隧道储罐泄漏气流扩散特征的可视化模拟算法研究*

房建东,赵智琦内蒙古工业大学金川校区,呼和浩特 010080

1.Introduction

With the fast development of industrial processes,the demand of hazardous gases gets increased in industry and other related industries as raw material or production of materials,the pressure of hazardous gas on the transportation vehicle gets increased in order to transport as more quantity of gas as possible at one time[1-2].Accidental release of hazardous gases often occurs due to the long distance,weather and other undetermined factors during the transportation process.Due to the toxic,flammable,explosive and other characteristics of hazardous gas,once the leakage occurs,it will cause serious damage and become a serious threat to the safety of personnel[3].Especially when the leakage of hazardous gases occurred in the tunnel,this situation will become more dangerous due to the explosive and flammable characteristics of gases.Since the tunnel is a kind of open road and the space in the tunnel is relatively small and closed,if the hazardous gases get fired,the temperature,concentration of harmful gas inside the tunnel will be expanded in a short period of time,and it might cause continuous combustion of vehicles or explosive chain reactions.Consequently,it might cause a great threat[4] to the life of passengers.Meanwhile,as an important transportation hub,tunnel fire will cause traffic disruption,long road congestion and big economic losses.In this paper,the real situation of tunnel is considered by using Fluent software,and the accident model for gas leakage was established and analyzed under the real circumstances.The main factors of airflow leakage diffusion were analyzed to understand the mechanism and occurrence of conditions about the accidental leakage.Therefore,this paper might provide a theoretical basis for the accident emergency rescue,and also could provide a reference to control and prevent the expansion of tunnel tank leakage damage and injury accidents[5].

2.Fluent simulation about the characteristics of airflow diffusion leaking from the tank in tunnel

Fluent software was used to simulate the distribution of the gas leakage in the tunnel.By solving the mass conservation equation and momentum conservation equations,the fluent constituted the basic framework to solve flow problems.

The conservation equation of mass could be written as follows:

Where,t represents the time,ρrepresents the density of fluid,u,v,w are the components of velocity vector in the x,y,z direction,respectively.

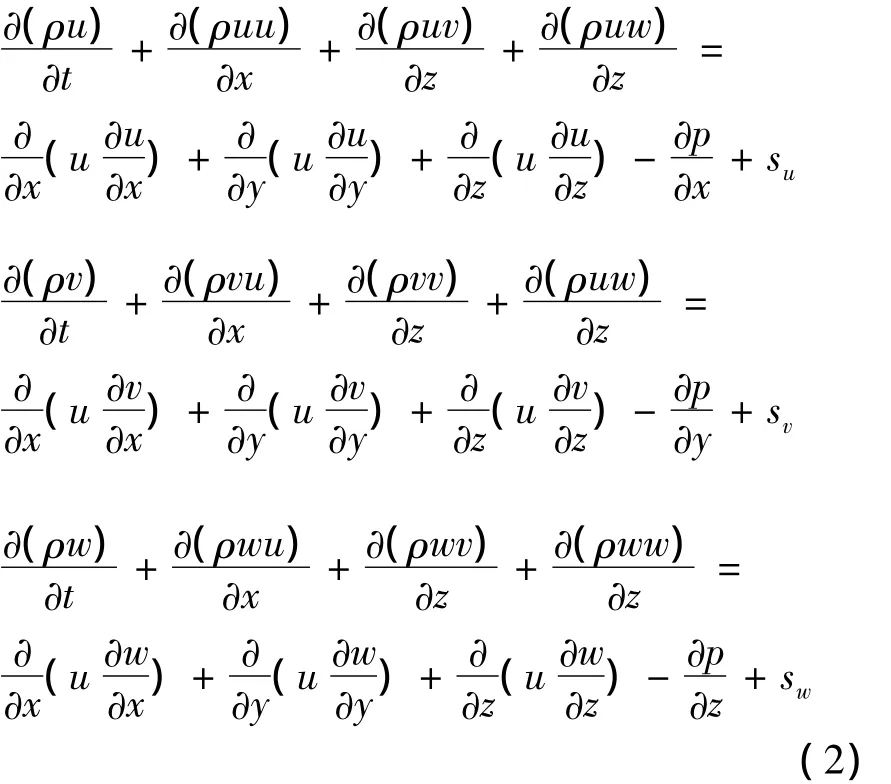

The conservation equations of momentum are as follows:

Where,u represents the dynamic viscosity;p is the pressure on the fluid micro unit;Su,Sv and Sw are the generalized source term of momentum equation.

2.1.Select the turbulence model

In the turbulent atmosphere,the air diffusion is controlled not only by the turbulence caused by its own gravitational settling,but also affected by the surrounding atmospheric turbulence,and this effect will build up as the diffusion goes on.The real environment is turbulent environment mostly,especially at the scene of accident,the environment is complex and the turbulence effect will be more obvious.Therefore,the establishment of air diffusion model in turbulent environment becomes very important for the research on gas leakage transportation.There are many models of turbulence such as Spalart-Allmaras,Reynolds stress,k- ε,and large eddy simulation[6].However,k- ε is widely used because it has the characteristics of processing the speed and length of the turbulent fluctuation simultaneously.k- ε could be classified as standard,overlapping technology and achievable.Standard k-εmodel is applicable to the initial iteration,design selection and parameter studies.Overlapping k-ε model is applicable to the complex shear flow which involves rapid strain,moderate vortex and local conversion,achievable k-εmodel has more accurate precisions than overlapping k-ε model in the real applications.According to the actual situation,the standard k-ε model is used in present paper.

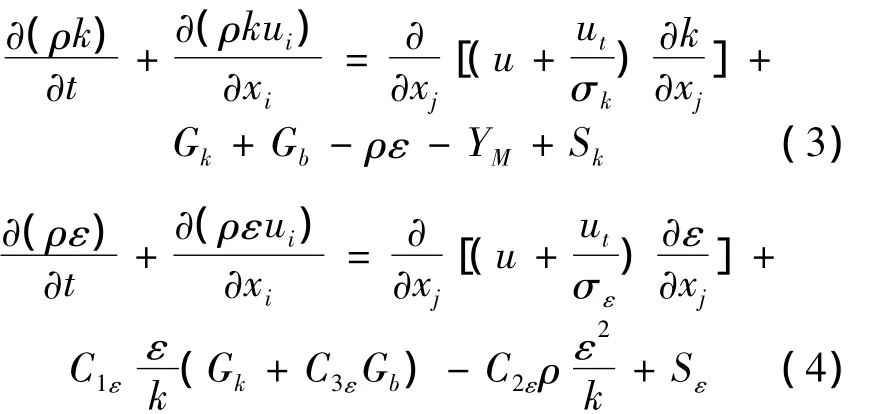

The transport equations of standard k-εmodel are as follows:

Where,Gkis produced by the turbulent kinetic energy which is caused by the average velocity gradient,and Gbis produced by the turbulent kinetic which is caused by the buoyancy influence.YMis the effect of compressible turbulent fluctuation expansion to the total dissipation law.C1ε,C2εand C3εare the empirical constants.In FLUENT default values for these parameters are as follows:C1ε=1.44,C2ε=1.92,C3ε=0.09;

2.2.Establish the geometric model and set the boundary condition

It is a non-steady-state diffusion process after the natural gas leaked and the gas concentration、turbulence intensity could be changed as the time goes by.Assume the fluid is homogeneous(i.e.,there is no phase change),the diffusion model of gas could be obtained.

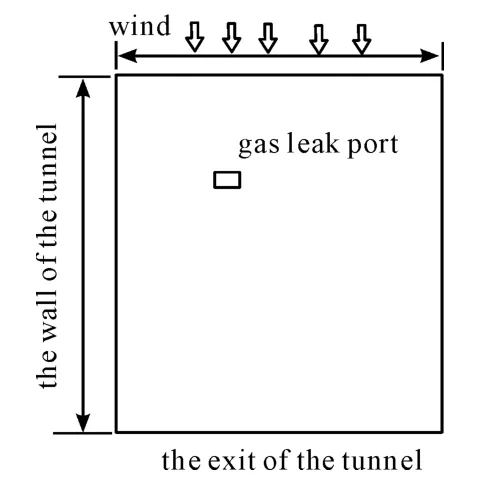

Before the airflow diffusion was simulated by Fluent,it is necessary to use Gambit to do some preparation[7]for the simulation inside a real tunnel.If the tunnel is along the direction of north to south and the leakage occurred at a distance of 9 meters close to the inlet.The drain port radius is 10 cm and the inlet velocity is 10 m/s.The geometrical model was shown in Figure 1.

Figure 1.The calculate area

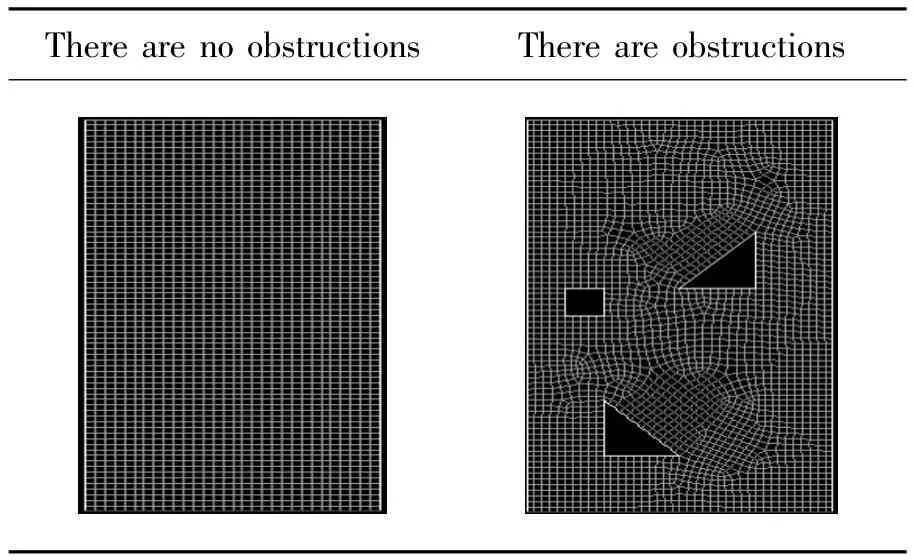

The mesh generated in XY plane is 10×50 by using Gambit based on the geometry as shown in Figure 1.The upper boundary is the inlet of tunnel and the boundary condition is set to Velocity-inlet.The left and right boundaries are the walls of tunnel and the boundary condition is set to Wall.The lower boundary condition is the exit of tunnel and the boundary condition is set to Pressure-outlet.The boundary condition of gas leakage port is set to Velocity-inlet.The boundary of obstacle is set to wall.The mesh model of this model is shown in Table 1.

Table 1.Meshing figure

2.3.Numerical simulation of the different factors about the characteristics of air diffusion leakage from the tank in tunnel

Since natural gas is a kind of multicomponent gas and it will mix with air during the leaking process,the Species Transport is used to simulate the leaking process of natural gas.This paper will simulate the spread of the leakage and it will not involve the chemical reaction,therefore,the chemical reaction model will not be activated[6].During the setting of boundary conditions,the temperature of gas at leakage port is 300 K and the mass concentration of component h2s is 0.029 and that of ch4is 0.971.The rate of gas leakage is 2.5 m/s,the turbulence intensity is 10 and the hydraulic radius is 0.2.The temperature of gas at the inlet is 300 K,the component of h2s and ch4remains 0.The velocity of inlet is 10 m/s,the turbulence intensity is 10 and the hydraulic radius is 5.The total pressure at the exit of tunnel is0,the turbulence intensity is10 and the hydraulic radius is 5.

1)The effect of different leakage time for natural gas leaking diffusion process is simulated in the following article.

Natural gas could become into the flammable gas when it is mixed with air.Then it will cause serious accidents such as fire or explosion when the mixture encounters a source of fire.The period of mixing time has a direct impact on the severity of the accident.Since the tunnel space is relatively closed,long time leakage of nature gas could cause a sharp increase of mass concentration for gas,and it will explode when the concentration of gas reaches the explosive limit and a fire source occurs at that time,therefore,the consequences could be disastrous.In order to avoid such disaster happen,the relationship between the concentration of the gas and the leakage time becomes very important to help people take the appropriate first aid treatments when the accident occurred.

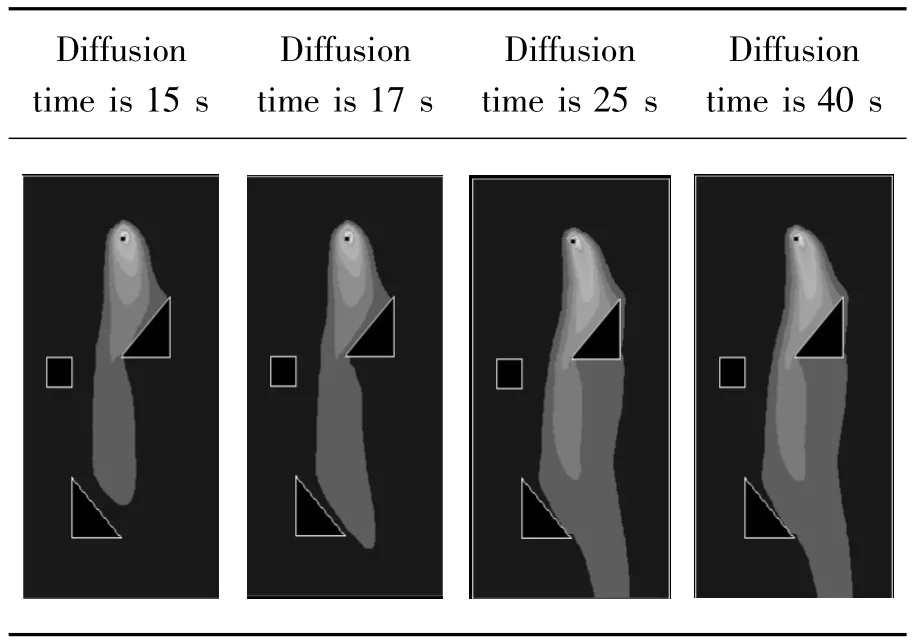

As shown in Table 2,the diffusion cloud of ch4 are presented at different diffusion times.

Table 2.The diffusion cloud of ch4

As shown in Table 2,the air velocity at inlet is 10 m/s,the rate of leakage is 2.5 m/s.At the beginning of gas leakage,distribution of the airflow diffusion concentration is more continuity and regularity,and the similar diffusion state with Gaussian model could be observed and the plume spread toward to the downwind.Over the time goes by,affected by the turbulence in the space field,the turbulence becomes apparent and the leaking airflow could diffuse throughout all the tunnel space,the concentration of gas could be gradually increased.After 20 seconds,the plume will fill out the tunnel.

2)The effect of obstacles for natural gas leak diffusion process is simulated in the following article.

Obstacle is an important factor affecting the airflow diffusion process.The shape and size of obstacle will directly influence the plume shape and turbulence effects during the airflow diffusion process.This paper placed some obstacles with different shapes and sizes in different place,the diffusion cloud of ch4 are shown in Table 3 at different times:

Table 3.The diffusion cloud of ch4 with obstacles

As shown in Table 3,the obstacles at exit could influence the diffusion of airflow.The leaked gas will bypass obstacles and diffuse along the outer contour of obstacles in the early stages of diffusion.With the development of airflow diffusion,the leakage of gas will eventually cross the obstacle[8].The obstacles at exit will enhance the turbulent of gas diffusion and the highest local concentration will appear around some obstacles.Meanwhile,the obstacles at exit will also increase the irregularities of airflow diffusion.

3)The effect of inlet velocity for natural gas leak diffusion process is simulated in the following article.

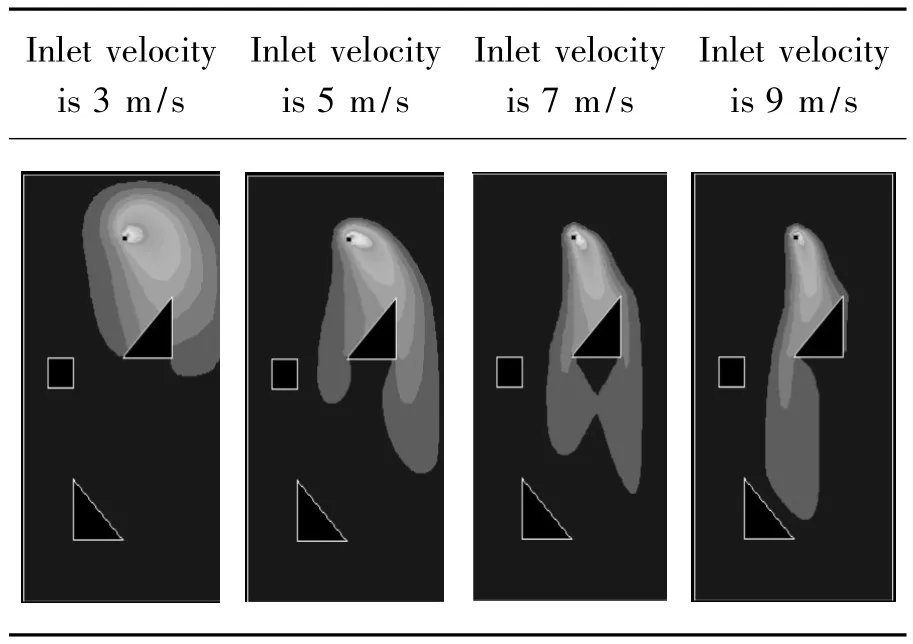

From the theoretical analysis,the advection transport of inlet wind plays a vital role in the airflow diffusion.Under the condition of tunnel with obstacles and the leakage rate of gas is 2.5 m/s,the diffusion of gas leakage with different inlet velocity were simulated.As shown in Table 4,the diffusion clouds of ch4 are presented with different inlet velocity at different time:

Table 4.The diffusion cloud of ch4 in different inlet velocity

As shown in Table 4,the diffusion process of airflow are presents when the inlet velocity is changed from 3 m/s to 9 m/s.With the increase of inlet velocity,the diffusion of airflow will be reduce in the lateral area and mainly spread along the longitudinal direction(i.e.,downwind direction),the irregularities of turbulent is more obvious.Meanwhile,the distance of diffusion could be increased with the increase of inlet velocity at the same diffusion time period,and the case of great local concentration will be reduced.The above simulation results show that the inlet velocity plays a decisive role for the diffusion distance and dispersion patterns of gas leakage.

3.Conclusion

This paper established a mathematical model by using Fluent for the leakage process of natural gas on the transportation vehicles,and provides a theoretical basis for the dangerous gas leakage accident occurred in the tunnel.The numerical simulation results showed that the parallel obstacles(the same direction as the wind direction)will hinder the diffusion of natural gas along the downwind direction in a large extent and the maximum concentration values at each point on the ground will be increased,but it will reduce the fluctuation range of the concentration.The different inlet velocity will directly affect the diffusion distribution of natural gas under the condition that leaked gas has the same concentration at the same diffusion time.The greater the wind speed,the farther the diffusion distance of airflow.Therefore,once the gas leakage occurred inside the tunnel,it is very important to promptly cut off the source of leakage and enhance the ventilation inside the tunnel to pre-vent the increase of gas concentration within the tunnel.

[1] Xuhai Pan,Chengjun Jiang.Statistical analysis of significant spills and accident patterns research[J].Chemical Industry and Engineering.2002,3(19):248-249.

[2] Hongjun Zhu,Yuanhua Lin.FLUENT 12 fluid analysis and engineering simulation[M].Beijing:Tsinghua University Press,2011,88-91.

[3] Xiuhai Pan,JunchengJiang.Risk analysis of hazard tank sudden spill for real-time environment[J].Journal of Environmental Sciences.2004,24(3):539-540.

[4] Jie Zhao,Sijing Ren,ChongxinCui.Dangerous operation robot manipulator control system design based on ARM[J].Industrial Instrumentation & Automation.2013,3:111-112.

[5] Weixing Xu,Shouqi Yuan.Submersible mixers stirring fluency analysis based on FLUENT[J].Mechanical Design and Manufacturing.2011,9:155-157.

[6] Chao Wang.Diffusion of atmospheric accidental release of dangerous chemicals[D].Dalian:The master’s degree thesis of Dalian Maritime University.2008:3-5.

[7] Zonghua Cheng,JianchunFan,Ming Du,Huan Jiang.Uncontrolled blowout toxic gas diffusion simulation based on FLUENT[J].China Safety Science and Technology.2013,9:24.

[8] Davies JK W.The CEc Major Technological Project BA:Research on Continuous and Instantaneous Heavy Gas Clouds.Journal of Hazardous Materials,1992(31):261-279.