Experimental and numerical investigation of a self-supplementing dual-cavity plasma synthetic jet actuator

Borui ZHENG (郑博睿),Qian ZHANG (张倩),Taifei ZHAO (赵太飞),Guozheng SONG (宋国正) and Quanlong CHEN (陈全龙)

1 School of Automation and Information Engineering,Xi’an University of Technology,Xi’an 710048,People’s Republic of China

2 Science and Technology on Plasma Dynamics Laboratory,Air Force Engineering University,Xi’an 710038,People’s Republic of China

3 The Green Aerotechnics Research Institute of Chongqing Jiaotong University,Chongqing 401120,People’s Republic of China

Abstract The primary issue regarding the plasma synthetic jet actuator(PSJA)is its performance attenuation at high frequencies.To solve this issue,a self-supplementing,dual-cavity,plasma synthetic jet actuator (SD-PSJA) is designed,and the static properties of the SD-PSJA are investigated through experiments and numerical simulations.The pressure measurement shows that the SD-PSJA has two saturation frequencies (1200 Hz and 2100 Hz),and the experimental results show that both the saturation frequencies decrease as the volume of the bottom cavity of the SD-PSJA increases.As the size of the supplement hole increases,the first saturation frequency increases continuously,while the second saturation frequency shows a trend of first decreasing and then increasing.Numerical simulations show that the working process of the SD-PSJA is similar to that of the PSJA,but the volume of the cavity in the SD-PSJA is smaller than that of the PSJA;the SD-PSJA can supplement air to the top cavity through two holes,thus reducing the refresh time and effectively improving the jet intensity of the actuator at high frequencies.

Keywords:plasma flow control,plasma synthetic jet actuator,pressure measurements,numerical simulations

1.Introduction

The plasma synthetic jet actuator (PSJA) was first proposed in 2003.The basic working principle of the PSJA is to use a pulsed arc to heat rapidly and pressurize the air inside a semi-enclosed cavity,which induces high-speed jet ejection [1].The working process of the PSJA in a cycle consists of three stages: energy deposition,jet expulsion/cavity pressurization,and refresh.Compared with dielectric barrier discharge plasma actuators(DBD-PAs),arc discharge plasma actuators (AD-PAs) and traditional piezoelectric/piston synthetic jet actuators,the PSJA actuator has a simple structure(several electrodes,one cavity,and a lid),a high jet velocity(>500 m s-1)and a high response speed(in microseconds) [2-4].Therefore,the PSJA immediately attracted widespread attention in the field of plasma flow control[4-9].

When the total input power is constant,the frequency characteristics of the PSJA are mainly determined by its geometrical parameters.When the cavity volume increases,the Helmholtz natural oscillation frequency of the PSJA decreases,and the peak jet velocity declines due to the decrease in the nondimensional energy deposition [10,11].The energy converting efficiency of the PSJA decreases with an increase in the cavity volume because the temperature ratio can be reached after the energy deposition decreases and the temperature distribution in the cavity becomes more nonuniform [12,13].Although the PSJA can work at higher frequencies by reducing its cavity volume,insufficient mass flow in a single jet pulse will reduce the jet strength inevitably.

As the throat length increases,the peak jet velocity and jet delay time show a slight increase,while the pulsed thrust remains almost constant [14].The saturation frequency and jet strength of the PSJA obviously decrease with the increase of throat length due to the increase of the throat gas inertial drag and viscous drag.Therefore,decreasing the throat length can improve the performance of the PSJA in the repetitive working stage.As the hole diameter increases,the jet duration time decreases due to a higher mass flow rate,whereas the saturation frequency increases [10,14].More substantial perturbation can be achieved by the PSJA with a more oversized hole diameter,enhancing its jet strength [15].Therefore,for the high-frequency performance of the PSJA,the hole diameter should be increased.

Based on these reviews,to improve the limited working frequency of the PSJA,it is necessary to increase the refilling rate.The idea inspired us to add an extra reservoir to the conventional PSJA,which can store the pressurized air in the jet stage and supplement the cavity during the refresh stage.This novel design is a self-supplementing,dual-cavity,plasma synthetic jet actuator (SD-PSJA).In this work,we compare a PSJA and a SD-PSJA with the same cavity volume,and the effects of the bottom cavity volume and supplement hole diameter on the SD-PSJA have been investigated.A digital pressure transducer measures the total pressure of the PSJA and SD-PSJA,and numerical simulations are carried out to assist the analysis.The experimental setup and computational setup are introduced in section 2.The results and analyses are presented in section 3.

2.Experimental setup

2.1.Actuator and discharge characteristic measurement

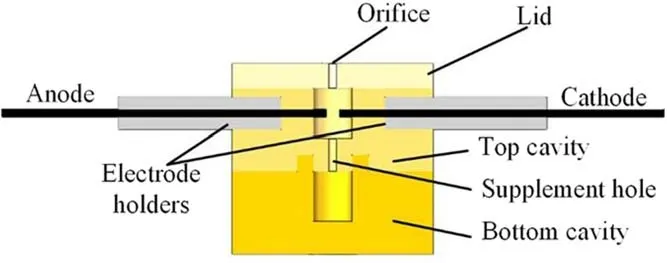

An SD-PSJA,including a lid,two cavities,and two electrodes,is designed as shown in figure 1.The electrodes are fixed in the electrode holders to ease the spacing adjustment.For the current study,the electrode gap is set to 2.5 mm.The actuator material is polyether ether ketone (PEEK),and the electrode material is tungsten needles (diameter = 1 mm).The top and bottom cavities of the SD-PSJA are cylindrical(diameter = 4.8 mm,height = 6.2 mm).The total volume of these two cavities is approximately227 mm.3 Both the jet hole and the supplement hole have a diameter of 1 mm.The throat lengths of the hole and supplement holes are 3 mm and 4 mm,respectively.

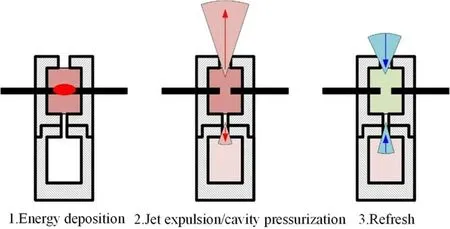

As shown in figure 2,the complete working cycle of the SD-PSJA consists of three stages: the energy deposition stage,the jet expulsion/cavity pressurization stage,and the refresh stage.During the energy deposition stage,the air in the cavity is heated rapidly by arc plasma,resulting in a sharp increase in the temperature and pressure in the top hole.Driven by the pressure differences,most of the gas in the entire cavity is expelled into the external environment,forming a high-speed jet.A small portion is simultaneously injected into the bottom cavity through the supplement hole,creating a high-pressure reservoir.After the jet expulsion/cavity pressurization terminates,the top cavity remains with a pressure lower than the gas pressure inside the lower cavity and the outside atmospheric pressure.Consequently,fresh gas is ingested into the top cavity from both the exit hole and supplement hole,requiring a much shorter refresh time to prepare for the next working cycle.

The actuator is powered by a nanosecond-pulse plasma power supply (output voltage: 0-20 kV; width: 0-1 ms; and output frequency: 1 Hz-20 kHz).To measure the discharge waveform of the SD-PSJA,a high-voltage probe (Tektronix P6015A),a current probe (Pearson 7877),and a digital oscilloscope (DPO4104B) are deployed.

Figure 3 shows a typical SD-PSJA discharge waveform measured at a rising/falling edge of 500 ns,a pulse width of 1000 ns,and an amplitude voltage of 8 kV.Since there is also a charging capacitor inside the nanosecond pulse power supply,the SD-PSJA has a reverse charging process under the nanosecond pulse so that the discharge current waveform will show bipolar characteristics [19].Before air breakdown(6.36 kV),the actuation voltage on the SD-PSJA increases nearly linearly over time.Once the threshold is exceeded,the actuation voltage shows a steep drop trend,and the current flowing through the actuator increases rapidly to the maximum of 10.6 A within 0.8 μs.The pulse width of the current waveform is about 1.6 μs.In addition,apparent oscillations with unphysical spikes are detected in the arc discharge process,which could be attributed to the inevitable electromagnetic interference.According to figure 3,the relationship between the discharge voltage and discharge current of SDPSJA under nanosecond pulse actuation can be obtained,and the energy of a single pulse discharge can be obtained by integrating the discharge voltage and discharge current through equations (1) and (2).

Figure 1.Configuration of SD-PSJA.

Figure 2. Three working stages of the SD-PSJA.

Figure 3.Discharge voltage and current waveform of the SD-PSJA.

Figure 4. Total pressure measurement system.

Figure 5.Computational mesh.

Once the SD-PSJA is working,the nanosecond pulse power supply is charged until the voltage across the capacitor reaches the breakdown voltage of the gas gap between the positive and negative electrodes of the actuator.At this time,the energy stored in the discharge capacitor reaches the maximum value.This part of the energy is named the capacitor energyEc,and it is the total energy consumed by the actuator during a single discharge; it is calculated by equation (1).

In equation (1),Ecis single pulse discharge capacitor energy,Cis the discharge capacitor of the nanosecond pulse power supply,andVis the air breakdown voltage.A discharge arc is generated between the positive and negative electrodes in the actuator cavity,and the energy of the arc is named arc energy; its calculation equation is equation (2).

In equation (2),EArepresents the arc energy,τrepresents the pulse discharge time,V(t) andI(t) are the discharge voltage and discharge current of SD-PSJA at timet,respectively.The calculated pulse energy is about 3 mJ.

There is a large amount of plasma in the discharge arc.The positive and negative charged particles in the plasma are accelerated under the action of the electric field force,and a part of the electric energy is rapidly converted into the internal energy of the gas.On the macroscopic level,the temperature of the gas increases,and the pressure increases at the same time [23].

2.2.Time-averaged total pressure measurement

A pitot tube,with a pressure transducer,is used to measure the time-averaged total pressure at the jet exit,which to a certain extent reflects the mechanical energy issued by the actuator,as shown in figure 4.The digital pressure transducer used in the pressure measurement experiment is DPT6000(WIKA Germany),the measurement range is from -1 to +1 kPa,the measurement accuracy is 0.1% full-scale (F.S),and the diameter of the selected total pressure probe is 1 mm,which is sufficient for the present study.The distance from the probe tip to the jet exit is approximately 1 mm,the sampling frequency of the pressure sensor is 100 Hz,and the sampling time is 2 s.Three repeated measurement experiments were carried out to reduce the uncertainty in each experimental condition.

2.3.Calculation model and grids

In this section,Fluent software was used to perform a 2D dynamic simulation of the SD-PSJA working process (mainly including energy deposition and jet expulsion)[20-22].Firstly,the 2D model is selected,and the turbulence model is set as the classicalk-ω model.The mesh model has been scaled and checked,and the mesh number of cells is 2.1 × 105.Set air as default fluid,set boundary conditions to adiabatic wall and pressure outlet.The calculation grid is shown in figure 5.The time step size in Fluent is set to 10-50000 ns.The red circle in figure 5 represents the energy deposition area in the center of the cavity,which is 1 mm in diameter.Finally,the heat source term equation is added to the energy equation.The SD-PSJA energy deposition process was simulated.

In equation(3),η represents the energy conversion rate(set as 40% according to reference [16]);Q0is the single pulse energy(about 3 mJ);pτis the discharge duration;Vhis the total volume of the heating region.

3.Results and analysis

3.1.Total pressure measurement results

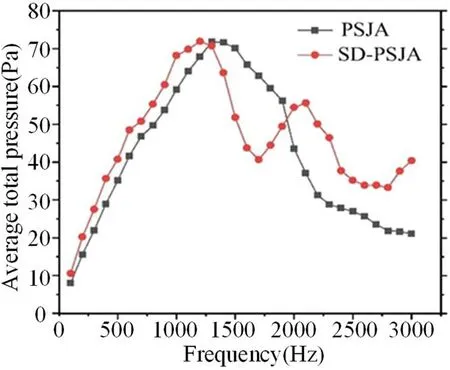

The electrical parameters mentioned in section 2.1 are employed throughout the following study unless otherwise noted.Figure 6 compares the variations in the time-averaged total pressure with discharge frequency for both the PSJA and SD-PSJA.Note that the total cavity volumes of these two actuators are kept constant.As the discharge frequency increases,the time-averaged total pressure of the PSJA has a pressure peak,and the discharge frequency corresponding to this pressure peak is referred to as the saturation frequency[15].It is evident that there is a saturation frequency of 1300 Hz for the PSJA and that the peak values of the total pressure of the SD-PSJA and PSJA are equivalent.Compared with the PSJA,a second saturation frequency of 2100 Hz is observed at the SD-PSJA,and the first saturation frequency of the SD-PSJA is 1200 Hz,which is similar to the saturation frequency of the PSJA.When the discharge frequency is less than the first saturation frequency,the total pressure of the SD-PSJA is always higher than that of the PSJA.As the discharge frequency is between the first and second saturation frequencies of the SD-PSJA,the total pressure of the PSJA is higher.However,for high frequencies(higher than the second saturation frequency),the performance of the SD-PSJA is better than that of the PSJA.The author believes that the lower cavity can reduce the air supply capacity of the upper cavity under high-frequency discharge,resulting in the highfrequency characteristics of the dual-cavity exciter approaching the PSJA composed of a single upper cavity.In contrast,the saturation frequency of the small PSJA is high,so the high-frequency outlet pressure rises.Although a small volume of PSJA has a high outlet pressure at high frequencies,its flow rate is low,and its flow control capability is limited.Therefore,the frequency characteristics beyond the second saturation frequency are not discussed in this paper,which is explained.

Figure 6.Comparison of the time-averaged total pressure between the SD-PSJA and the PSJA.

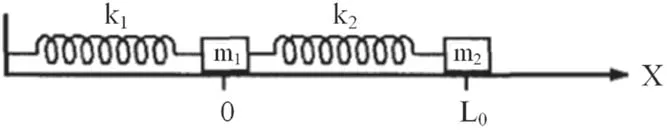

Figure 7.Double spring-mass-damper system.

In addition,a linear relation is exhibited between the total pressure and the discharge frequency atfd< 600 Hz,and the slope of this linear segment (k) is expressed mathematically,as shown in equation (4),wherePdenotes the time-averaged total pressure at the exit hole,Trepresents the discharge period,andPis the instantaneous jet total pressure at the exit hole.Physically,kreflects the contribution of a single jet to the time-averaged total pressure.Once this parameter is multiplied by the hole area (Ae),the actuator’s jet impulse (I)can be estimated,as shown in equation(5).Selecting figure 6 as an example,the jet impulses of PSJA and SD-PSJA are calculated to be 1.65 × 10-8and 1.85 × 10-8,respectively,reflecting that the jet strength of the SD-PSJA is higher than that of the PSJA.

The working process of PSJA can be linked to the spring-mass damping system.The saturation frequency is mainly the natural oscillation frequency (fh),and also includes atmospheric parameters and geometric parameters.As shown in equation (6).KandMare the equivalent stiffness of the air inside the cavity,,and the effective mass of the air at the hole,M=ρ0lthAe,respectively [16].

In equation (6),fhis the saturation frequency,γ is the specific heat ratio,Aeis the outlet pore area,ρ0is the air density,andlthrepresents the throat length [15,17].

Structurally,the SD-PSJA is equivalent to two PSJAs connected in series.Thus,a dual spring-mass-damper system can be described in figure 7,which possesses two Helmholtz natural oscillation frequencies.Selecting the top and bottom cavities of the SD-PSJA as two independent spring-massdamper systems,their Helmholtz natural oscillation frequencies are determined to befh1andfh2,respectively,whereK1andK2are the equivalent stiffnesses of the air inside the bottom cavity and top cavity,respectively,andM1andM2represent the effective masses of the air at the supplement hole and jet hole,respectively.

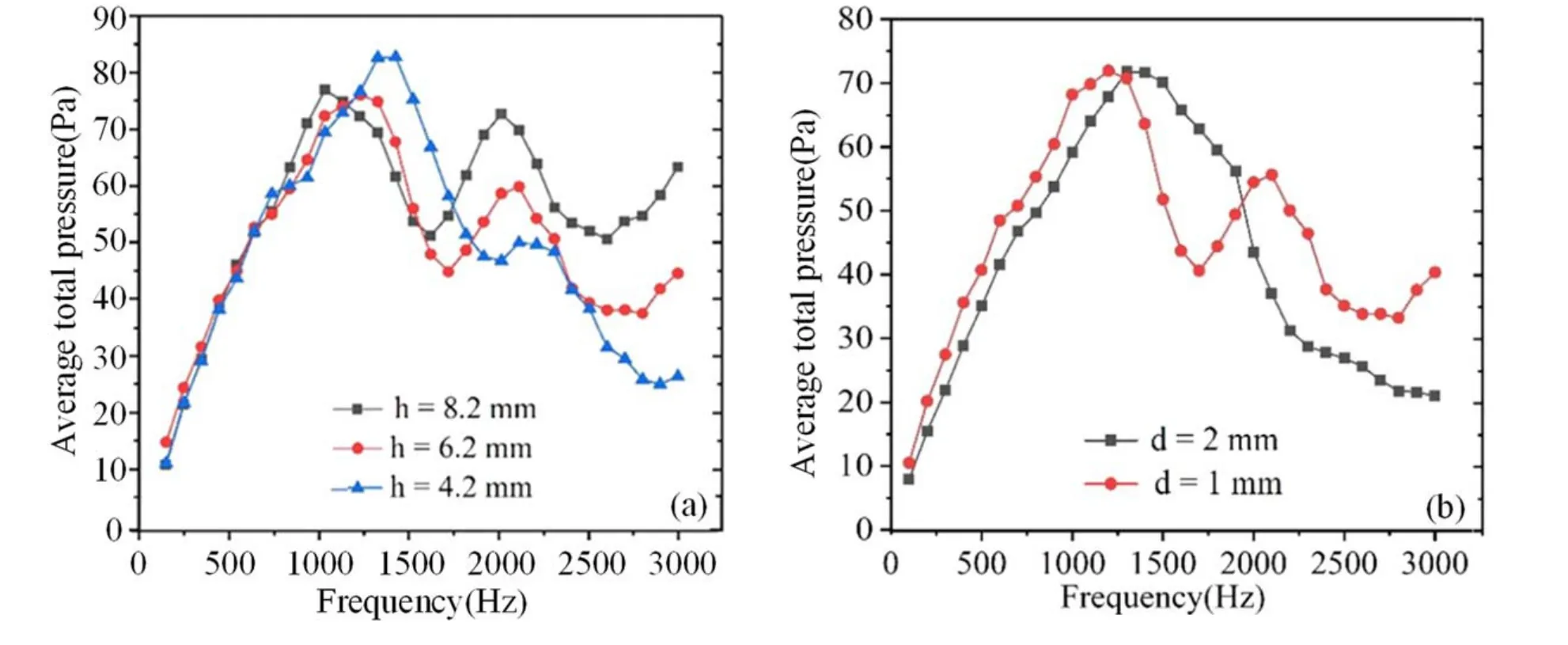

Furthermore,the effects of the bottom cavity volume and supplement hole diameter on the SD-PSJA are investigated in figure 8.All the bottom cavities with different volumes are cylinders with a diameter of 4.8 mm and heights are 4.2 mm,6.2 mm,and 8.2 mm.In addition,the two supplement holes have the same size of 4 mm and different diameters of 2 mm and 1 mm.Figure 8 shows that both the first and second saturation frequencies decrease with an increase in the bottom cavity volume and a decrease in the supplement hole diameter.The larger the first saturation frequency is,the greater the peak pressure of SD-PSJA.However,the more significant the second saturation frequency is,the smaller the force of the SD-PSJA at a high discharge frequency (higher than the second saturation frequency).Using the above calculation method,the variation in the two saturation frequencies with the bottom cavity volume and supplement hole diameter is consistent with the total pressure measurement.

3.2.Numerical calculation results

Numerical calculations are performed to study the working mechanism of the SD-PSJA.For a single cycle,the variations in the jet exit pressure at a distance of 1 mm from the holes are shown in figure 9(a),and the average pressure in the top cavity of the SD-PSJA and PSJA is compared in figure 9(b).Since the top cavity volume of the SD-PSJA is smaller than the cavity volume of the PSJA,the gas in the top cavity of the SD-PSJA is heated more uniformly,producing a relatively high-pressure peak compared with the PSJA.The pressure in the top cavity of the SD-PSJA decreases rapidly after the peak,similar to reducing the cavity of the PSJA.However,unlike the PSJA with a reduced cavity volume,the SD-PSJA can supplement air to the top cavity through the bottom cavity by itself,further enhancing the strength of the jet.The jet impulse of the actuator can be calculated by integrating the total pressure at the exit hole,as shown in equation (5).Through calculation,the jet impulses of t he PSJA and SD-PSJA are2.55 × 10-8and3.15 × 10-8,respectively.The jet impulse obtained by the numerical analysis is higher than that of the experimental result,which may be attributed to the measurement error caused by the consistency between the diameters of the total pressure probe and the hole,and an excessive energy conversion efficiency η in the numerical calculation.

Figure 10 compares the jet velocity of the PSJA and the SD-PSJA with the same total cavity volume in a single cycle.After energy deposition,the PSJA and SD-PSJA produced jets with the same intensity,and some pressurized gas entered the bottom cavity.The PSJA quickly transfers to the refresh stage.However,since the top cavity is supplemented by gas from the bottom cavity,the jet velocity is more stronger at the hole of SDPSJA.Moreover,the SD-PSJA inhales air from the outside faster than the PSJA,ensuring that it continuously produces jets at higher discharge frequencies than the PSJA.Therefore,the SD-PSJA has better performance than the PSJA with the same cavity volume at high discharge frequencies.

Figure 8.Impact of (a) bottom cavity volume and (b) supplement hole diameter on the time-averaged pressure of the SD-PSJA.

Figure 9. Time evolution of the major performance parameters pertaining to the PSJA and SD-PSJA.(a) Exit pressure and (b) averaged cavity pressure.

Figure 10.Comparison of the jet velocity contours produced by the PSJA and SD-PSJA with the same total cavity volume.

4.Conclusion and discussion

In this work,experimental investigations and numerical calculations were conducted to investigate the structure of a new actuator,the SD-PSJA.Furthermore,the effects of the bottom cavity volume and the supplement hole diameter on the SDPSJA are analyzed.The SD-PSJA has two saturation frequencies: the first saturation frequency (1200 Hz) is slightly smaller than the saturation frequency of the PSJA with the same cavity volume,and the second saturation frequency(2100 Hz)is much higher,about two times the first saturation frequency.When the discharge frequency is less than the first saturation frequency,because the energy conversion efficiency of the SDPSJA is higher than that of the PSJA,the total pressure of the SD-PSJA is consistently higher than that of the PSJA.As the discharge frequency is between the first and second saturation frequencies of the SD-PSJA,the total pressure of the PSJA is higher,which may be caused by gas entering the bottom cavity from the top cavity and affecting the regular operation of the SD-PSJA.However,for high frequencies (higher than the second saturation frequency),the performance of the SD-PSJA is better than that of the PSJA,supplemented by the bottom cavity.Furthermore,regarding the SD-PSJA as a dual spring-massdamper system,the two Helmholtz natural oscillation frequencies,similar to the first and second saturation frequencies,are presented in equations (4) and (5).The patterns of the first and second saturation frequencies,which change with the bottom cavity volume and the supplement hole diameter,have been obtained with these equations.With a larger bottom cavity,both the first saturation frequency and second saturation frequency decrease,but the high-frequency performance of the SD-PSJA is improved.As the supplement hole expands,the first saturation frequency increases,but the second saturation frequency initially decreases and then increases.In addition,the high-frequency performance of the SD-PSJA decreased with the volume of the supplementary holes.According to the numerical calculation results,the gas in the top cavity of the SD-PSJA is heated more uniformly,improving the average pressure peak.The pressure in the top cavity of the SD-PSJA decreases rapidly after the peak,which is similar to reducing the cavity of the PSJA.However,the SD-PSJA is different from the PSJA with the reduced cavity volume,and it can supplement air to the top cavity through the bottom cavity by itself,further enhancing the strength of the jet.With a larger cavity volume,more gas can be supplemented to the top cavity,which improves the high-frequency performance of the SD-PSJA.However,with a more giant supplement hole,too much gas in the bottom cavity of the SD-PSJA enters the top cavity.Nevertheless,the bottom cavity volume is unchanged,resulting in an insufficient amount of gas and the reduced highfrequency performance of the SD-PSJA.

In conclusion,the SD-PSJA has a larger bandwidth than the PSJA with the same cavity volume and simple structure.The bottom cavity volume should be appropriately increased for better high-frequency performance,and the supplement hole should be reduced.When designing the SD-PSJA,we need to comprehensively consider its various geometric parameters and make reasonable choices to ensure that it has a large bandwidth and a good high-frequency working performance.

Acknowledgments

The present study is supported by National Natural Science Foundation of China (No.61971345) and the Foundation for Key Laboratories of National Defense Science and Technology of China (No.614220120030810).

ORCID iDs

Plasma Science and Technology2023年2期

Plasma Science and Technology2023年2期

- Plasma Science and Technology的其它文章

- Efficient combination and enhancement of high-power mid-infrared pulses in plasmas

- Realization of Te0>10 keV long pulse operation over 100 s on EAST

- Solving Poisson equation with slowingdown equilibrium distribution for global gyrokinetic simulation

- Experimental studies of cusp stabilization in Keda Mirror with AXisymmetricity (KMAX)

- BITS: an efficient transport solver based on a collocation method with B-spline basis

- Comparing simulated and experimental spectral line splitting in visible spectroscopy diagnostics in the HL-2A tokamak