Preparation and Characterization of Insensitive Nano RDX

LIU Jie,WANG Long-xiang,LI Qing,ZENG Jiang-bao,ZHOU Sai,JIANG Wei,LI Feng-sheng(National Special Superfine Powder Engineering Research Center of China,Nanjing University of Science and Technology,Nanjing 210094,China)

Introduction

Ammonium nitrate explosives,such as RDX,got excellent detonation performances.However,the active mechanical sensitivities of those explosives restricted their practical application.Thus,more and more researches are focusing on how to decrease the sensitivity to improve the survivability of ammunitions.Surface coating had been researched to cut down the sensitivity of energetic materials.Synthesized particles of CL-20were coated to decrease the sensitivity.However,it was testified imperfect that the thermal decomposition property was influenced seriously by the coating materials[1-2].The impact and friction sensitivities of RDX,coated with TNT,were decreased obviously whereas the explosion heat had reduced in a certain extent[3].

As an inspiring fact,the particle size and particle size distribution affected the sensitivity of explosives significantly[4-5].The mechanical sensitivities of the explosives were decreased while their particle sizes decreased,and were varied with the changing of particle size distribution and particle morphology[6-11].Therefor,many efforts had been made to prepare ultrafine explosives,especially nano explosives.Nano RDX was fabricated by Rapid Expansion of Supercritical Solution(RESS)[12].Spin coating and Dip pen nanolithography had been employed to prepare nano-energetic materials such as PETN and HMX[13].The nano energetic materials could be also produced in a sol-gel synthetic approach[14-17],and the impact sensitivity of prepared nano-particles was decreased,compared with the raw materials[18].Nano-size HMX,with reticular structure,was prepared by reprecipitation at room temperature,and the impact sensitivity was lower than that of raw HMX[19].In addition,solvent/nonsolvent recrystallization was put in the use of preparation of nano-TATB with the size ranging from 27nm to 41nm[20].

However,the yield of nano RDX,prepared by the forementioned ways,is so low that it seems unexpectable to achieve scale-up.In this study,nano RDX was successfully fabricated 500grams per batch or 1000grams per batch,by use of the HLG-50machine.And the nano particles were extracted efficiently from the pulverized slurry.

1 Experiment

1.1 Material and machines

The raw RDX was made by Gansu Yinguang Chemical Industry Group Co,Ltd.The pulverized machine,named HLG-50,improved from the Bidirectional Rotating Grinding Mill which was designed by Prof.Fengsheng Li[21],was used to prepare nano RDX.

Malvern Mastersizer Micro and Malvern Zetasizer 3000HAS laser particle size analyzer,Malvern;S-4800ⅡScanning Electron Microscope,Hitachi High-Technologies Corporation;Nicolet iS 10Infrared Spectrometer,Nikon;JY HR800Raman Spectrometer,HORIBA Jobin Yvon;Advance D8 X-ray Diffractometer,Bruker;Jarrell-Ash J-A1100Inductively Coupled Plasma Atomic Emission S pectroscopy(ICP-AES),Jarrell-Ash were used to characterize the raw RDX and nano RDX.

1.2 Preparation of insensitive nano RDX

The raw RDX,processed in a weight from 500 to 1000grams per batch,was added into the disperse system mainly consisting of deionized water to get a suspension.The water content should surpass 70%in weight to ensure the safety of the process.This suspension was sent to the grinding cavity of the pulverized machine HLG-50automatically.The materials were smashed continuously until the particle size qualified and then they would be transmitted to the storing container by the component pump.

A dehydrator was employed to reduce the wa-ter content to 20wt% roughly.Then there were two ways to extract the particles from the slurry.The general method was to dry the particles directly using the vacuum oven.Another novel approach was to draw the particles through the azeotropy technique in a certain temperature,exhibited by the azeotropic liquid system which being formed by adding the particular solvents into the addressed slurry quantitatively to get a new stable disperse system.And then the properties of the particles were measured.

1.3 Tests of mechanical sensitivities

The friction sensitivity for the explosives was tested at two standards(80±1°,2.45 MPa;90±1°,3.92 MPa).Fifty units were carried out for each standard to obtain the explosion probability(P,%).The characteristic heightin which an explosive would explode at a probability of 50%,calculated statistically through the using of 25effective test values,was given to characterize the impact sensitivity,while the 2kilometer drop-hammer and the 5kilometer drophammer were used respectively.The Small Scale Gap Test(SSGT)was also taken to estimate the shock sensitivity.

2 Results and discussions

2.1 Size distribution

The size distribution of raw RDX and nano RDX was shown in Figure 1.

Fig.1 Size distribution curves of raw RDX and nano RDX

The raw RDX caught an average size of 83.64μm and the size distribution was widely ranging from submicron to several hundred micron.It was also showed that the mean size for pulverized nano RDX in the slurry was 63.7nm.The nano particles varied with the size from 8nm to 200nm,most of which were under 100nm.The size distribution of nano RDX was very narrow and uniform,compared with the raw materials.

2.2 Micrographs

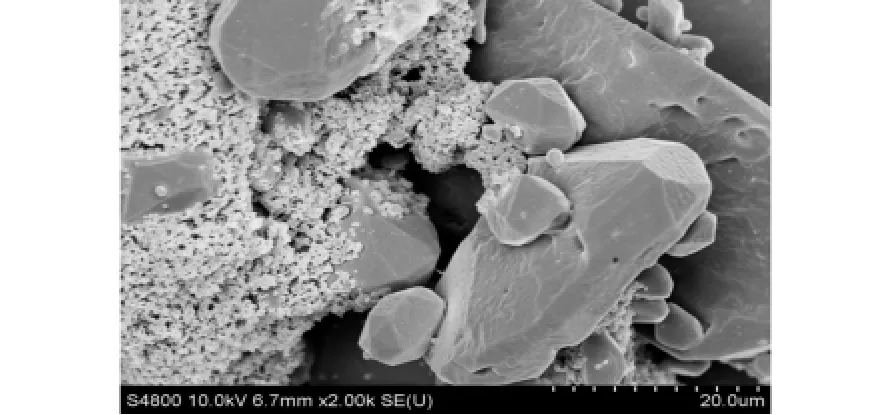

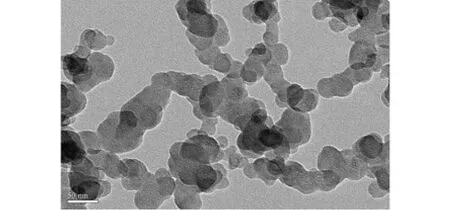

Figure 2 was the SEM image for particles picked up from the general liquid system and Figure 3 was the TEM image for particles extracted from the azeotropic liquid system.

Fig.2 SEM image for particles picked up from the general liquid system

Fig.3 TEM image for particles extracted from the azeotropic liquid system

It was shown in Figure 2that some of the particles,picked up by drying pulverized slurry directly,were in the micro level.The phenomenon that some particles existing in the surface of the big particles was observed distinctly,while a few of the implanted particles displaying nano dimensions.Figure 3implied that the particles extracted by azeotropy were spherical with a size under 50 nm.It could be concluded furthermore that the pulverized system was valid enough.It also showed that there was a difference in the particle size results between the TEM images and the size distribution curve of nano RDX.This might be reasonable because of the instrument residual.

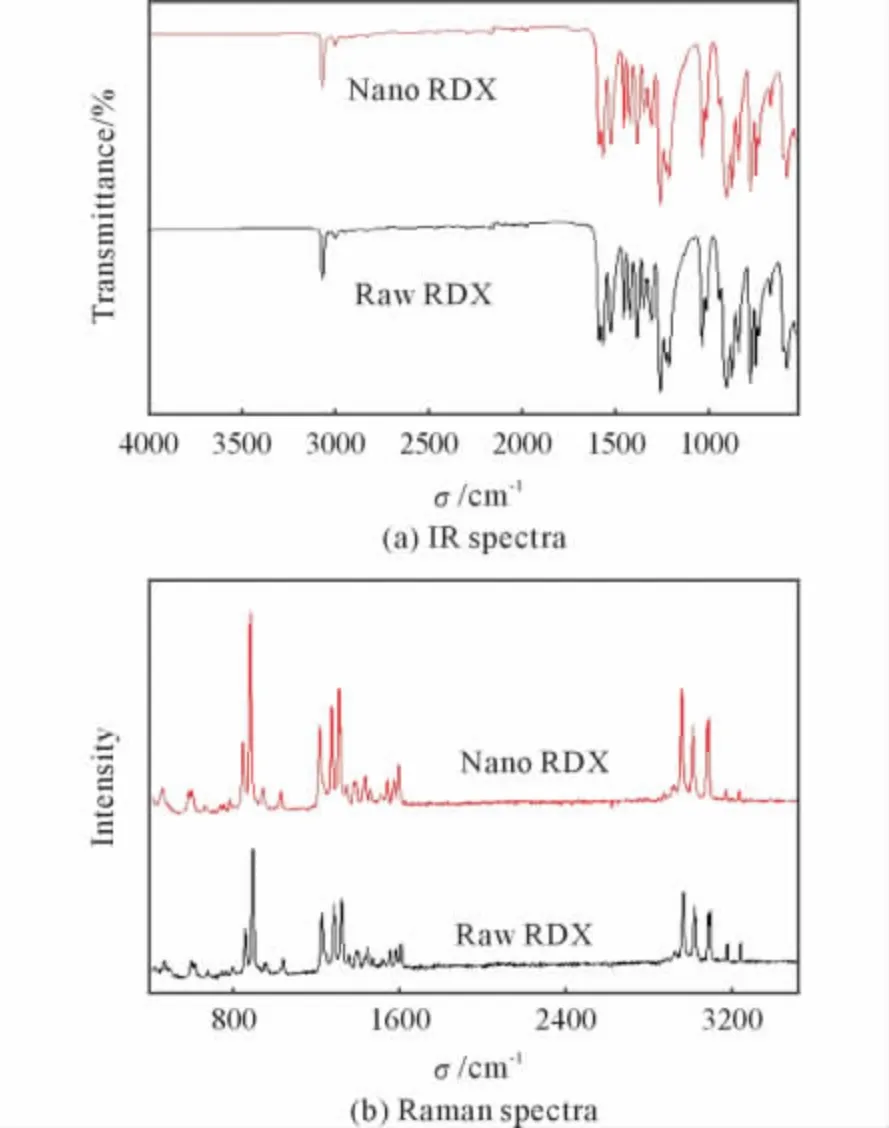

2.3 IR and Raman Spectra

Figure 4was the IR spectra and Raman spectra of raw RDX and nano RDX.

It was revealed from the IR spectra and the Raman spectra that the shape,the position,and the relative intensities of the peaks for the nano particles were consistent with those of the raw RDX.The components of the nano RDX were identical with those of the raw RDX.There was no solvent residual in the particles extracted from the azeotropic liquid system.

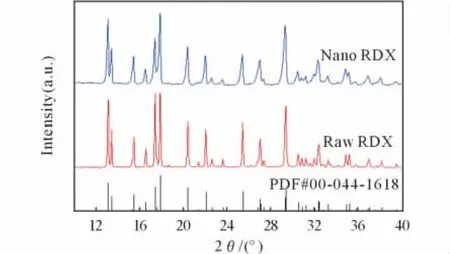

2.4 XRD

Figure 5 was the XRD patterns of raw RDX and nano RDX.

It was shown in Figure 5that the diffraction peaks of nano RDX were entirely accordant with those of the raw RDX and the standard pattern PDF#00-044-1618.The nano and raw particles had the same crystalline structure and there were no contaminants in nano RDX.This mechanical method to prepare nano RDX would not change the crystal form unlike the recrystallization methods such as RESS.Another phenomenon was obvious that the diffraction peaks of nano RDX were widened,compared with raw RDX.It would be explained well by Scherrer Formula which told us that the particle size was inversely proportional to the full width at half maximum of XRD diffraction peak.

Fig.4 IR spectra and Raman spectra of raw RDX and nano RDX

Fig.5 XRD patterns of raw RDX and nano RDX

2.5 ICP-AES

In consideration of the metallic elements existing in the machine HLG-50,the elements of Fe,Al and Zr were detected through ICP-AES.There were 0.1082mg Fe,0.0301mg Al and 0.0744mg Zr in per gram of RDX.The total metal impurities content was just 0.2127 mg in per gram of the sample.It was meaning that the purity of nano RDX was over 99.9%,compared with raw RDX.

2.6 Mechanical sensitivities

The mechanical sensitivities were shown in Table 1.Especially,the symbols,R-RDX,N-RDX and G-RDX,represented the raw RDX,the nano RDX and the RDX extracted by drying the slurry directly,respectively.

Table 1 showed that the extent of reduced sensitivity(RS-extent)for N-RDX,compared with R-RDX,was 26.0% when the standard was taken at(80±1)°,2.45 MPa.while the standard(90±1)°,3.92 MPa was taken,the RS-extent was dropped to 14.0%.However,the RS-extents for G-RDX were only 6.0% and 2.0% for each of those two standards.

The impact sensitivity for N-RDX was decreased 58.7%when the stimuli was the 2kg drophammer,compared with the R-RDX,while the RS-extent was 25.4%for the G-RDX.When the stimuli was added to 5kg drop-hammer,the RSextent was changed to 46.3%for N-RDX,17.2%for G-RDX.

The phenomenon,that the RS-extents of friction and impact sensitivities were reduced while the stimuli were increased,could be explained that the resolution was cut down when the given stimuli magnified.

At the same time,the shock sensitivity for NRDX,was decreased 44.8% and 18.6% for GRDX,compared with R-RDX.

The mechanical sensitivities for N-RDX,were dropped apparently,compared with the raw materials.However,the RS-extents,for the particles picked up in a general way,were much lower than those of N-RDX.

2.7 Azeotropic mechanism analysis

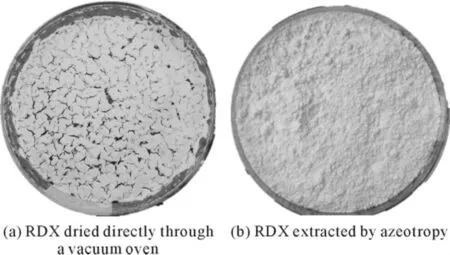

The dried state of RDX was shown in Figure 6.RDX dried directly through a vacuum oven was cracking and blocking,and it was difficult to handle the samples to match the subsequent tests,especially the tests of mechanical sensitivities.The particles were agglomerated seriously as shown in Figure 2.The samples extracted by azeotropy were powder.It required dispose scarcely.Further more,the particles demonstrated a favorable safety stability.

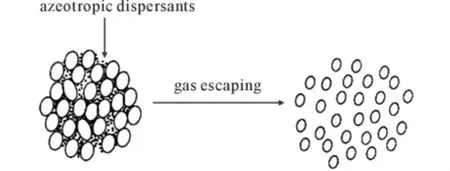

The mechanism of the azeotropic technique to extract nano RDX could be explained as the schematic diagram showed in Figure 7.When the azeotropic dispersants escaped simultaneously,the power of volume expansion would prevent the ag-glomeration of the nano particles efficiently so that the particles extracted safely.It was noteworthy that the formation of the azeotropic dispersants and the choice of the temperature were so important that any difference could lead to bad result.

Fig.6 The dried state of pulverized RDX

Fig.7 Schematic diagram for the azeotropic technique to extract nano RDX

3 Conclusions

(1)Nano RDX was pulverized and extracted safely in a batch of 500-1000grams.

(2)The formation of the azeotropic dispersants and the temperature were critically important to extract the nano particles.

(3)The product got a high purity,and the extracted nano RDX performed very well to improve the safety,compared with raw RDX.

[1]Tappan B C,Brill T B.Thermal decomposition of energetic materials 85:Cryogels of nanoscale hydrazinium hiperchlorate in hesorcinol-hormaldehyde[J].Propellants,Explosives,Pyrotechnics,2003,28(2):72-76.

[2]Tappan B C,Brill T B.Thermal decomposition of dnergetic materials 86.Cryogel synthesis of nanocrystalline Cl-20coated with cured nitrocellulose[J].Propellants,Explosives,Pyrotechnics,2003,28(5):223-230.

[3]An Chong-wei.,Li Feng-sheng.,Song Xiao-lan,et al.Surface coating of RDX with a composite of TNT and an energetic-polymer and its safety investigation[J].Propellants Explosives Pyrotechnics,2009,34(5):400-405.

[4]Song Xiao-lan,Li Feng-sheng,Zhang Jing-lin,et al.Influence of particle size,morphology and size distribution on the safety and thermal decomposition properties of RDX[J].Journal of Solid Rocket Technology,2008,31(2):168-172.

[5]Siviour C R,Gifford M J,Walley S M,et al.Particle size effects on the mechanical properties of a polymer bonded explosive[J].Journal of Materials Science,2004,39(4):1255-1258.

[6]Yang Bin-lin,Chen Rong-yi,Cao Xiao-hong.Influence of particle size of RDX on the detonation properties[J].Initiators and Pyrotechnics,2004,(3):50-53.

[7]Song Xiao-lan,Li Feng-sheng.Dependence of particle size and size distribution on mechanical sensitivity and thermal stability of hexahydro-1,3,5-trinitro-1,3,5-triazine[J].Defence Science Journal,2009,59(1):37-42.

[8]Liu Yu-cun,Wang Jian-hua,An Chong-wei,et al.Effect of particle size of RDX on mechanical sensitivity[J].Chinese Journal of Explosives and Propellants,2004,27(2):7-9.

[9]Song Xiao-lan,Wang Yi,An Chong-wei,et al.Dependence of particle morphology and size on the mechanical sensitivity and thermal stability of octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine[J].Journal of Hazardous Materials,2008,159(2/3):222-229.

[10]Song Xiao-lan,Guo Xiao-de,Zhang Jing-lin,et al.Dependence of size and size distribution on safety performance of nitramine explosives and the multi-component explosives[J].Initiators and Pyrotechnics,2007,(4):17-21.

[11]Sovizi M R,Hajimirsadeghi S S,Naderizadeh B.Effect of particle size on thermal decomposition of nitrocellu-lose[J].Journal of Hazardous Materials,2009,168(2-3):1134-1139.

[12]Stepanov V,Krasnoperov L N,Elkina I B,et al.Production of nanocrystalline RDX by rapid expansion of supercritical solutions[J].Propellants,Explosives,Pyrotechnics,2005,30(3):178-183.

[13]Nafday O A,Rajasekar P,Weeks B L,et al.Patterning high explosives at the nanoscale[J].Propellants,Explosives,Pyrotechnics,2006,31(5):376-381.

[14]Tillotson T M,Hrubesh L W,Simpson R L,et al.Solgel processing of energetic materials[J].Journal of Non-Crystalline Solids,1998,225(1):358-363.

[15]Cudzilo Stanislaw,Kicinski Wojciech.Preparation and characterization of energetic nanocomposites of organic gel-inorganic oxidizers[J].Propellants,Explosives,Pyrotechnics,2009,34(2):155-160.

[16]Tillotson T M,Gash A E,Simpson R L,et al.Nanostructured energetic materials using sol-gel methodologies[J].Journal of Non-Crystalline Solids,2001,285(1-3):338-345.

[17]Li J,Brill T B.Nanostructured energetic composites of Cl-20and binders synthesized by sol-gel methods[J].Propellants,Explosives,Pyrotechnics,2006,31(1):61-69.

[18]Song Xiao-lan,Li Feng-sheng,Zhang Jing-lin,et al.Preparation,mechanical sensitivity and thermal decomposition characteristics of RDX nanoparticles[J].Chinese Journal of Explosives and Propellants,2008,31(6):1-4.

[19]Zhang Yong-xu,Liu Da-bin,Lv Chun-xu.Preparation and characterization of reticular nano-HMX[J].Propellants,Explosives,Pyrotechnics,2005,30(6):438-441.

[20]Yang Guang-cheng,Nie Fu-de,Huang Hui,et al.Preparation and characterization of nano-TATB explosive[J].Propellants,Explosives,Pyrotechnics,2006,31(5):390-394.

[21]Li Feng-sheng,Bi-directional superfine milling,CN2766956[P].2006.