs in solid-core PCFs

We written FBGs in two different types of PCFs with a FS laser or an excimer laser and two-beam interference,as shown in Fig.5[20-21,34-35].In the case of FS inscription,FS pulses with a width of 350 fs,a wavelength of 262 nm,a repetition rate of 1 kHz and a pulse energy of 180 μJ were generated by tripling the frequency of the output pulses(130 fs,786 nm)from a Ti∶sapphire amplifier seeded by a FS laser oscillator.The FS laser beam with a diameter of 6 mm was focused to a focal line(6 mm× 30 μm)by a cylindrical lens with a focal length of 335 mm.In the case of excimer laser inscription,nanosecond(NS)pulses with a width of 20 ns,a repetition rate of 1 or 10 Hz,and a pulse energy of 160 mJ were generated by a 248 nm KrF excimer laser(Compex 150T,Lambda-Physics).The laser beam(20 mm ×7.5 mm)from the excimer laser was transmitted through a rectangle window(6 mm×5 mm)and then focused to a focal line(6 mm × 150 μm)by another cylindrical lens with a focal length of 500 mm.

In both cases,the laser beam behind the lens was diffracted at a phase grating with a grating period of 1 065.3 nm(for FS laser inscription)or 1 060.9 nm(for excimer laser inscription),the beam thereby being split into two equal parts.About 35%of the transmitted light was diffracted into each of the±1storder diffracted beams.Then the ±1storders diffracted beams were redirected and combined via two rotatable mirrors,producing an interference pattern on the fiber.For the excimer laser inscription,the PCFs were placed near the focal plane of a cylindrical lens,rather than on the focal line,in order to prevent the fiber from being destroyed by high local laser energy.The estimated mean flux of both diffracted orders together onto the fiber is about 180 mJ/cm2for each FS pulse and about 290 mJ/cm2for each NS pulse,respectively.The period of the grating is given by[20]

where λLis the wavelength of the laser beam and β is the half angle of the intersection of the ±1storder diffracted beams.Given the Bragg condition of λ =2neffΛ,the Bragg wavelength of FBG written in the fiber can be represented as

where neffis the effective index of the PCF core.It is obvious that the orientation of the rotatable mirrors defines the spatial frequency of the interference pattern and therefore the Bragg wavelength of the grating.Hence,FBGs with different Bragg wavelengths can be written in the PCFs with only a single phase grating employed in our experiments.

Fig.5 Experimental setup for writing FBGs with two-beam interference and a FS laser or an excimer laser[20]图5 飞秒激光和准分子激光通过双光束干涉原理制作光纤布拉格光栅的实验装置[20]

The two different types of PCFs employed are a pure-silica PCF(IPHT-84b1a)and a Ge-doped PCF(IPHT-282b5)from the Institute of Photonic Technology(http://www.ipht-jena.de),as shown in Fig.6.The central region of IPHT-282b5 with a diameter of about 0.8 μm is doped with a high concentration of germanium.In order to observe the development of transmission spectra with increasing exposure dose,each end of the pure-silica and the Ge-doped PCFs was spliced to a standard single mode fiber(SMF)with a splice loss of 1.5 and 1.0 dB,respectively,by means of arc fusion splicing techniques as reported in the references[36-37].The Bragg wavelength and attenuation in the transmission spectrum were monitored with a computer-controlled optical spectrum analyzer(OSA)during grating fabrication.For some cases the PCFs were loaded with hydrogen at a pressure of 180 bar and at a temperature of 80 ℃ during 13 days.

Fig.6 Cross section images of(a)pure-silica PCF(IPHT-84b1a)and Ge-doped PCF(IPHT-282b5)图6 (a)纯硅光子晶体光纤 (IPHT-84b1a)和(b)掺锗光子晶体光纤 (IPHT-282b5)的横截面

2 Applications of gratings written in PCFs

2.1 Strain sensors

The CO2-laser-induced LPFGs with physical deformations exhibit unique optical properties while a tensile strain is applied,thus being excellent strain sensing elements.As shown in Fig.7,periodic microbends will be induced while a CO2-laser-induced LPFG with asymmetric grooves is stretched[16,38-39].Such stretchinduced microbends effectively enhance refractive index modulation in the gratings.As a result,such a LPFG have an extremely high strain sensitivity of- 102.89 nm/με[38-39],which is two orders of magnitude higher than that of other CO2-laser-induced LPFGs without physics deformations in the same type of fibers[5].

A LPFG strain sensor with a high strain sensitivity of-7.6 pm/με and a very low temperature sensitivity of 3.91 pm/℃ has been developed by the use of focused CO2laser beam to carve periodic grooves on the large mode area PCF[16].Such a strain sensor can effectively reduce the cross-sensitivity between strain and temperature,and the temperature-induced strain error obtained is only 0.5 με/℃ without temperature compensation.Another strain sensor based on a CO2-laser-induced LPFG pair in a PCF exhibits a high stain sensitivity of about-3 pm/με and a low temperature sensitivity of about 4.6 pm/℃[40].Theoretical analysis reveals that a simple,low-cost LPG sensor with approximately zero temperature sensitivity but large strain sensitivity could be realized by selecting an appropriate grating period[41].

Fig.7 Schematic diagram of the CO2-laser-carved LPFG with asymmetric grooves(a)before and(b)after a stretching force is applied to the grating[39]图7 CO2激光制备的带有非对称刻槽的长周期光纤光栅在 (a)拉伸前和 (b)拉伸后的示意图[39]

2.2 Polarizers

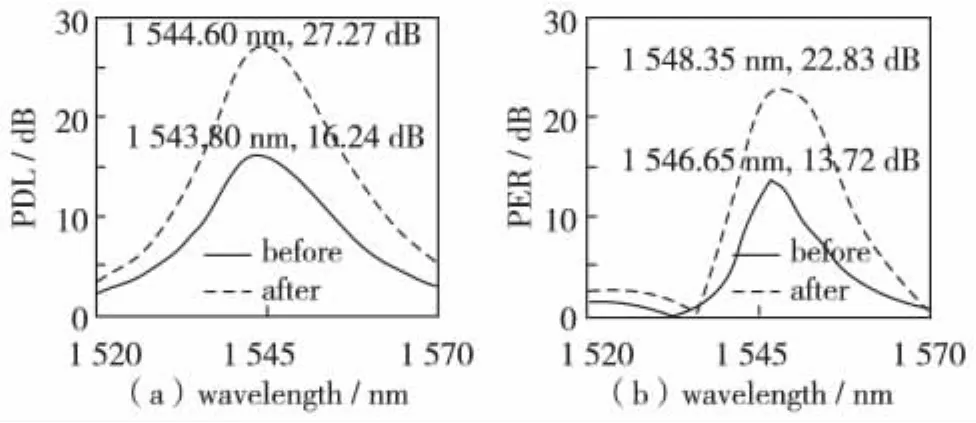

Compared with bulk waveguide polarizers,in-fiber polarizers are desirable devices in all-fiber communication systems because of their low insertion loss and compatibility with optical fiber.The CO2-laser-induced LPFGs have clear polarization dependence due to their asymmetric refractive index profile,resulting from single-side laser irradiation,within the cross-section of the gratings[38-39],thus being potential in-fiber polarizing device.Moreover,the polarization dependence of the CO2-laser-induced LPFG with periodic grooves can be greatly enhanced by applying a tensile strain[38]or increasing temperature[42].So a promising infiber polarizer based on a LPFG was developed by the use of a focused CO2laser beam to collapse or perturb periodically air holes in a pure-silica PCF[15].In practical operation,a stretch strain was applied to the LPFG-based polarizer to enhance the polarization dependence of the grating.As a result,the maximum PDL and the maximum polarization extinction ratio of the LPFG increased to 27.27 and 22.83 dB,respectively,as shown in Fig.8.Such a LPFG-based polarizer thus exhibits a high polarization extinction ratio of more than 20 dB over a wide wavelength range of about 11 nm near the communication wavelength of 1 550 nm[15].Moreover,this polarizer has a very low temperature sensitivity of 3.9 pm/℃,which overcomes the disadvantages of the temperature sensitivity in other in-fiber polarizers created in conventional glass fibers.

Fig.8 (a)Polarization dependent loss(PDL)and(b)polarization extinction ratio(PER)of the LPFG-based polarizer before(dashed curve)and after(solid curve)a stretch strain of 500 με is applied[15]图8 基于长周期光纤光栅的光纤型起偏器在发生500 με的拉伸应变前或后的(a)偏振相关损耗和 (b)偏振消光比[15]

Conclusions

Both LPFGs and FBGs could be written in different microstructured optical fibers,including solid-core PCFs and air-core PBGs.Compared with the UV laser exposure technique,the CO2laser irradiation technique is much more flexible and low cost because no photosensitivity and any other pretreated process are required to induce a grating in the glass fibers.Moreover,the CO2laser irradiation process can be controlled to generate complicated grating profilesviathe well-known point-to-pointtechnique without any expensive masks.In-fiber gratings written in PCFs have found promising sensing and communicati on applications.

/References:

[1] Rao Yunjiang.In-fibre Bragg grating sensors[J].Measurement Science& Technology,1997,8:355-375.

[2] Vengsarkar A M,Lemaire P J,Judkins J B,et al.Longperiod fiber gratings as band-rejection filters[J].Journal of Lightwave Technology,1996,14(1):58-65.

[3] Wang Yiping.Review of long period fiber gratings written by CO2laser[J].Journal of Applied Physics,2010,108(8):081101-1-081101-18.

[4] Davis D D,Gaylord T K,Glytsis E N,et al.Long-period fibre grating fabrication with focused CO2laser pulses[J].Electronics Letters,1998,34(2):302-303.

[5] Rao Yunjiang,Wang yiping,Ran Zengling,et al.Novel fiber-optic sensors based on long-period fiber gratings written by high-frequency CO2laser pulses[J].Journal of Lightwave Technology,2003,21(2):1320-1327.

[6] Rao Yunjiang,Zhu Tao,Ran Zengling,et al.Novel longperiod fiber gratings written by high-frequency CO2laser pulses and applications in optical fiber communication[J].Optics Communications,2004,229(1/2/3/4/5/6):209-221.

[7] Wang Yiping,Rao Yunjiang,Ran Zengling,et al.Bendinsensitive long-period fiber grating sensors[J].Optics and Lasers in Engineering,2004,41(1):233-239.

[8] Hwang I K,Yun S H,Kim B Y.Long-period fiber gratings based on periodic microbends [J].Optics Letters,1999,24(18):1263-1265.

[9] Kondo Y,Nouchi K,Mitsuyu T,et al.Fabrication of long-period fiber gratings by focused irradiation of infrared femtosecond laser pulses[J].Optics Letters,1999,24(10):646-648.

[10] Savin S,Digonnet M J F,Kino G S,et al.Tunable mechanically induced long-period fiber gratings[J].Optics Letters,2000,25(10):710-712.

[11] Lin C Y,Chern G W,Wang L A.Periodical corrugated structure for forming sampled fiber Bragg grating and longperiod fiber grating with tunable coupling strength [J].Journal of Lightwave Technology,2001,19(8):1212-1220.

[12] Knight J C,Birks T A,Russell P S,et al.All-silica single-mode optical fiber with photonic crystal cladding [J].Optics Letters,1996,21(19):1547-1549.

[13] Eggleton B J,Westbrook P S,Windeler R S,et al.Grating resonances in air-silica microstructured optical fibers[J].Optics Letters,1999,24(21):1460-1462.

[14] Eggleton B J,Westbrook P S,White C A,et al.Cladding-mode-resonances in air-silica microstructure optical fibers[J].Journal of Lightwave Technology,2000,18(8):1084-1100.

[15] Wang Yiping,Xiao Limin,Wang D N,et al.In-fiber polarizer based on a long-period fiber grating written on photonic crystal fiber[J].Optics Letters,2007,32(9):1035-1037.

[16] Wang Yiping,Xiao Limin,Wang D N,et al.Highly sensitive long-period fiber-grating strain sensor with low temperature sensitivity [J].Optics Letters,2006,31(23):3414-3416.

[17] Humbert G,Malki A,Fevrier S,et al.Electric arc-induced long-period gratings in Ge-free air-silica microstructure fibres[J].Electronics Letters,2003,39(4):349-350.

[18] Fu L B,Marshall G D,Bolger J A,et al.Femtosecond laser writing Bragg gratings in pure silica photonic crystal fibres[J].Electronics Letters,2005,41(11):638-640.

[19] Groothoff N,Canning J,Buckley E,et al.Bragg gratings in air-silica structured fibers [J].Optics Letters,2003,28(4):233-235.

[20] Wang Y,Bartelt H,Becker M,et al.Fiber Bragg grating inscription in pure-silica and Ge-doped photonic crystal fibers[J].Applied Optics,2009,48(11):1963-1968.

[21] Wang Y,Bartelt H,Ecke W,et al.Sensing properties of fiber Bragg gratings in small-core Ge-doped photonic crystal fibers[J].Optics Communications,2009,282(6):1129-1134.

[22] Rao Yunjiang,Zeng Xiangkai,Zhu Yong,et al.Temperature-strain discrimination sensor using a WDM chirped in-fibre Bragg grating and an extrinsic fabry-perot[J].Chinese Physics Letters,2001,18(5):643-645.

[23] Zhu Y,Shum P,Chong J H,et al.Deep-notch,ultracompact long-period grating in a large-mode-area photonic crystal fiber[J].Optics Letters,2003,28(24):2467-2469.

[24] Zhu Y,Shum P,Bay H W,et al.Strain-insensitive and high-temperature long-period gratings inscribed in photonic crystal fiber[J].Optics Letters,2005,30(4):367-369.

[25] Jin Long,Jin Wei,Ju Jian,et al.Coupled local-mode theory for strongly modulated long period gratings[J].Journal of Lightwave Technology,2010,28(12):1745-1751.

[26] Wang Yiping,Jin Wei,Jin Long,et al.Optical switch based on a fluid-filled photonic crystal fiber Bragg grating[J].Optics Letters,2009,34(23):3683-3685.

[27] Iredale T B,Steinvurzel P,Eggleton B J.Electric-arc-induced long-period gratings in fluid-filled photonic bandgap fibre[J].Electronics Letters,2006,42(13):739-740.

[28] Wang Yiping,Tan Xiaoling,Jin Wei,et al.Improved bending property of half-filled photonic crystal fiber[J].Optics Express,2010,18(12):12197-12202.

[29] Wang Yiping,Tan Xiaoling,Jin Wei,et al.Temperaturecontrolled transformation in fiber types of fluid-filled photonic crystal fibers and applications[J].Optics Letters,2010,35(1):88-90.

[30] Wang Yiping,Liu Shujing,Tan Xiaoling,et al.Selectivefluid-filling technique of microstructured optical fibers[J].Journal of Lightwave Technology,2010,28(22):3193-3196.

[31] Jin Long,Wang Zhi,Fang Qiang,et al.Bragg grating resonances in all-solid bandgap fibers[J].Optics Letters,2007,32(18):2717-2719.

[32] Wang Yiping,Jin Wei,Ju Jian,et al.Long period gratings in air-core photonic bandgap fibers[J].Optics Express,2008,16(4),2784-2790.

[33] Jin Long,Jin Wei,Ju Jian,et al.Investigation of longperiod grating resonances in hollow-core photonic bandgap fibers[J].Journal of Lightwave Technology,2011,29(11):1707-1713.

[34] Wang Y,Bartelt H,Ecke W,et al.Thermo-optic switching effect based on fluid-filled photonic crystal fiber [J].IEEE Photonics Technology Letters,2010,22(3):164-166.

[35] Wang Y,Bartelt H,Ecke W,et al.Investigating transverse loading characteristics of microstructured fiber Bragg gratings with an active fiber depolarizer[J].IEEE Photonics Technology Letters,2009,21(19):1450-1452.

[36] Wang Y,Bartelt H,Brueckner S,et al.Splicing Gedoped photonic crystal fibers using commercial fusion splicer with default discharge parameters[J].Optics Express,2008,16(10):7258-7263.

[37] Xiao L,Demokan M S,Jin W,et al.Fusion splicing photonic crystal fibers and conventional single-mode fibers:microhole collapse effect[J].Journal of Lightwave Technology,2007,25(11):3563-3574.

[38] Wang Yiping,Jin Wei,Wang D N.Strain characteristics of CO2-laser-carved long period fiber gratings[J].IEEE Journal of Quantum Electronics,2007,43(2):101-108.

[39] Wang Yiping,Wang D N,Jin Wei,et al.Asymmetric long period fiber gratings fabricated by use of CO2laser to carve periodic grooves on the optical fiber[J].Applied Physics Letters,2006,89(15):151105-1-151105-3.

[40] Shin W,Lee Y L,Eom T J,et al.Temperature insensitive strain sensor based on long period fiber grating pair in photonic crystal fibers[C] //The 14th International Conference on OptoElectronics and Communications.Hong Kong:IEEE Press,2009,1-2.

[41] Zhao Chunliu,Xiao Limin,Ju Jian,et al.Strain and temperature characteristics of a long-period grating written in a photonic crystal fiber and its application as a temperatureinsensitive strain sensor[J].Journal of Lightwave Technology,2008,26(2):220-227.

[42] Wang Yiping,Jin Wei,Wang D N.Unique temperature sensing characteristics of CO2-laser-notched long-period fiber gratings [J].Optics and Lasers in Engineering,2009,47(10):1044-1048.