Physicochemical,microbiological and sensory characteristics of irradiated pale,soft,exudative(PSE)pork

LIU Xian-de PIAO Ling-hua

(1.College of Agriculture,Hainan University,Haikou,Hainan570228,China;2.College of Preclinical Medicine,Hainan Medical University,Haikou,Hainan571199,China)

1 Introduction

Irradiation of meat provides consumers a reduced risks from pathogens and parasites.Radiolytic products produced from irradiated meat are neither unique nor toxicologically significant(Thayer,1994).Therefore,irradiation is best method to control microorganisms over any other non-heat treatment pasteurization.However,Murano(1995)reported that radiolysis of myoglobin and lipids by irradiation could lead to discoloration and rancidity or other off-odor production.Apart from microbial spoilage,lipid oxidation is the primary process by which quality loss of muscle food occurs(Buckley,Morrissey,&Gray,1995).

Initiators of lipid oxidation in irradiated meat are hydroxyl radicals generated by the interaction of ionizing energy with water molecules in muscle tissues or in meat products(Thakur &Singh,1994).Regardless of packaging type,irradiated raw pork patties produced more volatiles than nonirradiated ones and developed a characteristic aroma immediately after irradiation(Ahn,Olson,Jo,et al,1998).The odor of irradiated meat was also characterized as a barbecued corn-like odor(Ahn,Jo,Olson,et al,2000).The degree of color changes of irradiation was depended on animal species,muscle type and location in muscle,but are commonly related to the oxygen availability of meat at the time of irradiation and during storage.Jo,Jin,Ahn,et al(2000)also found the color was changed to the red from the processed meat products by irradiation after long term frozen storage.

Pale,soft,exudative meat,or PSE meat,describes a carcass quality condition known to occur in both pork and poultry.It is characterized by an abnormal color,consistency,and water holding capacity,making the meat dry and unattractive to consumers.The condition is believed to be caused by abnormal muscle metabolism following slaughter,due to an altered rate of glycolysis and a low pH within the muscle fibers.Genetic predispositions and stress levels prior to slaughter are known to affect the incidence of PSE meat(Adzitey &Nurul,2011).The ultimate pH of meat is also known to be a key factor of meat quality.Depending on the ultimate pH and color of meat,pork can be classified as normal,pale-soft-exudative(PSE),or dark-firm-dry(DFD).The distribution and proportion of free and bound water in normal,PSE and DFD pork are different,and their biological membrane function should be different as important barriers to deteriorative changes that can affect meat quality(Stanley,1991).PSE pork could be more susceptible to oxidative changes and could produce more off-flavor volatiles than normal or DFD meat on irradiation because of its denatured muscle membrane structure.Chen and Waimaleongora-Ek concluded that the lower the pH values in the raw chicken meat samples,the higher the TBARS values.Ahn,Jo,Du,et al(2000)reported that vacuum packaging was better than aerobic packaging for irradiation and subsequent storage of meat because of it minimized oxidative changes in pork during storage.

The objective of this study was to determine and compare to the effects of irradiation on lipid oxidation,color,and sensory characteristics of PSE pork during storage at 4 ℃.

2 Materials and methods

2.1 Sample

The PSE pork was obtained from Livestock Packing Center at Gimje,Korea.The loin muscle(longissimus dorsi)from 4different carcasses were selected,which were apparently thought to be severing PSE pork by an expert meat grader.The sample was put into and ice box and transferred to laboratory.

2.2 Mechanical

Irradiation and dosimetry were performed using a Co-60 gamma irradiator(Point source,AECL,IR-79,Nordion International Co.,Ltd,Ontario,Canada)and 5 mm-diameter alanine dosimeters(Bruker Instruments,Rhienstetten,Germany).pH and color were measured by pH meter(Model 520A,Orion Research Inc.,Boston,MA 02129,USA)and Color Difference Mater(Spectrophotometer CM-3500d,Minolta Co.,Ltd,Osaka,Japan).The absorbance was measured using a spectrophotometer(UV 1600 PC,Shimadzu,Tokyo,Japan).Homogenized(DIAX 900,Heidolph Co.,Ltd.,Schwabach,Germany).Centrifuge(UNION 5KR,Hanil Science Industrial,Co.,Ltd.,Incheon,Korea).

2.3 Methods

2.3.1 Irradiation Irradiation was performed next morning using a Co-60gamma irradiator with a source strength of 100kCi.The dose rate was 70Gy/min at 16±0.5 ℃and the absorbed dose was 0and 4.5kGy.Dosimetry was performed using 5mm-diameter alanine dosimeters,and the free radical signal was measured using a Bruker EMS 104 EPR Analyzer.The actual dose was within ±2% of the target dose.The irradiated pork were transferred to a 4℃refrigerator or a freezer(-20℃)and analyses were performed during 2weeks.

2.3.2 pH and color measurement pH was measured by pH meter adding 9part of deionized distilled water(DDW)into 1part of the sample.

For color measurement,sample were cut into a cm-thick pieces and measured on the plate of the Color Difference Mater.The instrument was calibrated to standard black and white tiles before analysis.Eight pieces per treatment were measured and mean values were used for replication.A medium size aperture was used and the measurement was duplicated.The Hunter color L*-,a*-,and b*-values were reported through the computerized system using Spectra Magic Software(version 2.11,Minolta Cyberchrom Inc.Japan).

2.3.3 Lipid oxidation Lipid oxidation was determined as a 2-thiobarbituric acid reactive substances(TBARS)value by using a spectrophotometer.Five gram sample is homogenized in a 50mL centrifuge tube with a 50Lof BHA (7.2%in ethanol)and 15 mL of distilled water by using a homogenized.One milliliter of the homogenate was mixed with 2mL of a thiobarbituric acid(TBA)/trichloroacetic acid(TCA)solution(20mM TBA in 15% TCA),heated in boiling water,and centrifuge.The absorbance of the supernatant was measured at 532nm by using a spectrophotometer.The concentration(mg/kg sample on the basis of wet weight)was calculated by using a determination curve.

2.3.4 Microbial analysis Twenty five grams of sample was put into a sterile plastic bag and stomached with 225mL of 0.1% peptone solution at a high speed for 2 min.After serial dilutions,0.1 mL aliquots were plated onto a plate count agar for the total plate counts and onto eosin methylene blue agar for Escherichia coli counts by using a standard spread plate method.Duplicate plates for each sample were incubated at 30 ℃for 48hfor the total plate counts and 37 ℃for 48hfor the E.coli counts.

2.3.5 Sensory evaluation Sensory analysis was performed with 10panel members,who were semi-trained and accustomed to the color and flavor of the normal pork before analysis.Sensory scores were evaluated with a 7-point scale:1,very poor through 7,very good.The sensory parameters including flavor and color were evaluated independently by the panel members at 3different times using raw sliced pork.

2.3.6 Statistical analysis Analyses of variance were performed using SAS software and Student-Newman-Keul’s multiple range tests was used to compare differences among mean values.Mean values and standard deviation were reported,and the significance was defined at P<0.05.

3 Results and discussion

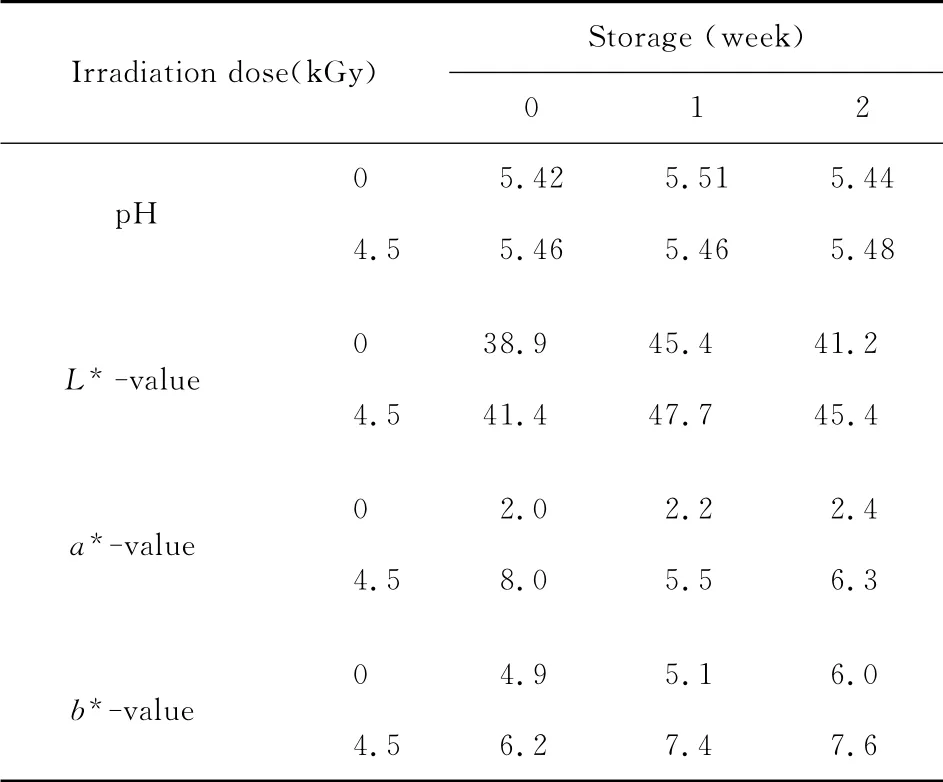

3.1 pH and color

The pH values of non-irradiated and 4.5kGy irradiated PSE raw pork loin were not different(Table 1).The original ultimate pH was also maintained during 2weeks of storage.The ultimate pH of the sample was 5.42-5.46,which better than that of normal pork(pH 5.6-5.8)and was agreed well to the pale appearance of the sample when collected.Nam,Du,&Jo(2002)also demonstrated that irradiation of normal,PSE and DFD pork showed no effect on the pH of all three pork types.

Table 1 pH and Hunter color values of irradiate pale-softexudative(PSE)pork loin during storage at 4 ℃

Hunter color L*-value of irradiated meat was not changed during storage except for the sample at 2 weeks storage at 4 ℃ (Table 1). However, Hunter color a*-value,which represents redness of meat surface showed significant increase in the irradiated pork loin at 4.5kGy.This higher Hunter color a*-value maintained stable during 2 weeks of storage.The Hunter color b*-value also increased the surface meat color by irradiation.Jo,et al(2000)reported that a*-valued of the surface of irradiated sausage without sodium nitrite were increased as a dose dependent manner.Previous studies also indicated that irradiation increased redness of pork in vacuum packaging state (Luchsinger,Kropf,Garcia,et al,1996;Nanke,Sebranek,& Olson,1998).Nam,et al(2002)reported that the a*-value in normal,PSE,and DFD pork with vacuum packaging decreased after 5days of storage,but increased after 10days of storage.The authors discussed this phenomenon as the residual oxygen in the vacuum packaging bag could have oxidized myoglobin at the early part of the storage time.

3.2 Lipid oxidation

The 2-thiobarbituric acid reactive substances(TBARS)value of PSE pork loin was ranged from 0.37to 0.40and there was no difference between non-irradiated and irradiated sample(Fig.1).

Figure 1 2-thiobarbituric acid reactive substances(TBARS)value of irradiated pale-soft-exudative(PSE)pork loin during at 4 ℃

The storage effect was also not found.DFD pork was stable and resistant to both irradiation and storage in terms of quality of pork(Nam,et al,2002).Yasosky,Aberle,and Peng(1984)reported that the ultimate pH of ground pork was negatively correlated with the TBARS value of pork after 12days of storage at 2 ℃.Low pH values in meat play an important role in lipid oxidation by denaturing antioxidant proteins,disrupting cell structure,and exposing membrane lipids to free radicals.The distribution of water and its location,where hydroxyl radicals are formed by irradiation and storage,could be critical for the irradiation-dependent reaction.Therefore,it was expected that the denatured membrane structure of PSE pork would make it more susceptible to lipid oxidation than normal pork.However,there was no difference found in the present study.

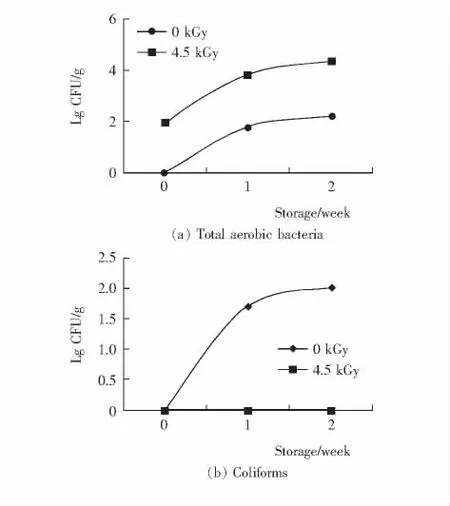

3.3 Microbial quality

The original microbial contamination was about 1.14×102CFU/g in meat.The number of total aerobic bacteria increased during storage for 2weeks(Fig.2).After 2weeks,the total aerobic bacterial count reached to 6.0×104CFU/g.Irradiation at 4.5kGy significantly reduced the number of total aerobic bacteria.At week 0,bacteria were not detected but after 1and 2weeks,the bacterial number was increased.However,approximately 2log reduction was achieved by irradiation of 4.5kGy during 2 weeks of storage when compared with non-irradiated control.

Figure 2 The number of total aerobic bacteria and coliforms in irradiated pale-soft-exudative(PSE)pork loin during storage at 4 ℃

Irradiation is known to be the best method for the control of potentially pathogenic microorganisms in raw meat(Farkas,1998).Because of irradiation’s effectiveness in controlling common food-borne pathogens and treating packaged food,thereby minimizing the possibility of cross contamination prior to consumer use,most food safety officials critical control point in a Hazard Analysis and Critical Control Points(HACCP)system was established for meat and poultry processing(Satin,2002).Application of gamma radiation up to a dose level of 10kGy can be used to eliminate or greatly reduce the numbers of food spoilage microorganisms as well as food-borne pathogens in food products without compromising the nutritional or sensory quality (Abu-Tarboush,Al-Kahtani,Abou-Arab,et al,1996;Youssef,1994).Jo,Lee,Kang,et al(2005)reported that the range of the D10value was from 0.24to 0.45among the 4strains including Staphylococcus aureus, Listeria ivanova,Salmonella Typhimurium,and Escherichia coli.

3.4 Sensory quality

Sensory analysis was conducted for the parameters of color and flavor because this study was only tested for raw meat state.Sensory panelists prefer the color of irradiated PSE meat which showed redder than that of non-irradiated control(Fig.3).

Figure 3 Sensory preference of irradiated pale-soft-exudative(PSE)raw pork loin during storage at 4 ℃

This provides a possibility that irradiation may be used to improve color of PSE meat if other quality characteristics after irradiation are not significantly changed.The significant difference was found until 1week storage but the difference was not found at 2week.Odor preference between non-irradiated and irradiated PSE meat was not shown in all storage period(P>0.05).Usually irradiation of meat produces characteristic irradiation odor since S-containing volatile compounds are produced by irradiation treatment.As the irradiation odor intensity increased,the preference of meat odor decreased(Nam,et al,2002).Hashim,Resurrection,&Macwatters(1995)showed that irradiating uncooked chicken breast and thigh produced a characteristic bloody and sweet aroma that remained after the thighs were cooked,but was not detectable after the breasts were cooked.Nam,et al(2002)reported that panelist could easily distinguish odors of irradiation but not among normal,PSE,and DFD meat types.However,Ahn,et al(2000)reported that panelists detected irradiation odor from irradiated pork loin and described it as a‘barbecued corn-like’odor but no objection to the odor was observed.Other scientist also indicated that the lipid oxidation was increased by irradiation in fermented food,but this was not unacceptable(Kim,Jang,Song,et al,2008;Song,Kim,Yun,et al,2009).

4 Conclusion

Form the results it is possible to useful irradiation technology to improve not only microbiological safety but also the color of meat,which has severe defect such as PSE.However,the considerable assessment of meat quality should be tested before its application for industry.Though we known that irradiation may improve the color of PSE meat but,mechanisms is unclear.Therefore,further investigation is needed to evaluate protein modification after irradiation,which probably is associated with meat color change.

1 Abu-Tarboush H M,Al-Kahtani H A,Abou-Arab A A,et al.Sensory and microbial quality of chicken as affected by irradiation and post-irradiation storage at 4 ℃[J].Journal of Food Protection,1996(60):761~770.

2 Adzitey F,Nurul H.Pale soft exudative(PSE)and dark firm dry(DFD)meats:causes and measures to reduce these incicences–a mini review[J].International Food Research Journal,2011(18):11~20.

3 Ahn D U,Jo C,Olson D G,et al.Analysis of volatile components and the sensory characteristics of irradiated raw pork[J].Meat Science,2000(54):209~215.

4 Ahn D U,Olson D G,Jo C,et al.Effect of muscle type,packaging,and irradiation on lipid oxidation,volatile production,and color in raw pork patties[J].Meat Science,1998(49):27~39.

5 Ahn D U,Jo C,Du M,et al.Quality characteristics of pork patties irradiated and stored in different packaging and storage conditions[J].Meat Science,2000(54):205~209.

6 Buckley D J,Morrissey P A,Gray J I.Influence of dietary vitamine E on the oxidative stability and quality of pig meat[J].Journal of Animal Science,1995(73):3 122~3 130.

7 Farkas J.Irradiation as a method for decontamination food A review[J].International Journal of Food Microbiology,1998(44):189~204.

8 Hashim I B,Resurrection A V A,Macwatters K H.Disruptive sensory analysis of irradiated frozen or refrigerated chicken[J].Journal of Food Science,1995(60):664~666.

9 Jo C,Jin S K,Ahn D U.Color changes in irradiated pork sausage with different fat sources and packaging during storage[J].Meat Science,2000(55):107~113.

10 Jo C,Lee N Y,Kang H,et al.Inactivation of pathogens inoculated into prepared seafood products for manufacturing Kimbab,a steamed rice rolled by dried seaweed,by gamma irradiation[J].Journal of Food Protection,2005(68):396~402.

11 Kim B,Jang A,Song H P,et al.Microbiological quality of Myungran Jeotkal and its ingredients and improvement of shelf stability by gamma irradiation[J].Journal of Korean Food Preservation,2008(15):606~611.

12 Luchsinger S E,Kropf D H,Garcia C M,et al.Color and oxidative rancidity of gamma and electron beam-irradiated boneless pork chops[J].Journal of Food Science,1996(61):1 000~1 005.

13 Murano P S.Quality of irradiated foods[M].Food Irradiation:A sorcebook,Ames,Iowa,Iowa State University Press,1995.

14 Nam K C,Du M,Jo C.Effect of ionizing radiation on quality characteristics of vacuum-packaged normal,Pale-soft-exudative,and dark-firm-dry pork[J].Innovative Food Sci.Emerging Technology,2002(3):73~79.

15 Nanke K E,Sebranek J G,Olson D G.Color characteristics of irradiated vacuum packaged pork,beef,and turkey[J].Journal of Food Science,1998(63):1 001~1 006.

16 Satin M.Use of irradiation for microbial decontamination of meat:situation and perspectives[J].Meat Science,2002(62):277~283.

17 Song H P,Kim B,Yun H,et al.Inactivation of 3-strain cocktail pathogens inoculated into Bajirak Jeotkal,salted,seasoned,and fermented short-necked clam(Tapes pilppinarum)by gamma and electron beam irradiation[J].Journal of Food Control,2009(20):580~584.

18 Stanley D W.Biological membrane deterioration and associated quality losses in food tissues[J].Critical Rev.Food Sci.Nutrition,1991(30):487~553.

19 Thakur B R,Singh R K.Food irradiation-chemistry and application[J].Food Rev.Internation,1994(10):437~473.

20 Thayer D W.Wholesomeness of irradiated foods[J].Food Technology,1994(148):132~135.

21 Yasosky J L,Aberle E D,Peng E D,et al.Effects of pH and time of grinding on lipid oxidation of fresh ground pork[J].Journal of Food Science,1984(49):1 510~1 512.

22 Youssef M B.Microbial flora of frozen beef burger as affected by gamma irradiation[J].Egypt.Journal of Microbiology,1994(29):105~113.