Auxetic Woven Fabrics — Pores' Parameters Observation

VYSANSKA Monika ,VINTROVA Petra

1 Department of Textile Technologies,Faculty of Textile Engineering,Technical University of Liberec,Liberec 46117,Czech Republic

2 Department of Design,Faculty of Textile Engineering,Technical University of Liberec,Liberec 46117,Czech Republic

Introduction

Word auxetic originates from the Greek word auxetos meaning“that which grows”.The first example of a synthetic auxetic occurred in the late 1980s when Roderic Lakes developed a route to convert conventional open-cell polyurethane foams into an auxetic form[1].

Auxetic materials are characterized with their negative Poisson's ratio value.This value is a negative ratio between transversal and axial deformation.Usually, the standard materials have the value of Poisson's ratio between 0 and 0.5,which means positive.For example the standard woven fabric samples are during straining process elongated in the direction of force and at the same time compressed in perpendicular direction.Their pores are probably getting smaller and smaller till the break.In this paper,woven fabrics will behave differently,because of their supposed auxetic character.

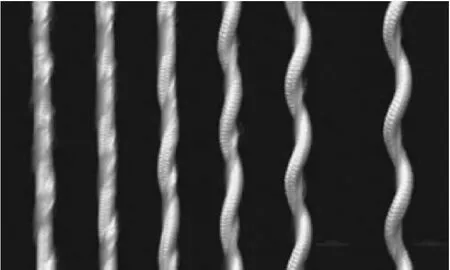

Hook et al.[2]from the University of Exeter produced a multifilament construction in which a high-stiffness filament was wrapped helically around a thicker,low-stiffness filament.Neither of the constituent filaments is required to be auxetic.The overall multifilament construction exhibits auxetic behavior upon stretching due to straightening of the high-stiffness filament causing the lower stiffness filament to helically wrap around it.This yarn calls a helical auxetic yarn (HAY)[3],see Fig.1.

Alderson et al.[1]from Bolton University found out,that auxetic fabrics could be used for“smart”bandage — capable of releasing a useful agent from within pores of the filaments making up the structure.Breathable fabric demonstrating increased porosity variation due to the high volume change associated with this unusual behavior.

Our contribution joins auxetic properties of HAY in three kinds of woven fabrics different in the waves and hopefully final auxetic fabric with expanding pores under the straining process.The benefit of presented work is hidden in a precise description of chosen pores' parameters and porosity changes during the tensioning.

1 Technology-Production of Auxetic Linear and 2D Textile Fabrics

1.1 Technology of HAY production

Two types of “single threads”were used for the final HAY,for core industrially produced polyester elastic band with the fineness of 922 tex and polypropylene multifilament yarn 2× 72 tex with preventive twist for sheet.The final linear product,HAY,see Fig.1,was produced by two-head braiding machine with 16 bobbins,see Fig.2.Just one bobbin carried multifilament yarn,and the core was fed manually.

Fig.1 Straining process of HAY yarn

Fig.2 Two-head braiding machine used for HAY production

1.2 Technology of woven fabrics production

Production of three kinds of woven fabrics with the HAY in weft direction was realized on a hand weaving loom with eight shafts,see Fig.3.

Fig.3 Hand weaving loom with eight shafts

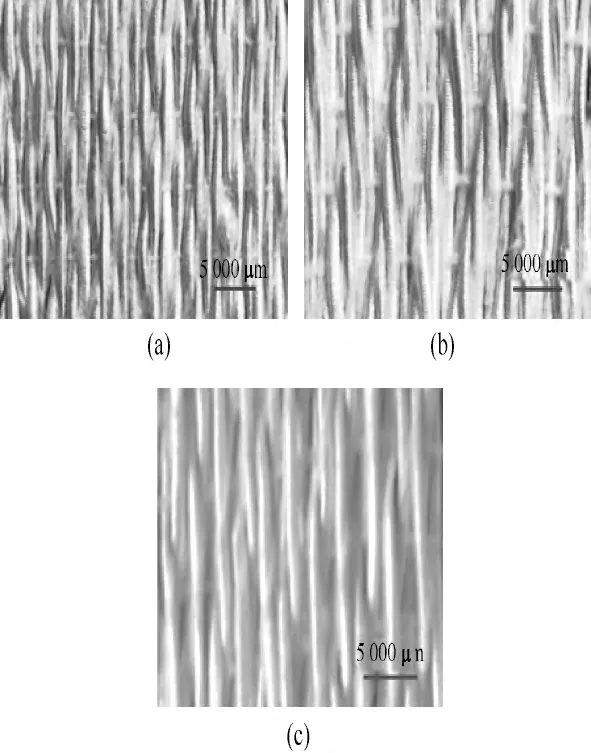

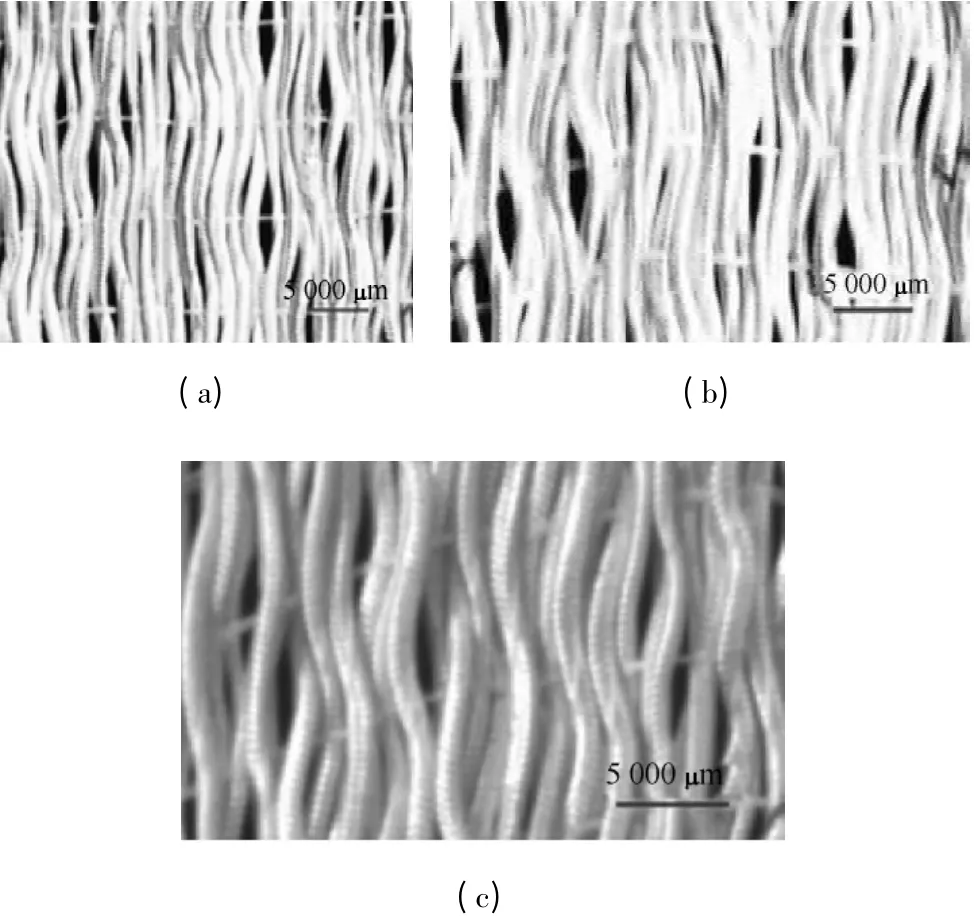

Final woven fabrics were in plain,2/2 twill,and 3/5 (3)satin pattern,always with polypropylene two ply multifilament yarn 2 ×72 tex in warp direction and with the warp sett of 2 threads/cm,and weft sett was always 9 threads/cm,see Fig.4.

Fig.4 Three kinds of woven fabrics:(a)plain,(b)2/2 twill,and (c)3/5 (3)satin pattern

2 Measurements

The auxetic character of the HAY was proved in Ref.[4].

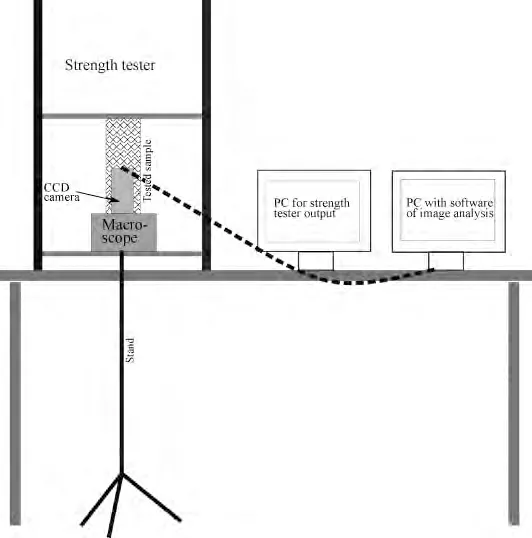

Made fabrics were tested on dynamometer Instron according to the Czech standard[5](rectangular sample with size of 5 cm × 30 cm,test speed 100 mm/min,and final gauge length 20 cm)and at the same time each 10th second scanned by CCD camera to the system of image analysis NIS Elements.Setting of the experiment is clear from Fig.5.

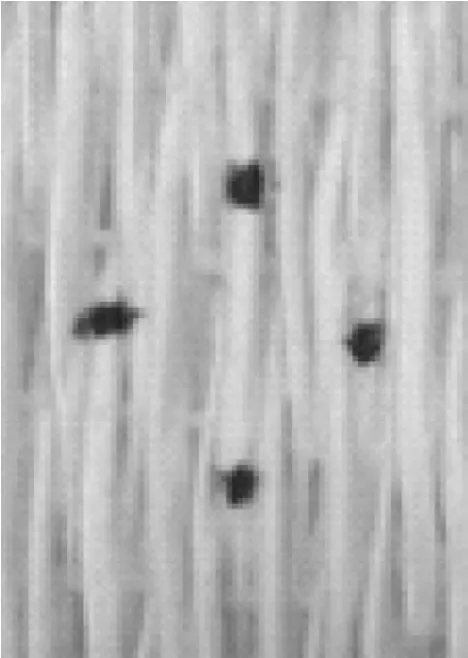

The auxetic character (negative Poisson's ratio of tested fabric during the straining process)of the woven fabrics with above-mentioned constructions was tested by the connection between dynamometer and image analysis.Four points(distance of each other is 1 cm at the beginning of the test)were drawn in the middle of each 5 cm ×20 cm sample,see Fig.6.

Finally Poisson's ratio values for the concrete deformation were calculated from the actual distances of points directly in the system of image analysis (Points were identified by threshold and then system of image analysis measured their coordinates).

The following parameters of pores were evaluated from the images in the system of image analysis:

(1)porosity:areal fraction,means total pores' area divided by measured area of woven fabric;

Fig.5 Sketch of whole experiment performance

Fig.6 Placement of four points for Poisson's ratio evaluation

(2)number of pores in m2;

(3)equivalent diameter of pore:diameter of circle with the same area like the pore has;

(4)the minimal Feret diameter:the minimal perpendicular distance of tangents to the pore's border;

(5)the maximal Feret diameter: the maximal perpendicular distance of tangents to the pore's border;

(6)circularity of pore:ratio between real area of pore and area of circle with the same perimeter.Circularity of circle is equal to 1.

All parameters were evaluated in each 10th second of the straining process by threshold of the color image of tested fabric to get its binary image.The system NIS Elements allow to analyze parameters of objects (for us pores)in binary image.System finds all objects on image defined by pixel number 1(pixel number 0 represents background)and automatically measures chosen parameters,see list of them above.

3 Results and Discussion

3.1 Proof of auxetic behavior

All three woven fabrics were tested under the same climatic and mechanical conditions with constant increment of displacement-deformation.Changes of their structure caused by deformation process are visible well from Fig.7,where three kinds of woven fabrics are scanned in around 40% of their deformation during the straining process.

Fig.7 Woven fabrics of (a)plain,(b)2/2 twill,and (c)3/5 (3)satin pattern in deformation of approximately 40%

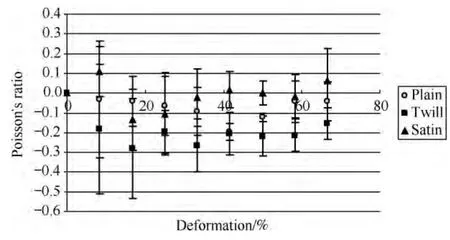

Figure 8 shows that somewhere around this deformation the progress of Poisson's ratio has its maximum.

Fig.8 Relation between Poisson's ratio and deformation

The most auxetic and stable (in all tested deformations)behavior according to the Poisson's ratio values we can observe for twill weave followed by plain and satin weaves.Just five samples were proved for each weave,so the intervals of confidence are relatively large.Nevertheless we can say plain and twill weaves have significantly different behavior from the third observed weave.The plain and twill weaves have similar behavior in point of view of Poisson's ratio.This fact can be probably caused by so called floating threads,a length of the HAY in a direction of acting force (weft direction)between two binding points,which have the same length for plain and twill pattern and are longer for satin weave.Differences between plain and twill patterns can be given by different interactions(caused by different patterns)between two systems of threads.

3.2 Analysis of stress-strain curve

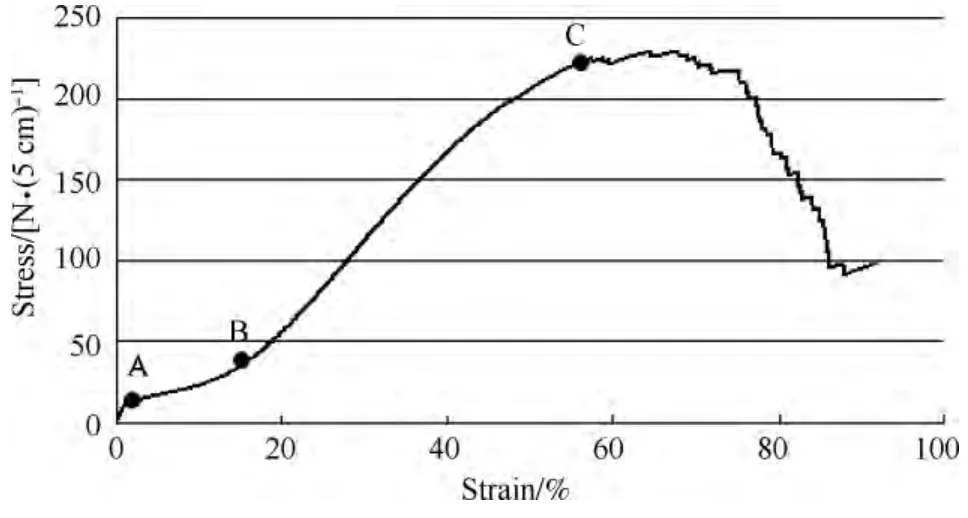

For explanation it is necessary to analyze the stress-strain process,curve respectively,see Fig.9.

Fig.9 Stress-strain curve of auxetic woven fabric with twill pattern

The progress of stress-strain curve looks similar (in case of important regions)for all tested patterns.At the beginning of auxetic woven fabric straining process 0-A,the fabric is stiff,what is probably caused by friction between two constituents of the HAY.Then linear region A-B follows,which represents decrimping of weft threads.The next part of stress-strain curve B-C shows the second linear part,where the HAYs are strained themselves and pores' size is expanded.The final part belongs to the breakage of thinner yarn in the HAY and relates straightening of the second part of the HAY.

The standard woven fabric is missing part 0-A and in region A-B the force is zero with increasing deformation,what is caused by decrimping of the yarns in fabric.It means huge decrimping of the threads of strained system followed by straightening of these threads,and there is probably no pores'expansion,because of the negative transversal deformation caused by standard yarn in this direction.

3.3 Pores' parameters

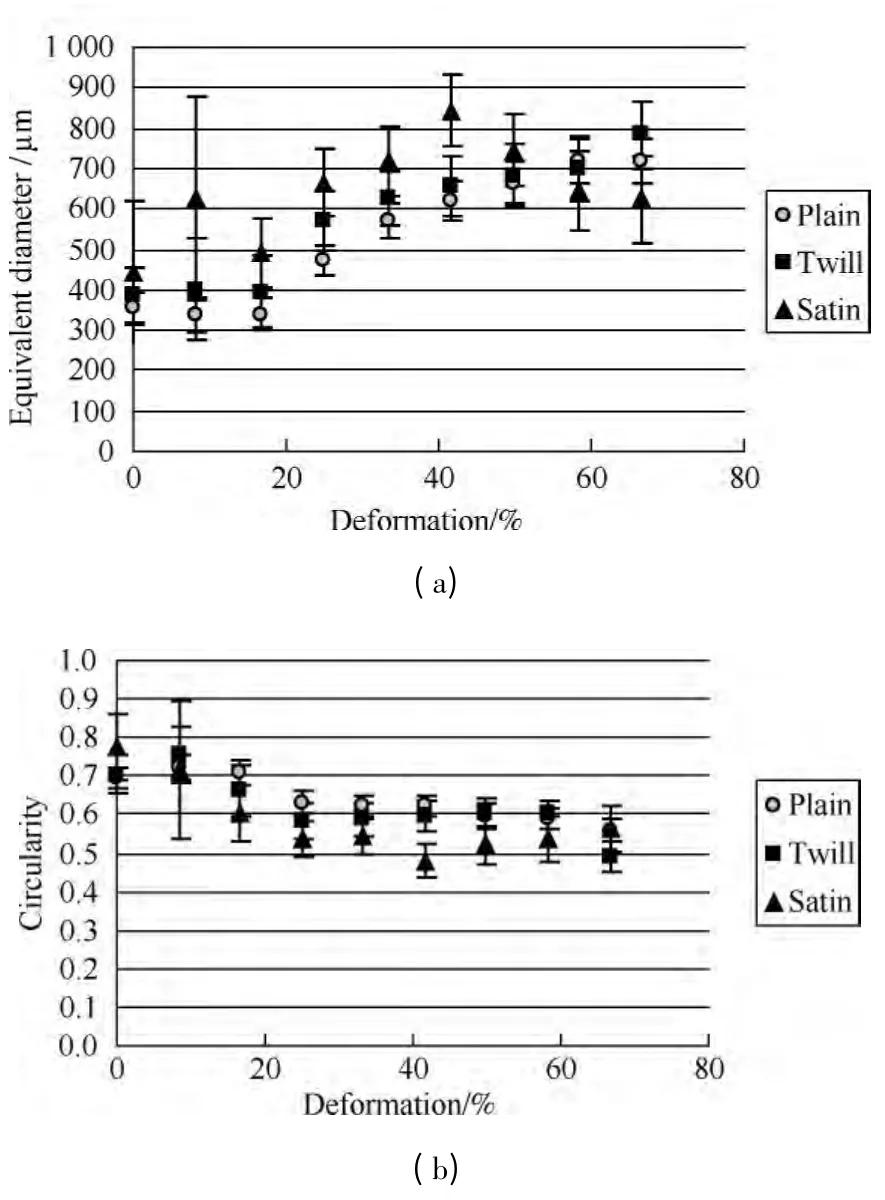

The pores' expansion is shown in Figs.10-12.

Fig.10 Geometrical parameters of the pores:(a)equivalent diameter and (b)circularity of pores

Let's start from the graph of the circularity progress on Fig.10(b).For all tested patterns the progress of circularity is till the deformation of approximate 20% constant,what is given by the stress-strain process,see explanation below Fig.9.Then the pores' circularity lightly decreases with increasing deformation, because of higher axial deformation than transversal one.

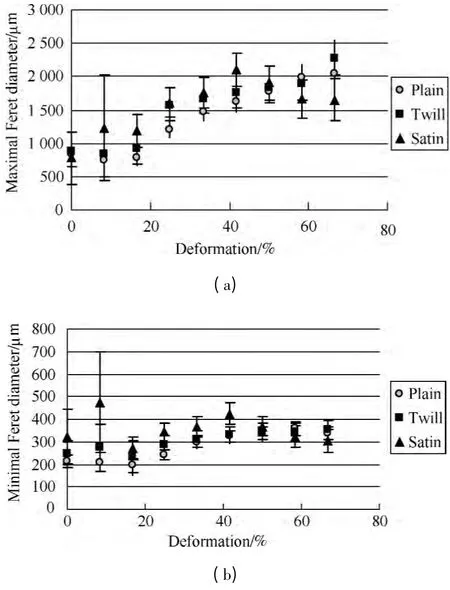

Fig.11 Geometrical parameters of the pores:(a)the maximal Feret diameter of pores and (b)the minimal Feret diameter of pores

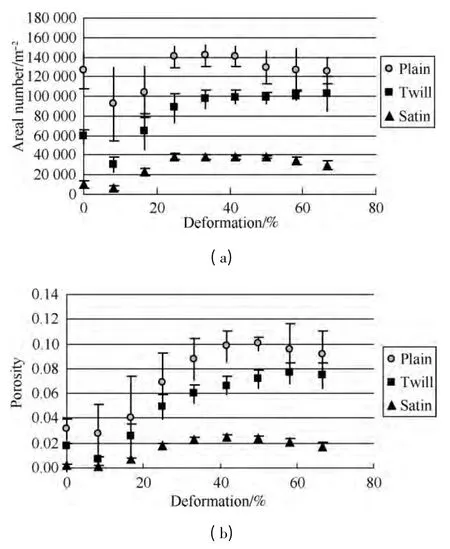

Fig.12 Geometrical parameters of the pores:(a)number of pores and (b)porosity

For all measured pores' parameters (except the circularity)the same progress in relation with deformation is valid,what originates from the stress-strain curves of auxetic woven fabrics and their explanation,see Fig.9.Pores' parameters are till approximately 20% of deformation almost constant,what is given by the process in auxetic fabric in areas 0-A and A-B,see Fig.9.After these regions the pores' parameters values increase,pores expand up to various levels of deformation,which depend on weave of fabric.

Interesting is also the comparison between deformation,the number of pores,and the porosity,respectively (Figs.12(a)and (b))and the pores' parameters (Figs.10(a),11(a),and 11(b)).The highest porosity has plain pattern,significantly different and lower porosity has twill,and finally the lowest has satin pattern.The pores' parameters behave by contraries.The biggest pores are located in satin woven fabric,then twill and finally in plain woven fabric.It is necessary to say,that these differences are not statistically significant.

3.4 Summary

For region 0-B of stress-strain curve (to about 20% of sample deformation)-decrimping is valid.

(1)Pores' size (represented by equivalent diameter,the minimal and the maximal Feret diameters)is according to Figs.10(a),11(a),and 11(b).Values are for all three tested patterns similar.

(2)Number of pores and porosity is almost constant.Both are higher for plain pattern followed by twill and satin patterns.

(3)Circularity has decreasing trend for all observed patterns,and the values are similar without any statistically significant differences.

So neither porosity,number of pores nor pores' parameters don't change during the decrimping process,pores just vary their shape from almost circular to almost elliptical.

For region B-C of stress-strain curve (from 20% to about 60% of sample deformation)- important for fabric auxetic behavior realization-can be observed.

(1)Pores' size increases till approximate 40% of fabric deformation,then slightly drops.This can be likely caused by a little buckling of auxetic structure (binding points don't stay on stable place during the straining process).This fact is observed for all tested patterns.The satin pattern has the bigger pores and smaller pores occur by plain pattern.But these differences are not statistically significant.

(2) For number of pores and porosity the opposite situation is valid.But there are statistically significant differences among the three observed patterns.The highest have plain pattern and the smallest figures have satin pattern.So plain pattern has the greatest number of pores and porosity but the smallest pores,and satin pattern behaves by contraries.

(3)The circularity of pores stays for all patterns constant-close to elliptical shape.

4 Conclusions

Three types of woven fabrics various in patterns were made with the HAY in weft direction.The auxetic behavior of these fabrics (with negative Poisson's ratio)was proved by special experiment with using of dynamometer and image analysis and consequent outputs synchronization.The stress-strain curves were analyzed and compared with standard woven fabric stressstrain progress.

Different auxetic behavior of three observed patterns doesn't statistically significantly manifest in pores' parameters,but is obvious on porosity.Plain pattern together with twill pattern behaves most auxetically,and satin pattern is statistically significantly less auxetic.

It is found that less auxetic behavior causes less porosity.Auxetic behavior of our structures is likely influenced by floating threads in a structure.Less auxetic structure has longer floating threads.They have more space in the woven structure for their transversal deformation than structures with short floating threads,which have to apply pressure on nearby threads to transversally deform themselves and finally transversally extend woven fabric.Less auxetic structure(satin)with longer floating threads embodies bigger pores'size and less circularity.

[1]Alderson A,Alderson K.Expanding Materials and Application:Exploiting Auxetic Textiles[J].Technical Textiles International,2005,14(6):29-34.

[2]Hook P B,Evans K E,Hannington J P,et al.Snapping Fabrics,KR20060009826[P].2006.

[3]Sloan M R,Wright J R,Evans K E.The Helical Auxetic Yarn— A Novel Structure for Composites and Textiles;Geometry,Manufacture and Mechanical Properties [J].Mechanics of Materials,2011,43(9):476-486.

[4]Vintrova P, Drasarova J.Knitted Auxetic Fabric [C].International Conference Strutex,Liberec,2011.

[5 ](800812)CˇSN EN ISO 13934-1 Areal Textiles.Measurement of Tenacity and Breaking Elongation in Tension [S].2000(Analogy to ASTM D5035-11 Standard Test Method for Breaking Force and Elongation of Textile Fabrics (Strip Method)).

Journal of Donghua University(English Edition)2013年5期

Journal of Donghua University(English Edition)2013年5期

- Journal of Donghua University(English Edition)的其它文章

- Electrospun Small Diameter Tubes to Mimic Mechanical Properties of Native Blood Vessels Using Poly(L-lactide-co-ε-caprolactone)and Silk Fibroin:a Preliminary Study

- Properties of Scaffold Reinforcement for Tendon Tissue Engineering in vitro Degradation

- Mineralized Composite Nanofibrous Mats for Bone Tissue Engineering

- Promoted Cytocompatibility of Silk Fibroin Fiber Vascular Graft through Chemical Grafting with Bioactive Molecules

- Fatigue Performance of Fabrics of Stent-Grafts Supported with Z-Stents vs.Ringed Stents

- Effect of Media on the in vitro Degradation of Biodegradable Ureteral Stent