一步可控合成二氧化硅纳米管和空心球

刘 旸 潘兆瑞 石翛然 郎雷鸣*,

(1南京晓庄学院环境科学学院,南京市功能材料重点实验室,南京 211171)

(2南京大学化学化工学院,生命分析化学国家重点实验室,南京 210023)

0 Introduction

In the past decades,much attention has been paid on hollow structure nanomaterials including nanotubes and nanospheres because they show unique optical,drug delivery,chemical storage,sensor and catalytic properties different from those of the corresponding bulk materials[1-6].Up to now,many inorganic oxide nanotubes and hollow spheres have been prepared successfully,such as SiO2[7-16],TiO2[17-19],ZrO2[20-21],Fe2O3[22-24].Among them,silica nanotubes and hollow spheres are of special interest due to their hydrophilic nature,easy colloidal suspension formation,surface functionalization and room-temperature light-emission characteristics in the visible range.Various approaches for the synthesis of silica hollow porous nanomaterials have been proposed[25-27].Some research groups use proper templates to fabricate silica nanotubes,for example,anodic aluminum oxide[9],nanowires[10-13]and multiwalled carbon nanotubes[14-15]and bio-templates[16].Compared with these template-based approaches,the synthetic methods including sol-gel,hydrothermal and microemulsion have been verified to be simple and effective to obtain silica nanotube[28-31].

Recently,Matsui′s[30]and Wang′s[31]groups used the simple organic small molecular acids including d/l-tartaric acid and citric acid (CA)as structuredirecting agent to prepare silica nanotubes by sol-gel method in an ethanol/water/NH3·H2O/TEOS reaction system.Zhu et al.[32]prepared InOOH hollow spheres by a simple CA assisted hydrothermal process.Although CA can be used to obtain the hollow structure inorganic oxide,controllable synthesis of silica nanotubes and hollow spheres in the same reaction system has never been reported.Herein,we report that different hollow structure silica nanomaterials can be achieved by the same sol-gel procedure using CA and ammonium citrate (AC)as a soft template,respectively,and propose the possible growth mechanism,where CA and AC play an important role in the formation of hollow spheres and tubes.This approach is simple,low-cost and suitable for environmentally friendly large-scale production.

1 Experimental

1.1 Materials

Tetraethyl orthosilicate (TEOS),citric acid(CA),ammonium citrate(AC),ammonium hydroxide(28%),ethanol(≥99.7%)were obtained from Sinopharm Chemical Reagent Co.,Ltd.All chemicals were of analytical grade without further purification.

1.2 Synthesis of silica nanotubes and hollow spheres

The silica nanotubes were synthesized by simple sol-gel method. Briefly,in a typical synthetic procedure,the mixed solution can be obtained by adding the 50 mL of ethanol to the 5 mL of aqueous solution containing of 1 mmol ammonium citrate.Then,1 mL of TEOS and 1.5 mL of NH3·H2O(28%aqueous solution)were added dropwise into the mixed solution successively under slow stirring at room temperature.The precipitate was centrifuged after 24 h,washed with distilled water and dried in an oven at 75℃.Finally,the product was calcined at 500 ℃ for 2 h to obtain silica nanotubes.For comparison,additional silica materials were also synthesized according to the similar procedure under different conditions.

The synthetic method of silica nanospheres is similar to that of nanotubes except that 1 mmol citric acid and 2.5 mL NH3·H2O were used.

1.3 Characterization

The morphologies of the catalyst were characterized by transmission electron microscopy(TEM)and high-resolution TEM(HRTEM)(Japan JEOL-2100,U=200 kV).SEM images and the energy dispersive spectrum(EDS)were obtained by a JEOL S-4800 apparatus (U=10 kV,I=10 mA).The phase purity of the products was characterized by X-ray powder diffraction (XRD)over a 2θ range of 10°~80°with a scanning rate of 5°·min-1(Shimadzu XD-3A X-ray diffractometer with Cu Kα radiation,λ=0.154 17 nm,U=40 kV,I=30 mA).The N2adsorption-desorption was measured by ASAP2020(Micromeritics,United States).

2 Results and discussion

The silica nanotubes were synthesized by simple sol-gel method using AC as a structure-directing agent in the mixed solution including ethanol and water.The morphology and microstructure of the sample were observed by scanning electron microscopy(SEM)and transmission electron microscopy (TEM).Fig.1 shows the SEM and TEM images of the prepared samples.The bundle-like silica nanotubes can be seen from the large scale SEM image (Fig.1a),where the average width of a single nanotube was about 250 nm.The magnified SEM image (Fig.1b)showed the obvious open tubular structure and some particles adhering on the surface of the nanotubes.After calcination at 500 ℃ for 2 h,no obvious change of the silica nanotubes morphology indicates the good stability of the tube-like structure(Fig.1c).TEM image provided an insight into the microstructure of product.Fig.1d shows the hollow porous structure of silica nanotubes clearly,where the thickness of the tube wall was about 20 nm.

The X-ray diffraction(XRD)analysis was used to determine the chemical composition and crystal structure of the sample.Fig.2a is the wide-angle X-ray diffraction (XRD)pattern of silica nanotubes over a range of 10°~80°.A broad peak at 20°~30°(2θ)corresponds to the amorphous SiO2.The energy dispersive spectrum (EDS,Fig.2b)showed that the atomic fraction of Si and O were 34.2%and 65.8%,respectively,matching the atomic ratio of Si and O for SiO2perfectly.The N2adsorption-desorption isotherm in Fig.2c showed a typeⅣcurve with a hysteresis loop,which indicates the porous characteristic of silica nanotubes.The specific surface area of silica nanotubes can be obtained by the calculation of BET(Brunauer-Emmett-Teller)method,which was about 27 m2·g-1.The pore distribution curve is showed in Fig.2d with a peak at about 3.4 nm,which might be attributed to the mesopores within the amorphous walls of nanotubes and nanoparticles.However,the relatively wide peak (Fig.2d)indicates the pores are not very uniform,which can be proved from further TEM investigations (Supporting Information,Fig.S1)and cause the small BET surface area finally.

In order to understand the possible formation process of silica nanotubes,it is very important to investigate the AC crystal morphology.The precipitate of AC crystals were rapidly obtained according to a similar process as for nanotubes preparation without TEOS (Fig.S2).The SEM images of obtained AC crystals showed that most of the crystals had thin pillar-like morphologies and gathered together due to the dry process(Fig.3a).The bundle structure of AC crystals can be seen from Fig.3b,which showed the similar morphology to silica nanotubes (Fig.1).According to the previous report about the ammonium tartrate crystals as the template for preparation of silica nanotubes[27],the AC crystal may act as a structuredirecting agent in the preparation of tubular morphologies.As shown in Fig.3c,the bundle AC crystals with many pillar-like fibers provided the substrate for silica colloids to form the tube wall.Then,the silica nanotubes were achieved by removing the inner crystal with water washing.On the basis of the above discussion,it can be concluded that formation of the silica nanotubes is due to the gradual aggradation of colloids on the surface of AC crystals.

Fig.2 XRD pattern(a)and EDS spectrum(b)of silica nanotubes;Nitrogen adsorption/desorption isotherm(c)and Barrett-Joyner-Halenda(BJH)pore size distribution(d)of silica nanotubes

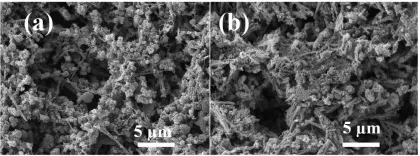

Fig.3 SEM images(a,b)of AC crystals and formation process of silica nanotubes(c)

It was believed that the ratio of water and ethanol plays an important role to control the morphology of silica samples.A plenty of nanoparticles were found in the mixed solution with a little amount of water (Fig.4a).With the increase content of water,more silica nanotubes generated (Fig.4b)and the desired nanotubes were prepared at the volume ratio of water and ethanol being 5:50 (Fig.4c).Further increasing the ratio of water,the morphology has no obvious change except the increase of diameter of nanotubes(Fig.4d).The possible reason for the effect of water amount is that the AC crystals show the morphology of nanoparticles in ethanol,while the thin pillar-like morphology in the mixed solution with the proper ratio of water and ethanol.The AC nanoparticles are major under a little amount of water.With the increase of water,AC nanoparticles can extend to the pillar-like morphology.Although AC is a soluble salt in water,it is not soluble in ethanol.The large amount addition of ethanol decreases the solubility of AC crystals in water greatly.What′s more,the amount of water is much less than the ethanol amount.Therefore,proper increase of water amount would benefit for the formation of silica nanotubes.The TEOS addition and stirring rate also have an influence on the silica morphology.When TEOS was mixed with the reaction solution rapidly,it hydrolyzed quickly to generate a large number of free nanoparticles,which was proved by SEM image in Fig.5a.The AC crystals could keep pillar-like morphologies in the solution under moderate stirring rate or static condition.However,it was easy to be disturbed by the external force of drastic stirring,which finally leaded to the compromised products of mixed nanoparticles and short nanotubes,rather than uniform nanotubes(Fig.5b).Therefore,the guided nucleation and outgrowth process of silica nanotubes need slow stirring rate.

The time-dependent evolution of the silica nanotubes was also investigated in our study,and Fig.6 shows SEM images of silica samples at different times.At the beginning stage of the reaction,some nanoparticles and a few of nanotubes were found(Fig.6a).With the reaction proceeding,silica nanotubes had an obvious increase (Fig.6b)because of the gradual aggradation of silica colloids.The uniform silica nanotubes were obtained when the reaction time is up to 12 h (Fig.6c)and did not grow up when the reaction time was prolonged to 24 h(Fig.6d).

Fig.4 SEM images of different silica samples prepared with various volume ratios of water and ethanol:(a)1∶50,(b)3∶50,(c)5∶50,(d)10∶50

Fig.5 SEM images of different silica samples under different reaction conditions:(a)fast addition,(b)drastic stirring

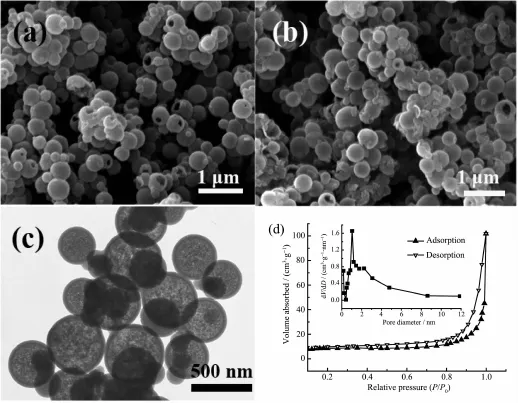

The synthetic method of silica nanotubes can be explored to prepare silica hollow spheres.SEM and TEM images show that the spheres had smooth surfaces and uniform diameters of~400 nm.Some broken openings of spheres could be seen clearly from Fig.7a and 7b.The nitrogen adsorption-desorption result indicates silica hollow spheres have the porous characteristics.The calculated BET surface area was about 29 m2·g-1and pore size is ~1.5 nm(Fig.7d),which can be verified by TEM image(Fig.7c).In terms of the formation process,the silica hollow spheres showed a minor difference with that of silica nanotubes.When we prepared the silica nanotubes,the initial template was AC crystals.But for the silica hollow spheres,CA was the starting material in the mixed solution.During this reaction,the CA reacted with the added NH3·H2O in the solution immediately to form AC crystal nanoparticles under continuous stirring,which served as the structure-directing agent to obtain the silica hollow spheres.Fig.S3 is the SEM image of the formed AC,which proves the sphere-like structure template for the formation of silica hollow spheres.

Fig.6 Time-dependent SEM images of silica samples at different times:(a)2 h,(b)6 h,(c)12 h,(d)24 h

Fig.7 SEM(a,b)and TEM(c)images of silica hollow spheres:(a)before and(b),(c)after calcination;(d)Nitrogen adsorption-desorption isotherm and Barrett-Joyner-Halenda(BJH)pore size distribution(inset)of silica hollow spheres

3 Conclusions

Novel uniform s ilica nanotubes and hollow spheres were synthesized controllably by a simple solgel process in the same reaction system.SEM,TEM images and N2adsorption-desorption isotherm show the prepared products had the obviously hollow porous structure.The formation process investigation of silica nanotubes discloses the gradual aggradation of silica colloids on the surface of AC crystals,which act as a template to construct the tubular structure.The different reaction conditions were also investigated for the synthesis of silica nanotubes.The results show that the optimum conditions are slow addition and stirring rate of TEOS,5:50 volume ratio of water and ethanol and 12 h reaction time.The silica hollow spheres can also be prepared in the same reaction system using CA instead of AC crystals,which show similar formation mechanism to that of silica nanotubes.The synthetic method is simple,green and suitable for large-scale production,which can also be employed to prepare other similar hollow structure metal oxides.

Supporting information is available at http://www.wjhxxb.cn